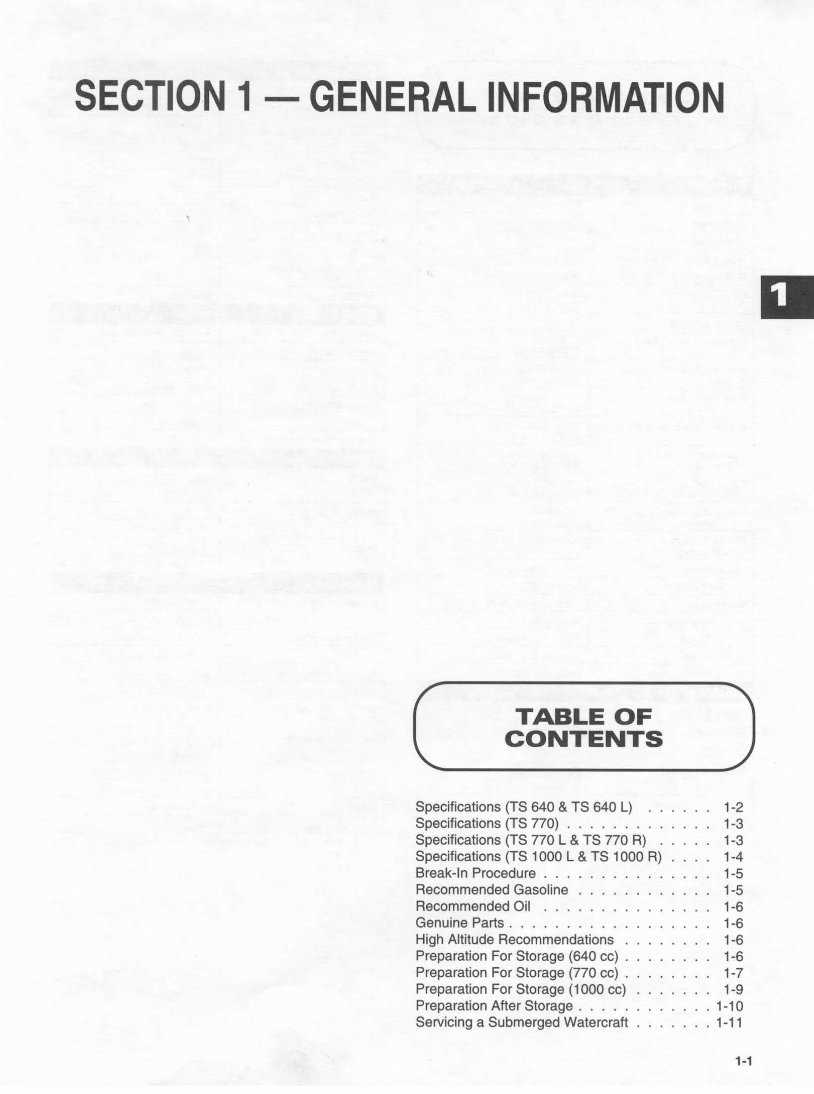

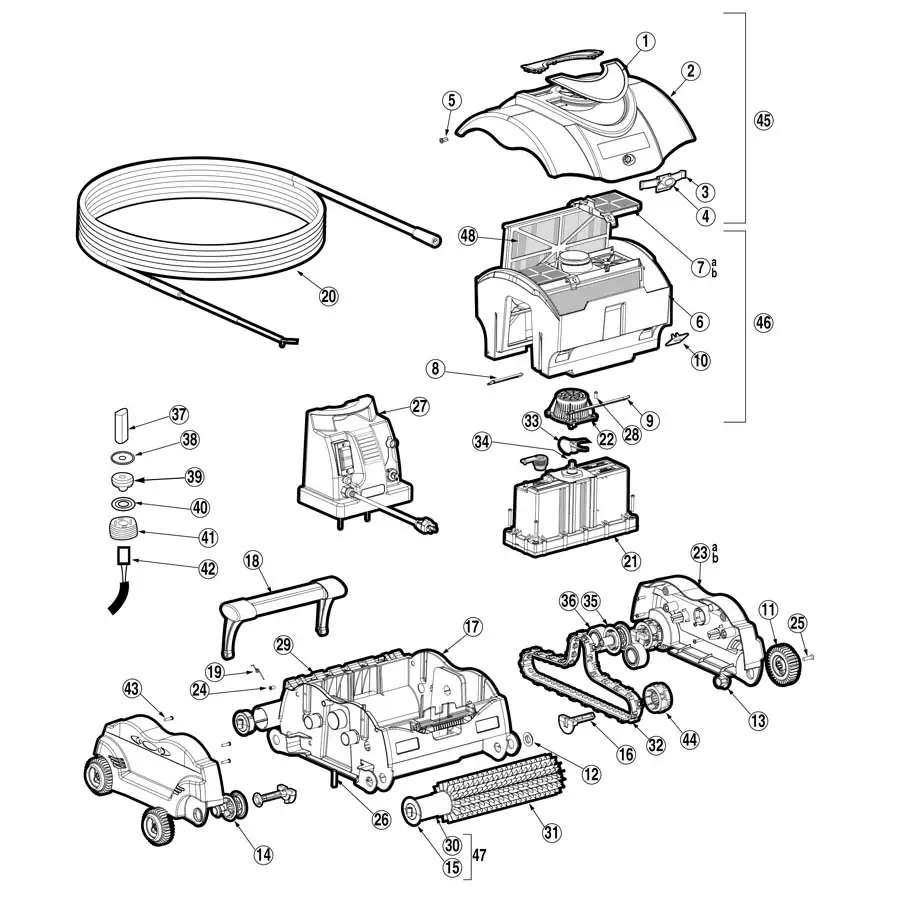

Tigershark Parts Diagram Overview

Exploring the intricacies of machinery often involves a comprehensive look at their individual elements and how they interconnect. This section provides a thorough overview of the essential elements that make up a particular watercraft model, offering insights into their functionalities and arrangements.

By examining the specific layout of these components, users can gain a clearer understanding of how each piece contributes to the overall performance of the vessel. This knowledge is invaluable for both maintenance and repair, ensuring that enthusiasts can keep their watercraft operating efficiently.

In this guide, readers will find detailed visual representations that elucidate the relationship between various components. Such resources can be instrumental in troubleshooting issues or planning modifications, ultimately enhancing the experience of operating these remarkable machines.

