Comprehensive Guide to Steam Boiler Parts Diagram

In the realm of thermal energy generation, a thorough grasp of the individual elements that contribute to efficient operation is essential. These components work in harmony to convert energy from one form to another, ensuring optimal performance and safety. A well-structured overview of these elements can provide insights into their functions and interrelationships.

Identifying the Key Elements is crucial for anyone involved in the design, maintenance, or operation of thermal systems. Each component plays a specific role, influencing both efficiency and reliability. By breaking down the system into its essential elements, we can better understand how they collaborate to facilitate the desired outcomes.

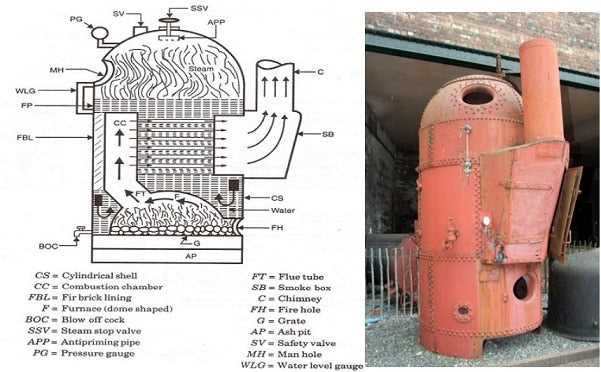

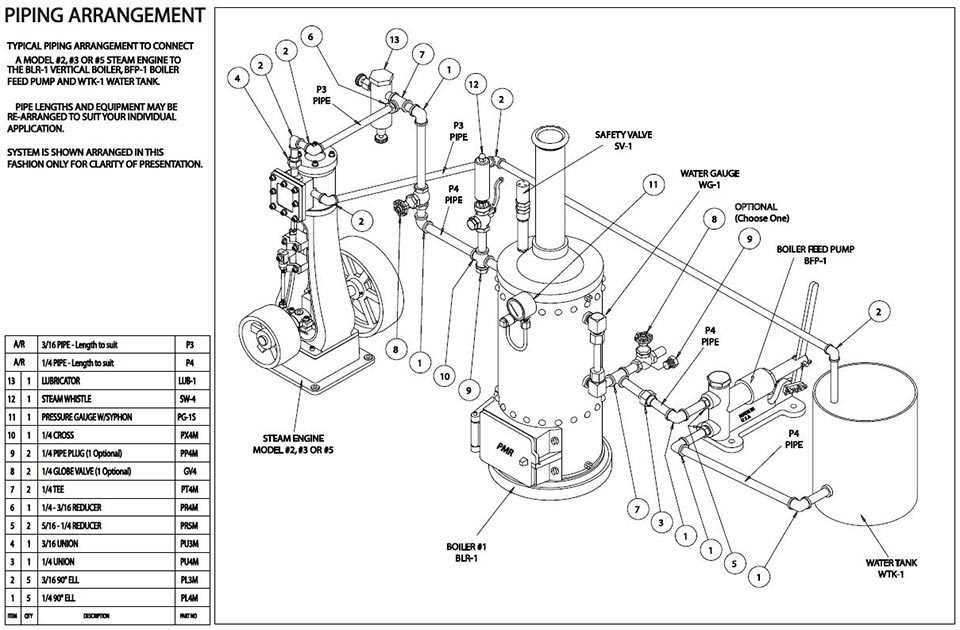

Moreover, visual representations of these components can greatly enhance comprehension, allowing for a more intuitive grasp of their configurations and connections. This exploration into the structure of thermal systems not only aids in troubleshooting but also fosters innovation in energy management practices.

