Understanding the Components of an Alternator

The efficient operation of a vehicle’s power system relies on various key elements working in harmony. These essential units convert mechanical energy into usable electrical power, ensuring smooth functionality for various systems within the vehicle. Understanding how these components interact provides insight into their roles and importance in maintaining optimal performance.

At the heart of the system, several intricate components come together to produce and regulate electricity. From the main unit that generates power to smaller elements that manage distribution, each component has a distinct purpose, contributing to the overall efficiency. The interaction between these parts is crucial for maintaining stable voltage and preventing system failure.

To fully grasp the inner workings, it is important to visualize the connections and flow of energy. By studying the layout and function of these components, one can better appreciate the complexity and reliability of the power generation process in modern vehicles.

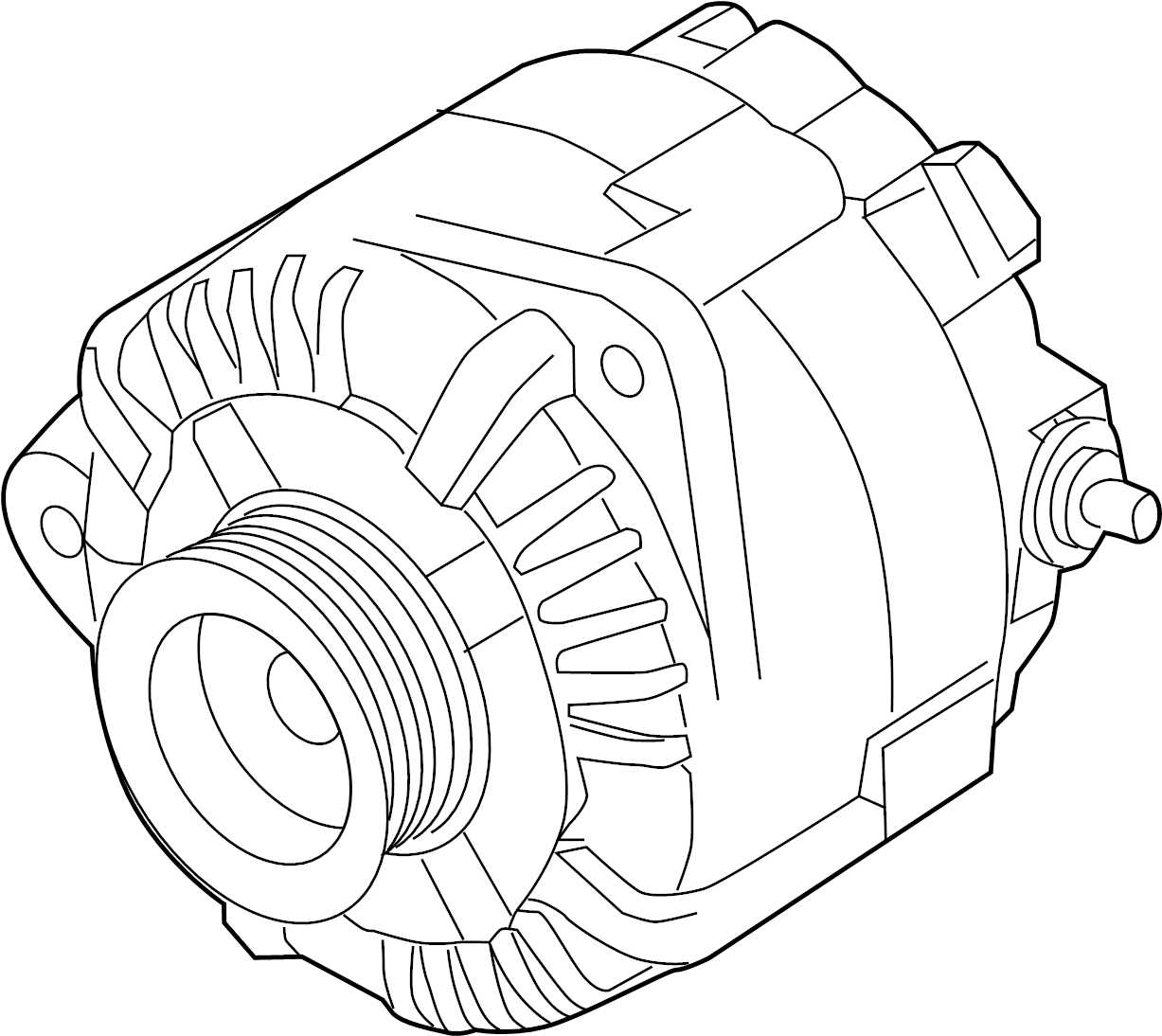

Components of an Alternator

Every electrical generator consists of several key elements that work together to produce and regulate power output. These components play crucial roles in converting mechanical energy into usable electricity, ensuring the system operates efficiently and reliably under various conditions.

