Understanding the Components of a Sink Drain

The area beneath the basin is a complex assembly of elements that work together to ensure proper water flow and disposal. Each element has its own function, contributing to the efficient removal of liquids and preventing blockages. In this section, we will explore the essential elements of this system and how they interact.

Key components of this setup are carefully designed to facilitate the smooth operation of the system. These pieces help manage the water flow and prevent unwanted materials from causing issues. By understanding how these parts work together, you can easily maintain or repair any issues that may arise.

Exploring these elements will give you insight into how the entire system functions, from the top connection point to the exit. Whether you’re troubleshooting or simply learning more about the mechanisms involved, a basic knowledge of this assembly will prove useful.

Key Components of a Sink Drain System

The fluid removal system beneath the basin consists of several crucial elements that ensure the smooth evacuation of liquids. These components work together to guide wastewater through a sequence of pathways, preventing blockages and leaks. Understanding these elements helps maintain the efficiency and longevity of the setup.

Primary Structure Elements

- Piping network: A series of tubes that channel liquid away from the basin, connecting to the household’s larger waste disposal system.

- Connector pieces: Attach different sections of the piping system, ensuring a secure fit and preventing leaks at the joints.

- Control mechanism: A device that manages the flow, allowing users to release or retain liquids as needed.

Sealing and Protection

- Seal rings: These ensure tight connections between parts, preventing unwanted fluid escape.

- Protective covers: Positioned at key points, these prevent debris from entering the system and causing clogs.

Understanding the Drain Pipe Structure

The configuration of pipes beneath a fixture is designed to efficiently transport wastewater while preventing blockages and ensuring a smooth flow. This system involves several interconnected components, each playing a crucial role in maintaining proper function.

Main Sections of the Pipe System

The pipe setup generally consists of distinct sections that are strategically placed to ensure water moves through effectively. These sections help direct water to its intended destination and manage potential issues like buildup or overflow.

- Vertical pipe: This part carries water downward, using gravity to guide the flow towards the main exit.

- Curved section: Positioned to capture debris, this section ensures that solids are not flushed too quickly into the larger system.

- Connecting joints: These links ensure all parts of the system work together, preventing leaks and maintaining the flow’s consistency.

Additional Elements for Stability

To maintain the pipe network’s stability, various supports and fasteners are used. These ensure that the entire system remains securely in place, even with constant water movement and usage.

P-Trap: Purpose and Design

The P-trap plays a crucial role in ensuring proper functionality within plumbing systems. Its specific shape and configuration are essential for preventing certain issues that can occur in the piping. This simple yet effective structure is designed to maintain smooth operation and protect the overall system from unwanted elements.

Design of the P-trap is based on a curved segment that retains a small amount of liquid. This retained liquid acts as a barrier, stopping gases from passing through and keeping the environment safe. Its unique form ensures continuous flow, while also making maintenance straightforward.

