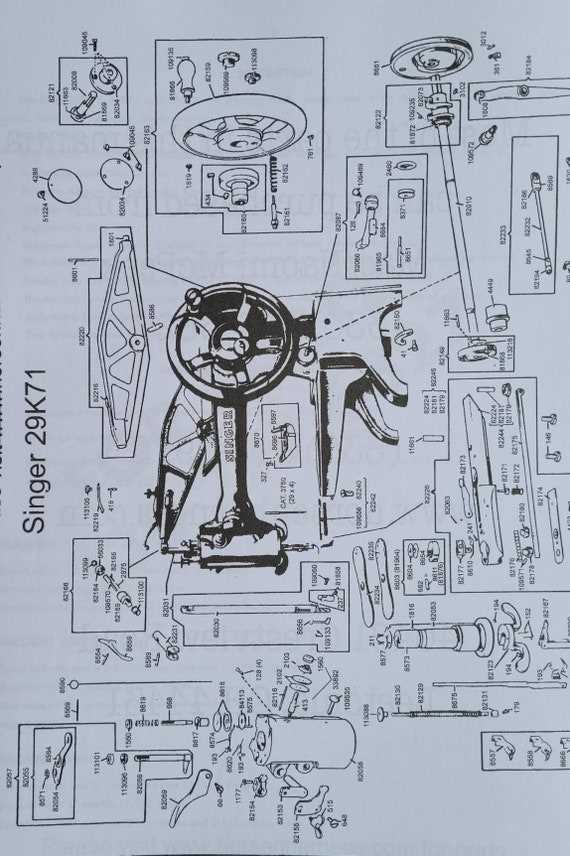

Complete Parts Diagram for the Singer 29k Sewing Machine

For those who cherish the art of stitching, a thorough comprehension of the various elements that make up their beloved equipment is essential. Each piece plays a crucial role in ensuring smooth operation and optimal performance. By delving into the intricacies of these components, enthusiasts can enhance their sewing experience and troubleshoot issues effectively.

Many individuals may find themselves curious about the configuration and relationships between different sections of their machine. A well-organized overview can serve as an invaluable resource, illuminating the purpose of each part and how they contribute to the overall functionality. Gaining insights into these elements not only empowers users but also fosters a deeper appreciation for the craftsmanship involved in sewing.

Whether you are a novice or a seasoned professional, familiarizing yourself with the setup can lead to more confident and efficient use of your equipment. By exploring the layout and interconnectivity of various segments, you can optimize your sewing practices and ensure longevity in your machinery. This knowledge acts as a foundation for creative exploration, enabling you to embark on exciting projects with ease.

Overview of the Classic Sewing Machine

This section provides a comprehensive look at a notable model in the world of stitching. Renowned for its durability and performance, it has become a favorite among enthusiasts and professionals alike. Understanding its key features and components is essential for effective use and maintenance.

Key Features

- Robust construction for longevity

- Versatile capabilities for various fabric types

- Precision stitching for high-quality results

- Accessible controls for ease of use

Essential Components

- Needle mechanism for accurate needle placement

- Feed dogs that assist in fabric movement

- Bobbin system ensuring consistent thread tension

- Presser foot for fabric control during stitching

Understanding the Machine Components

In any mechanical device, a clear comprehension of its various elements is crucial for optimal performance and maintenance. Each component plays a significant role, contributing to the overall functionality and efficiency of the system.

The framework provides the essential support structure, ensuring stability during operation. Within this, the driving mechanism translates energy into motion, allowing for seamless interaction between different parts. Furthermore, the control systems govern the operations, facilitating precise adjustments and enhancing usability.

Lastly, regular assessment and familiarization with these elements enable users to troubleshoot issues effectively, ensuring the machine remains in peak condition throughout its lifespan.

Importance of a Parts Diagram

A visual representation of components is crucial for understanding the intricate workings of machinery. Such illustrations provide a clear overview, allowing users to identify individual elements and their relationships. This clarity is especially beneficial when it comes to maintenance and repairs, as it helps streamline the process and minimizes the risk of errors.

Having a detailed schematic enables users to quickly locate specific pieces, making it easier to assess wear and tear or diagnose issues. Additionally, it serves as an essential reference for assembling or disassembling equipment, ensuring that every part is correctly positioned. This not only enhances the longevity of the device but also promotes efficient operation.

Furthermore, a comprehensive visual guide aids in educating new users, offering them insights into the functionality of each component. This understanding fosters a deeper appreciation for the craftsmanship involved and encourages responsible usage. Ultimately, a well-crafted visual representation is an invaluable tool for both novices and experienced operators alike.

