Understanding the Tap Parts Diagram for Better Maintenance

In the realm of mechanical design and functionality, the arrangement and relationship of various elements play a crucial role in ensuring efficiency and performance. A comprehensive exploration of these configurations allows for a deeper insight into the mechanisms at play, revealing how each unit interacts with others within a system.

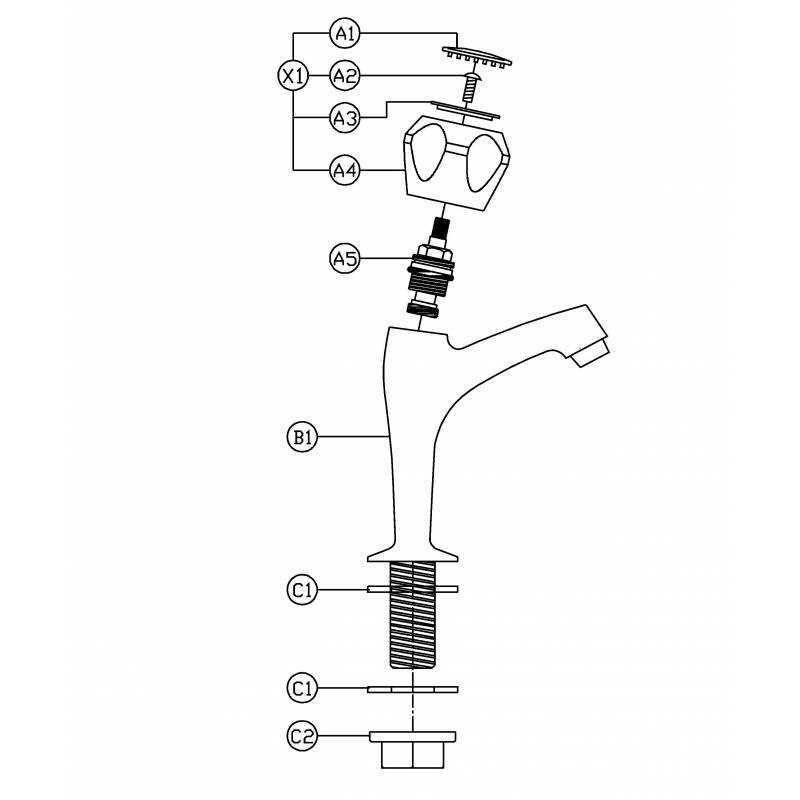

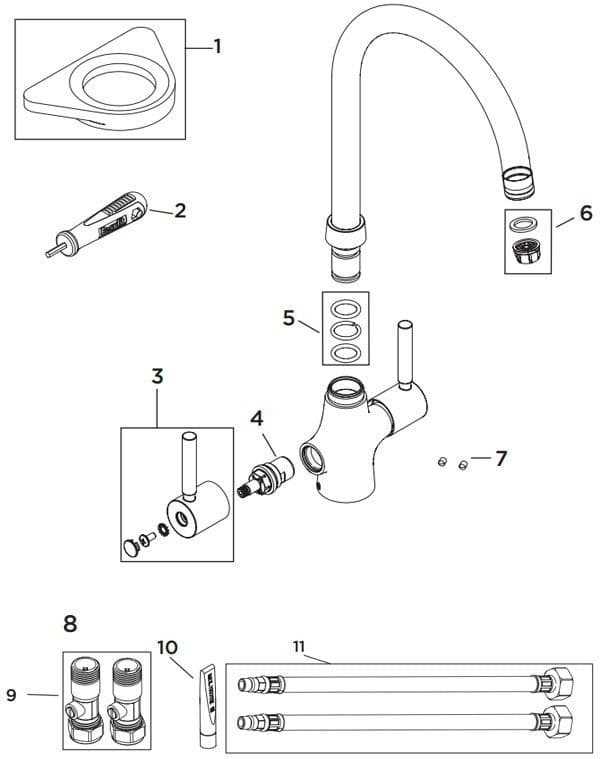

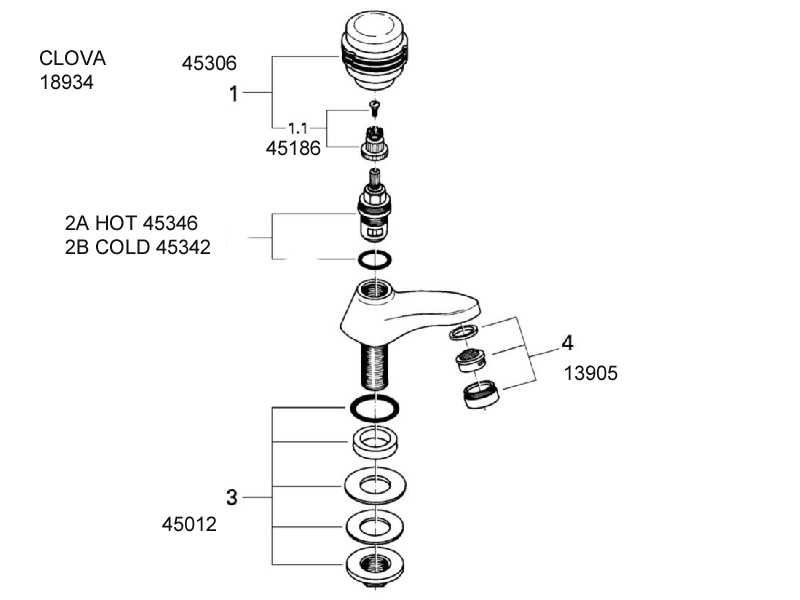

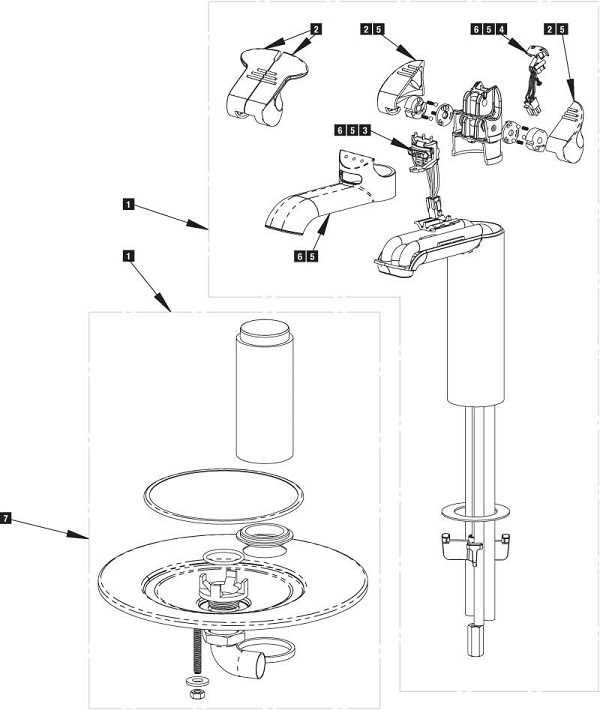

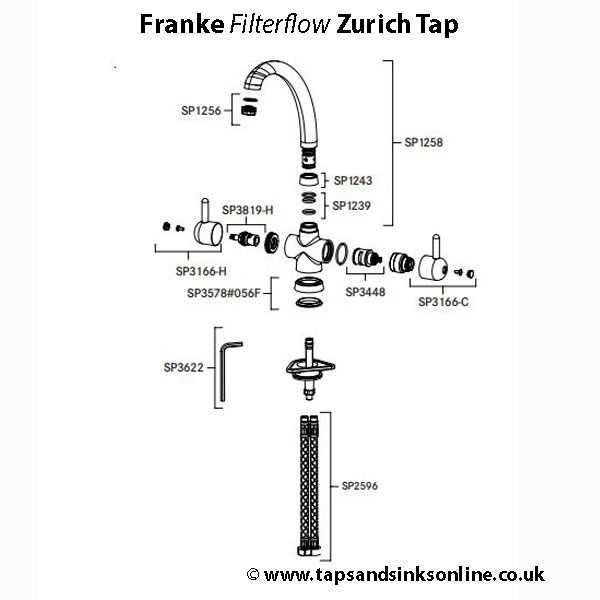

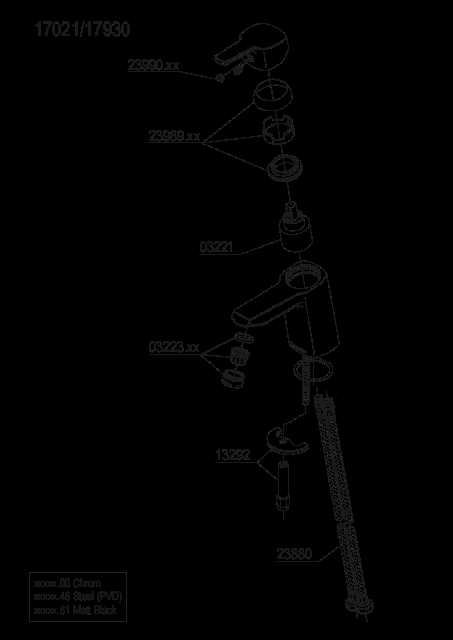

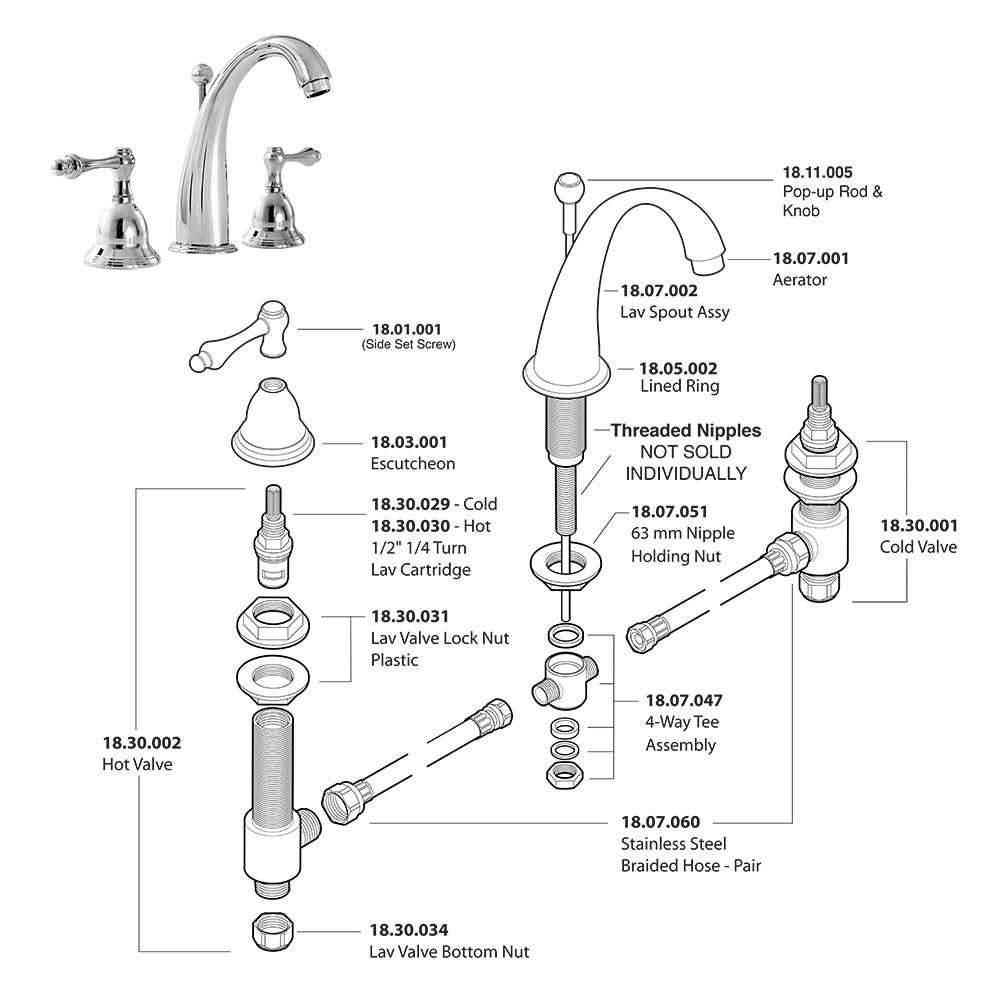