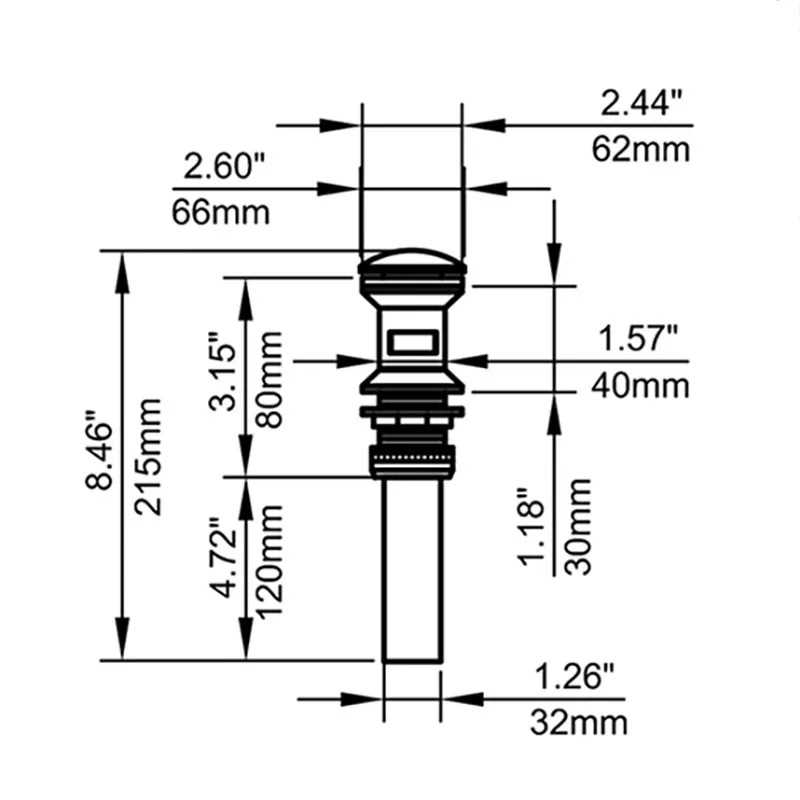

Role of the Tailpiece in Drainage

The tailpiece is a crucial element that connects the basin outlet to the plumbing system, allowing water to flow efficiently from the basin to the pipes below. Its function is to ensure smooth passage of liquids while minimizing the risk of leaks or blockages in the connecting pipes.

- Connection to plumbing: The tailpiece links the basin’s waste outlet to the piping, ensuring a seamless transition of water into the underlying system.

- Leak prevention: Proper installation of this component reduces the risk of water escaping at the junction between the outlet and the piping.

- Material and design: Typically made from durable materials, the tailpiece is built to withstand constant exposure to moisture and other substances.

- Adjustability: The tailpiece is often adjustable to accommodate different basin heights, ensuring compatibility with various configurations.

