Understanding the Key Components of an Exhaust Diagram

The intricate network within a vehicle’s emission framework plays a vital role in ensuring optimal performance and environmental compliance. Each element functions harmoniously to regulate and minimize harmful outputs, thereby enhancing efficiency.

From the initial stages of gas processing to the final release, every segment is designed with precision. Understanding these interconnected elements can provide valuable insights into how modern vehicles achieve their ultimate goals of sustainability and performance.

By delving into the specific functionalities and interrelations of these components, one can appreciate the engineering marvel behind contemporary automotive design. This exploration not only highlights the significance of each segment but also underscores the importance of maintenance for overall system integrity.

Understanding Exhaust System Basics

The system responsible for channeling harmful gases away from an engine plays a crucial role in vehicle performance and environmental impact. A well-functioning setup not only enhances efficiency but also minimizes noise and emissions, contributing to a cleaner atmosphere.

Key functions of this mechanism include:

- Directing gases safely away from the engine

- Reducing noise generated during operation

- Enhancing overall engine performance

- Facilitating the treatment of pollutants before they exit

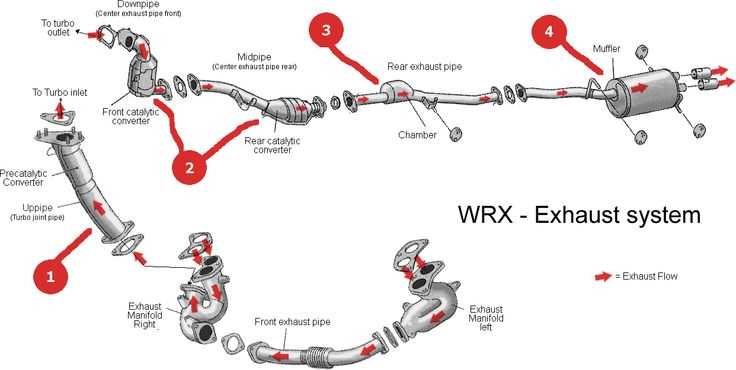

To grasp how this system operates, it’s essential to understand its main components:

- Headers: These collect gases from the engine cylinders and direct them into the main pathway.

- Manifold: Serves as the initial gathering point for gases before they travel further.

- Converter: A vital element that reduces harmful emissions through chemical reactions.

- Muffler: Designed to minimize noise, ensuring a quieter ride.

- Pipes: These create the passage through which gases flow to the outside atmosphere.

Understanding the importance and functionality of this assembly can help vehicle owners maintain their cars effectively, ensuring optimal performance and compliance with environmental standards.

