Understanding Supra Parts Diagram for Easy Maintenance

For any mechanical or technical system, understanding the layout of its elements is key to effective maintenance and repair. When dealing with complex assemblies, it’s essential to have a clear view of how various sections fit together, ensuring smooth operation and easier troubleshooting.

Each component in a system has its own role, whether it contributes to the overall function or supports another element. Identifying the connections between these elements helps users not only recognize potential issues but also optimize performance. A thorough understanding can make any adjustments or replacements more efficient.

By exploring how individual units interact within the system, you gain a deeper appreciation for the intricate design that powers its functionality. Knowing where each part belongs makes it easier to navigate through the system, ultimately leading to better results in maintenance or enhancements.

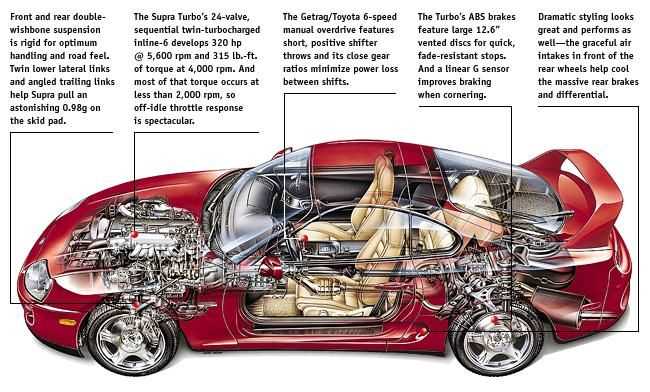

Supra Parts Diagram Overview

The layout of the vehicle’s key components provides a clear understanding of how the various elements function together. Each section of the design plays a critical role in ensuring overall performance, highlighting the interconnectedness of the system. The arrangement focuses on the relationship between mechanical elements, electrical systems, and structural integrity.

| Component | Function |

|---|---|

| Engine Assembly | Powers the vehicle and ensures efficient operation. |

| Transmission System | Manages the transfer of power from the engine to the wheels. |

| Suspension Setup | Maintains stability and comfort by absorbing road impacts. |

| Braking Mechanism | Provides control and safety during deceleration. |

| Exhaust Configuration | Channels gases away from the engine to reduce emissions. |

Key Engine Components Breakdown

The internal combustion engine relies on a set of crucial elements working together to ensure smooth operation and power generation. These components are designed to manage fuel, air intake, and the controlled explosion process that drives the entire system. Understanding the primary elements that compose this system is essential for maintaining efficiency and performance.

The heart of the engine includes several major sections. The combustion chamber is where the mixture of fuel and air ignites. Pistons move within this chamber, translating energy into motion. Connected to the pistons, the crankshaft converts this linear motion into rotational force, which powers the drivetrain. The valve system regulates airflow, ensuring the right mixture enters and exits the combustion process. The cooling system works to prevent overheating, while the lubrication mechanism reduces friction between moving parts, extending the life of the engine.

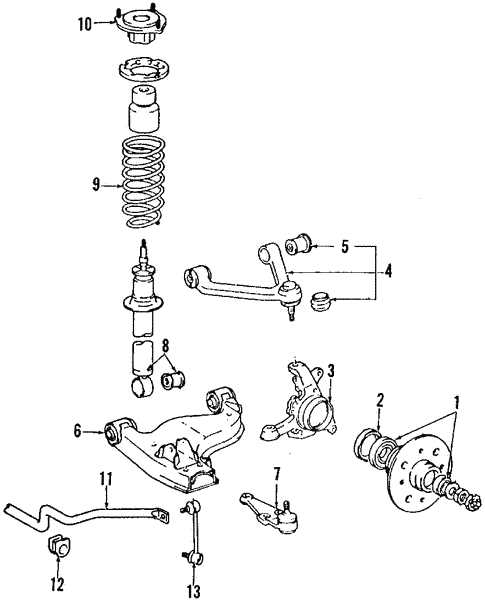

Suspension System Structure Explained

The suspension system plays a crucial role in ensuring smooth handling and stability of any vehicle. Its primary function is to absorb shocks from the road and keep the tires in contact with the surface, allowing for better control. Understanding its layout and components helps to appreciate how it contributes to driving comfort and safety.

