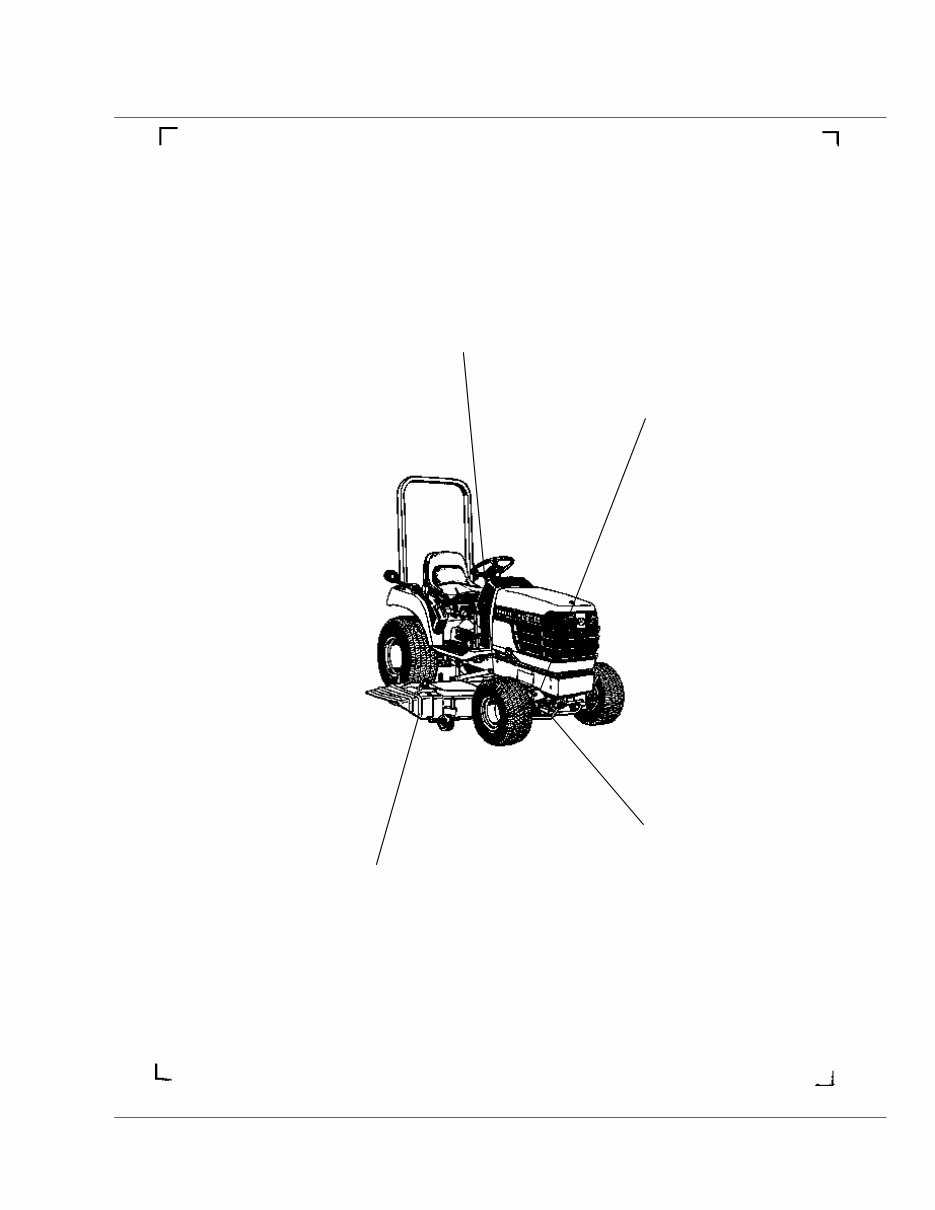

RCK60B-22BX Parts Diagram Overview

In various types of machinery, understanding how each element contributes to the whole system is essential for ensuring smooth operation and maintenance. Every component plays a crucial role in the overall functionality, and recognizing these elements helps users perform necessary adjustments or repairs.

