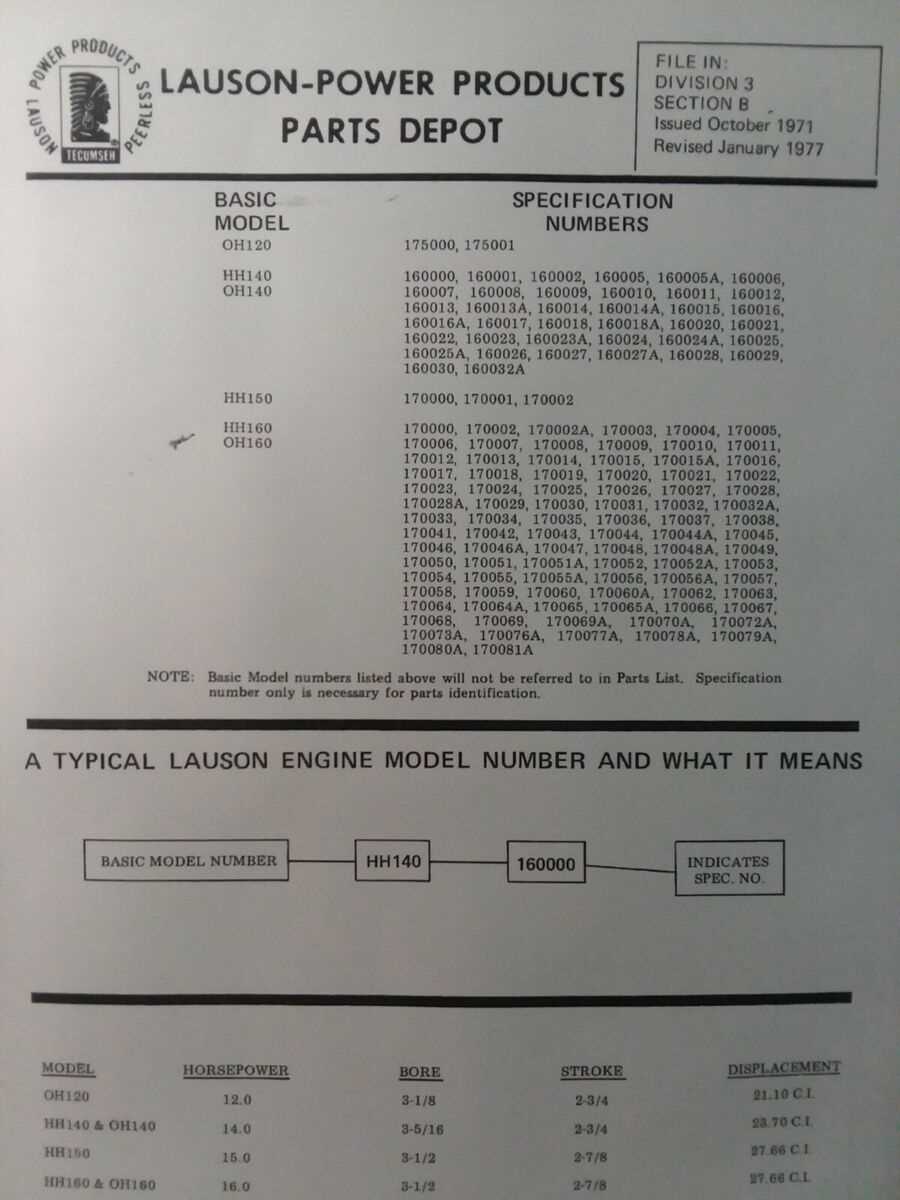

Tecumseh 10 HP Parts Diagram Overview

When working with small engines, particularly those with a specific horsepower rating, having a clear understanding of the individual components is essential. This knowledge not only aids in effective maintenance but also enhances the overall performance of the machinery. Familiarity with the various elements can significantly reduce downtime and improve operational efficiency.

Exploring the intricate relationships between different engine parts provides valuable insights into their functionality. Each component plays a vital role in ensuring that the engine operates smoothly and efficiently. By comprehensively analyzing these elements, users can troubleshoot issues more effectively and perform necessary repairs with confidence.