Key Components of the Suspension System

- Springs: These absorb vertical forces from the road, reducing the impact felt inside the vehicle.

- Shock Absorbers: These work together with springs to dampen any excess motion, ensuring smoother transitions.

- Control Arms: These connect the wheels to the frame, guiding their movement while maintaining proper alignment.

- Anti-roll Bars: These reduce body roll during sharp turns, enhancing stability.

How It All Works Together

Each component contributes to the overall system, balancing weight distribution, enhancing grip, and improving the vehicle’s response to steering inputs. The interaction of springs and shock absorbers ensures that the wheels move independently, allowing the vehicle to adapt to uneven road surfaces while maintaining control and minimizing wear.

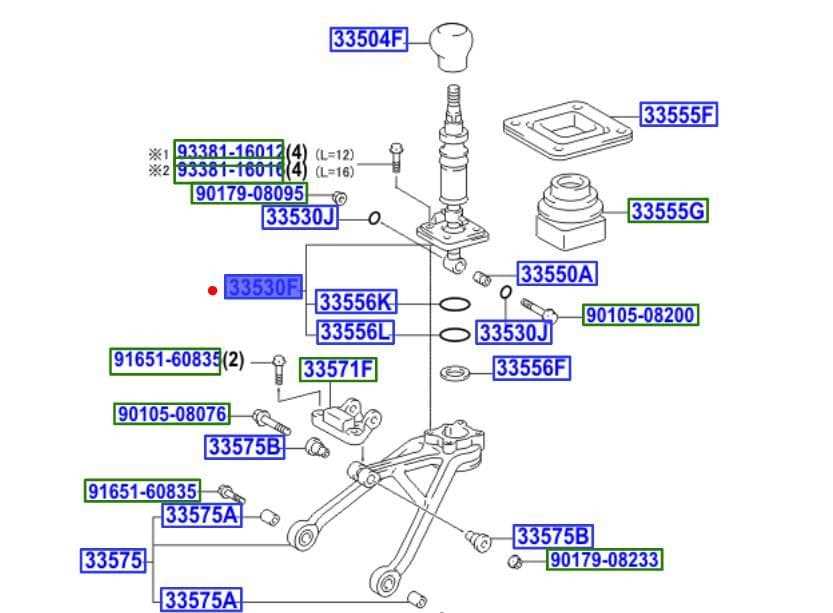

Detailed View of the Transmission

The transmission is a crucial component of any vehicle’s drivetrain, responsible for delivering power efficiently from the engine to the wheels. Understanding the layout and function of each element within the system is key to maintaining smooth performance and longevity. Below is an in-depth look at the main components that form this system.

Main Components

- Gearbox: The heart of the system, allowing for different speed and torque outputs depending on driving conditions.

- Clutch: Engages and disengages power transfer, ensuring a smooth shift between gears.

- Driveshaft: Transmits power from the gearbox to the differential, enabling the vehicle’s movement.

- Synchros: Help align the gear speeds during shifting, making gear changes smoother and preventing wear.

Additional Elements

- Shift Linkage: Connects the gear lever to the internal mechanisms, facilitating gear selection.

- Torque Converter: Converts engine torque into usable power, particularly in automatic transmissions.

- Bell Housing: Encloses the clutch and flywheel assembly, protecting it from external elements.

A proper understanding of these elements ensures that the transmission operates at optimal efficiency, promoting long-term reliability and performance.

Brake Assembly and Configuration

The braking system is a crucial component designed to ensure safety and control during motion. This assembly involves multiple interconnected elements that work together to apply force and bring the vehicle to a stop. The overall structure is engineered to handle the demands of various driving conditions, providing both reliability and effectiveness in operation.

