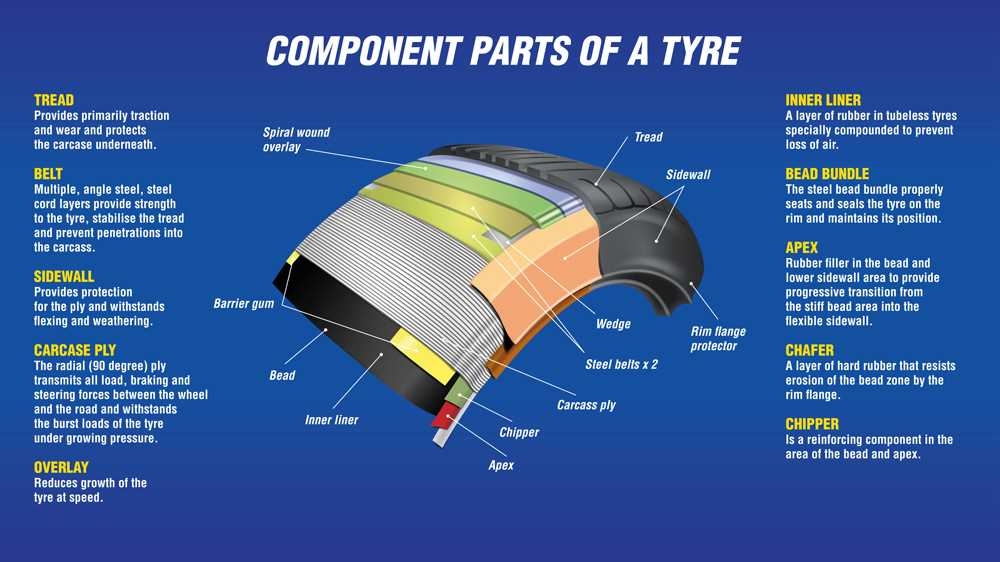

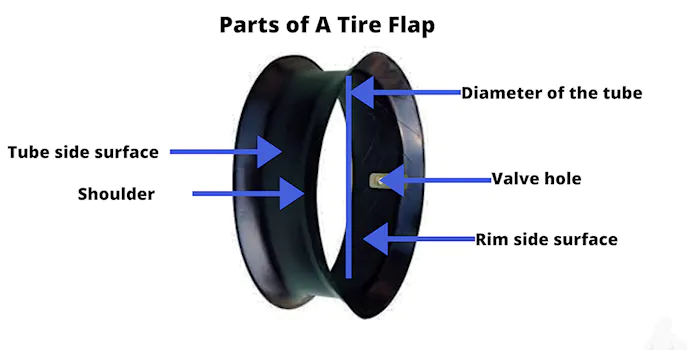

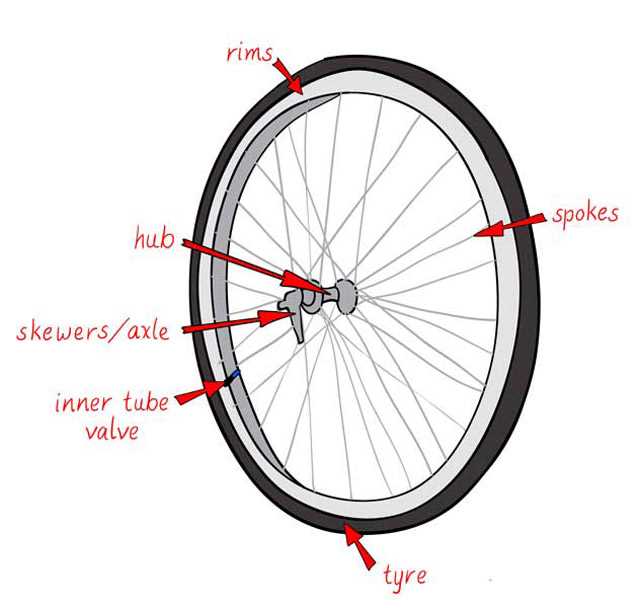

Key Components of a Tyre Diagram

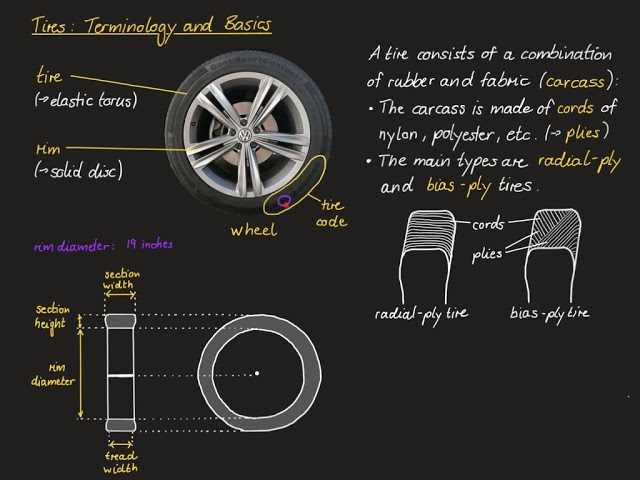

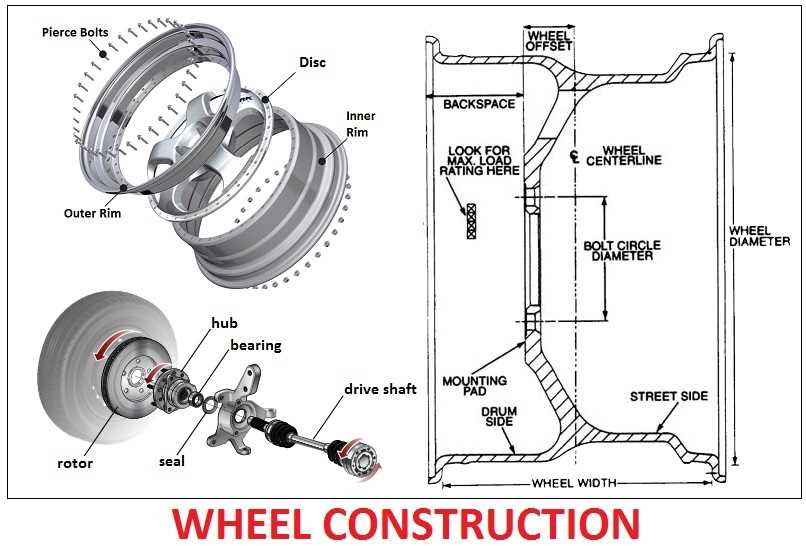

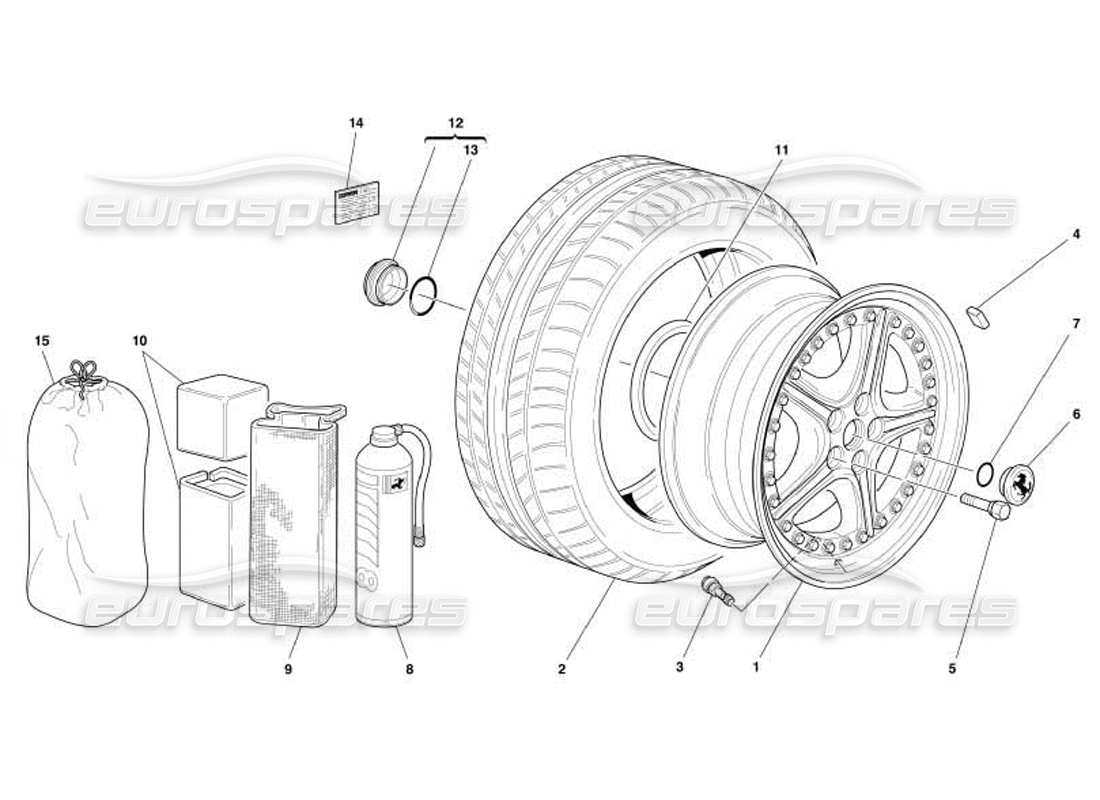

Understanding the various elements that make up a vehicle’s rolling system is key to ensuring optimal performance and safety on the road. Each element plays a critical role in ensuring the smooth operation and durability of the system. This section