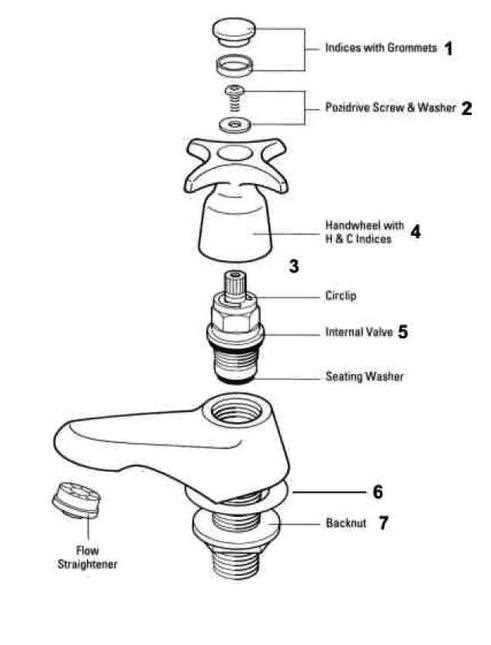

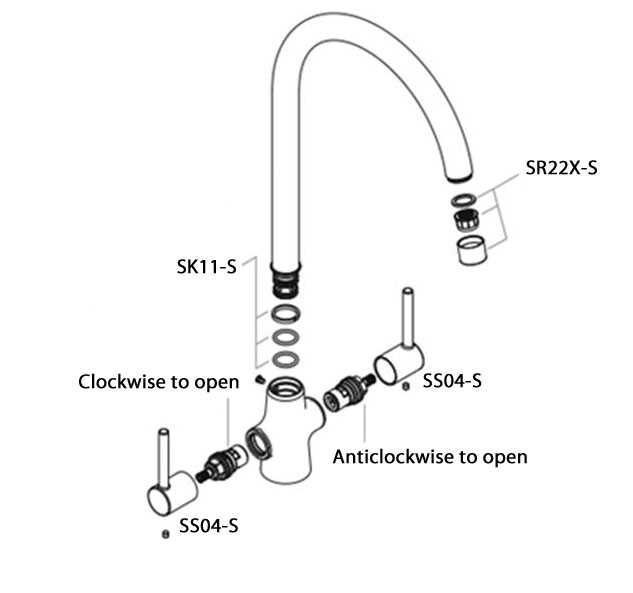

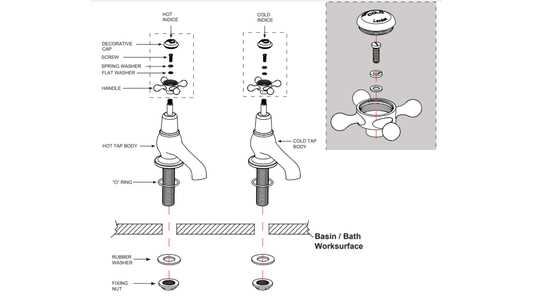

By examining visual representations that depict the arrangement of these essential elements, one can gain clarity on their individual roles and contributions. Such illustrations serve not only as a guide for assembly but also as an invaluable tool for troubleshooting and maintenance, highlighting the interconnectedness of the components.

Moreover, this study transcends mere representation; it fosters a greater understanding of the underlying principles governing the functionality of these assemblies. Engaging with these layouts encourages both novices and seasoned professionals to appreciate the intricacies involved in the design and operation of mechanical systems.

Understanding Tap Parts Diagrams

Grasping the intricacies of mechanical components is essential for efficient repairs and maintenance. Visual representations serve as invaluable tools, allowing individuals to decode the structure and function of various elements in a system. By familiarizing oneself with these illustrations, one can enhance both understanding and proficiency in handling the machinery involved.

Components and Their Functions

Each element depicted plays a crucial role in the overall mechanism. From controlling flow to regulating pressure, the function of every piece is interconnected. Recognizing these relationships is vital for troubleshooting and ensuring optimal performance. A well-detailed representation allows users to identify not only individual components but also their interactions within the system.

Benefits of Familiarization

Becoming adept at reading these representations equips individuals with the knowledge needed to make informed decisions during repairs. It reduces the likelihood of errors and streamlines the maintenance process. Additionally, understanding the configuration of these components fosters a deeper appreciation for the technology involved, promoting both safety and efficiency in operation.