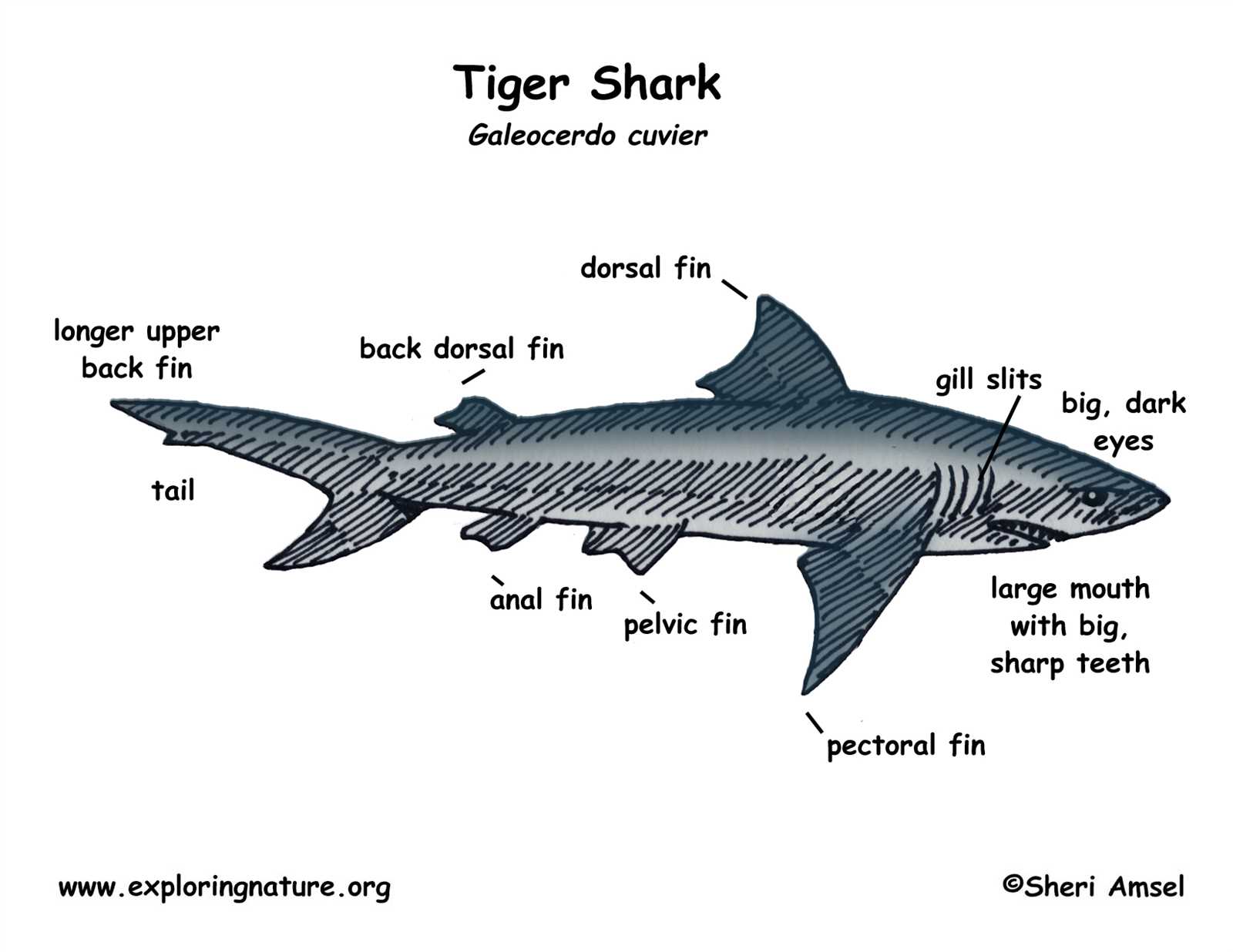

Understanding Key Components

Comprehending the essential elements of aquatic vehicles is crucial for efficient operation and maintenance. Each segment plays a vital role in ensuring optimal performance and reliability. By familiarizing oneself with these integral parts, users can enhance their understanding of how these machines function and can identify potential issues.

Main Functional Elements

The primary components of a watercraft are designed to work in harmony, facilitating smooth navigation and functionality. Below are some of the key sections that are commonly found in these vehicles:

| Component | Function |

|---|---|

| Hull | Provides structure and buoyancy, enabling the craft to float. |

| Engine | Drives the vehicle and powers other onboard systems. |

| Steering System | Allows for navigation and control over the direction of travel. |

| Propulsion Unit | Generates thrust to move the craft through water. |

Importance of Regular Inspection

Regular checks of these crucial components can prevent malfunctions and enhance safety. Understanding the function of each element aids in identifying signs of wear or potential failures, ensuring timely interventions and repairs.

Diagram Explanation and Use

This section aims to provide a comprehensive understanding of a visual representation that outlines the components and their interrelations within a specific machine. Such illustrations are essential for both enthusiasts and professionals, as they facilitate the identification and comprehension of various elements that contribute to the overall functionality.

Utilizing this graphical layout enables users to effectively analyze and troubleshoot issues, ensuring smoother maintenance and repair processes. Familiarity with these visuals empowers individuals to navigate the intricacies of the machine with greater confidence.

| Component | Description | Function |

|---|---|---|

| Element A | Primary structural part | Provides support and stability |

| Element B | Connecting section | Links different parts together |

| Element C | Functional unit | Enables specific operations |

Importance of Parts Identification

Recognizing and understanding the components of any mechanical system is essential for effective maintenance and repair. Each element plays a crucial role in ensuring optimal functionality and performance. Accurate identification helps in diagnosing issues, sourcing the correct replacements, and enhancing the longevity of the equipment.

Benefits of Accurate Identification

- Improved Maintenance: Knowing each component allows for better scheduling of maintenance tasks.

- Efficient Repairs: Quick identification minimizes downtime during repairs.