Whether you are a seasoned technician or a DIY enthusiast, visualizing the arrangement and connection of engine elements can simplify the repair process. A well-structured representation of these components serves as a handy reference, facilitating a deeper understanding of how everything works together harmoniously. This approach ultimately leads to better care and longevity of the equipment.

Tecumseh 10 HP Overview

This section provides an insight into a well-regarded engine known for its reliability and performance in various applications. Designed for efficiency, this model is a favorite among enthusiasts and professionals alike, delivering robust power suitable for outdoor machinery and equipment.

With a focus on durability, this engine incorporates high-quality materials and advanced engineering techniques. Users often praise its ability to handle demanding tasks while maintaining a relatively low maintenance profile. The compact design facilitates easy integration into different systems, making it a versatile choice for many projects.

In terms of performance, it offers impressive torque and horsepower, enabling smooth operation in diverse environments. Whether utilized in lawn care, snow removal, or other heavy-duty tasks, this engine demonstrates remarkable capability and reliability.

Overall, this power unit stands out for its blend of efficiency, longevity, and adaptability, making it an excellent option for those seeking dependable performance in their machinery.

Understanding Engine Components

Engines are intricate systems composed of various elements that work together to convert fuel into motion. Each part plays a crucial role in ensuring optimal performance and efficiency, contributing to the overall functionality of the machine. A clear grasp of these components allows users to better maintain and troubleshoot their engines.