will explore the crucial components that contribute to the proper functioning of a wheel assembly.

From the structural elements that provide stability to the materials designed for efficient movement, the entire setup is an intricate balance of engineering. By examining the distinct elements in detail, you can gain a deeper appreciation of how each one contributes to the overall system.

Proper maintenance and regular inspections are essential for extending the life of these components. Recognizing signs of wear early on can prevent more serious issues from developing, making it easier to maintain control and efficiency.

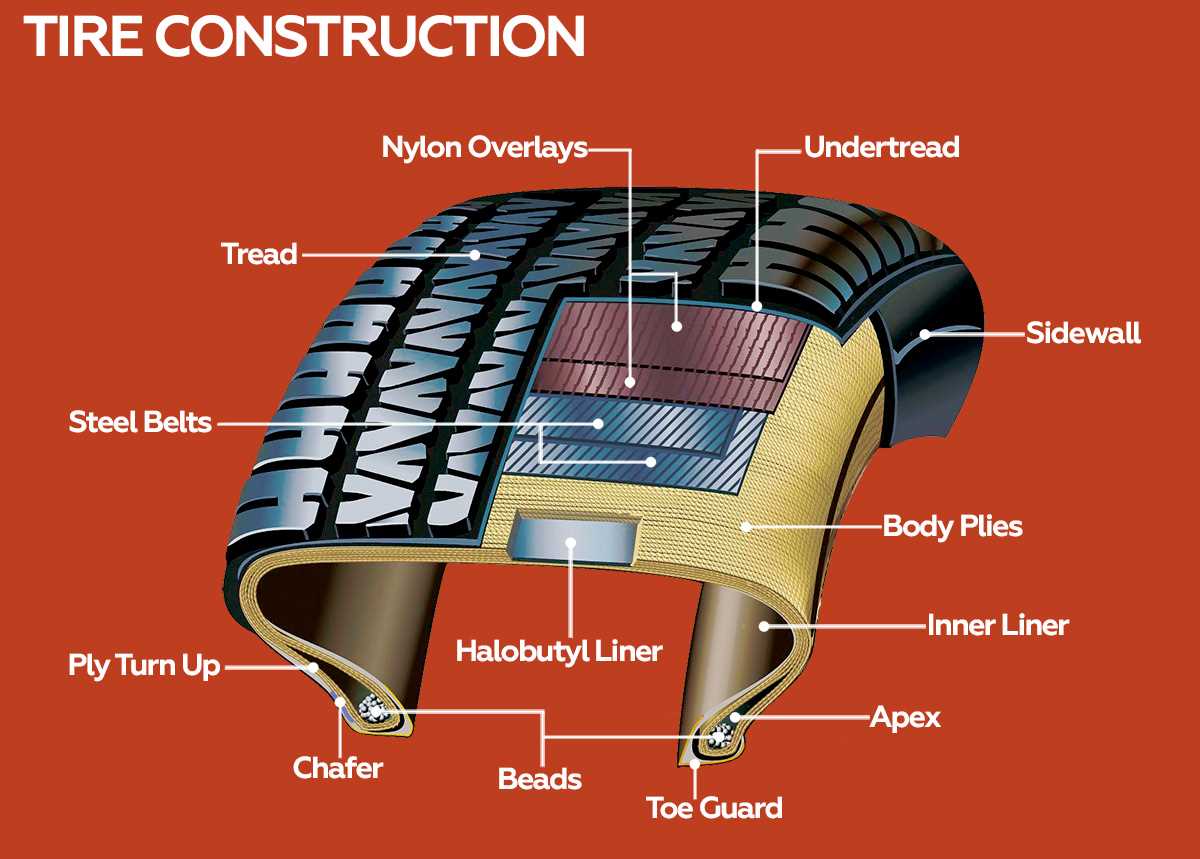

Understanding the Anatomy of a Tyre

Every wheel is composed of several essential elements that contribute to its performance and durability. These components are designed to work together to provide a smooth ride, ensure safety, and handle different road conditions. By learning more about these elements, one can better understand how they function to keep your vehicle moving efficiently.