For those working with mechanical systems, visual representations of the individual elements and their arrangement are often indispensable. They provide a clear overview of how different elements interact with each other, making the identification and replacement of key elements easier.

By studying these layouts, users gain a deeper insight into the inner workings of complex systems, enhancing their ability to troubleshoot and maintain the equipment effectively. It simplifies not only the installation but also the ongoing care and optimization of the system.

Overview of RCK60B-22BX Components

This section provides a detailed description of the various elements that make up the functioning of the model. Each element plays a crucial role in ensuring smooth operation and reliability.

Key Structural Elements

- Frame: Supports the overall structure, providing stability and durability during use.

- Blades: Responsible for efficient cutting, ensuring precision and high performance.

- Mounting Hardware: Ensures all components are securely attached, contributing to safety and longevity.

Operational Components

- Engine Assembly: Powers the system, ensuring it runs at optimal capacity for prolonged periods.

- Drive Mechanism: Transmits power effectively, converting energy into mechanical action.

- Control Levers: Allow for precise adjustments, offering flexibility in operation.

Together, these parts form a cohesive system that provides reliable performance and ease of maintenance.

Main Features of RCK60B-22BX Model

This model stands out due to its impressive performance capabilities and reliable design, making it suitable for various applications. Its structure is built to endure demanding conditions, ensuring long-lasting operation with minimal maintenance.

Durability and Efficiency

- Engineered with robust materials that withstand heavy use.

- Offers high efficiency, ensuring optimal functionality over extended periods.

- Low maintenance requirements due to its streamlined design.

Advanced Operational Capabilities

- Equipped with modern features for enhanced control and precision.

- Capable of seamless integration into different systems, boosting overall productivity.

- Ensures safe operation with built-in protective mechanisms.

This model provides users with a dependable and high-performing solution, ideal for both industrial and specialized uses.

Internal Mechanisms and Key Parts

The system’s internal workings consist of various crucial elements that ensure smooth functionality. These components work in harmony to maintain efficiency and reliability in operation. Understanding how these elements interact can provide valuable insights into optimizing performance.

- Control Unit: The central hub that manages all signals and regulates the overall system behavior, ensuring proper coordination.

- Motor Assembly: This drives the entire mechanism, converting energy into motion, and is vital for consistent output.

- Transmission Components: Responsible for transferring energy between sections, allowing the system to function seamlessly under various conditions.

- Sensors: These detect environmental factors and provide feedback to adjust operations dynamically for optimal performance.

- Structural Framework: Provides stability and support to all other elements, ensuring durability and longevity.

Each element has its specific role, contributing to the overall functionality and making the system adaptable to various scenarios.

Electrical System Structure

The electrical configuration of this equipment is designed to ensure efficient power distribution and proper functioning of all integrated components. This section outlines the organization of key elements that control the flow of electricity, focusing on their interaction and placement within the system.

| Component | Function |

|---|---|

| Power Supply | Provides the necessary voltage to activate the system’s various modules. |

| Wiring Network | Distributes electrical energy between different components to maintain connectivity. |

| Control Unit | Regulates the power flow and coordinates operations between different elements. |

| Fuses and Relays | Protect the system from overload and ensure safe operation by interrupting excessive currents. |

Cooling and Ventilation Assembly

The cooling and ventilation system plays a crucial role in maintaining the optimal temperature and airflow. It ensures that heat is effectively dissipated while fresh air circulates, preventing the equipment from overheating and ensuring reliable operation.

Key Components and Functions

Within this system, several elements work together to ensure efficiency. Fans are responsible for driving air through various channels, helping to cool internal mechanisms. Heat exchangers contribute by transferring excess warmth away from sensitive parts, protecting the system from damage.

Maintenance and Care

Regular upkeep is essential for the long-term performance of the cooling system. Cleaning the ventilation pathways and ensuring fans operate without obstruction helps prevent overheating. Proper maintenance ensures uninterrupted functionality and extends the life of the system.

Control Panel Layout

The control panel is a vital component that enables users to interact with the system effectively. It serves as the interface through which various functions and settings can be accessed, ensuring smooth operation and control over the equipment. Understanding the arrangement and functionality of the controls is essential for optimal usage and maintenance.