Common Issues with Singer 29K

The classic sewing machine model, known for its durability and functionality, often faces certain challenges that users may encounter. Understanding these frequent problems can help in maintaining optimal performance and ensuring a smooth sewing experience.

One common issue involves tension adjustments, which may lead to uneven stitching or thread breakage. Users often find that the tension settings can be finicky, requiring periodic calibration to achieve consistent results.

Another prevalent concern is related to the machine’s feeding mechanism. Malfunctions can occur, resulting in fabric not being fed properly, which can disrupt the workflow and affect the quality of the finished product.

Oil and lubrication are crucial for the longevity of this equipment. Insufficient maintenance can lead to increased friction, causing the machine to operate less efficiently or even stall during use.

Finally, users may experience difficulties with needle compatibility. Choosing the wrong type or size can affect performance and result in damage to both the fabric and the machine itself. Regularly checking and replacing needles is essential for optimal operation.

How to Locate Replacement Parts

Finding the right components for your sewing machine can seem daunting, but with a systematic approach, it becomes manageable. Identifying the necessary elements involves understanding your device’s model and specifications, which will guide you in sourcing the correct items. This section outlines effective strategies to assist you in your search for these essential components.

Start by consulting the user manual or documentation that accompanied your machine. This often includes valuable information about the specific components used. If you do not have access to the original manual, many manufacturers provide downloadable versions on their websites.

| Method | Description |

|---|---|

| Online Retailers | Websites dedicated to sewing supplies typically offer a wide selection of components. Use the search feature with your model number for targeted results. |

| Local Shops | Visit local craft or sewing supply stores. Staff may assist in finding compatible components and provide personal recommendations. |

| Forums and Communities | Online groups and forums can be excellent resources. Experienced users often share insights and can point you toward reputable suppliers. |

| Manufacturer Contact | Reaching out directly to the manufacturer can yield precise information on where to obtain the correct elements for your device. |

By utilizing these methods, you will streamline your search and increase the likelihood of finding the components needed to keep your machine functioning optimally.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues with your sewing machine. By following these detailed instructions, you will be able to identify problems and perform necessary repairs efficiently, ensuring your device operates smoothly and reliably.

Identifying Common Issues

The first step in the repair process is to recognize the symptoms of malfunction. Common issues may include thread jams, inconsistent stitching, or unusual noises. Carefully examine the machine to pinpoint the source of the problem. Ensure you have the appropriate tools on hand, such as screwdrivers and cleaning brushes, to facilitate the repair.

Step-by-Step Repair Process

Once you have identified the issue, proceed with the following steps:

- Turn off the machine: Always ensure the device is powered down to avoid accidents.

- Access the internal components: Remove any covers or panels as needed to reach the affected areas.

- Clean and inspect: Use a brush to remove dust and debris. Check for any worn or damaged parts.

- Replace or adjust: If you find defective components, replace them with suitable replacements or make necessary adjustments to align the mechanisms properly.

- Reassemble and test: After repairs, reattach any covers and power on the machine to check functionality.

Following these steps methodically will help restore your sewing device to optimal performance. Regular maintenance will also prolong its lifespan and enhance your sewing experience.

Tools Needed for Maintenance

Proper upkeep of your sewing machine requires a variety of essential instruments to ensure smooth operation and longevity. Having the right tools on hand not only simplifies the maintenance process but also enhances the overall performance of your device.

Begin with a set of screwdrivers in various sizes to tackle different screws. A pair of tweezers will help you handle small components with precision, while a brush is essential for removing lint and dust. Additionally, a soft cloth for cleaning and lubricating oil will keep mechanical parts functioning optimally. Finally, a needle threader can ease the task of threading, making your sewing experience more efficient.

Detailed Parts Diagram Explanation

This section aims to provide a comprehensive overview of the intricate components that contribute to the functionality of a specific sewing machine model. By breaking down the various elements, one can better appreciate how each piece works harmoniously to ensure optimal performance.

Understanding each component is crucial for both maintenance and effective operation. Each segment has a unique role, influencing the overall efficiency and longevity of the device. Familiarity with these parts empowers users to troubleshoot issues, perform repairs, and make informed decisions regarding replacements.

Additionally, having a visual reference aids in recognizing the location and arrangement of these essential elements. This knowledge not only enhances the user experience but also fosters a deeper connection with the machinery itself.

Identifying Each Component’s Function

Understanding the roles of individual elements within a complex mechanism is crucial for effective operation and maintenance. Each component contributes to the overall functionality, working in harmony to achieve the ultimate performance. By examining these elements, one can enhance both efficiency and longevity.