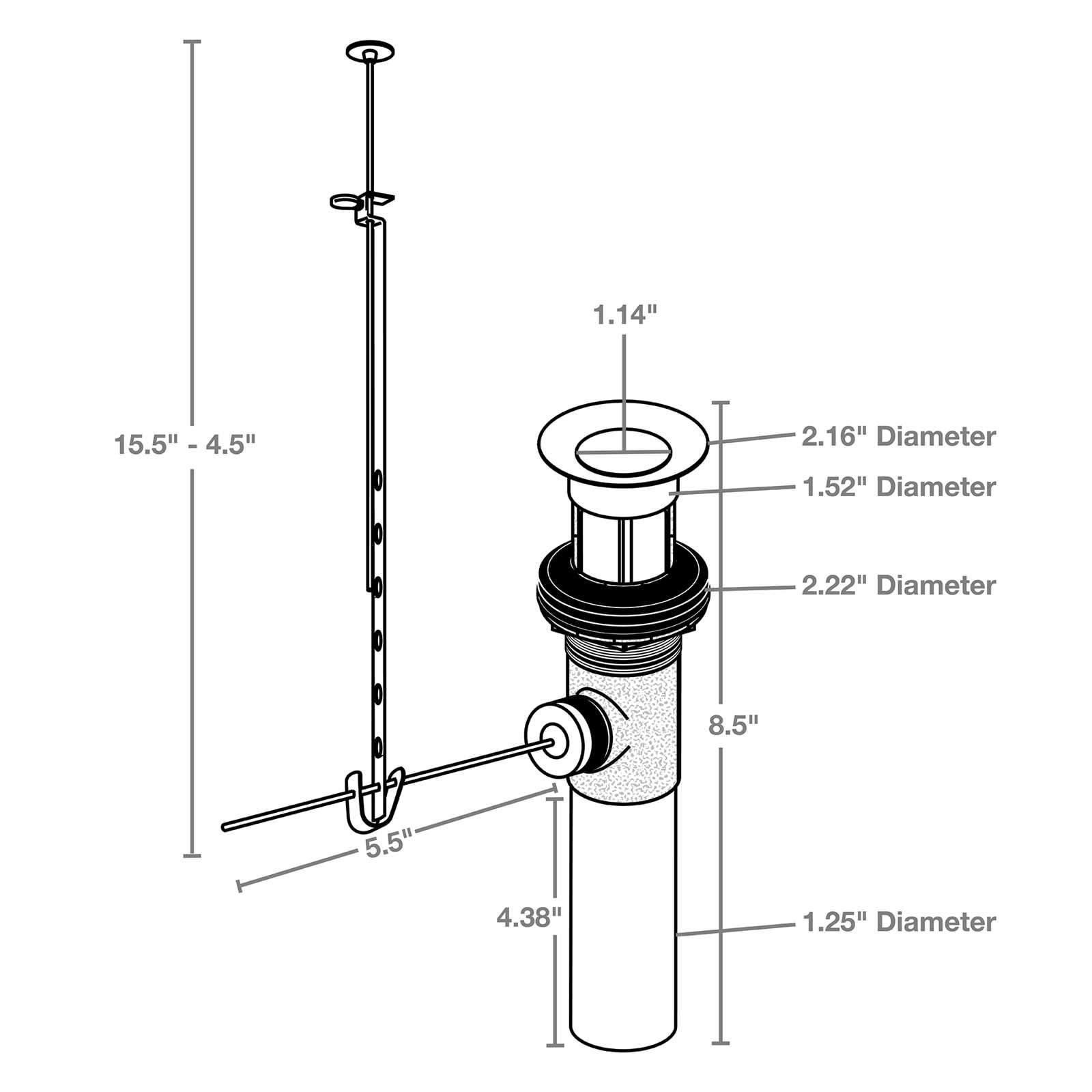

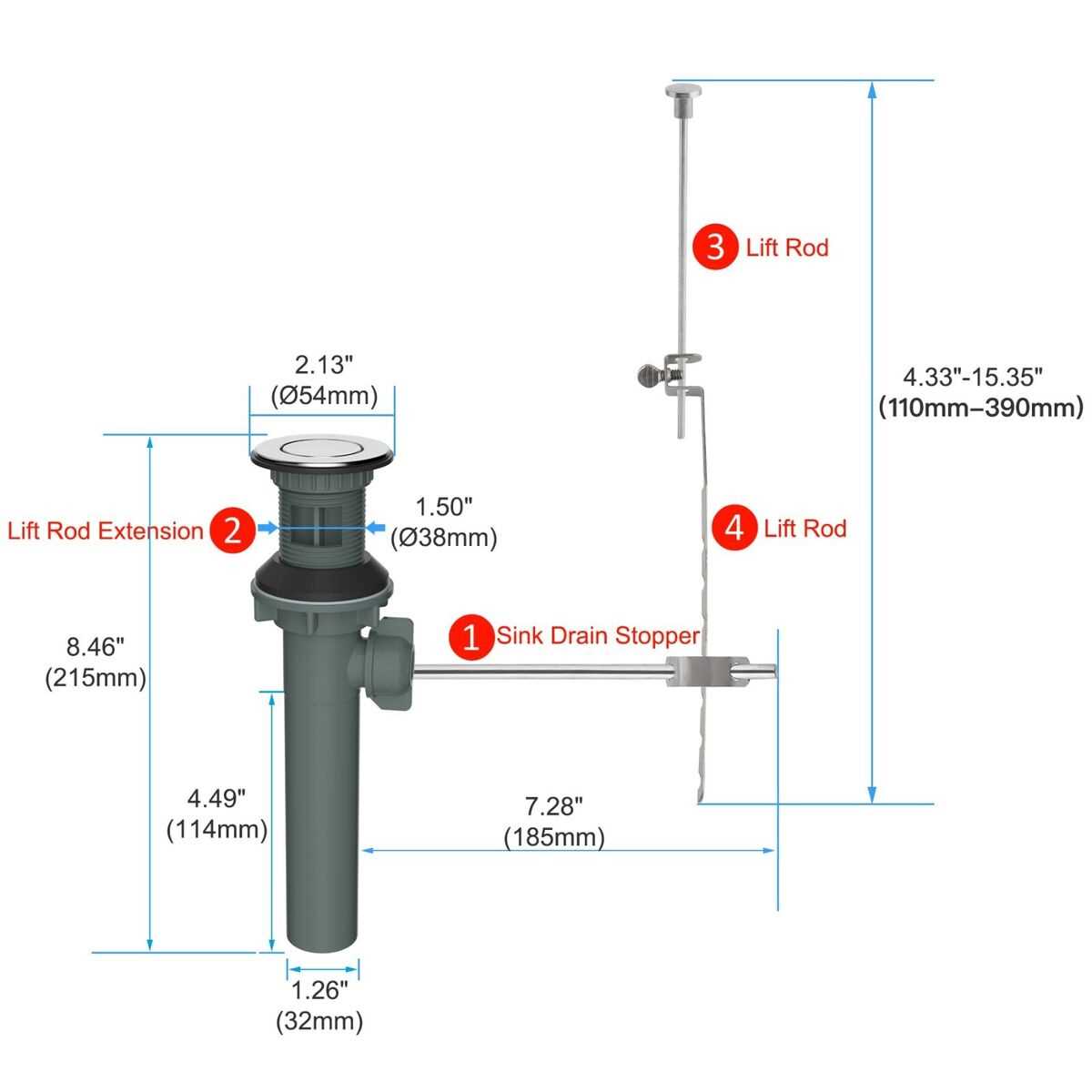

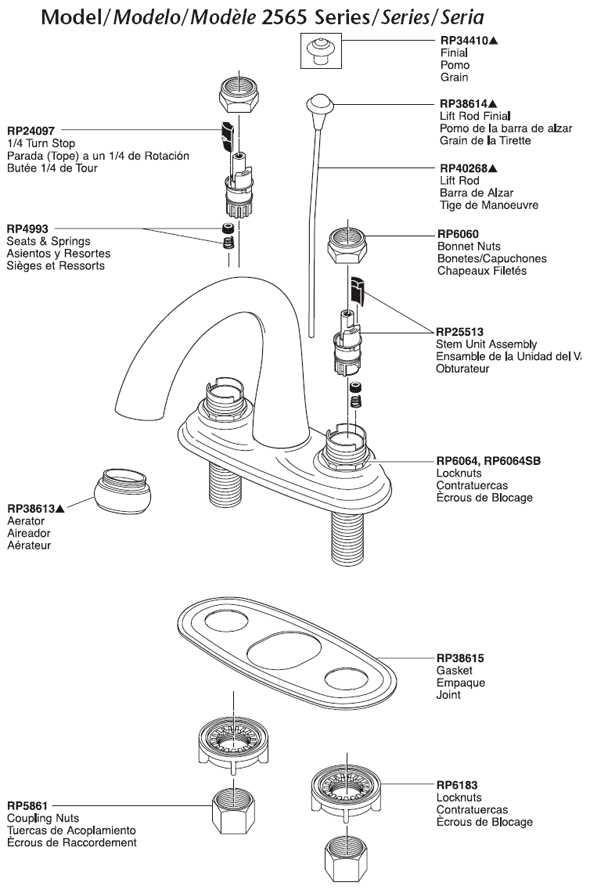

How the Pop-Up Stopper Functions

The pop-up stopper is an essential mechanism that helps control the flow of water, allowing it to be retained or released as needed. By lifting and lowering the stopper, users can manage the closure and opening of the outlet. This system is designed to provide convenience and control during water usage.

Mechanism of Operation

When activated, the stopper is connected to a lever or rod that lifts or drops the plug. The motion of this rod is controlled by a knob or lever located on the fixture, enabling the stopper to be raised or lowered with ease. This simple yet effective design ensures that the water is held securely when needed and released smoothly.

Maintenance and Adjustment

Over time, the stopper may require adjustment to maintain a perfect seal or to move smoothly. Cleaning and minor adjustments can often restore the original functionality, ensuring that the system continues to operate efficiently without causing interruptions to water flow management.

Significance of the Drain Flange

The component known for its crucial role in the plumbing system serves as a pivotal interface between various elements, ensuring seamless operation and functionality. It is vital for maintaining the integrity of water flow, preventing leaks, and contributing to overall efficiency. Understanding this element’s importance can enhance awareness of plumbing systems and their effective management.

Ensuring Proper Sealing