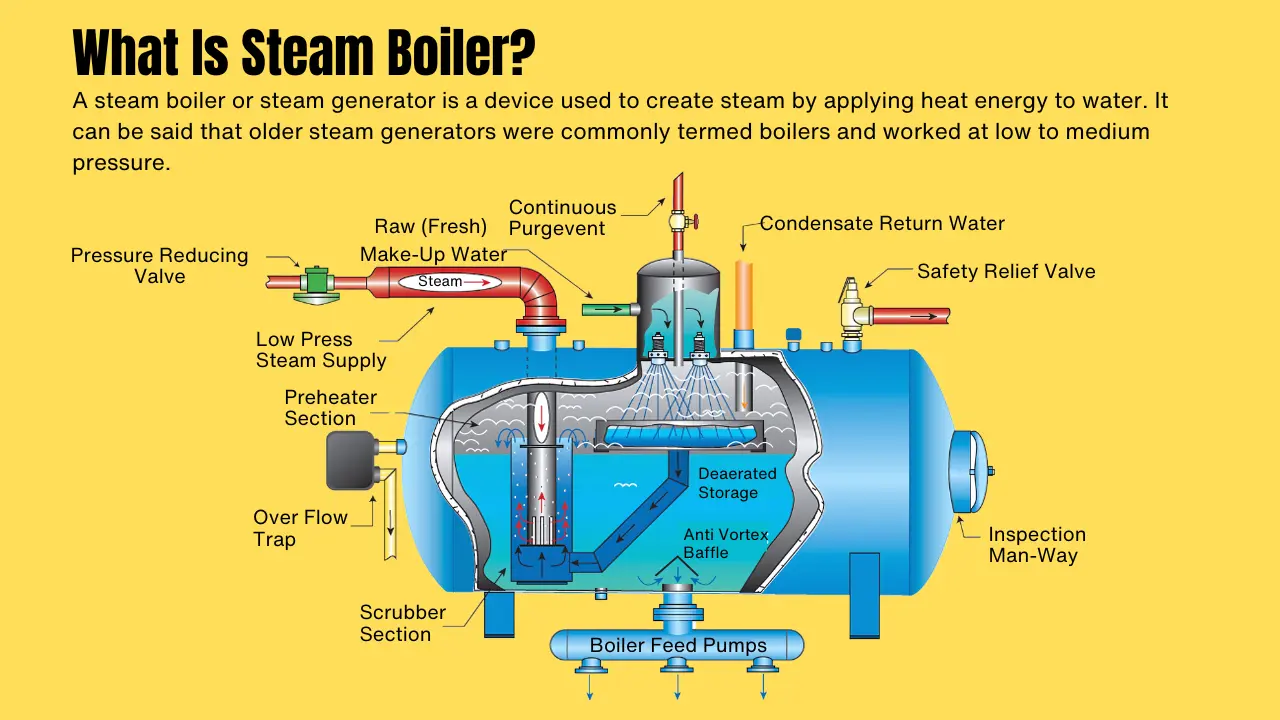

Understanding Steam Boiler Components

In any thermal system designed to generate and manage pressurized vapor, various integral elements work in harmony to ensure efficiency and safety. Familiarizing oneself with these critical components is essential for effective operation and maintenance.

Each element plays a unique role, contributing to the overall functionality of the system. Recognizing how these components interact can lead to improved performance and longevity of the equipment.

| Component | Description |

|---|---|

| Furnace | The chamber where fuel is combusted to produce heat. |

| Heat Exchanger | Transfers heat from the combustion process to the working fluid. |

| Drum | Collects and separates vapor from the liquid, ensuring quality. |

| Pipes | Transport the working fluid throughout the system. |

| Safety Valve | Prevents excessive pressure build-up by releasing vapor when necessary. |

| Control Panel | Monitors and manages the operation of the entire system. |

Understanding these essential components and their functions is vital for anyone involved in the operation or maintenance of such systems. Proper knowledge can lead to enhanced efficiency and reduced risks associated with malfunctioning elements.

