Understanding the Components of a Tye Grain Drill Parts Diagram

In the realm of modern farming, the efficiency of machinery plays a pivotal role in ensuring optimal crop production. A comprehensive grasp of the essential elements that constitute these tools is crucial for operators and enthusiasts alike. By familiarizing oneself with these mechanisms, one can enhance maintenance practices and operational effectiveness.

The intricate layout of these machines showcases various functionalities, each contributing to the overall performance. Recognizing the significance of each section empowers users to make informed decisions regarding repairs and upgrades. This knowledge ultimately leads to improved yield and sustainable farming practices.

As we explore the intricacies of these implements, the emphasis will be on understanding the interconnections between the different components. This examination will serve as a valuable resource for those seeking to deepen their expertise in agricultural technology and enhance their operational capabilities.

Tye Grain Drill Overview

This section provides a comprehensive look at an essential piece of agricultural equipment designed for efficient sowing of seeds. Understanding its components and functionality can significantly enhance farming practices, ensuring optimal crop yield and soil management.

Features of this implement include precision in seed placement, adaptability to various soil types, and ease of operation. These attributes allow farmers to cultivate land more effectively, reducing waste and maximizing efficiency during planting seasons.

In addition, the machine is engineered to withstand diverse weather conditions, making it a reliable tool in any agricultural setting. Its robust construction ensures longevity, providing a good return on investment for growers.

By familiarizing oneself with the structure and operation of this essential equipment, farmers can improve their planting strategies and contribute to sustainable agricultural practices.

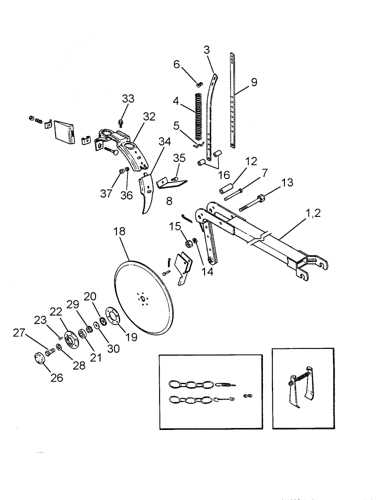

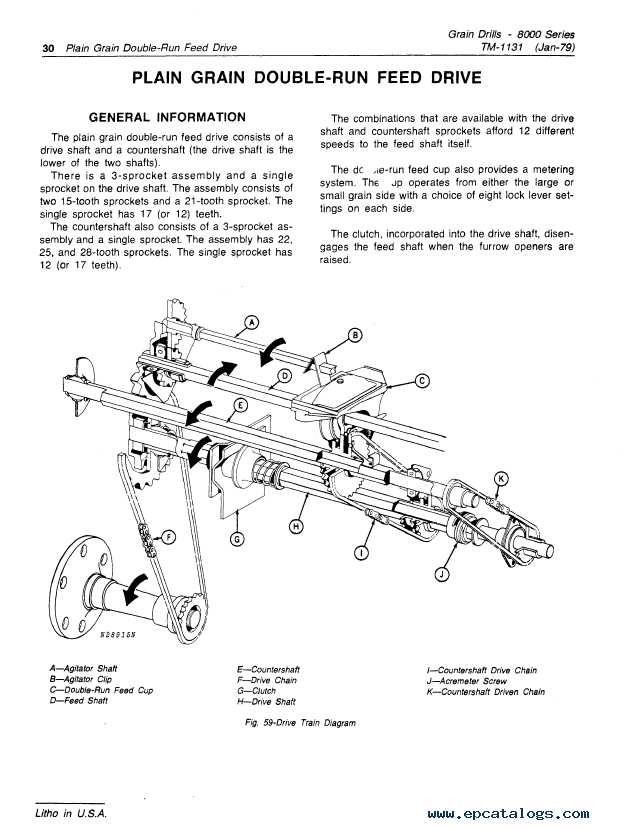

Understanding Grain Drill Components

In the realm of agricultural machinery, comprehending the individual elements that contribute to efficient sowing practices is essential for optimal crop production. Each component plays a vital role in ensuring that seeds are accurately placed in the soil, facilitating healthy growth and maximizing yield. An in-depth knowledge of these elements not only enhances operational efficiency but also aids in troubleshooting and maintenance.

The foundation of any sowing implement typically includes a robust frame designed to withstand various field conditions. This structure supports all other components and provides stability during operation. Attached to this frame are various mechanisms that perform distinct functions, such as seed distribution and soil penetration. Understanding the interplay between these mechanisms is crucial for effective use and longevity of the equipment.