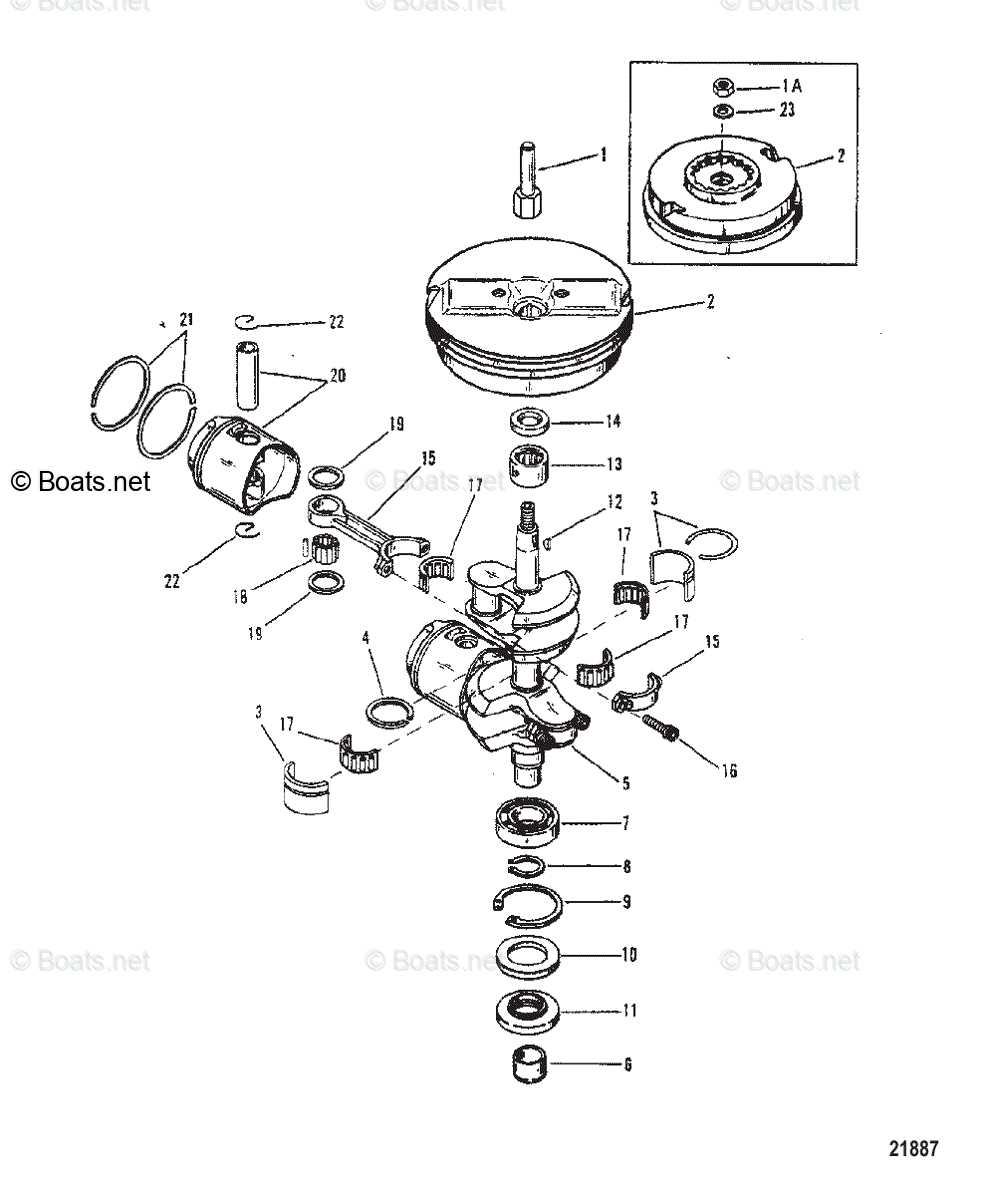

At the heart of an engine lies the cylinder, where the combustion process takes place. This is surrounded by pistons that move up and down, translating the energy produced into mechanical work. The crankshaft, connected to the pistons, transforms this linear motion into rotational force, which ultimately drives the machinery.