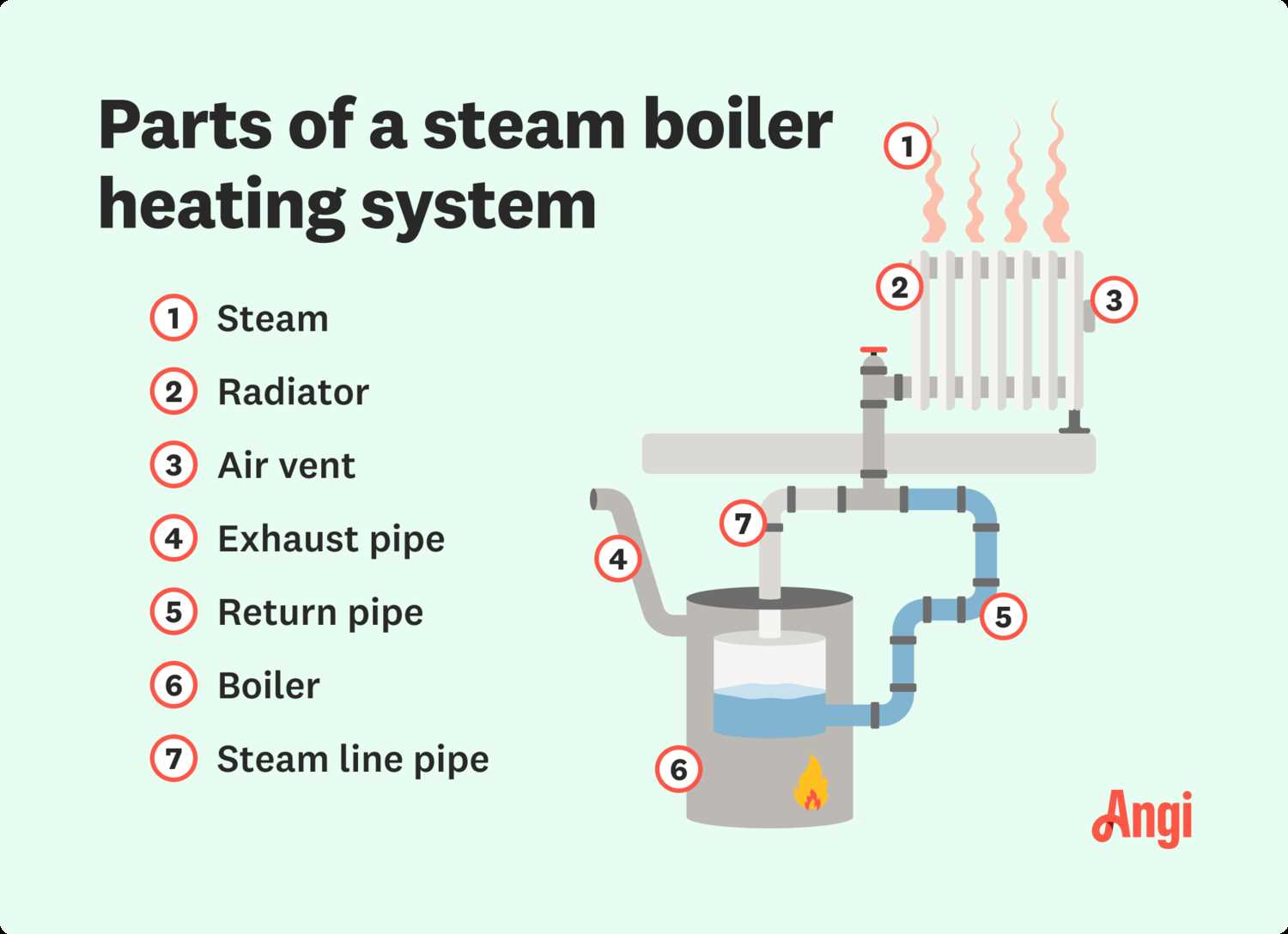

Essential Parts of a Steam Boiler

The fundamental components of a thermal generator play a crucial role in its overall efficiency and functionality. Understanding these key elements is vital for optimal performance and maintenance. Each section contributes to the system’s ability to generate heat and manage pressure effectively.

The furnace is where the combustion occurs, providing the necessary heat. Adjacent to it is the heat exchanger, which transfers thermal energy to the water. Additionally, the water level indicator is essential for monitoring the liquid’s status, while safety valves ensure that pressure remains within safe limits. The feedwater pump plays a critical role in supplying water to the system, maintaining a steady operation.

Lastly, the insulation protects against heat loss, enhancing energy efficiency. Together, these components create a harmonious system capable of generating the energy needed for various applications.