Key Components

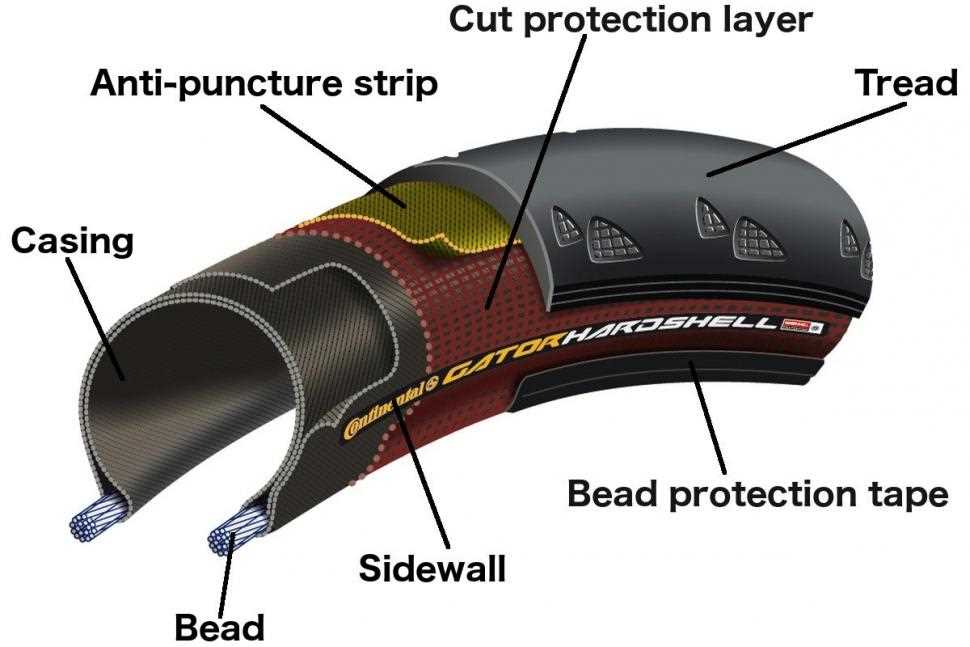

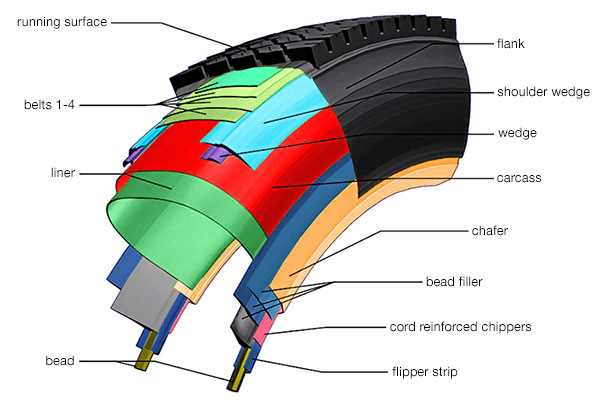

- Outer Layer: This external section provides grip and traction, helping maintain control on various surfaces.

- Support Structure: Beneath the surface, this frame ensures stability and supports the overall shape, maintaining integrity under pressure.

- Inner Core: Often overlooked, this area is vital for maintaining air pressure and providing a cushion to absorb shocks from the road.

Internal Layers

- Protective Belt: Positioned beneath the outer shell, this layer helps prevent punctures and adds strength to the surface.

- Reinforcement Fibers: These materials run through the structure, providing additional durability and flexibility.