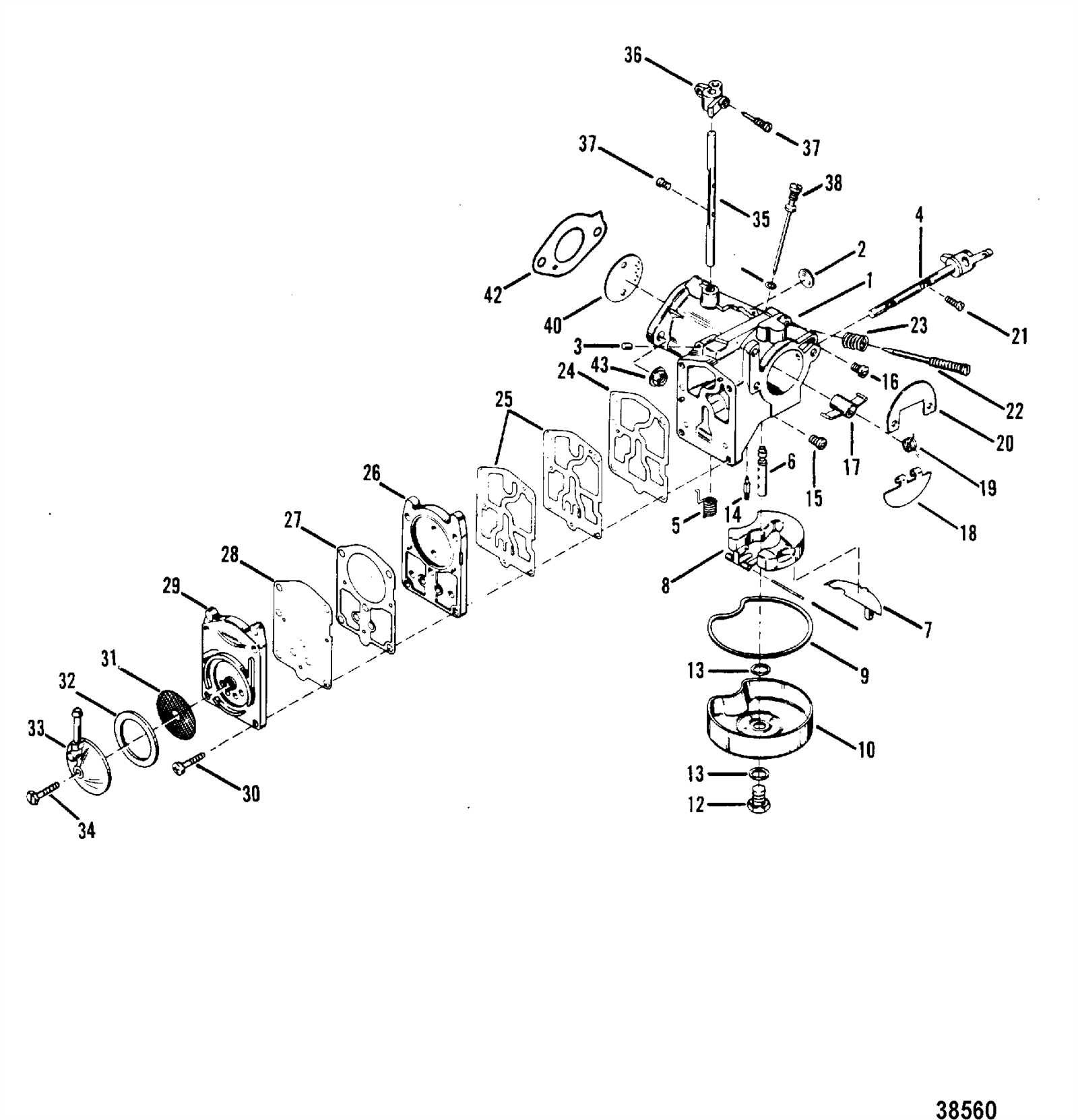

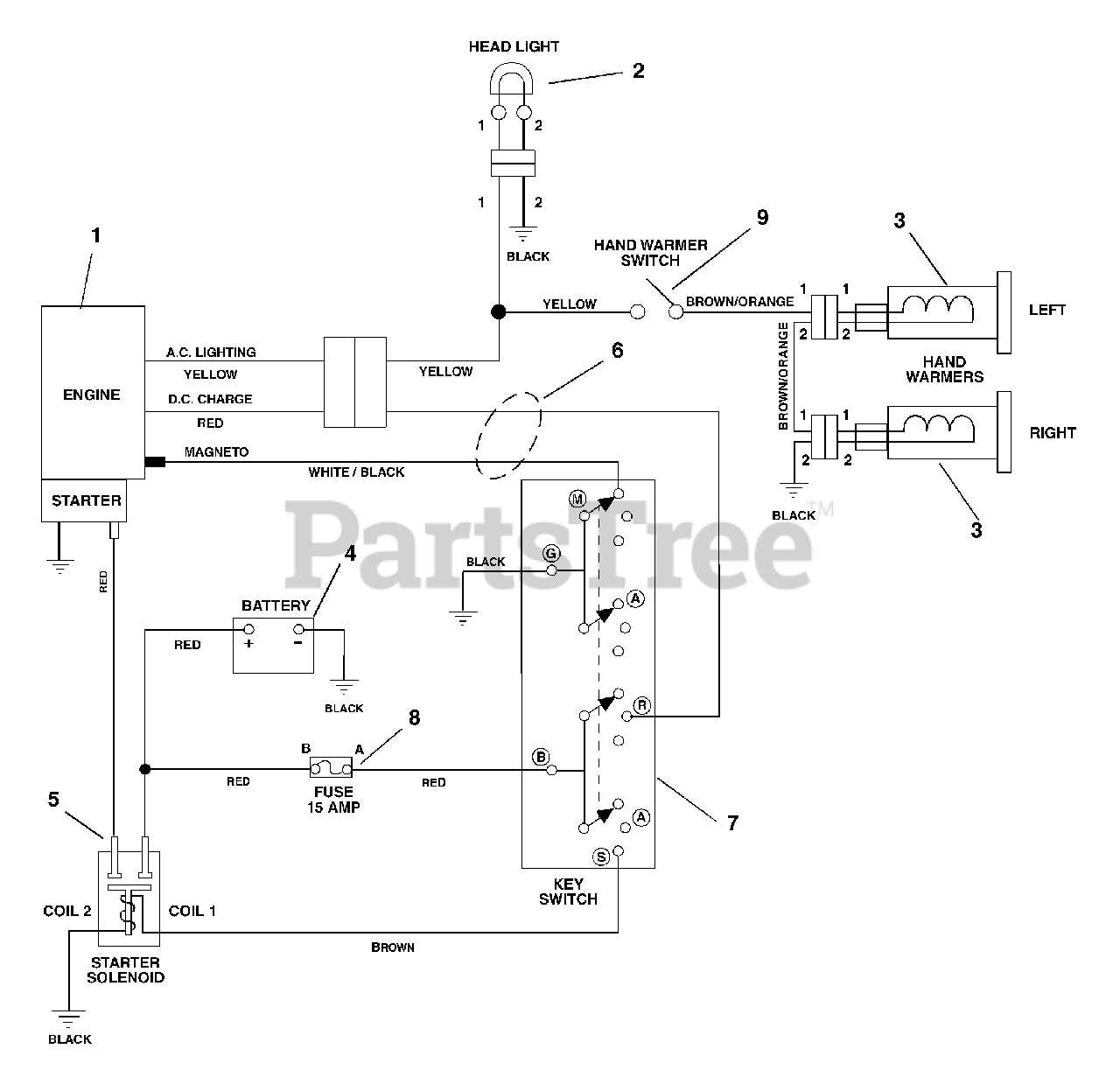

Another key component is the carburetor, responsible for mixing air and fuel in the right proportions for combustion. Additionally, the ignition system is vital for initiating the burning process, ensuring that the engine runs smoothly. Lubrication systems help minimize friction between moving parts, enhancing durability and performance.

Understanding these fundamental components not only aids in effective maintenance but also empowers operators to recognize issues early, thereby prolonging the lifespan of their engines. A well-informed approach to engine management leads to improved efficiency and reliability in various applications.