How a Boiler Functions

The operation of a thermal system involves the conversion of energy sources into heat, which is then utilized for various applications. This intricate process hinges on several interconnected components working harmoniously to ensure efficiency and safety.

| Component | Function |

|---|---|

| Heat Exchanger | Transfers heat from the combustion process to the working fluid. |

| Burner | Ignites the fuel, producing the necessary heat energy. |

| Control System | Regulates temperature and pressure to maintain optimal operation. |

| Feed Water System | Supplies the necessary fluid for heating and ensures proper levels. |

| Insulation | Minimizes heat loss, improving energy efficiency. |

By carefully managing these elements, the system effectively transforms energy into thermal output, facilitating a wide range of industrial and residential uses.

Importance of Each Component

Every system designed for heating and pressure management consists of various integral elements, each serving a crucial role in ensuring efficiency, safety, and reliability. Understanding the significance of these components helps in maintaining optimal functionality and prolonging the lifespan of the entire system.

Core Functions

The fundamental duties of each element can significantly impact overall performance. For instance, some components are responsible for generating heat, while others facilitate the safe movement of fluids. Efficiency is achieved when all elements work harmoniously, preventing energy loss and enhancing output. Recognizing the unique contribution of each segment allows for targeted maintenance and timely repairs.

Safety and Compliance

Another vital aspect is the safety features incorporated into each unit. Certain components are designed to manage pressure and temperature levels, mitigating the risk of malfunctions. Compliance with industry standards is paramount, as it ensures that every part functions within the required safety parameters. Regular inspection and understanding the role of each segment contribute to a secure operational environment.