Main Functional Elements

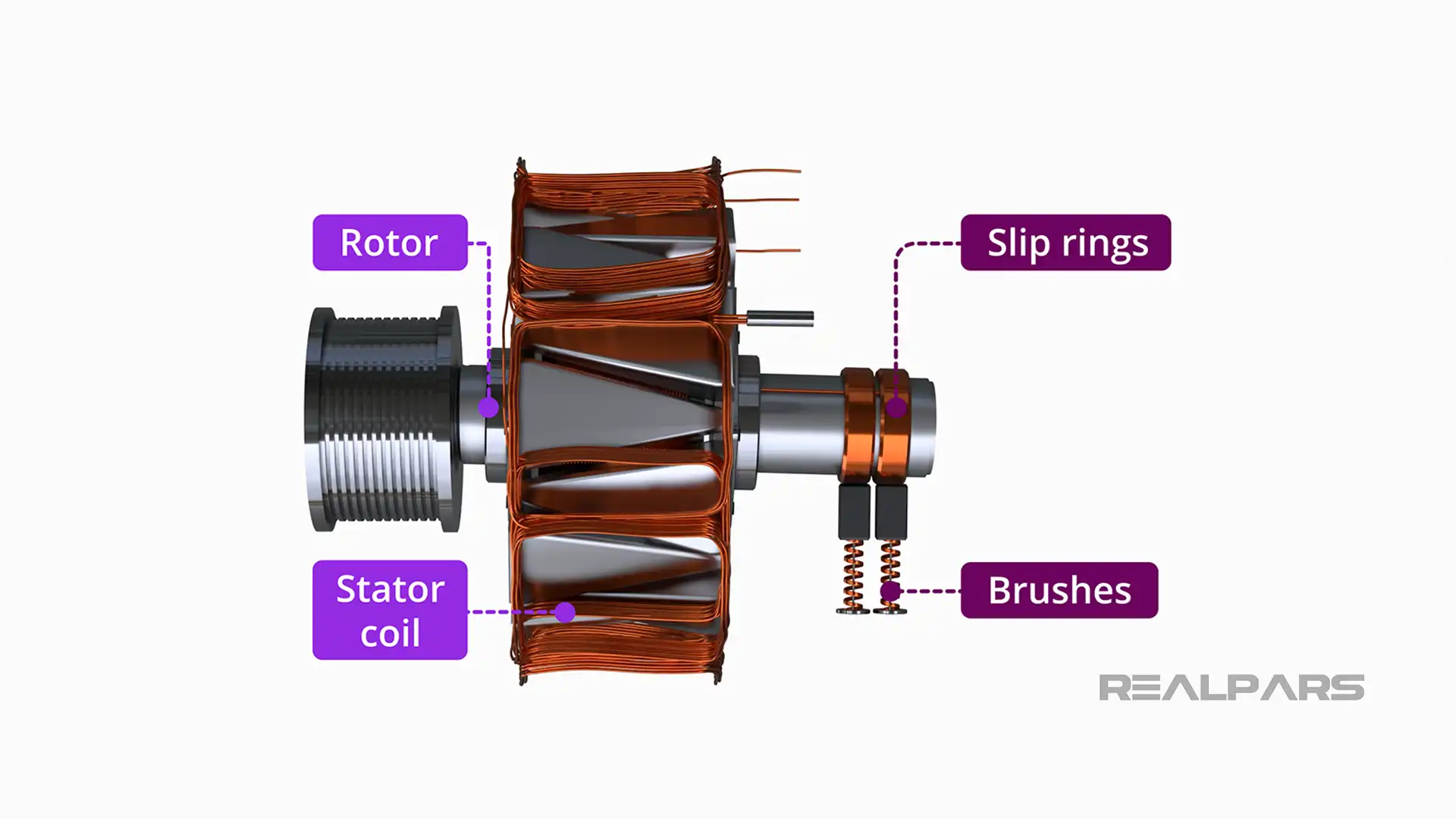

- Rotor: The rotating element responsible for creating the magnetic field that induces electricity.

- Stator: The stationary part where electrical energy is generated through electromagnetic induction.

- Slip Rings: Provide continuous electrical contact between the stationary and rotating parts of the system.

- Brushes: Maintain contact with the slip rings to transfer the generated electrical current.