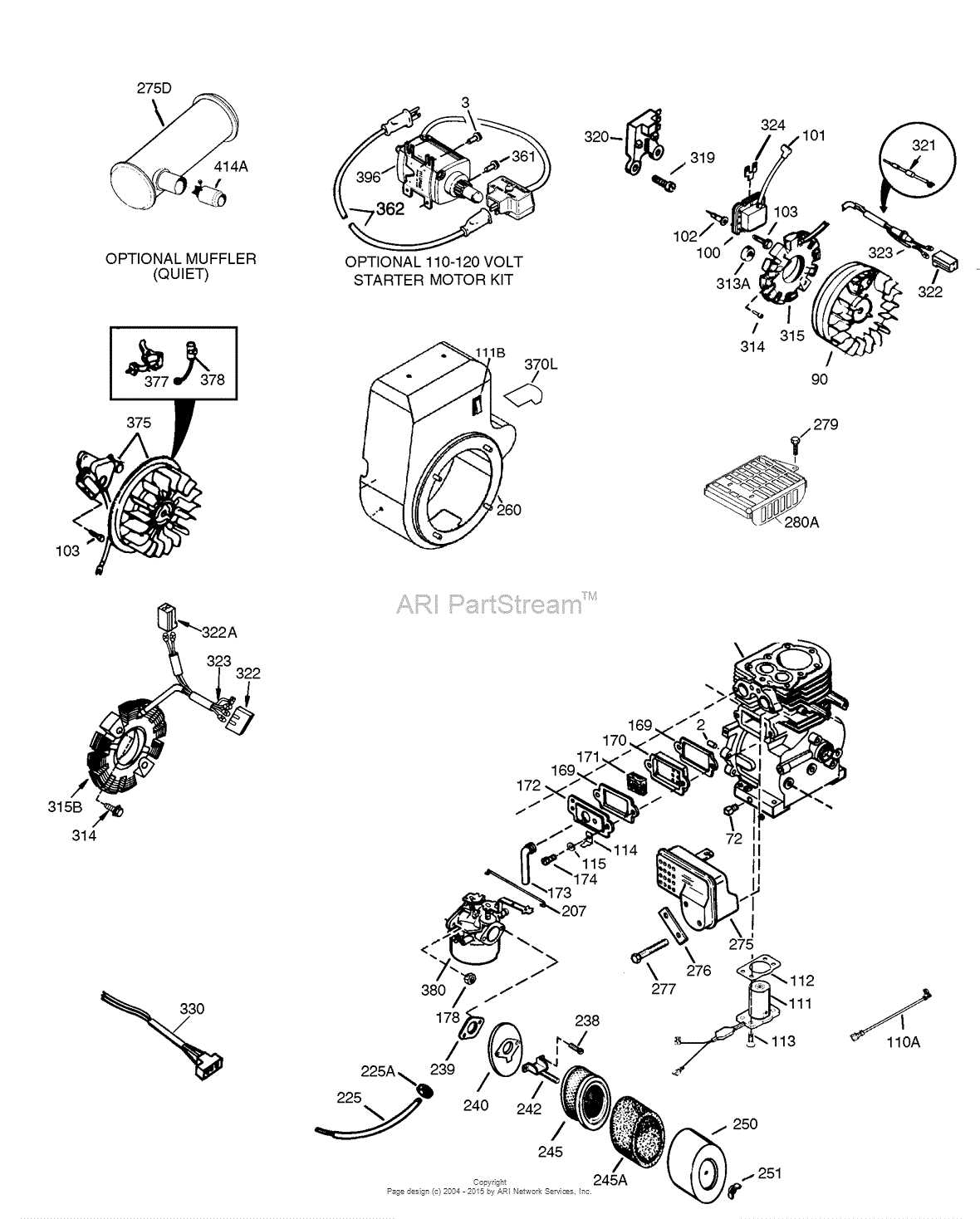

Parts Diagram Explanation

This section aims to provide clarity on the visual representation of components within an engine system. Understanding the arrangement and function of each element is essential for effective maintenance and repair. A comprehensive overview aids users in identifying individual pieces and their interrelations, ensuring smoother operations and troubleshooting.

Understanding Component Layout

The visual guide illustrates how each element is situated within the overall structure. By analyzing this layout, one can appreciate the connectivity and interaction between various units. Recognizing the location and purpose of each segment enhances the efficiency of servicing tasks.

Importance of Accurate Identification

Accurate recognition of individual components is crucial for effective repairs. Misidentification can lead to improper fixes and potential damage. Utilizing a visual reference not only streamlines the repair process but also contributes to a deeper understanding of the machinery’s functionality.

Common Issues and Solutions

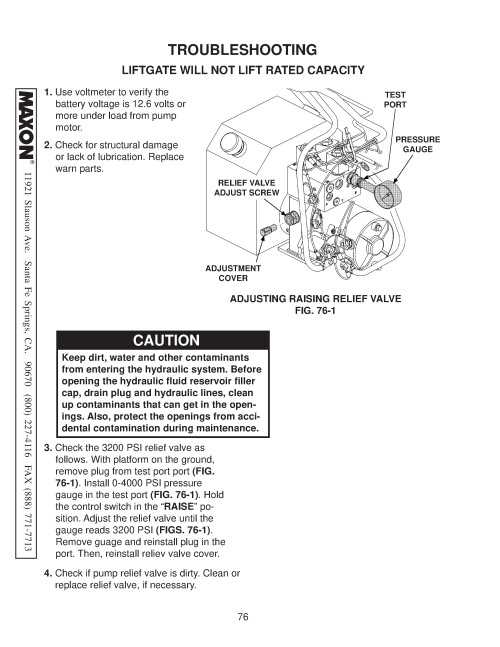

When operating small engines, users often encounter various challenges that can affect performance and efficiency. Understanding these common problems, along with their potential solutions, can greatly enhance the longevity and functionality of the equipment. This section explores frequent issues and offers practical remedies.

Engine Won’t Start

One of the most prevalent concerns is when the engine fails to ignite. This could stem from several factors, including fuel delivery issues or electrical faults. Ensure the fuel is fresh and adequately reaching the carburetor. Additionally, check the spark plug for wear or damage. Replacing a faulty spark plug can often resolve ignition problems.