The drive mechanism is responsible for converting energy into motion, powering the entire system. Its reliability ensures smooth operation, making it a vital aspect of the assembly.

The needle holder plays an essential role in securely positioning the needle, allowing for precision and control during usage. A stable holder contributes to consistent stitching quality.

The tension assembly regulates the thread tension, ensuring that the fabric feeds correctly. Proper tension adjustment is necessary for achieving desired stitch effects.

The feed dogs engage the fabric, moving it through the mechanism. Their design and movement are crucial for the accurate progression of material, influencing the overall output.

The presser foot applies pressure on the fabric, maintaining stability while stitching. Its appropriate use enhances fabric handling and prevents slipping.

By delving into each component’s purpose, one can better understand the intricacies involved, leading to improved operation and troubleshooting capabilities.

Where to Buy Genuine Parts

When seeking authentic components for your sewing machine, it’s essential to know the right sources to ensure quality and compatibility. Reliable suppliers provide peace of mind and maintain the longevity of your equipment.

Authorized dealers are a top choice, as they offer original items with warranties. You can often find them through the official website of the manufacturer or in reputable sewing specialty stores.

Another option includes online marketplaces known for their robust return policies and customer reviews. Ensure the seller has a solid reputation to avoid counterfeit products.

Additionally, local repair shops might stock genuine components or be able to order them for you. Establishing a relationship with these professionals can lead to valuable advice on maintenance and care.

Finally, consider community forums and groups where enthusiasts share their experiences and recommendations for sourcing authentic items. This can lead to discovering lesser-known but trustworthy vendors.

Tips for Efficient Repairs

When tackling mechanical maintenance, adopting a strategic approach can greatly enhance your productivity and effectiveness. Understanding the components involved and having a clear plan can save time and minimize frustration during the repair process.

Preparation is Key

Before starting any fixing task, ensure you have all necessary tools and replacement elements on hand. Organizing your workspace can prevent unnecessary delays. A clean and well-arranged area allows for better focus and efficiency. Additionally, familiarizing yourself with the system’s intricacies can aid in identifying issues quickly.

Follow a Systematic Approach

Utilizing a methodical technique can streamline the troubleshooting process. Begin with a thorough examination to pinpoint the root cause of the malfunction. Documenting your findings during each step can help track progress and avoid repeated mistakes. After resolving the issue, re-evaluate your work to ensure everything is functioning correctly, thereby enhancing the longevity of your equipment.

Preventative Maintenance Practices

Implementing a regular maintenance routine is essential for ensuring the longevity and optimal performance of your equipment. By proactively addressing potential issues before they escalate, users can significantly reduce downtime and repair costs. This section will outline key strategies and practices that help maintain functionality and efficiency.

One crucial practice is to conduct routine inspections, which allow for the early detection of wear and tear. Regularly examining components for signs of damage or malfunction can prevent minor issues from developing into major failures. Additionally, keeping a detailed log of maintenance activities can help track performance trends and highlight areas requiring attention.

Another important aspect is lubrication, which minimizes friction and wear on moving parts. Using the appropriate type and amount of lubricant at regular intervals ensures that machinery operates smoothly. It’s essential to follow manufacturer guidelines for lubrication to avoid any adverse effects.

Cleaning is equally vital in maintenance efforts. Dust, lint, and debris can accumulate over time, potentially leading to overheating or mechanical issues. Establishing a cleaning schedule will help keep equipment in peak condition and prolong its lifespan.

Lastly, staying informed about updates or improvements in maintenance practices can lead to better outcomes. Participating in workshops or training sessions can provide valuable insights into effective care techniques and emerging technologies that enhance performance and reliability.

Resources for Further Learning

Enhancing your knowledge about sewing machines can be a rewarding journey. Various materials and references are available to help enthusiasts understand the intricate mechanisms and improve their skills. These resources range from online tutorials to printed manuals, offering valuable insights for both beginners and seasoned users.

Online Tutorials and Courses

Numerous websites provide comprehensive courses that cover the basics as well as advanced techniques. Engaging with video content can greatly enhance your practical understanding, allowing you to delve into specific functionalities and repairs. Platforms like YouTube feature countless creators who share their expertise through step-by-step guides.

Books and Manuals

For those who prefer traditional learning, a variety of books offer in-depth explanations and detailed illustrations. Investing in a good manual can provide the ultimate reference for troubleshooting and maintenance, ensuring your machine operates smoothly. Libraries often stock useful guides, and many titles are available for purchase online.