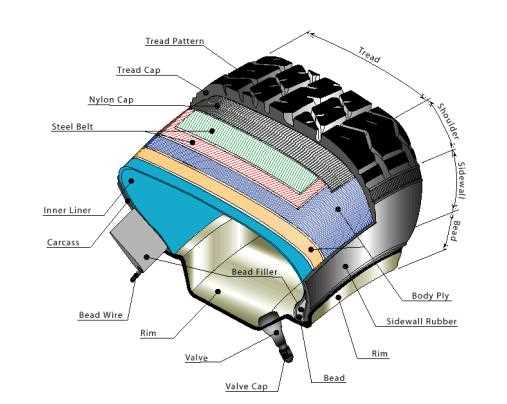

- Main Components of a Standard Tyre

Understanding the structure of a vehicle’s rolling surface is crucial for maintaining performance and safety. The key elements that make up this essential part of the wheel system contribute to its durability, grip, and overall function. Below is a breakdown of the most important elements found in every such product used on the road.

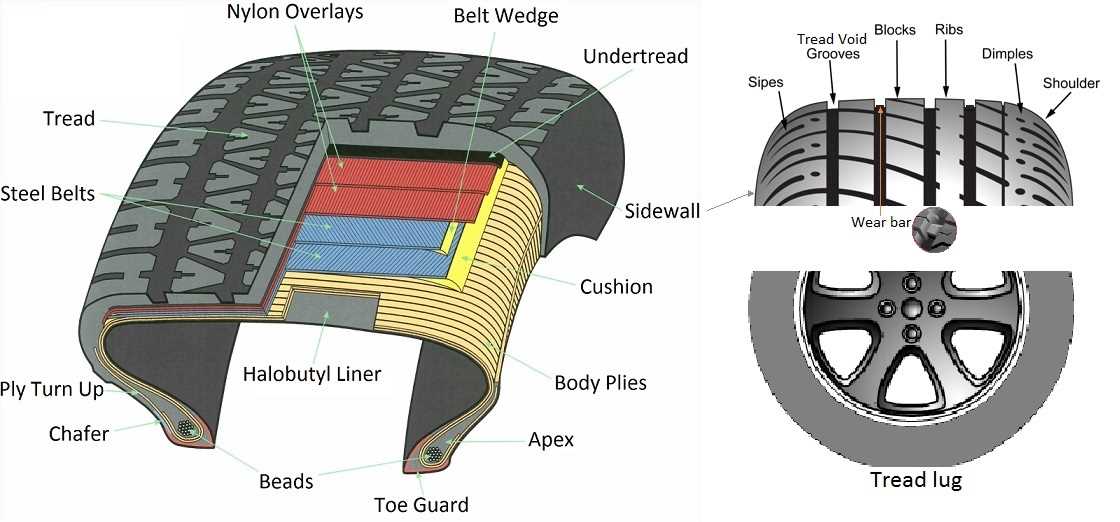

Tread

The uppermost layer, responsible for traction and handling, is the patterned outer surface that makes contact with the road. It helps disperse water, provides grip on various surfaces, and protects the underlying structure from wear and tear.

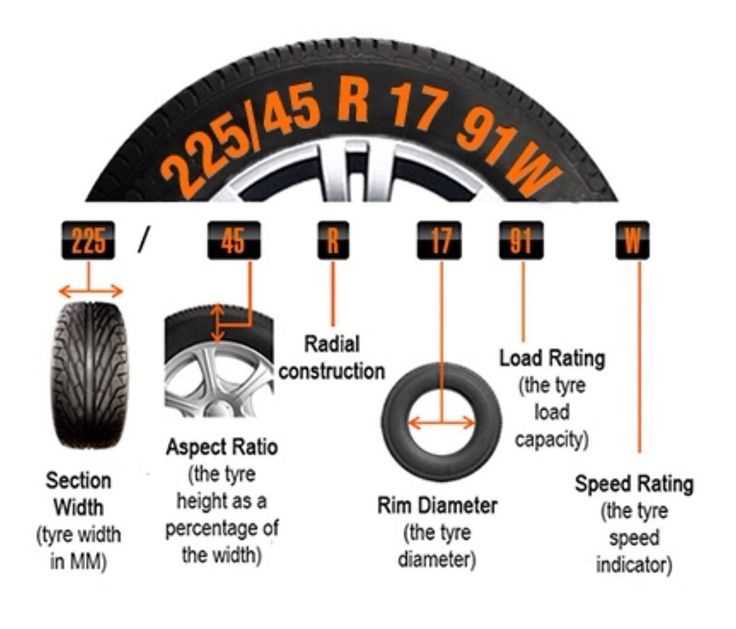

Sidewall

This section connects the outer surface to the inner ring, providing flexibility and cushioning. It also houses important information about the product’s specifications, including dimensions and performance ratings. The sidewall helps absorb impact and maintain the product’s shape during operation.