Effective sealing is essential in any plumbing installation, as it prevents unwanted leaks that can lead to water damage. The flange acts as a reliable barrier, securing connections and reducing the risk of moisture escape, which is particularly significant in areas where water is consistently present.

Facilitating Maintenance and Repairs

In addition to its sealing capabilities, this component simplifies maintenance procedures. By providing easy access to the inner workings of the system, it allows for efficient repairs and inspections, ensuring that any issues can be promptly addressed without extensive dismantling.

Sealing Mechanisms: Gaskets and Washers

In plumbing systems, effective sealing components play a crucial role in preventing leaks and ensuring optimal functionality. These essential elements help create a tight barrier between connected fixtures, minimizing the risk of water escape and subsequent damage.

Gaskets are commonly used in various applications to provide a secure seal. Typically made from materials such as rubber or silicone, they are designed to compress under pressure, filling gaps and irregularities in surfaces. This compression creates a reliable barrier against moisture.

Washers, on the other hand, serve a similar purpose but are often used in conjunction with screws or bolts. They distribute load and pressure evenly, which helps maintain the integrity of the seal over time. Choosing the right type of washer can significantly enhance the durability of the connection.

Both gaskets and washers come in different shapes and sizes, allowing for versatile applications in various systems. Regular maintenance and inspection of these components are essential to ensure long-lasting performance and prevent potential leaks.