Supporting Elements

- Rectifier: Converts alternating current (AC) to direct current (DC), ensuring compatibility with battery systems.

- Voltage Regulator: Monitors and adjusts the output to maintain consistent voltage levels.

- Cooling Fan: Helps dissipate heat generated during the operation, maintaining optimal temperature levels.

- Housing: Provides structural support and protection for internal components, preventing damage from external elements.

Understanding the Stator Windings

The core component that generates electrical power in a rotational energy system relies heavily on a carefully wound structure, which plays a key role in the conversion process. This element consists of a series of conductive loops that are strategically positioned to interact with the magnetic field, producing an electric current as the system operates. Understanding how these coils are arranged and function is essential to appreciating the efficiency and effectiveness of energy conversion in such systems.

Structure and Function of Windings

The windings are made from high-conductivity materials, often copper, wound in a specific pattern to create a magnetic interaction. As the system’s rotor moves, it induces a changing magnetic field that the windings are designed to capture, generating an alternating current. This process, known as electromagnetic induction, is fundamental for the production of electricity in rotational devices.

Factors Affecting Efficiency

Efficiency is influenced by the number of coils, their arrangement, and the quality of materials used. A higher number of turns in the winding can increase the voltage produced, while the design of the coils ensures that the magnetic flux interacts optimally with the moving part. Environmental factors, such as temperature and exposure to wear, can also affect the performance and longevity of the windings.

The Role of the Rotor Assembly

The rotor assembly plays a critical function in the energy conversion process within a generating system. This component is responsible for creating the magnetic field necessary to induce electrical current. By rotating within the system, it ensures that the necessary electromagnetic interaction takes place, enabling power generation. Its movement is essential for converting mechanical energy into electrical energy effectively.

Central to the rotor’s function is the interaction between its magnetic field and the stator. This interaction is what drives the creation of alternating current. As the rotor spins, it induces a flow of energy through the surrounding coils, a process that relies on precise engineering and consistent performance.

Without the rotor assembly, the system would fail to generate power, highlighting its indispensable role in the overall functionality. Its efficiency and durability are crucial for maintaining consistent power output and reliable operation.

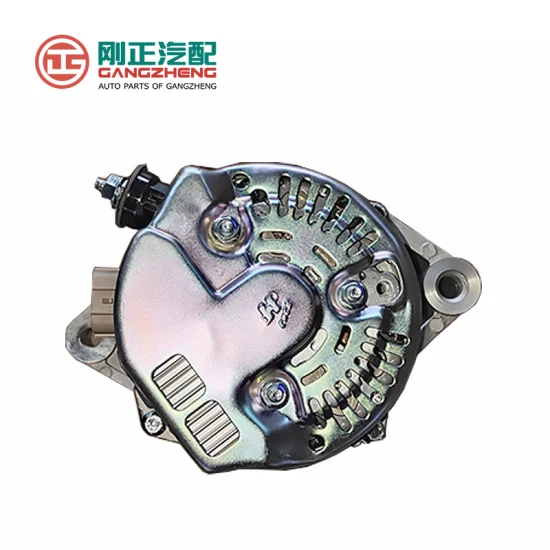

Alternator Housing and Its Importance

The enclosure that surrounds a generator’s essential components plays a critical role in maintaining its proper function. This structure serves as the first line of defense against external elements while ensuring that the internal systems remain intact and operate efficiently. The quality and design of this enclosure can significantly affect the overall performance and longevity of the machine.

Protection from External Factors

The outer casing shields the internal components from dirt, moisture, and physical damage. Without this protective layer, exposure to the elements could cause short circuits, corrosion, or wear over time, leading to system failures. The material and design choices for this casing are vital to ensuring optimal protection, especially in harsh environments.

Heat Dissipation and Ventilation

Efficient heat management is another key function of the housing. The enclosure not only protects but also contributes to temperature regulation by facilitating airflow and preventing overheating. A well-designed casing allows for sufficient ventilation, ensuring that the system’s components do not suffer from excessive heat, which could compromise performance and durability.

Exploring the Rectifier Bridge

The rectifier bridge is a crucial component in the conversion of electrical energy. It ensures the smooth transition of current, transforming it into a usable form for various systems. Without this mechanism, the flow of energy would remain unstable, affecting the overall performance.

This element functions by directing electrical flow in a specific direction, allowing for effective regulation of power. Its role in smoothing out the fluctuations in current ensures the system operates without interference, providing consistent output.

Each connection within the bridge is designed for precision, ensuring that the direction of the current remains controlled and efficient. The result is a more reliable and stable energy flow, essential for maintaining the integrity of the system’s operations.