Key Components of the System

The brake system consists of several essential parts that work in unison. These include mechanisms for generating friction, such as pads and rotors, as well as hydraulic components responsible for transferring pressure. Each element plays a significant role in maintaining stability and reducing speed efficiently.

Configuration for Optimal Performance

Proper arrangement and adjustment of the braking components are critical for ensuring optimal functionality. By correctly configuring the system, the vehicle achieves balanced performance, preventing wear and improving safety. Regular maintenance ensures that all elements operate harmoniously under various conditions.

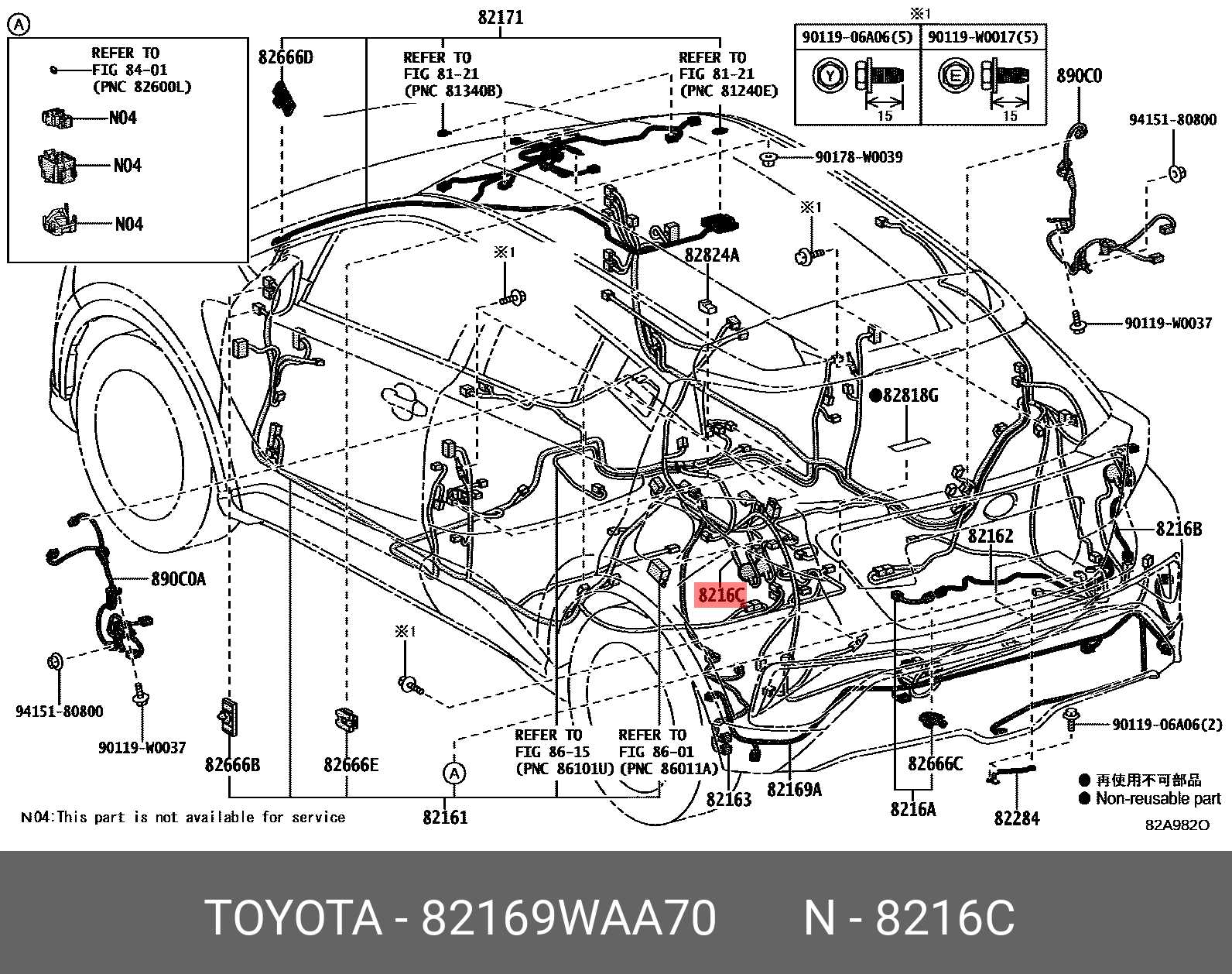

Electrical Wiring Layout and Connections

The arrangement of electrical wiring and the corresponding connections play a crucial role in ensuring the efficient operation of various devices. Properly structured wiring enhances functionality and promotes safety, reducing the likelihood of malfunctions or hazards. Understanding the basic principles behind electrical setups is essential for effective troubleshooting and maintenance.

Key Components and Their Functions

This section outlines the main elements involved in electrical wiring, highlighting their roles in the overall system. Recognizing each component’s function can aid in achieving optimal performance.

| Component | Function |

|---|---|

| Power Source | Provides the necessary electrical energy |

| Wires | Conduct electricity between components |

| Connectors | Join different wiring sections securely |

| Switches | Control the flow of electricity |

| Grounding | Ensures safety by preventing electrical shock |

Best Practices for Wiring

Adhering to best practices when arranging electrical connections is vital for maintaining safety and efficiency. Proper insulation, organized layout, and regular inspections can significantly enhance the reliability of the wiring system.

Fuel System Parts and Functionality

The fuel delivery system plays a crucial role in ensuring that the engine receives the right amount of fuel for efficient operation. This system comprises various components that work together seamlessly to optimize performance and maintain the vehicle’s functionality.

Key elements of this system include:

- Fuel Tank: This is where the fuel is stored before it is delivered to the engine.

- Fuel Pump: Responsible for transporting fuel from the tank to the engine, maintaining adequate pressure.

- Fuel Filter: Helps to remove impurities and contaminants from the fuel, ensuring that only clean fuel reaches the engine.