- Cost Savings: Proper knowledge helps avoid unnecessary purchases of incorrect items.

- Enhanced Safety: Understanding each element’s function contributes to safer operation.

Strategies for Effective Identification

- Utilize reference guides or manuals specific to the equipment.

- Keep a catalog of components with images and descriptions for easy access.

- Engage with online forums or communities for advice and insights.

- Conduct regular training sessions for staff to familiarize them with the system.

Commonly Replaced Components

In any aquatic vehicle, certain elements tend to wear out more frequently due to their regular exposure to harsh conditions. Understanding these components can help owners maintain optimal performance and extend the lifespan of their machinery. Identifying which parts are most often substituted ensures that users can keep their vessels in peak condition, minimizing downtime during maintenance.

Key Elements for Replacement

Among the frequently swapped items are the propulsion system components, such as impellers and bearings. These parts experience significant stress and can degrade over time, leading to reduced efficiency. Regular inspections and timely replacements are crucial for maintaining a smooth ride.

Electrical System Components

Another area of concern involves electrical elements like batteries and ignition systems. These components are vital for the operation of the craft, and their failure can lead to significant performance issues. Ensuring that these parts are in good condition is essential for reliable functionality.

Maintenance Tips for Parts

Ensuring the longevity and optimal performance of components is crucial for any watercraft. Regular upkeep not only enhances efficiency but also prevents potential issues from arising. Here are some essential practices to maintain your equipment effectively.

- Regular Inspections: Conduct frequent checks to identify wear and tear before they escalate. Focus on areas prone to damage, such as seals and joints.

- Cleanliness: Keep all components free from dirt and debris. Use a soft cloth and mild detergent for cleaning, especially after usage in harsh environments.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear. Ensure you follow the manufacturer’s recommendations for the right type of lubricant.

- Storage Practices: Store your equipment in a dry, cool place when not in use. Cover it to protect from dust and moisture that can lead to corrosion.

- Replacement Schedule: Adhere to a regular replacement schedule for wear items. Consult the maintenance manual for guidance on recommended intervals.

By following these guidelines, you can maintain the functionality of your equipment and extend its lifespan, ensuring a smooth and enjoyable experience on the water.

Where to Find Replacement Parts

Finding suitable components for your watercraft can greatly enhance its performance and longevity. There are various sources where enthusiasts and owners can locate essential items needed for maintenance or repairs. Understanding these avenues will streamline the process and ensure that you can keep your vessel in optimal condition.

Authorized Dealers

One of the most reliable sources for obtaining necessary components is through authorized retailers. They typically offer:

- Genuine items that meet quality standards.

- Expert advice and support for installation and compatibility.

- Warranty options for peace of mind.

Online Marketplaces

The internet provides a vast array of platforms where you can purchase various components. Consider the following:

- Specialty websites that focus on marine equipment.

- General e-commerce sites with user reviews to guide your choices.

- Online forums or groups where members share links to trustworthy sellers.

By exploring these options, you can effectively find the necessary components to keep your watercraft running smoothly.

Understanding Engine Assembly

The assembly of an engine is a crucial aspect of its overall functionality and performance. This intricate process involves the careful integration of various components, each playing a significant role in ensuring the engine operates efficiently. A comprehensive understanding of how these elements work together can enhance maintenance practices and troubleshooting efforts.

Key Components of Engine Assembly

Several essential elements come together in the engine assembly, including the block, pistons, crankshaft, and cylinder head. Each component is designed to perform specific functions, contributing to the engine’s power generation and efficiency. Familiarizing oneself with these parts allows for better insights into potential issues and optimizations.

Importance of Proper Assembly

Accurate assembly is vital for the engine’s longevity and performance. Misalignment or improper installation of any component can lead to significant mechanical failures, affecting the overall operation of the vehicle. Regular inspections and understanding the assembly process can help mitigate such risks and ensure smooth functionality.

Electrical System Components

The electrical system of a watercraft plays a crucial role in its overall functionality and performance. It encompasses various elements that work together to ensure reliable operation, safety, and user convenience. Understanding these components is essential for effective maintenance and troubleshooting.