What Is the Voltage Regulator?

The voltage regulator is a critical component responsible for maintaining a stable voltage level in a system, ensuring that electrical devices operate efficiently and safely. It plays a key role in controlling fluctuations in voltage that could otherwise damage sensitive electronics.

In essence, this device monitors and adjusts the power output to ensure it stays within a specified range, preventing both overvoltage and undervoltage conditions. By doing so, it protects the connected components and enhances the overall performance of the electrical system.

Without this regulation, systems would be prone to damage due to inconsistent or excessive electrical supply. Therefore, the voltage regulator ensures longevity and reliable operation of devices that depend on precise electrical input.

The Significance of the Diode Plate

The diode plate plays a crucial role in converting electrical current to a usable form. This component ensures the proper functioning of the electrical system by allowing current to flow in one direction, thus maintaining stable output. Its efficiency directly affects the performance and reliability of the system, making it an essential element for energy conversion mechanisms.

Typically made up of several diodes, the plate acts as a bridge, transforming alternating current (AC) into direct current (DC). This process is vital in ensuring that electrical devices receive the necessary current to operate correctly.

| Function | Importance |

|---|---|

| Current Conversion | Ensures stable DC output from AC input |

| Current Flow Regulation | Prevents backflow, ensuring safety and reliability |

| Heat Dissipation | Maintains component longevity by managing temperature |

Alternator Brushes and Their Function

In many electrical systems, there are components designed to facilitate the transfer of electrical current. These specific elements play a crucial role in maintaining consistent energy flow, especially in dynamic environments where parts experience continuous movement. Their purpose is to ensure proper contact with rotating components, allowing the system to function effectively without interruptions.

Role in Energy Transfer

These components are essential for maintaining a steady connection between stationary and moving elements. They help in directing power to specific parts by ensuring reliable conductivity, even under varying conditions. Their design allows them to work in high-friction environments, ensuring long-term efficiency and durability.

Key Features and Maintenance

Proper maintenance is vital to ensure their longevity and optimal performance. Over time, wear can reduce their effectiveness, which may lead to inefficient operation. Regular inspection and timely replacement help to avoid potential issues and ensure that the system continues to run smoothly.

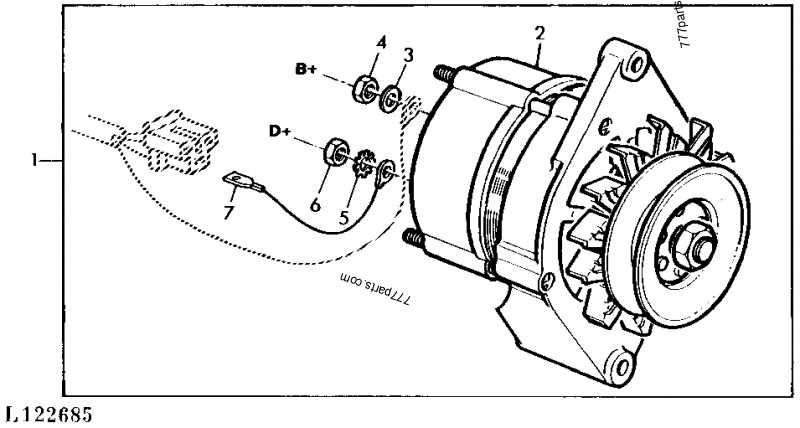

Battery and Alternator Connection Overview

Understanding the relationship between the energy storage unit and the power generation system is essential for maintaining proper vehicle operation. These two components work together to ensure that the vehicle’s electrical needs are met, with one unit supplying energy when necessary and the other ensuring a continuous flow of power during operation.

Energy Flow and Management

The flow of electricity is a dynamic process where energy is transferred from one unit to another. The connection between these two systems is vital for maintaining a stable voltage throughout the electrical network. In the charging system, one component ensures the battery remains charged, while the other draws power to maintain performance across various systems in the vehicle.

Maintaining Optimal Efficiency

For effective power management, the link between the storage and generation systems must remain secure and functional. Any disruption in this connection can lead to power imbalances, reducing the overall efficiency. Regular inspection and maintenance of the connection are crucial to avoid performance degradation and ensure reliable energy flow.

Understanding the Slip Rings Mechanism

The slip rings play a crucial role in enabling the smooth transfer of electrical energy from a rotating component to a stationary one. This mechanism is fundamental for maintaining a continuous flow of power in rotating systems, ensuring that electricity reaches the necessary components without interruption. The rings work in harmony with brushes to facilitate this transfer while minimizing wear and maintaining efficiency.