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective communication and understanding within technical fields. Clear and detailed illustrations serve as essential tools that bridge the gap between complex concepts and practical applications. When these visuals are meticulously crafted, they enable users to grasp intricate systems and components quickly and accurately.

Accurate visual aids enhance efficiency by reducing errors during assembly, maintenance, or troubleshooting. They allow for seamless collaboration among team members, ensuring that everyone is on the same page. Furthermore, precise representations help in training and onboarding new personnel, equipping them with the necessary knowledge to operate effectively.

| Benefits of Accurate Visuals | Implications of Inaccuracy |

|---|---|

| Enhanced communication | Increased risk of errors |

| Improved efficiency | Wasted resources and time |

| Streamlined training processes | Confusion and misinterpretation |

| Better collaboration | Reduced productivity |

In summary, the significance of creating high-quality visuals cannot be overstated. They are not merely supplementary; rather, they are foundational elements that support the entire operational framework of any technical endeavor.

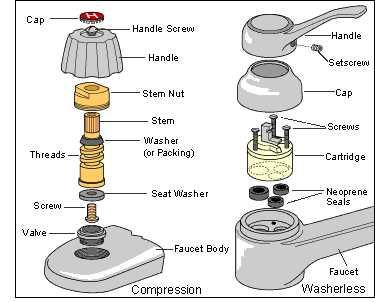

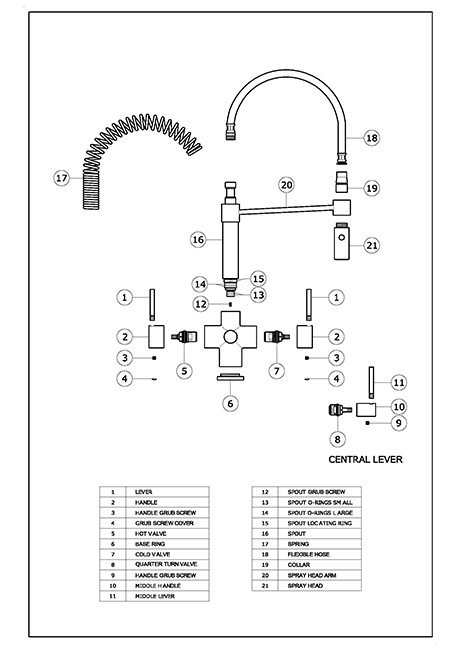

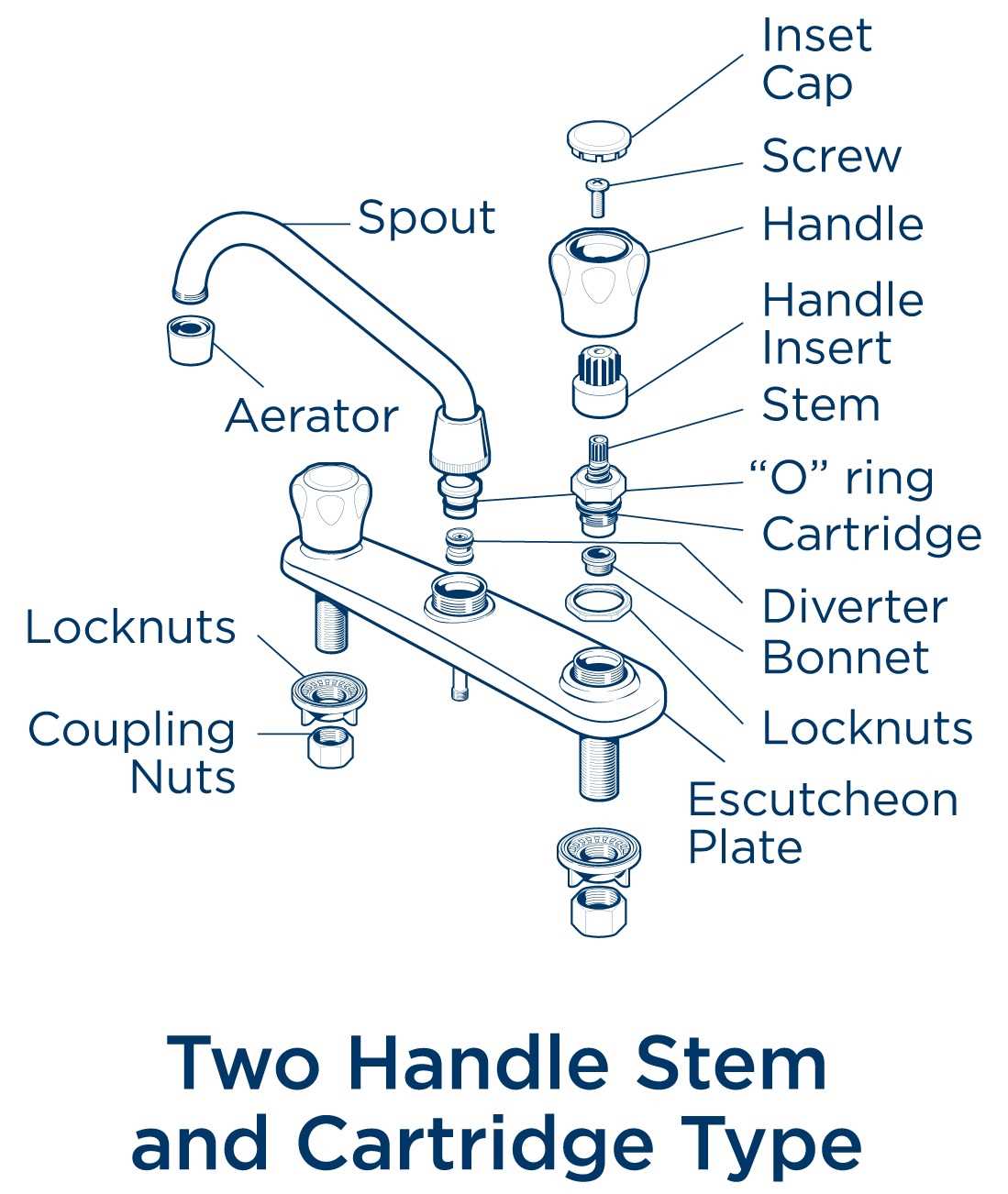

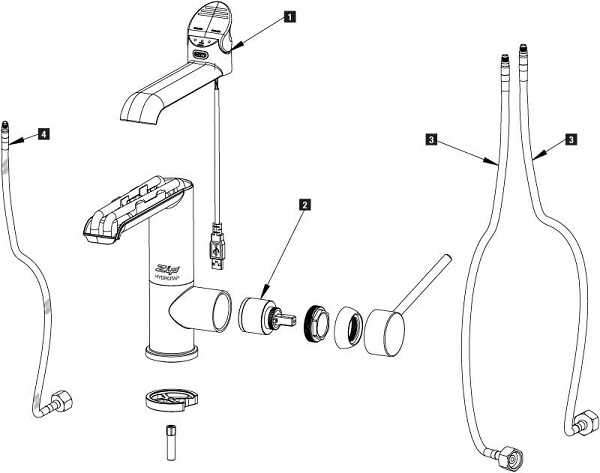

Common Components in Tap Systems

Understanding the essential elements within fluid control systems is crucial for efficient operation and maintenance. Each component plays a specific role in ensuring proper flow and functionality. Below are some of the most common elements found in these systems:

- Valve: This regulates the flow of liquid, allowing for control over the volume and pressure.

- Faucet body: The main structure that houses other components and provides the connection to the plumbing system.

- Spout: This directs the flow of liquid to the desired location, often designed for ergonomic use.

- Handle: The mechanism that allows the user to adjust the flow and temperature by manipulating the valve.

- Washer: This component helps create a seal, preventing leaks and ensuring a tight fit between elements.

- Cartridge: A replaceable unit that contains the valve mechanism, often allowing for easier maintenance and upgrades.

Each of these components works in harmony to facilitate the delivery of fluids in various settings, from residential to commercial environments. Regular inspection and replacement of these elements can enhance performance and extend the lifespan of the entire system.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective assembly and maintenance. These illustrations provide a visual guide, enabling users to identify and locate various elements quickly.