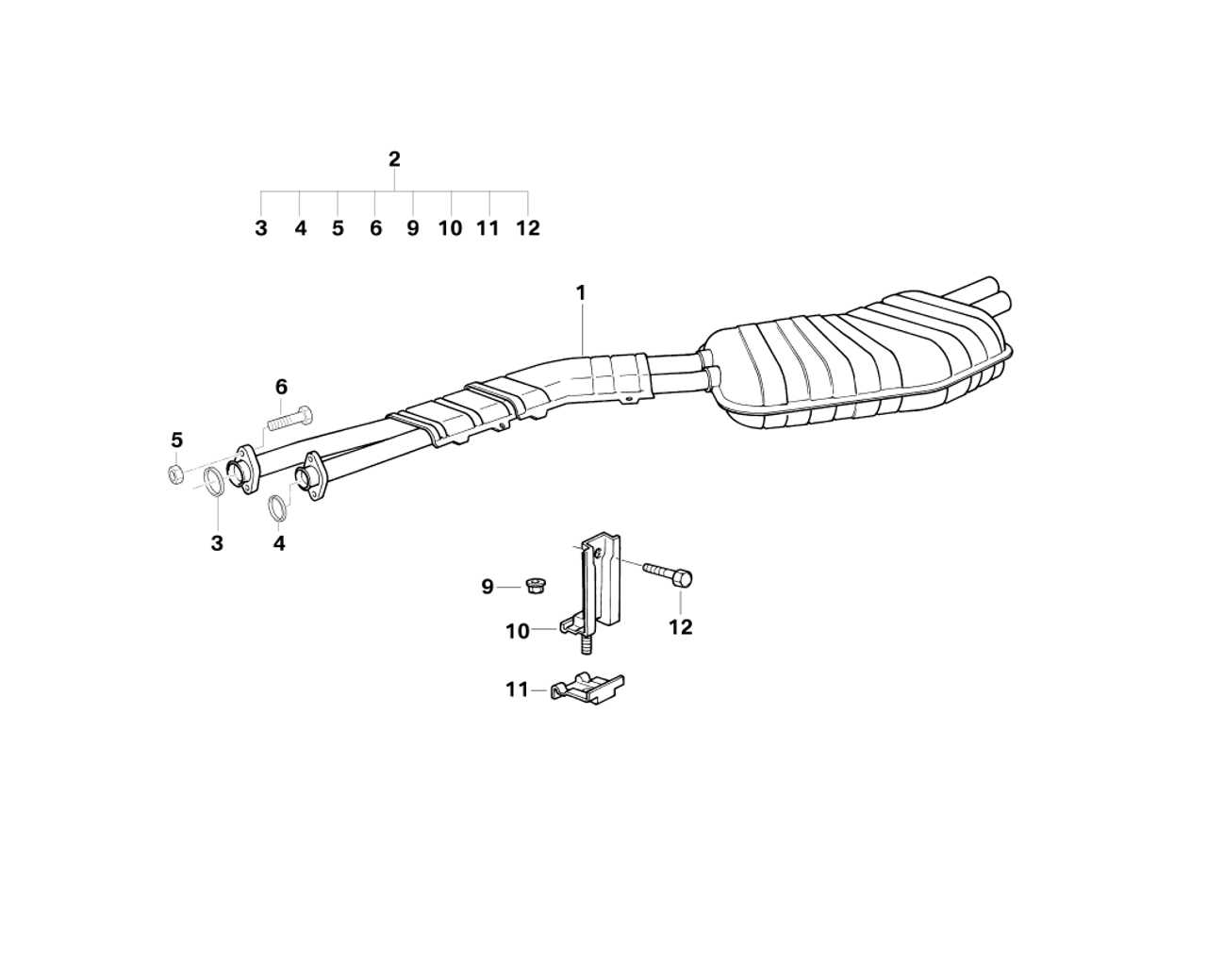

Key Components of Exhaust Diagrams

This section explores the essential elements that form the backbone of a vehicle’s emission system layout. Understanding these crucial aspects is vital for anyone looking to grasp how these systems operate efficiently and effectively.

| Component | Description |

|---|---|

| Manifold | Directs gases from the engine to the next stages. |

| Catalytic Converter | Transforms harmful emissions into less toxic substances. |

| Muffler | Reduces noise produced by the engine’s operation. |

| Tailpipe | Exits the system, allowing gases to exit the vehicle. |

Functions of the Exhaust System

The system responsible for managing gases generated during combustion plays a crucial role in vehicle performance and environmental protection. Its design ensures the effective removal of byproducts, contributing to a smoother operation of the engine and enhancing overall efficiency.

One primary function is the reduction of harmful emissions. By facilitating the conversion of toxic gases into less harmful substances, this system helps meet stringent environmental regulations and promotes cleaner air quality.

Another important aspect is noise control. The components are engineered to minimize sound levels produced during operation, allowing for a more pleasant driving experience while also adhering to legal noise limits.

Furthermore, the assembly supports optimal engine performance. By maintaining proper back pressure, it ensures that the engine operates efficiently, maximizing power output and fuel economy.

Lastly, the system aids in heat management. By directing hot gases away from the engine, it helps prevent overheating, thereby prolonging the life of engine components and enhancing reliability.

Common Types of Exhaust Layouts

Understanding the various configurations for vehicle emission systems is essential for optimizing performance and sound. Each design serves a unique purpose, affecting everything from efficiency to noise levels. Below are some prevalent configurations used in automotive engineering.