Key Elements of the Electrical System

Several integral parts contribute to the efficiency of the electrical network, each serving a specific purpose. From power generation to distribution, these components are vital for the smooth functioning of electrical systems in watercraft.

| Component | Function |

|---|---|

| Battery | Stores electrical energy for starting the engine and powering accessories. |

| Alternator | Generates electricity while the engine runs, recharging the battery. |

| Ignition System | Initiates the combustion process in the engine. |

| Wiring Harness | Facilitates connections between various electrical components. |

| Fuse Box | Protects electrical circuits from overloads by interrupting power flow. |

Maintenance and Troubleshooting

Regular inspection and upkeep of the electrical system components are vital to prevent potential issues. Familiarity with each part’s function aids in diagnosing problems efficiently and ensures the longevity of the entire system.

Hull and Structural Elements

The integrity and performance of any watercraft significantly depend on its foundational components. These elements contribute to the overall durability, stability, and functionality of the vessel, ensuring a smooth experience on the water. Understanding the structure is crucial for maintenance and performance optimization.

Key structural features include the outer shell, which protects the internal mechanisms, and various reinforcements that enhance resilience against aquatic conditions. Proper care and awareness of these components can extend the lifespan of the craft and improve its efficiency.

| Element | Description | Function |

|---|---|---|

| Hull | The main body of the vessel, providing buoyancy and structural support. | Ensures stability and navigation efficiency. |

| Deck | The flat surface on top of the hull, used for movement and storage. | Provides accessibility and safety for passengers and equipment. |

| Transom | The rear part of the hull, typically supporting the motor or engine. | Stabilizes the craft and aids in propulsion. |

| Stringers | Longitudinal supports within the hull. | Adds strength and maintains the shape of the structure. |

Impeller and Pump Functions

The functionality of watercraft systems relies heavily on the interaction between the impeller and the pumping mechanism. These components work in unison to facilitate the movement of fluids, ensuring optimal performance and efficiency during operation. Understanding their roles is crucial for maintaining and enhancing the overall functionality of the vessel.

Role of the Impeller

The impeller plays a vital role in creating the necessary flow of water. It operates by converting rotational energy into kinetic energy, effectively drawing water into the system. This process is essential for various applications, including propulsion and cooling systems.

- Fluid Movement: The impeller’s blades generate a centrifugal force, pushing water outward and creating a vacuum that draws more fluid in.

- Efficiency: A well-designed impeller maximizes fluid transfer while minimizing energy consumption.

- Versatility: Impellers can be tailored for specific applications, allowing for adjustments based on performance needs.

Pumping Mechanism Overview

The pumping mechanism works in tandem with the impeller, ensuring a consistent flow of water throughout the system. It is responsible for transferring the fluid to various areas of the watercraft, enabling essential functions such as cooling and propulsion.

- Types of Pumps: Various types of pumps are utilized, including centrifugal and positive displacement pumps, each serving unique purposes.

- Flow Regulation: The pump ensures that the fluid is delivered at the correct pressure and flow rate, essential for system efficiency.

- Maintenance Needs: Regular inspection and maintenance of the pumping system are crucial to avoid malfunctions and ensure longevity.

Safety Features and Components

This section provides an overview of the essential safety elements and components found in personal watercraft, emphasizing their importance for safe operation and user protection.

Effective safety mechanisms are crucial for ensuring the well-being of riders and passengers. These features are designed to minimize risks and enhance the overall experience on the water.

- Emergency Cut-off Switch: A vital device that stops the engine in case of an emergency, preventing accidents and injuries.

- Floating Design: The construction of the craft allows it to remain buoyant, reducing the risk of capsizing.

- Stable Hull: A well-designed hull structure contributes to better balance and handling, promoting safer navigation.

Additional components can also enhance safety:

- Safety Lanyard: Connects the rider to the craft, ensuring that it remains operational even if the rider falls off.

- Reflective Markings: Increases visibility during low-light conditions, making the craft easier to see by others.

- Integrated Navigation Lights: Essential for safe operation during night-time or poor visibility conditions.

Investing in proper safety components is key to enjoying a secure and enjoyable experience on the water.