- Fuel Injectors: These components spray the fuel into the engine’s combustion chamber in a precise manner for optimal combustion.

- Fuel Lines: Tubes that connect the tank, pump, filter, and injectors, allowing for the flow of fuel throughout the system.

Each of these elements is essential for the proper functioning of the engine, contributing to fuel efficiency, performance, and overall reliability. Regular maintenance of the fuel delivery system can help prevent issues and prolong the life of the vehicle.

Exhaust System Diagram and Components

The exhaust system is a crucial aspect of a vehicle’s performance, responsible for directing exhaust gases away from the engine. Understanding its layout and individual elements is essential for maintenance and troubleshooting. This section delves into the various components involved, highlighting their roles and interconnections.

Main Components of the Exhaust System

The exhaust assembly comprises several key components that work in harmony to ensure efficient gas expulsion and noise reduction. These parts include the manifold, catalytic converter, muffler, and various pipes. Each element plays a specific role in the overall functionality.

Component Overview Table

| Component | Function |

|---|---|

| Manifold | Collects exhaust gases from the engine cylinders. |

| Catalytic Converter | Reduces harmful emissions through chemical reactions. |

| Muffler | Minimizes noise produced by the engine’s exhaust. |

| Exhaust Pipes | Transport exhaust gases to the rear of the vehicle. |

Cooling System Elements and Placement

The efficiency of a vehicle’s cooling mechanism is critical for optimal performance and longevity. Understanding the components involved and their arrangement can aid in better maintenance and troubleshooting. This section focuses on the various elements that constitute the cooling system, highlighting their functions and how they are strategically placed within the assembly.

Key components of the cooling mechanism include the radiator, water pump, thermostat, and coolant hoses. Each part plays a vital role in regulating the temperature of the engine. The radiator dissipates heat, while the water pump circulates coolant through the system. The thermostat monitors and controls the temperature, ensuring that the engine operates within the desired range. Proper placement of these elements is essential to ensure efficient airflow and fluid movement, minimizing the risk of overheating.

Interior Parts and Dashboard Layout

The arrangement and functionality of the interior components significantly enhance the overall driving experience. A well-designed dashboard not only provides essential information but also contributes to the comfort and aesthetic appeal of the vehicle’s cabin.