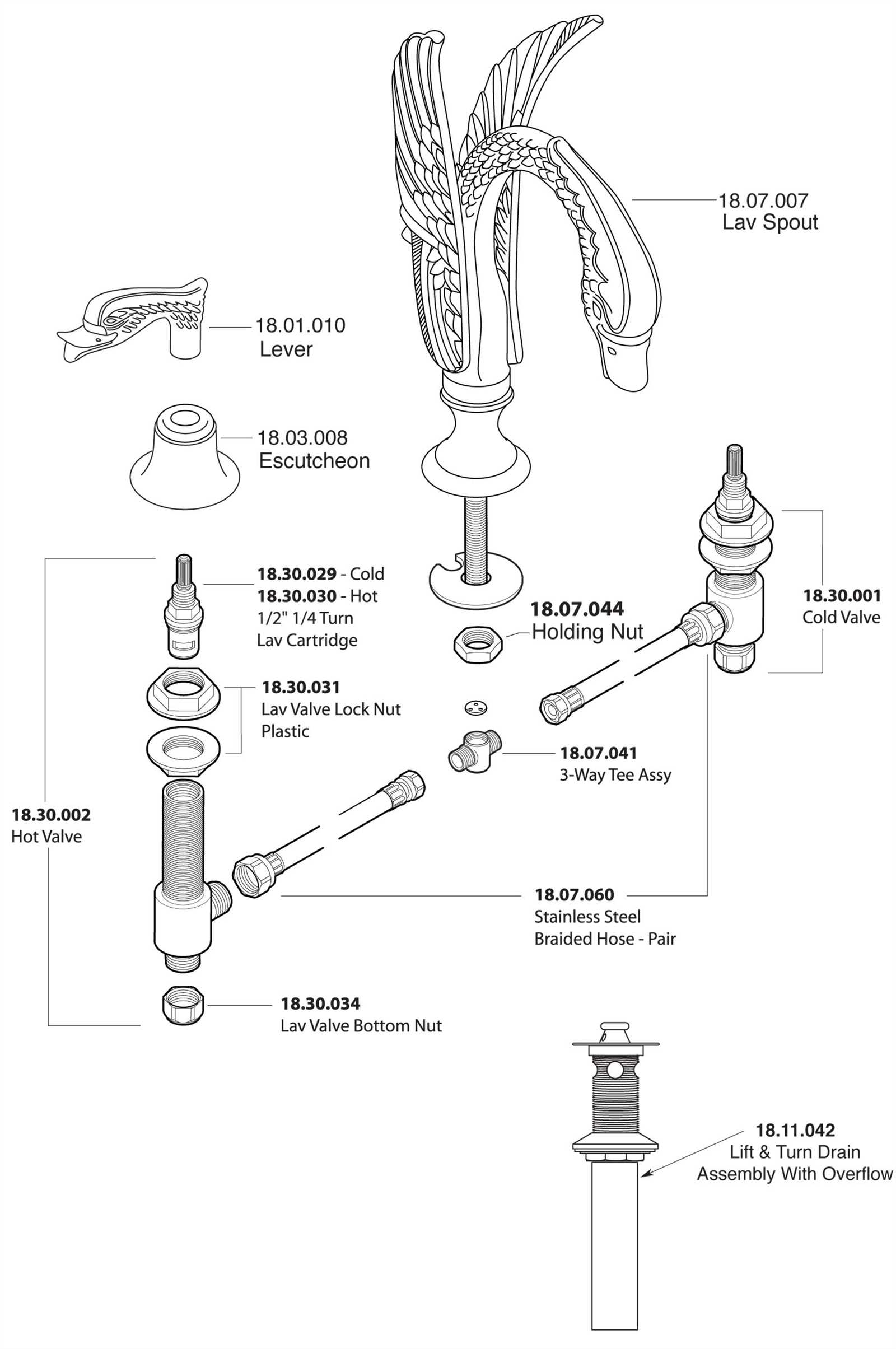

Escutcheon: Decorative and Protective Function

An escutcheon serves both aesthetic and functional roles in various installations. This component is designed to cover gaps and imperfections around fixtures, ensuring a polished appearance. By integrating this element, the overall visual appeal of the surrounding area is enhanced while also providing necessary protection against potential damage and moisture intrusion.

Design and Aesthetics

The design of an escutcheon can significantly influence the ambiance of a space. Available in a variety of materials and finishes, it can complement the style of surrounding decor. Whether sleek and modern or ornate and traditional, the choice of an escutcheon contributes to the overall harmony of the environment.

Protection Against Elements

Beyond its decorative qualities, this element plays a crucial role in safeguarding surfaces from water exposure and potential wear. By covering exposed edges and joints, it prevents moisture accumulation, which can lead to deterioration over time. This protective function is essential for maintaining the integrity of both the fixture and the surrounding area.