Overheating

Another significant issue is overheating, which can lead to severe damage if not addressed. Common causes include inadequate cooling airflow or a malfunctioning cooling system. Regularly inspect the air intake for obstructions and clean the cooling fins to maintain optimal airflow. If the cooling system shows signs of failure, consider flushing it and replacing any defective components.

How to Interpret Diagrams

Understanding visual representations of mechanical systems is essential for effective maintenance and repair. These illustrations often encapsulate complex information in a clear and concise format, allowing users to identify components and their relationships. By learning to read these visuals, individuals can enhance their troubleshooting skills and ensure proper assembly and disassembly.

Familiarize Yourself with Symbols

Different visuals employ various symbols to denote specific elements. Recognizing these icons is crucial for accurate interpretation. Often, manuals will include a legend that explains what each symbol represents. Spend time reviewing this legend, as it will provide a solid foundation for understanding the entire schematic.

Follow the Flow of Information

Each visual is designed to guide the user through the connections and functions of different parts. Pay attention to the direction of arrows and lines, as they illustrate the flow of energy or movement. By tracing these pathways, you can gain insight into how the system operates as a whole, enabling you to pinpoint areas that may require attention.

Finding Replacement Parts Easily

Locating necessary components for your machinery can be a straightforward process if you know where to look. Understanding the common sources and methods can save time and effort, ensuring that your equipment is back in working order quickly.

Here are some effective strategies to help you find what you need:

- Online Retailers: Many websites specialize in providing components for various machinery. Searching for specific items or model numbers can yield quick results.

- Local Dealers: Establishing a relationship with local distributors can be beneficial. They often have inventory on hand or can quickly order what you need.

- Manufacturer Websites: Visiting the official website of the manufacturer can lead you to authorized dealers or direct purchasing options.

- Forums and Online Communities: Engaging with fellow enthusiasts or professionals in online forums can provide insights on where to find specific components or recommendations for reliable sources.

- Repair Manuals: Consulting manuals can help identify specific items required for your machinery and may offer guidance on where to procure them.

By utilizing these avenues, you can streamline the process of acquiring essential components, ensuring your machinery operates smoothly and efficiently.

Maintenance Tips for Longevity

Ensuring the long-term functionality of machinery requires regular attention and care. By adhering to a few essential practices, users can enhance performance and prolong the life of their equipment. Implementing these strategies not only reduces the likelihood of malfunctions but also optimizes efficiency during operation.

Regular Inspection and Cleaning

Routine checks are crucial for identifying potential issues before they escalate. Inspecting components for wear and tear allows for timely replacements. Cleaning parts to remove debris and buildup can significantly improve performance. Regular maintenance minimizes the risk of overheating and mechanical failures.

Proper Lubrication and Storage

Using appropriate lubricants ensures smooth operation and reduces friction between moving parts. Applying lubricants at recommended intervals is essential. Additionally, proper storage away from moisture and extreme temperatures helps maintain functionality and protects against corrosion, ultimately contributing to a longer service life.

Comparing Tecumseh Models

When exploring various engine options, it’s essential to understand the differences among models to choose the best fit for specific applications. Each variant offers unique features and specifications, making it vital to analyze their performance, reliability, and usability in different contexts.

Performance Metrics

Performance is a critical factor when selecting an engine. Different models may exhibit varying horsepower ratings, torque outputs, and fuel efficiency. Evaluating these metrics helps users determine which engine can best meet their power demands and operational efficiency. For instance, some may excel in high-torque applications, while others might be more suitable for tasks requiring speed.

Durability and Maintenance

Another crucial aspect to consider is the longevity and upkeep of the engines. Some models are designed with robust materials that enhance their durability, reducing the frequency of repairs and replacements. Additionally, ease of maintenance can significantly impact user experience. Users should assess the accessibility of components and the overall design to ensure manageable upkeep.

Upgrading Your Engine Performance

Enhancing the functionality of your engine can significantly improve its efficiency and overall power output. By focusing on various components and making targeted modifications, you can achieve remarkable results that elevate your machine’s performance to new heights. This section explores practical strategies for maximizing engine capabilities while ensuring reliability and longevity.