Single Exit systems feature one outlet, providing a straightforward and often lightweight solution. This layout is common in compact vehicles, emphasizing simplicity and cost-effectiveness.

Dual Exit designs incorporate two outlets, enhancing sound and aesthetics. This setup is frequently seen in performance-oriented cars, where a more aggressive tone is desired.

Quad Exit systems are characterized by four outlets, offering an even bolder sound and appearance. This configuration is popular in high-performance models, showcasing a powerful presence on the road.

Side Exit arrangements direct emissions to the side of the vehicle, often enhancing the visual appeal. This layout is commonly used in custom builds and racing applications, providing a unique style.

Dump Style layouts terminate the flow before reaching the standard outlet, producing a raw and unfiltered sound. This option is typically favored in racing environments where maximum performance is prioritized.

Each configuration can greatly influence the overall driving experience, making it crucial to choose the right one for your vehicle’s needs.

Importance of Proper Exhaust Flow

Effective movement of gases is crucial for optimal engine performance. When this process is well-managed, it leads to enhanced efficiency, reduced emissions, and improved overall functionality of the vehicle. Understanding the significance of this aspect can lead to better maintenance and performance outcomes.

Benefits of Efficient Gas Flow

- Improved Fuel Efficiency

- Enhanced Engine Power

- Lower Emission Levels

- Extended Engine Life

Consequences of Poor Flow

- Reduced Performance

- Increased Fuel Consumption

- Higher Emission Output

- Potential Engine Damage

Ensuring a smooth and effective route for gases is, therefore, the ultimate goal for any vehicle owner seeking to maximize their engine’s potential and longevity.

How Mufflers Impact Performance

Mufflers play a crucial role in enhancing vehicle functionality by influencing sound output and airflow dynamics. Their design and structure can significantly alter engine behavior, affecting both efficiency and power delivery. Understanding their impact can help enthusiasts make informed choices about modifications.

Sound Quality and Engine Response

A well-engineered muffler not only minimizes noise but also optimizes the resonance characteristics of the engine. This can lead to a more satisfying auditory experience while driving, as well as improved throttle response. By tuning the sound frequencies, a muffler can create a harmonious blend that complements the vehicle’s performance.

Flow Efficiency and Performance Gains

Effective muffler designs promote better airflow, reducing back pressure that can hinder engine output. When air moves more freely, the engine can perform at its ultimate potential, enhancing acceleration and overall power. Upgrading to a performance muffler can lead to noticeable gains, making it a popular choice among car enthusiasts.

Role of Catalytic Converters

Catalytic converters play a crucial function in modern automotive systems, significantly influencing environmental outcomes. These devices facilitate chemical reactions that transform harmful emissions into less damaging substances, thereby promoting cleaner air and reducing pollution levels.

| Function | Description |

|---|---|

| Reduction of Emissions | Transforms toxic gases such as carbon monoxide and nitrogen oxides into harmless byproducts. |

| Enhancement of Efficiency | Improves overall engine performance by optimizing fuel consumption and emission outputs. |

| Environmental Impact | Contributes to decreased air pollution, supporting public health and environmental sustainability. |

Ultimately, the integration of these converters is vital for achieving stringent regulatory standards and fostering a healthier ecosystem.

Exploring Exhaust Manifold Designs

In the realm of automotive engineering, the configuration of the component that collects gases from the engine plays a crucial role in performance. Variations in design can significantly influence efficiency, power output, and overall vehicle dynamics. Understanding these designs allows for a deeper appreciation of how vehicles operate at their best.

Types of Configurations

There are several configurations available, each tailored to specific performance needs. Equal-length designs promote uniform gas flow, reducing turbulence and enhancing efficiency. In contrast, shorty manifolds focus on increasing low-end torque, making them ideal for certain driving conditions.

Materials and Their Impact

The choice of materials is also essential in determining durability and thermal management. Stainless steel and cast iron are popular for their strength and heat resistance. Advanced composites are emerging as lightweight alternatives that promise to improve performance without compromising structural integrity.