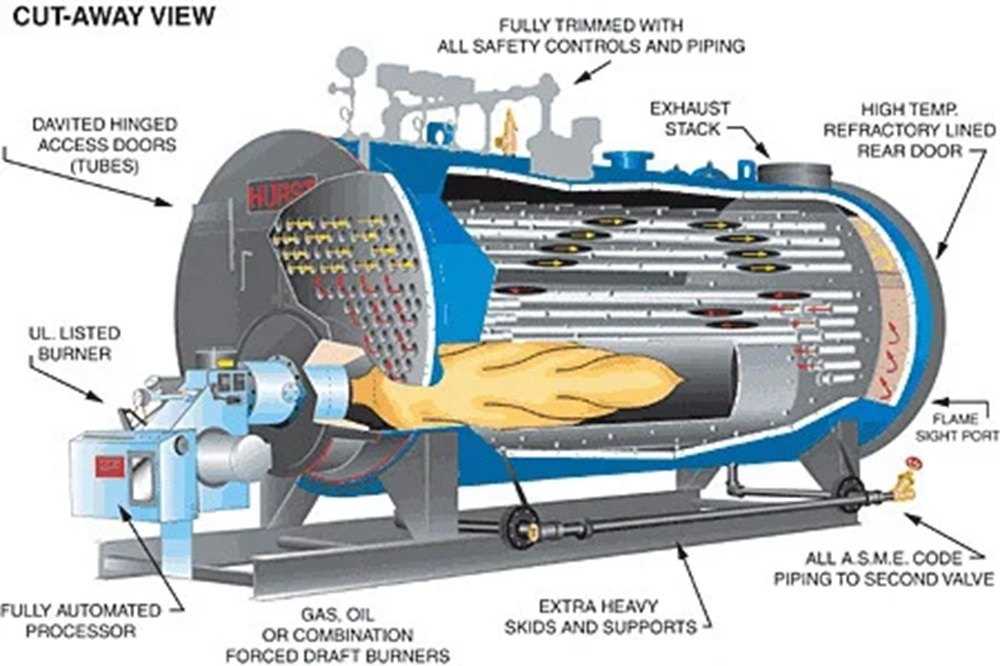

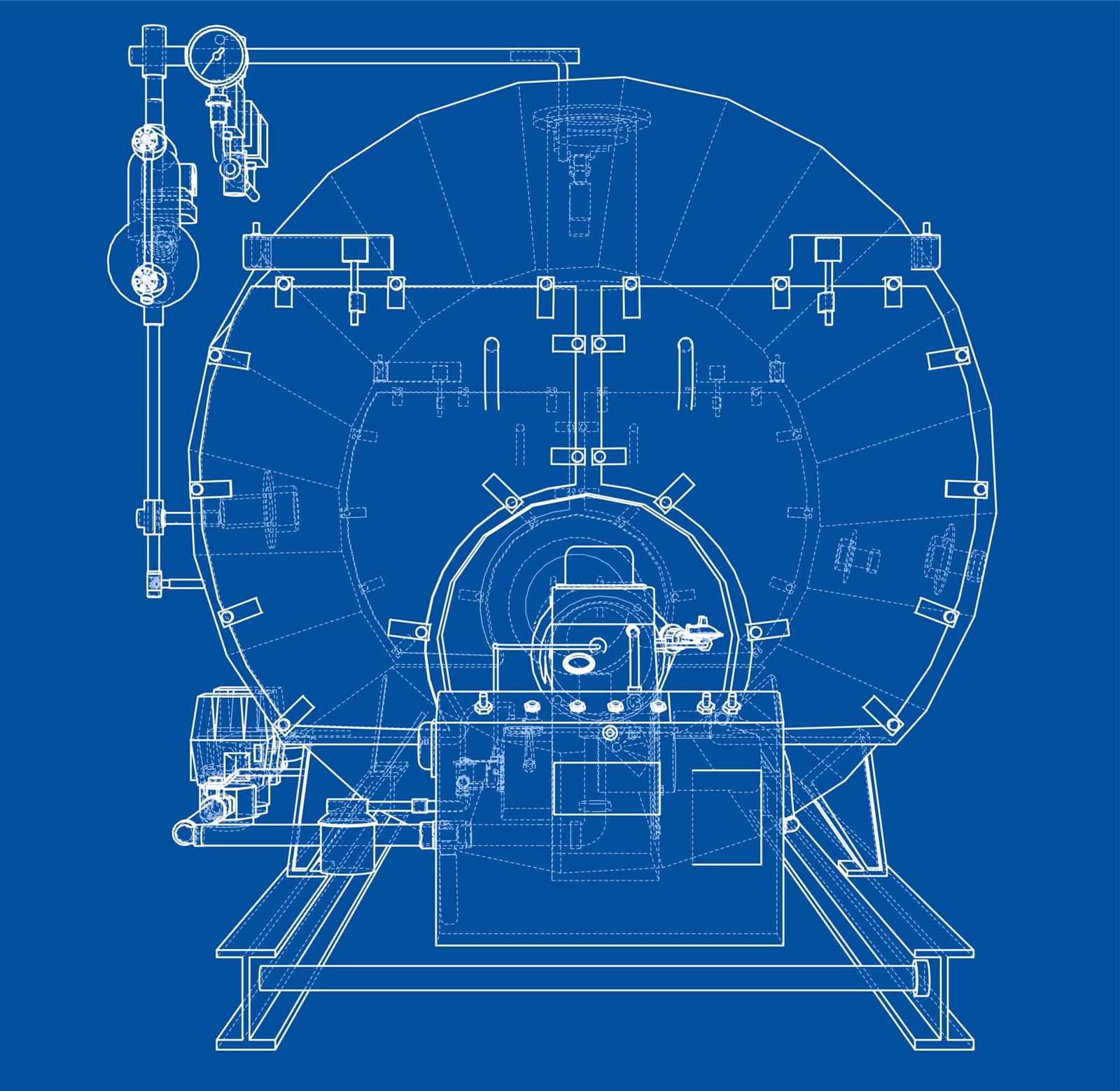

Common Types of Steam Boilers

Various systems are employed to generate heated vapor for industrial and commercial applications. Each design serves specific operational requirements and efficiency levels, catering to diverse needs across sectors.

| Type | Description | Applications |

|---|---|---|

| Fire-Tube | Features hot gases passing through tubes surrounded by water, providing efficient heat exchange. | Heating, power generation, and processing industries. |

| Water-Tube | Utilizes water-filled tubes with combustion gases on the outside, allowing for high-pressure operations. | Power plants, large industrial facilities. |

| Electric | Uses electrical energy to heat water, offering a cleaner alternative with lower emissions. | Small-scale applications, remote locations. |

| Combination | Incorporates features of both fire-tube and water-tube designs, enhancing versatility. | Varied industrial processes and energy production. |