Seed placement systems, often featuring precision engineering, ensure that seeds are deposited at the correct depth and spacing. This is vital for achieving uniform germination and growth. Additionally, some machines incorporate advanced technologies that monitor soil conditions and adjust settings in real time, further enhancing performance.

Moreover, the maintenance of these tools requires familiarity with their individual functions and how they contribute to the overall system. Regular inspection and timely repairs not only prevent breakdowns but also promote optimal performance throughout the planting season. In essence, a thorough understanding of these components empowers operators to make informed decisions, leading to improved agricultural outcomes.

Functionality of Each Part

This section explores the roles and contributions of various components within a seeding mechanism. Understanding these functions is crucial for optimal operation and maintenance.

Key Components and Their Roles

- Seeder Mechanism: Responsible for precise placement of seeds in the soil.

- Hopper: Stores the seeds before they are distributed.

- Distributors: Ensure even spreading of seeds across the designated area.

- Depth Control: Regulates how deep the seeds are planted for optimal growth.

Supporting Features

- Transport Wheels: Facilitate easy movement across fields.

- Adjustable Settings: Allow customization of seed spacing and depth.

- Frame Structure: Provides stability and support during operation.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in facilitating understanding and effective communication within various technical fields. They serve as visual guides that clarify complex mechanisms, ensuring that users can navigate and operate equipment efficiently. By providing a clear representation of components and their relationships, these visuals enhance the overall comprehension of intricate systems.

In maintenance and repair scenarios, accurate visuals are indispensable. They allow technicians to identify parts quickly, streamlining troubleshooting processes and minimizing downtime. When detailed representations are readily available, the risk of errors decreases, leading to improved safety and reliability in operations.

Furthermore, high-quality illustrations aid in training and educational contexts. They can significantly enhance the learning experience by allowing trainees to visualize concepts that might otherwise be abstract. This fosters a deeper understanding, enabling learners to grasp operational procedures and mechanical interactions more effectively.

Overall, the significance of precise representations cannot be overstated. They are vital for successful operation, maintenance, and education, ultimately contributing to enhanced productivity and safety in various industries.

Common Issues with Grain Drills

A variety of challenges can arise when utilizing seeding equipment, impacting both efficiency and crop yield. Understanding these common problems is essential for maintaining optimal performance and ensuring successful planting operations.

Wear and Tear: Over time, components may experience significant wear, leading to uneven distribution and decreased effectiveness. Regular inspections and timely replacements are crucial to prevent this issue from escalating.

Clogging: Soil debris and seed buildup can obstruct the flow mechanisms, resulting in inconsistent seeding patterns. Keeping the machinery clean and free of obstructions can mitigate this risk.

Calibration Issues: Incorrect settings can lead to improper seed placement. Ensuring that equipment is accurately calibrated according to seed type and field conditions is vital for achieving optimal results.

Alignment Problems: Misalignment of components can cause uneven sowing and damage. Regular checks and adjustments are necessary to maintain proper alignment and functionality.

Hydraulic Failures: Hydraulic systems are integral to the operation of these machines, and any failure can halt productivity. Routine maintenance and prompt repairs are essential to prevent hydraulic issues from arising.

How to Maintain Your Equipment

Proper upkeep of machinery is essential for ensuring longevity and optimal performance. Regular maintenance not only prevents breakdowns but also enhances efficiency.

- Inspect regularly: Check for signs of wear and tear on all components.

- Clean thoroughly: Remove dirt and debris to prevent corrosion and blockages.

- Lubricate moving parts: Apply appropriate oils to reduce friction and wear.

- Adjust settings: Ensure that all calibrations are accurate for optimal operation.

- Replace worn components: Swap out any parts that show significant deterioration.

By adhering to these guidelines, you can significantly extend the life of your machinery and enhance its performance over time.

Repairing Worn Out Parts

Maintaining optimal performance in equipment often hinges on addressing components that show signs of wear. Proactive repair can prevent further damage and ensure longevity, allowing for smoother operations.

Identifying worn elements is crucial. Here are steps to guide you through the process:

- Inspection: Regularly examine each component for signs of degradation.

- Assessment: Determine the severity of the wear and whether repair or replacement is necessary.

- Cleaning: Remove debris and buildup to facilitate a thorough evaluation.