Effects of Exhaust Backpressure

The phenomenon of resistance within a vehicle’s discharge system can significantly influence engine performance and efficiency. Understanding how this pressure affects overall operation is crucial for optimizing performance and achieving desired power outputs.

Impact on Performance

When resistance increases, it can lead to a decrease in horsepower and torque. The engine may struggle to expel combustion gases efficiently, resulting in a loss of power. Optimal flow is essential for maintaining engine health and maximizing output.

Fuel Efficiency and Emissions

Increased backpressure can also affect fuel consumption. Engines may compensate for reduced efficiency by injecting more fuel, leading to higher emissions and a decrease in overall fuel economy. Therefore, managing this resistance is vital not only for performance but also for environmental considerations.

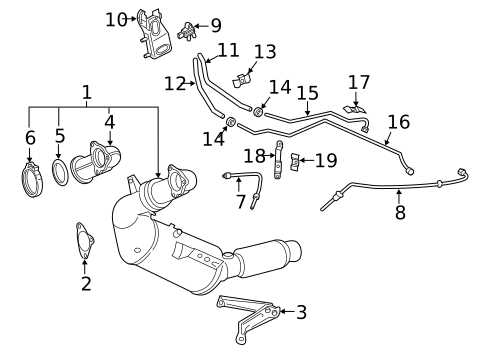

Visualizing Exhaust Pipe Configurations

Understanding the layout of a vehicle’s emission system is essential for optimizing performance and efficiency. Various arrangements can significantly influence how gases flow and how effectively they are expelled. By exploring these configurations, one can appreciate the intricate balance between design and functionality.

Curved Sections: Curved segments facilitate smooth transitions, reducing turbulence and enhancing gas flow. The radius of these bends plays a crucial role in maintaining velocity and minimizing back pressure.

Joint Types: Different connection styles, such as flanges and welds, are used to join segments. Each type affects the overall integrity and longevity of the system, contributing to its performance under various conditions.

Resonators: Integrating specific components can alter sound characteristics and assist in tuning the system. These additions can create a more refined acoustic profile while ensuring efficient expulsion of byproducts.

Termination Points: The exit design impacts how gases disperse into the atmosphere. Strategies such as using angled tips can help direct flow and reduce potential disturbances around the vehicle.

By visualizing these configurations, one gains insight into the complexities of automotive engineering, highlighting the interplay between design, performance, and environmental considerations.

Maintenance Tips for Exhaust Systems

Regular upkeep of your vehicle’s ventilation system is crucial for optimal performance and longevity. Ensuring that this component functions effectively not only enhances engine efficiency but also minimizes environmental impact.

- Conduct visual inspections periodically for signs of wear, corrosion, or damage.

- Listen for unusual noises that may indicate leaks or loose connections.

- Check for rust, especially in regions with heavy salt use during winter.

Additionally, consider the following practices:

- Schedule professional inspections at least once a year.

- Replace worn or damaged components promptly to prevent further issues.

- Use high-quality materials when making repairs or replacements.

Adopting these practices will help you maintain your vehicle’s efficiency and extend its lifespan.

Upgrading Your Exhaust System Effectively

Enhancing the performance of your vehicle’s emission system can lead to significant improvements in power, efficiency, and sound. A well-planned upgrade not only optimizes engine output but also contributes to a more engaging driving experience. Whether you’re looking for better airflow or a sportier tone, understanding the options available is crucial.

First, it’s essential to assess your current setup. Identifying any limitations in the existing configuration will guide you in selecting the right components for your needs. This evaluation will help determine whether a simple modification or a complete overhaul is necessary.

Next, consider the materials involved. High-quality metals, such as stainless steel, offer durability and resistance to corrosion, ensuring longevity. Additionally, the diameter of the piping can influence back pressure, affecting performance. Opting for larger pipes may enhance airflow but could also require tuning adjustments to maximize benefits.

Finally, always keep in mind the sound characteristics that come with modifications. Whether you prefer a subtle tone or a more aggressive growl, choosing the right configuration can greatly influence the overall experience. Listening to audio samples or visiting shops for live demonstrations can help in making an informed decision.