One effective method is to improve the air intake system. Increasing the flow of fresh air can lead to better combustion and, consequently, enhanced power. Consider upgrading to a high-performance air filter or an aftermarket intake system designed for optimal airflow. This simple change can make a noticeable difference in throttle response and acceleration.

Another critical area for improvement lies in the exhaust system. A more efficient exhaust allows for quicker expulsion of gases, which can reduce back pressure and increase engine efficiency. Upgrading to a performance muffler or exhaust manifold can significantly enhance exhaust flow, resulting in increased horsepower and torque.

Tuning the engine is also vital for unlocking its potential. This may involve adjusting the fuel mixture or reprogramming the engine control unit (ECU) to optimize performance parameters. Investing in a quality tuning service or software can help you tailor the engine’s performance to match your specific needs, whether it’s for speed, torque, or fuel efficiency.

Lastly, consider the overall condition of your engine components. Regular maintenance and timely replacement of worn parts can prevent performance drops. Utilizing high-quality lubricants and fluids can also support smoother operation, extending the life of your engine while keeping it performing at its best.

Tools Required for Repairs

When tackling maintenance tasks, having the right tools is essential for ensuring efficiency and accuracy. Proper equipment not only facilitates the repair process but also minimizes the risk of damage to the components involved. Understanding the necessary tools can greatly enhance your repair experience and outcomes.

Essential Tools

Below is a list of fundamental tools you will need for effective repairs:

| Tool | Description |

|---|---|

| Wrench Set | Used for loosening and tightening bolts and nuts of various sizes. |

| Screwdriver Set | Includes flathead and Phillips types, essential for removing and securing screws. |

| Socket Set | Provides a range of sockets to fit different fasteners, allowing for better leverage. |

| Pliers | Useful for gripping, twisting, and cutting wires or small parts. |

| Torque Wrench | Ensures that bolts are tightened to the specified torque level, preventing damage. |

Optional Tools

In addition to the essential tools, some optional equipment can make the repair process easier:

| Tool | Description |

|---|---|

| Impact Driver | Helps loosen stubborn screws and bolts with high torque. |

| Multimeter | Used for diagnosing electrical issues by measuring voltage, current, and resistance. |

| Work Light | Provides adequate lighting in dark or tight spaces during repairs. |

Online Resources and Communities

In today’s digital age, finding support and information for small engine maintenance and repair has become more accessible than ever. Various online platforms offer valuable insights, detailed guides, and interactive discussions, making it easier for enthusiasts and professionals alike to enhance their knowledge and skills.

Forums and Discussion Groups

Many forums serve as vibrant communities where individuals share their experiences and troubleshoot issues collaboratively. These platforms provide a wealth of knowledge, often featuring threads that delve into specific challenges, solutions, and tips for optimal performance. Engaging with fellow members can foster connections and expand one’s understanding of engine mechanics.

Video Tutorials and Guides

Video content has revolutionized the way information is disseminated, allowing users to visually learn complex techniques. Numerous channels focus on repair and maintenance, offering step-by-step tutorials that can guide users through various processes. This multimedia approach often enhances comprehension, making it easier to grasp intricate details.

Leveraging these resources can significantly enhance one’s ability to maintain and repair small engines, ensuring they operate efficiently and reliably.

Safety Precautions When Working

Ensuring a safe working environment is essential for preventing accidents and injuries. Proper precautions should always be taken to mitigate risks, especially when handling machinery or performing repairs. Awareness of potential hazards and adherence to safety protocols can significantly enhance personal protection and overall workplace safety.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is crucial. Items such as safety goggles, gloves, and steel-toed boots can provide essential protection against flying debris, sharp edges, and heavy objects. It is important to choose PPE that is suitable for the specific tasks at hand to ensure maximum safety.

Work Area Organization

Maintaining a clean and organized workspace helps to minimize hazards. Tools and materials should be stored properly when not in use, and spills should be cleaned immediately to prevent slips and falls. Regularly inspecting the area for potential dangers can help create a safer environment for all workers.