Key Components

Typically, the control panel consists of a variety of buttons, switches, and indicators. Each element is strategically placed to facilitate intuitive operation. Common features may include power controls, adjustment knobs, and status indicators, all designed to provide clear feedback to the user regarding the system’s performance.

Functionality Overview

Each control element plays a specific role, contributing to the overall efficiency of the system. For instance, control switches may allow users to toggle between different operational modes, while adjustment knobs can fine-tune settings to meet specific requirements. Familiarity with these components enhances user confidence and ensures effective management of the equipment.

Maintenance Guidelines for RCK60B-22BX

Regular upkeep of machinery is essential to ensure optimal performance and longevity. Implementing effective maintenance practices can help prevent unexpected breakdowns and enhance the efficiency of the equipment.

Routine Inspections: Conduct frequent evaluations to identify any signs of wear or damage. Check all components for proper functionality and replace any defective elements promptly.

Lubrication: Apply appropriate lubricants to moving parts to minimize friction and reduce wear. Ensure that lubrication is carried out according to the manufacturer’s specifications.

Cleaning: Keep the machinery clean and free from debris. Accumulated dirt can hinder performance and lead to premature failure. Utilize suitable cleaning agents that do not harm the equipment.

Calibration: Regularly calibrate the settings to maintain accuracy. Proper calibration ensures that the machinery operates within the required parameters, enhancing overall efficiency.

Documentation: Maintain a log of all maintenance activities. Recording inspections, repairs, and replacements can help track the history of the equipment and inform future maintenance schedules.

Wiring and Connections Overview

This section provides a comprehensive insight into the electrical setup and interconnections essential for optimal functionality. Understanding these connections is vital for ensuring the system operates smoothly and efficiently, allowing for effective communication between various components.

Key Electrical Components

Each device within the system is equipped with specific electrical elements that facilitate its operation. These components, which include connectors, wires, and terminals, play a crucial role in maintaining reliable communication and power transfer.

Connection Techniques

Proper techniques for establishing connections are critical to avoid issues such as signal loss or electrical interference. Employing techniques like secure soldering or utilizing high-quality connectors can significantly enhance the overall performance and longevity of the system.

Motor and Drive System Parts

The motor and drive system serves as the backbone of machinery, playing a crucial role in its operation and efficiency. Understanding the various components within this system is essential for maintenance and troubleshooting. Each element contributes to the overall functionality, ensuring that power is effectively converted and transmitted to perform specific tasks.

- Electric Motor: The primary component that converts electrical energy into mechanical energy, facilitating movement.

- Gearbox: A critical unit that adjusts the torque and speed of the motor output, allowing for optimal performance.

- Belt or Chain Drive: A method of transferring power from the motor to other moving parts, ensuring smooth operation.

- Couplings: Connectors that join two shafts, allowing for flexibility in alignment and reducing vibration.

- Bearings: Essential for minimizing friction between moving parts, enhancing the longevity of the system.

- Control Systems: Electronic or mechanical devices that regulate the motor’s speed, direction, and performance.

Regular inspection and maintenance of these components are vital for the longevity and efficiency of the entire system. Identifying wear and tear early can prevent larger issues and ensure continuous operation.

Replacement Parts and Their Functions

Understanding the components of a device and their specific roles is essential for efficient maintenance and operation. Each element plays a vital part in ensuring the system functions smoothly and effectively. Knowing the purpose of each piece can aid in troubleshooting and replacement, enhancing overall performance.

Replacement components serve various functions that contribute to the operational integrity of the entire system. Below is a table summarizing key components and their respective roles:

| Component | Function |

|---|---|

| Motor | Drives the main operations, providing necessary power. |

| Filter | Cleans the air or fluid, preventing contaminants from affecting performance. |

| Sensor | Monitors specific parameters, providing data for system adjustments. |

| Housing | Protects internal components from environmental factors and damage. |

| Control Unit | Manages operations and settings, ensuring efficient functioning. |