How Slip Rings Work

Slip rings are typically circular conductors that rotate with a central shaft. As they spin, brushes placed in contact with the rings allow electricity to flow from the rotating part to the stationary system. This continuous connection is essential for generating a stable current, especially in systems that require constant rotational motion.

Advantages of Using Slip Rings

One of the key benefits of utilizing slip rings is their ability to provide a reliable and efficient means of energy transfer without the need for complex wiring. This design reduces the risk of overheating and energy loss, offering an optimized solution for many applications that rely on rotating systems.

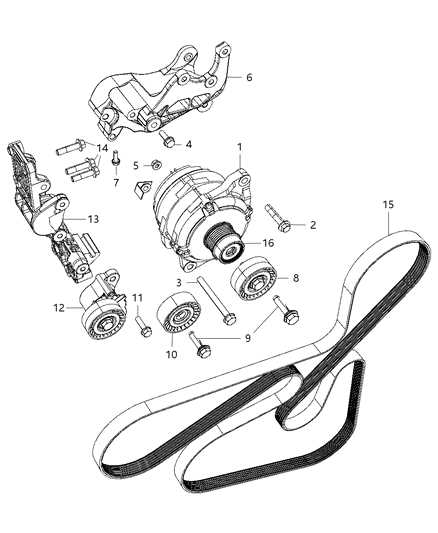

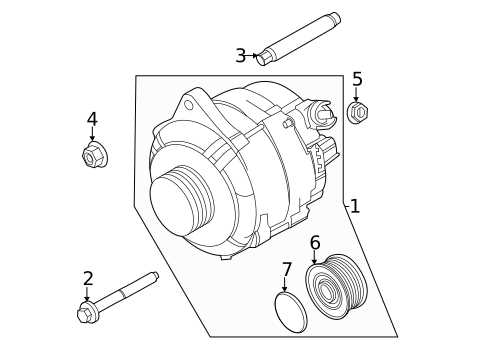

Impact of the Alternator Pulley

The component responsible for connecting the rotational motion from the engine’s crankshaft to the power generation unit plays a crucial role in its efficiency and overall performance. This part ensures that energy is properly transmitted, helping the system to maintain its functions and power output. If not properly maintained, it can lead to mechanical issues, affecting the power production capacity.

Role in Power Transmission

As the engine operates, the rotational force is transferred to this component, which in turn drives the internal mechanisms of the unit. The smooth transfer of energy is vital for consistent performance, and any malfunction here can cause strain, reducing the overall functionality of the system.

Effects of Wear and Tear

Over time, wear on the component can lead to improper functioning, causing the mechanism to operate inefficiently. A worn-out part can result in slipping, excessive friction, or even a complete failure to transmit energy, ultimately impacting the system’s ability to generate power when needed.

The Fan and Cooling System

The cooling mechanism plays a crucial role in maintaining optimal operating temperatures for the generator. Efficient heat dissipation is vital for preventing overheating and ensuring consistent performance over time. This system typically relies on airflow created by a fan, which aids in reducing the temperature of internal components during operation.

Function of the Cooling Fan

The fan is designed to direct airflow over key components, allowing heat to be expelled and preventing buildup. It operates continuously while the device is in motion, ensuring that the temperature remains within safe limits. This airflow process is essential for enhancing efficiency and reducing the risk of damage due to excess heat.

Maintaining Proper Cooling

To ensure optimal performance, regular maintenance of the cooling system is necessary. Dust and debris can obstruct airflow, which may cause the system to become less effective. Proper cleaning and checking the fan’s integrity are key practices in extending the longevity of the system. A well-maintained fan ensures steady airflow, which is critical for the reliable operation of internal components.

Diagnosing Common Alternator Problems

When it comes to vehicle electrical systems, several issues can arise that affect the generation and distribution of power. Recognizing the signs early can save time and cost in repairs. This section outlines how to identify common issues related to power generation components and their performance, which could lead to electrical malfunctions.

Several factors can indicate problems, ranging from irregular power flow to visible symptoms like warning lights. Understanding these indicators is essential in addressing underlying issues before they escalate into more severe damage.

| Symptom | Possible Cause | Suggested Action |

|---|---|---|

| Dim or flickering lights | Insufficient power output | Check the power generation unit for wear or faulty connections |

| Battery warning light on | Weak power supply | Inspect connections and test the voltage output |

| Dead battery | Failure in charging component | Test the charging unit for faults and replace if necessary |

| Unusual noise | Wear on internal components | Inspect internal components for wear and tear, replace if needed |