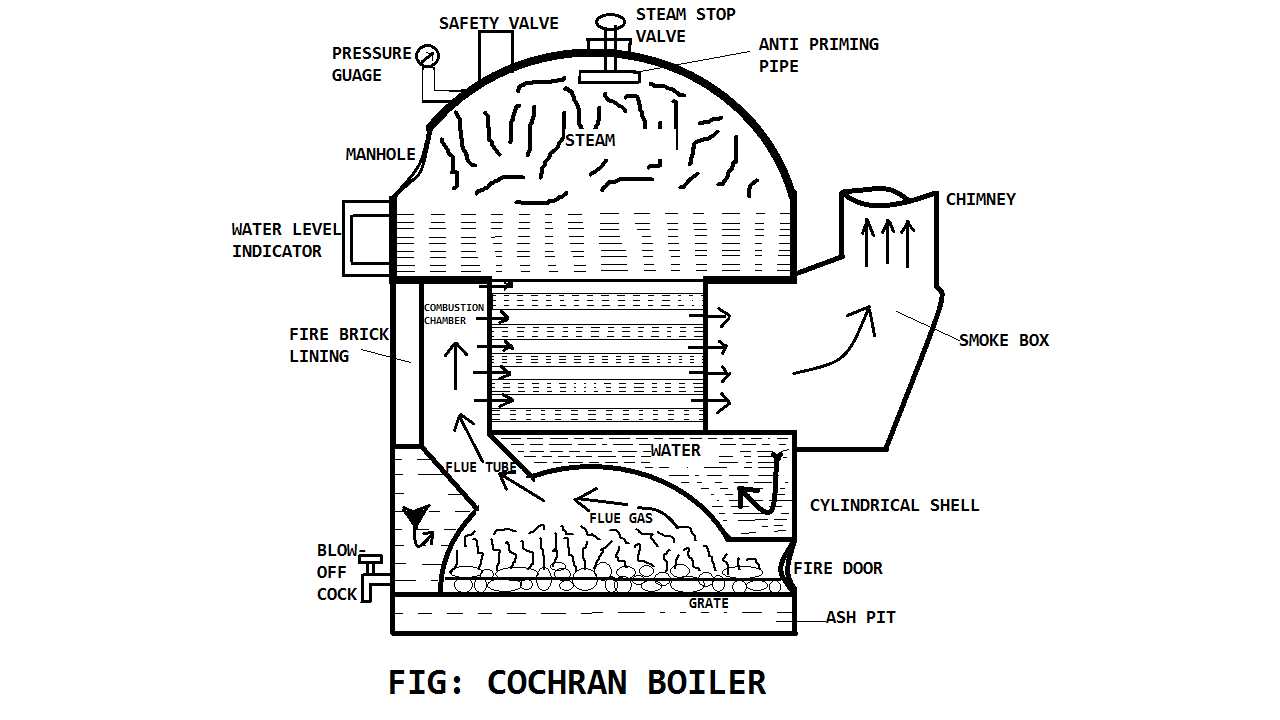

Diagram Overview of Boiler Parts

This section provides a comprehensive examination of the essential components that contribute to the functionality and efficiency of thermal systems. Understanding these elements is crucial for anyone involved in the operation or maintenance of heating equipment.

Key Elements

- Fuel Supply System

- Combustion Chamber

- Heat Exchanger

- Circulation System

- Control Mechanisms

Importance of Each Component

- Fuel Supply System: Ensures a steady flow of energy for heat generation.

- Combustion Chamber: Where the energy transformation takes place, crucial for efficiency.

- Heat Exchanger: Transfers heat to the fluid, maximizing output.

- Circulation System: Maintains fluid movement for optimal performance.

- Control Mechanisms: Regulates temperature and pressure for safe operation.

Key Materials Used in Construction

The selection of materials is crucial in ensuring the efficiency and durability of various thermal systems. Each component must withstand high temperatures and pressures, making material choice a fundamental aspect of design and functionality.

Steel is often the primary choice due to its remarkable strength and ability to handle thermal stress. Various grades of steel can be utilized depending on the specific requirements of the system.

Cast iron is another material frequently employed, renowned for its excellent heat retention and resistance to corrosion. Its ability to endure extreme conditions makes it suitable for various structural elements.

Insulation materials, such as mineral wool or ceramic fiber, play a vital role in maintaining efficiency by reducing heat loss. These materials help in creating a safer operational environment while improving overall performance.