To interpret such a representation effectively, follow these steps:

- Familiarize Yourself with Symbols: Different shapes and lines represent various components. Ensure you know what each symbol signifies.

- Identify Key Sections: Most schematics are divided into distinct areas. Recognize these sections to streamline your navigation.

- Check the Legend: Often, a legend accompanies the visual, detailing symbols and colors. Refer to this for clarification.

- Trace Connections: Follow the lines to understand how different components interact with one another. This is crucial for troubleshooting and assembly.

- Cross-Reference with Documentation: If available, use manuals or guides to gain deeper insights into specific elements or configurations.

By practicing these techniques, you will enhance your proficiency in decoding visual representations, leading to more efficient work processes.

Identifying Different Tap Types

Understanding the various forms of water-dispensing mechanisms is essential for effective selection and maintenance. Each design serves distinct functions and environments, influencing user experience and functionality. Recognizing these variations can greatly enhance both convenience and efficiency in daily tasks.

Common Variants

Several well-known configurations are frequently encountered in both residential and commercial settings. Each variant boasts unique features suited to specific needs.

| Type | Characteristics | Applications |

|---|---|---|

| Compression | Uses a rubber washer to seal; typically requires turning. | Common in older homes and bathroom sinks. |

| Ball | Consists of a single handle over a sphere; allows for easy temperature control. | Popular in modern kitchens and utility areas. |

| Ceramic Disc | Features two ceramic discs; known for durability and smooth operation. | Often found in high-end installations. |

| Cartridge | Contains a cartridge that controls flow; can be single or dual handled. | Widely used in various types of sinks and showers. |

Selection Criteria

When choosing among these configurations, consider factors such as durability, ease of use, and compatibility with existing plumbing. An informed decision can lead to improved functionality and satisfaction in everyday usage.

Materials Used in Tap Construction

The quality and durability of plumbing fixtures are significantly influenced by the materials employed in their fabrication. Different substances impart various characteristics, such as corrosion resistance, strength, and aesthetic appeal. Understanding these materials is essential for making informed choices regarding installation and maintenance.

Common Materials

Brass is one of the most widely utilized materials due to its excellent resistance to corrosion and wear. It combines strength with a pleasing appearance, making it a popular choice for both functionality and design. Stainless steel, known for its durability and sleek finish, is often favored in modern applications, offering a contemporary look while resisting rust and tarnish.

Specialized Materials

In some cases, plastics are employed for their lightweight properties and cost-effectiveness. These materials can be engineered to resist chemicals and moisture, making them suitable for specific environments. Additionally, composites and ceramics are increasingly being used for their unique properties, providing both performance benefits and innovative design possibilities.

Maintenance Tips for Tap Components

Proper upkeep of essential fixtures is crucial for ensuring their longevity and optimal performance. Regular attention can prevent wear and tear, leading to smoother operation and reducing the likelihood of costly repairs. This section offers guidance on maintaining various components effectively.

First and foremost, regular inspection is key. Check for any signs of leaks or corrosion, as these can indicate underlying issues. Addressing them promptly can save time and resources in the long run.

Cleaning is another vital aspect. Accumulation of mineral deposits can hinder functionality. Use a soft cloth and mild cleaning solution to gently wipe surfaces, ensuring all areas are free from grime and buildup.

Lubrication plays a significant role in maintaining moving elements. Apply appropriate lubricants sparingly to joints and seals to ensure smooth operation without attracting dirt.

Additionally, consider replacing worn-out components periodically. Identifying parts that show signs of fatigue can prevent further damage and enhance overall efficiency.

Finally, familiarize yourself with the manufacturer’s recommendations. Each fixture may have specific care instructions that cater to its design and materials, ensuring the best practices are followed.

Common Issues with Tap Parts

In any plumbing system, components can encounter various challenges that lead to inefficiencies and malfunctions. Understanding these common problems is essential for maintenance and timely repairs. Identifying issues early can save time, resources, and prevent more severe damage in the long run.