Waste Arm and Its Installation

The waste arm plays a crucial role in the plumbing system, facilitating the movement of wastewater away from the basin. Understanding its structure and function is essential for effective installation and maintenance, ensuring optimal performance and preventing leaks.

To begin the installation process, gather the necessary tools, including a wrench, Teflon tape, and a basin wrench. First, ensure that the area is clear and accessible. Begin by attaching one end of the waste arm to the trap, ensuring a snug fit to avoid any leakage. Use Teflon tape on the threads for a secure seal.

Next, position the other end of the arm towards the outlet pipe. Align it properly to ensure a straight connection, minimizing any potential blockages. Once aligned, tighten the connections carefully with a wrench, ensuring not to overtighten, as this could damage the fittings.

Finally, check for any signs of leakage by running water through the system. Make any necessary adjustments to secure a proper seal. Regular inspection of the waste arm will help maintain its functionality and prolong the lifespan of the plumbing system.

Connection Points: Nuts and Couplings

The interconnection of plumbing components is crucial for ensuring proper functionality. This section explores essential fasteners and fittings that facilitate secure links between various elements, providing stability and preventing leaks in the system.

Fasteners and couplings play a vital role in maintaining effective connections within plumbing systems. They are designed to create reliable seals and support structural integrity. Understanding these components can aid in efficient installations and repairs.

| Component | Description |

|---|---|

| Nuts | Hexagonal or round fittings that secure pipes and prevent disconnection. |

| Couplings | Connectors used to join two sections of pipe, ensuring a tight seal. |

| Washers | Flat discs that provide a sealing surface, preventing leaks at connection points. |

| Adapters | Special fittings that allow different pipe sizes or materials to connect seamlessly. |

The Role of Venting in Sink Drains

Proper ventilation is essential in any plumbing system, ensuring efficient waste removal and preventing unpleasant odors. This mechanism allows air to circulate within the piping, balancing pressure and facilitating smooth drainage. Without adequate ventilation, clogs and backups can occur, leading to more significant plumbing issues.

How Venting Works

The ventilation system consists of pipes that connect to the main waste line, extending above the roofline. This design permits air to enter the plumbing network, helping to maintain atmospheric pressure. When water flows through the pipes, it creates a vacuum that can hinder drainage if not balanced by incoming air. Therefore, an effective venting system is crucial for optimal functionality.

Benefits of Effective Ventilation

Investing in a well-designed ventilation system brings multiple advantages, including:

| Benefit | Description |

|---|---|

| Prevention of Odors | Proper airflow prevents the buildup of foul smells that can emanate from waste. |

| Reduced Risk of Clogs | A balanced pressure system minimizes the chance of blockages in the plumbing lines. |

| Enhanced Flow Rate | Improved air circulation allows for quicker and more efficient waste removal. |

| Longer Lifespan of Pipes | Minimized strain on the plumbing system leads to reduced wear and tear over time. |

Common Materials for Drain Parts

Understanding the various materials used in plumbing components is essential for ensuring durability and efficiency. Different substances offer distinct advantages, from resistance to corrosion to ease of installation. This section will explore the most frequently utilized materials in plumbing fixtures and their respective benefits.

Metals

Metals are often favored for their strength and longevity. Common choices include copper and brass, known for their excellent resistance to rust and decay. These materials can withstand high pressures and temperatures, making them suitable for various applications.

Plastics

Plastics, such as PVC and ABS, provide lightweight and cost-effective alternatives. These synthetic materials are resistant to chemicals and corrosion, making them ideal for use in moisture-prone environments. Additionally, their flexibility allows for easy installation and modifications.

Maintaining and Replacing Sink Drain Components

Proper upkeep and timely replacement of plumbing fixtures are essential for ensuring optimal functionality and preventing potential issues. Regular attention to these elements can enhance longevity and improve overall performance. Understanding the necessary steps and components involved in this process is crucial for effective maintenance and repair.

Routine Maintenance Practices

To keep the plumbing system in good working order, periodic inspections should be conducted. Cleaning the connections and checking for signs of wear can help identify issues early on. Additionally, utilizing suitable cleaning agents can prevent clogs and buildup, promoting a smoother flow and reducing the risk of leaks.

Replacement Guidelines

When components show significant wear or damage, timely replacement is vital. Begin by disconnecting the existing fixtures carefully. Selecting high-quality replacements that match the existing setup is essential. Follow the manufacturer’s instructions for installation to ensure a secure fit, and always test for leaks after completing the process.