Composite materials, which combine different substances, are gaining popularity for their enhanced properties. They can offer a balance of weight, strength, and thermal resistance, making them ideal for modern applications.

Understanding these key materials enables engineers and designers to create more effective and reliable systems that meet the demands of their applications.

Maintenance of Boiler Parts

Regular upkeep is crucial for the longevity and efficiency of any heating system. By adhering to a structured maintenance routine, one can ensure optimal performance and prevent costly breakdowns.

- Conduct periodic inspections to identify wear and tear.

- Clean components to remove accumulated debris and prevent corrosion.

- Lubricate moving elements to reduce friction and enhance efficiency.

- Check and replace worn-out seals and gaskets as needed.

- Monitor pressure levels to ensure they remain within recommended ranges.

Establishing a maintenance schedule and keeping detailed records will help in addressing issues proactively. Ultimately, a well-maintained system leads to improved safety and performance.

Safety Features in Steam Boilers

Ensuring the highest level of security in thermal systems is paramount for safe operation and reliability. Various mechanisms are designed to prevent accidents, protect personnel, and maintain operational efficiency. These features are integral to managing pressure, temperature, and other critical parameters effectively.

Pressure Relief Mechanisms

One of the primary safety elements involves pressure relief systems, which act as a safeguard against excessive buildup. These devices automatically release steam or gas when predetermined limits are exceeded, thus preventing catastrophic failures. Regular maintenance and testing of these mechanisms are crucial for optimal performance.

Temperature Control Systems

Another vital aspect is the implementation of temperature regulation technologies. These systems monitor heat levels and adjust fuel supply accordingly to maintain safe operating conditions. Advanced sensors and automated controls enhance accuracy, ensuring that the unit operates within designated thermal ranges, minimizing risks associated with overheating.

Troubleshooting Common Issues

Maintaining optimal performance in thermal systems requires vigilance and prompt action when problems arise. This section provides guidance on identifying and resolving frequent complications that may occur during operation, ensuring efficiency and safety in the process.

Low Pressure and Inefficiency

One of the primary concerns is low pressure, which can lead to reduced efficiency. This issue may stem from leaks, improper settings, or malfunctioning components. Inspect connections for any signs of leakage and ensure that the system is correctly calibrated. If pressure readings remain below the normal range after these checks, further investigation into the regulating devices may be necessary.

Unusual Noises and Vibrations

Uncommon sounds and excessive vibrations often indicate underlying problems. These disturbances could result from worn-out bearings, loose fittings, or even cavitation in pumps. Address these symptoms immediately to prevent further damage. Begin by tightening any loose parts and assessing the condition of mechanical elements to restore smooth operation.

Upgrading Boiler Components

Enhancing essential equipment can significantly improve efficiency and longevity. By focusing on specific elements, operators can optimize performance and reduce operational costs. Upgrades not only ensure safety but also comply with modern standards, making systems more reliable and environmentally friendly.

Identifying Key Areas for Improvement

Start by assessing components that show signs of wear or inefficiency. Prioritize items such as valves, pumps, and control systems. Upgrading these elements can lead to enhanced functionality and overall productivity.

Benefits of Modern Technology

Incorporating advanced technology offers numerous advantages. Smart controls enable precise monitoring, while energy-efficient solutions reduce consumption. Embracing innovation ultimately leads to better performance and lower operational expenses.

Future Trends in Boiler Technology

The advancement of thermal systems is poised to revolutionize energy efficiency and sustainability in various industries. As the demand for greener solutions intensifies, innovations in design and materials will play a crucial role in enhancing performance and reducing environmental impact.

Smart Technology Integration: The incorporation of IoT and AI will lead to improved monitoring and control systems, allowing for real-time adjustments and predictive maintenance. This will ultimately enhance operational efficiency and reliability.

Alternative Fuels: The shift towards renewable energy sources will encourage the development of systems that can utilize biofuels and hydrogen, making thermal energy generation more sustainable.

Modular Designs: The trend towards modular units will facilitate easier installation and maintenance, enabling facilities to adapt quickly to changing demands and regulations.

In conclusion, as industries evolve, the future of thermal energy systems will focus on innovation, sustainability, and efficiency, paving the way for a cleaner and more responsive energy landscape.