Key features of the interior layout include:

- Instrument cluster: Displays crucial data such as speed, fuel level, and engine temperature.

- Control panel: Houses various controls for air conditioning, entertainment systems, and navigation.

- Storage compartments: Offer convenient spaces for personal items and essential tools.

- Seating arrangement: Ensures comfort for both the driver and passengers, with ergonomic support.

- Interior lighting: Enhances visibility and ambiance within the cabin.

Understanding the configuration of these elements is vital for maintenance and customization, allowing users to tailor their vehicle to their preferences.

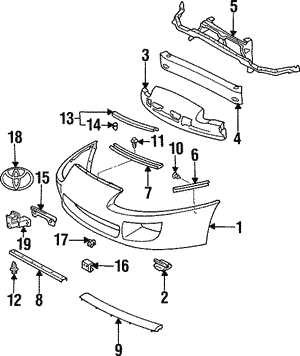

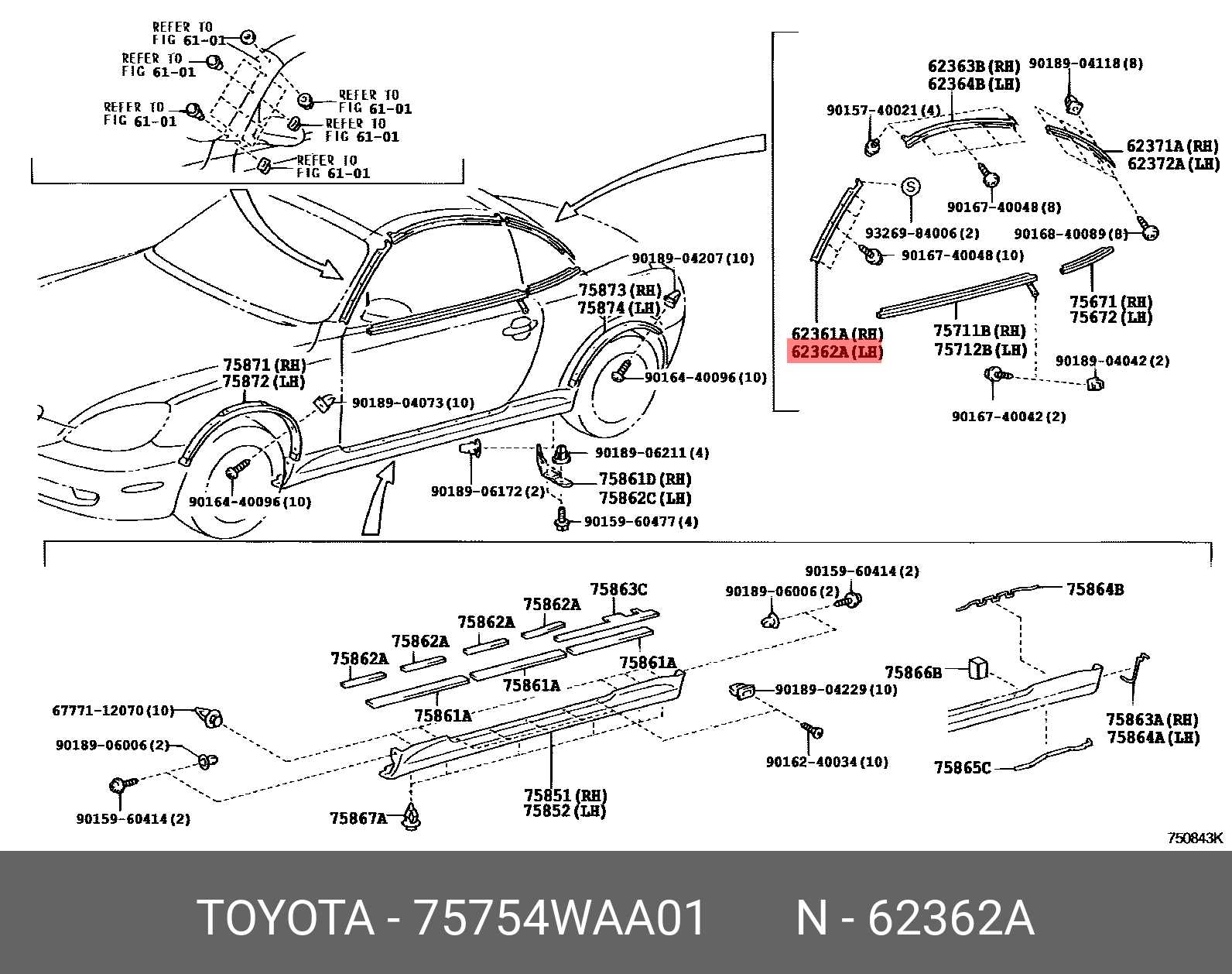

Body Panels and Frame Structure

The construction of the exterior and underlying components plays a crucial role in the overall performance and aesthetic appeal of a vehicle. These elements are meticulously designed to provide strength, rigidity, and lightweight characteristics, ensuring a harmonious balance between durability and efficiency.

Outer Panels serve not only as the first line of defense against external elements but also contribute to the vehicle’s distinctive visual identity. Each section is engineered to enhance aerodynamics while offering protection from environmental factors.

Chassis Framework is fundamental to the vehicle’s integrity, providing a solid foundation for various systems. The design prioritizes stability and safety, ensuring that all components work seamlessly together. Proper alignment and reinforcement are essential to withstand forces encountered during operation.

Overall, the interplay between the outer panels and the frame structure is vital for optimizing performance and ensuring longevity. A thorough understanding of these components is essential for effective maintenance and modifications.

Wheels, Tires, and Alignment Overview

Understanding the components that affect vehicle mobility is essential for optimal performance and safety. The relationship between the rolling elements, supporting surfaces, and their precise positioning greatly influences handling, comfort, and durability. This section explores how these elements interact to enhance driving experiences.