Frequent Problems Encountered

Several issues are often seen with these fixtures, ranging from minor leaks to complete failures. Below are some typical concerns:

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Dripping | Worn seals, loose fittings | Replace seals, tighten connections |

| Low flow | Clogged aerator, pipe obstructions | Clean aerator, check for blockages |

| Corrosion | Water quality, age of materials | Inspect and replace affected components |

| Unusual noises | Air trapped in pipes, loose components | Bleed the system, secure loose fittings |

Preventive Measures

To mitigate these issues, regular inspections and maintenance are crucial. Ensuring that all connections are secure, cleaning components periodically, and replacing worn elements can significantly prolong the lifespan of the system. By staying proactive, you can minimize the risk of encountering major disruptions in functionality.

Upgrading Your Tap Assembly

Enhancing your faucet assembly can significantly improve both functionality and aesthetics. By selecting high-quality components and modernizing the design, you can transform the overall experience in your kitchen or bathroom. This process not only boosts efficiency but also contributes to the longevity of the installation.

Begin by assessing your current setup. Identify any outdated or inefficient components that may be affecting performance. Consider factors such as water flow rate, ease of use, and overall appearance. Upgrading these elements can lead to a more enjoyable and practical environment.

Next, explore the various options available. Whether you’re interested in sleek finishes or innovative features, there’s a wide array of selections to choose from. Look for high-performance alternatives that promise durability and enhanced functionality.

Don’t forget to focus on installation. Ensure that all new components are compatible with your existing configuration. Proper installation is crucial for maximizing the benefits of your upgrade. If necessary, consult with a professional to guarantee everything is set up correctly.

Finally, regular maintenance of the upgraded assembly will help sustain its performance over time. Periodically check for wear and tear, and replace any components as needed to keep your setup running smoothly. An upgraded system not only elevates your space but also enhances your daily routine.

Tools Needed for Tap Repairs

When it comes to fixing a faucet, having the right instruments at your disposal is crucial for a successful repair. This section outlines the essential equipment that will aid in addressing common issues, ensuring that the task is carried out efficiently and effectively.

Firstly, a good-quality adjustable wrench is necessary for gripping and turning various fittings. A set of screwdrivers, including both flathead and Phillips types, will help in removing screws that secure different components. Additionally, a pair of pliers can provide extra grip when dealing with tight spaces.

Don’t forget to have a basin wrench on hand, which is specifically designed to reach those hard-to-access nuts. A utility knife can be useful for cutting through any old seals or gaskets that need replacing. Lastly, having some plumber’s tape and a selection of replacement washers will ensure you have the materials needed to prevent future leaks.

Where to Find Parts Diagrams

Locating detailed schematics for various devices can significantly enhance repair and maintenance efforts. These visual resources provide clarity on component arrangement and function, making them invaluable for both professionals and DIY enthusiasts. Understanding where to source these illustrations is crucial for efficient troubleshooting and part replacement.

Online Resources

The internet is a treasure trove for technical visuals. Manufacturer websites often host a wealth of information, including comprehensive guides and specific images that cater to their products. Additionally, dedicated forums and online communities frequently share useful resources and links that can lead to valuable insights and documentation.

Retail and Service Centers

Physical stores and authorized service centers can also be excellent places to seek out these valuable illustrations. Many establishments maintain printed catalogs or digital access to technical information, often providing support for specific models. Engaging with knowledgeable staff can also yield personalized guidance and recommendations tailored to your needs.

DIY vs. Professional Repairs

The choice between self-repair and hiring a specialist can significantly impact the outcome of a project. Each approach offers unique advantages and challenges that cater to different needs and skill levels. Understanding these factors is crucial for making an informed decision.

Advantages of DIY Repairs

Engaging in self-repair allows individuals to save on labor costs and gain hands-on experience. It promotes problem-solving skills and a sense of accomplishment. Furthermore, with access to online resources and community support, many are empowered to tackle minor issues effectively. This approach can be particularly rewarding for those who enjoy working with their hands and prefer a personal touch.

Benefits of Professional Assistance

On the other hand, enlisting the help of a trained expert ensures a high level of quality and efficiency. Professionals bring extensive knowledge and experience, minimizing the risk of mistakes that could lead to further complications. Additionally, they often have access to specialized tools and materials that may not be readily available to the average person. For complex tasks or time-sensitive situations, relying on a professional can be a wise investment.