- Repair Techniques: Utilize appropriate methods such as welding, grinding, or replacement of specific sections.

- Testing: After repairs, conduct tests to ensure functionality meets required standards.

By adhering to these steps, you can effectively restore efficiency and prolong the life of your equipment.

Tools Needed for Repairs

When it comes to maintaining and restoring equipment, having the right instruments is essential for efficiency and effectiveness. Proper tools not only simplify the process but also ensure that repairs are completed to a high standard, extending the lifespan of the machinery.

Essential Instruments

- Wrenches

- Screwdrivers

- Pliers

- Socket set

Specialized Gear

- Torque wrench

- Multimeter

- Lubrication tools

- Safety equipment

Having a comprehensive toolkit ready allows for seamless repairs, minimizing downtime and enhancing productivity.

Upgrades for Enhanced Performance

Enhancing the efficiency and functionality of agricultural machinery can lead to significant improvements in productivity. By integrating advanced features and technologies, operators can achieve optimal results in their operations.

Technological Innovations

Incorporating cutting-edge technology, such as precision seeding systems, can greatly enhance accuracy and reduce waste. Automated controls and real-time monitoring help ensure that resources are utilized effectively, maximizing yield potential.

Durability Enhancements

Upgrading components with high-quality materials can lead to increased longevity and reduced maintenance costs. Reinforced frames and enhanced wear-resistant elements provide added strength, allowing equipment to withstand harsh conditions and prolonged use.

Comparison with Other Drill Models

When evaluating various seeding implements, it’s essential to understand their differences in design, functionality, and efficiency. Each model brings unique features that cater to specific agricultural needs, impacting planting precision and soil health. This section explores how one model stands out when juxtaposed with others in the market.

One of the key differentiators is the mechanism employed for seed placement. Some models utilize a simple gravity-fed system, while others incorporate advanced metering technology, ensuring consistent seed depth and spacing. This precision can significantly affect crop yield and overall field performance.

Additionally, build quality and durability vary between different machines. Certain implements are constructed with heavy-duty materials, designed to withstand harsh field conditions, whereas others may be lighter and less robust, potentially limiting their lifespan in challenging environments.

Another factor to consider is the ease of maintenance. Some models offer user-friendly access to components for routine servicing, while others may require specialized tools or expertise, impacting long-term operational costs and downtime.

Lastly, technological integrations, such as GPS and automated controls, are becoming increasingly common in newer models. This advancement allows for greater efficiency and data-driven decision-making, setting a new standard in agricultural practices. Comparing these aspects provides valuable insights for farmers seeking the most effective solutions for their planting needs.

Best Practices for Operation

Effective functioning of agricultural equipment is crucial for achieving optimal yields and efficiency. Adhering to best practices can significantly enhance performance and extend the lifespan of machinery. Proper preparation, routine maintenance, and mindful usage are key components that contribute to successful operations.

Preparation and Setup

Before initiating work, ensure that all components are thoroughly inspected and calibrated. Check for wear and tear on critical elements to prevent malfunction during operation. Additionally, familiarize yourself with the equipment’s manual for detailed instructions on adjustments that align with specific tasks.

Routine Maintenance

Implementing a schedule for maintenance is essential. Regularly clean moving parts and lubricate them as needed. Consistent upkeep not only improves functionality but also minimizes the risk of breakdowns, ensuring seamless productivity throughout the season.

Safety Measures During Use

Ensuring a secure environment while operating machinery is crucial for preventing accidents and injuries. Adhering to safety protocols not only protects the operator but also enhances the efficiency of the task at hand.

Pre-Operation Checks

Before engaging in any task, it’s essential to conduct thorough inspections of the equipment. Verify that all components are in optimal condition and free from defects. Additionally, ensure that safety features are functioning properly to mitigate risks.

Personal Protective Equipment

Wearing appropriate protective gear is vital. This includes gloves, goggles, and ear protection. These items are designed to shield against potential hazards, allowing for a safer working experience.

Resources for Further Learning

Expanding your knowledge on the subject can significantly enhance your understanding and practical application. Various materials are available to provide deeper insights and broaden your expertise.

Books and Publications

- Technical manuals on machinery and equipment.

- Industry-related journals that cover advancements and techniques.

- Textbooks focusing on agricultural practices and machinery operations.

Online Platforms

- Websites offering instructional videos and tutorials.

- Online forums where enthusiasts and professionals exchange knowledge.

- Webinars and virtual workshops hosted by experts in the field.