Wheels play a crucial role in ensuring stability and control. They serve as the connection between the vehicle and the road, impacting traction and maneuverability. Proper selection and maintenance of wheels are vital for achieving desired performance characteristics.

Tires are equally important, as they provide the necessary grip and support. The right type and condition of tires directly affect ride quality and fuel efficiency. Regular inspections and timely replacements can prevent issues that may compromise safety and performance.

Alignment refers to the adjustment of the vehicle’s suspension system to ensure that the wheels are positioned correctly. Proper alignment minimizes tire wear, enhances handling, and ensures that the vehicle tracks straight. Regular alignment checks are recommended to maintain optimal driving conditions.

In summary, the interplay between wheels, tires, and alignment is critical for a well-functioning vehicle. Understanding these components and their maintenance can significantly enhance driving safety and performance.

Steering System Parts Identification

The steering system is a crucial component of any vehicle, enabling drivers to maneuver effectively and maintain control. Understanding its components is essential for proper maintenance and troubleshooting. This section will outline the various elements involved in the steering mechanism, providing clarity on their functions and locations.

Key Components of the Steering Mechanism

- Steering Wheel: The primary interface between the driver and the vehicle, allowing for directional control.

- Steering Column: Connects the steering wheel to the steering gear, providing support and housing for wiring.

- Steering Gear: Translates the rotational motion of the steering wheel into lateral movement of the wheels.

- Linkages: Transfer the motion from the steering gear to the wheels, ensuring smooth turning.

- Power Steering Pump: Supplies hydraulic fluid to assist in turning the wheels with less effort.

Understanding Each Element’s Function

- The steering wheel allows for intuitive driver input.

- The steering column serves as a pathway for the steering shaft and wiring connections.

- The steering gear converts the driver’s motion into wheel movement, crucial for responsive handling.

- Linkages ensure that movement is efficiently transmitted to the wheels, enhancing agility.

- The power steering pump significantly reduces effort needed for steering, improving driving comfort.