Key Functions of Different Tyre Parts

Understanding the structure of a wheel’s components is essential for grasping how each element contributes to performance and safety. Each section of the wheel plays a vital role in ensuring optimal functionality, influencing everything from stability to wear resistance.

Outer Layer: The outermost section is designed to protect the internal elements from external damage, providing traction and preventing slippage on various surfaces.

Inner Support: This portion ensures proper pressure distribution, contributing to overall stability and preventing potential imbalances during motion.

Side Sections: The sides are responsible for supporting the weight of the vehicle while absorbing impact, enhancing comfort and maintaining shape under pressure.

Base Structure: Located beneath, this layer ensures a firm connection with the road surface, providing essential grip and control during acceleration, braking, and cornering.

Material Composition in Modern Tyres

Modern rubber-based products are crafted from a variety of materials, each chosen for its specific properties and role in ensuring optimal performance. These components are engineered to provide durability, grip, and safety on the road. The selection of materials has evolved significantly with advancements in technology, leading to more efficient and environmentally friendly designs.

Core Materials

The main structure relies on several key substances, combining both synthetic and natural compounds to enhance overall functionality. These core ingredients provide the necessary balance between strength and flexibility.

- Rubber blends – A mix of natural and synthetic types, providing elasticity and wear resistance.

- Silica – Used to reduce rolling resistance and improve fuel efficiency.

- Carbon black – Adds reinforcement, increasing the lifespan of the product and enhancing heat dissipation.

Additional Components

Alongside the core elements, additional ingredients are integrated to address specific performance needs. These materials play a crucial role in optimizing road grip, reducing noise, and maintaining structural integrity over time.

- Steel and textile cords – These reinforcements give the structure strength and flexibility, helping it withstand various forces during use.

- Resins

Importance of the Tread Pattern Design

The structure of grooves and blocks on a wheel surface significantly influences driving performance. Its arrangement plays a key role in ensuring safety, control, and durability on various road conditions. This section will explore how different designs contribute to handling, fuel efficiency, and wear resistance.

Improved Handling and Stability

A well-crafted groove layout enhances road grip, especially in wet conditions. It helps direct water away from the surface, reducing the chance of slipping and improving overall stability. Designs with specific block arrangements allow for better cornering and maneuverability.

Fuel Efficiency and Durability

The arrangement of blocks and channels can reduce rolling resistance, which directly impacts fuel consumption. Optimized designs not only improve fuel efficiency but also extend the longevity of the surface by distributing wear more evenly.

- Better traction in varied weather conditions

- Enhanced safety through improved grip

- Longer lifespan with reduced wear and tear

Inner Liner: Role in Air Retention

The inner liner serves a crucial function in maintaining air pressure within a rubber wheel. This component acts as a barrier, preventing air from escaping and ensuring optimal performance during operation. Its design and material composition play a significant role in overall efficiency and durability.

Functionality and Materials

This layer is typically crafted from specialized polymers that possess excellent impermeability. The choice of materials is vital, as it directly influences the effectiveness of air retention. Additionally, the construction methods employed can enhance the liner’s resilience against wear and environmental factors.

Impact on Performance

A well-designed inner liner contributes significantly to the longevity and safety of the wheel. By minimizing air loss, it enhances stability and traction, which are essential for smooth handling and maneuverability. Consequently, investing in high-quality materials and engineering ensures optimal functionality.

Impact of Sidewall on Tyre Performance

The sidewall of a wheel covering plays a crucial role in determining its overall efficiency and handling characteristics. This section explores how variations in the sidewall design influence various aspects of performance, including traction, stability, and ride comfort.

Influence on Handling and Stability

A well-engineered sidewall contributes significantly to a vehicle’s handling dynamics. The flexibility or rigidity of the sidewall can affect cornering stability and response to steering input. For instance, a stiffer sidewall tends to enhance stability during sharp turns, while a more flexible design may provide a smoother ride on uneven surfaces.

Effects on Traction and Comfort

The construction of the sidewall also impacts grip on different terrains. A robust sidewall can improve contact with the ground, enhancing traction. Furthermore, the sidewall’s design influences the overall comfort level experienced by passengers, as it helps absorb shocks from road irregularities. Therefore, selecting the appropriate sidewall design is essential for achieving a balance between performance and comfort.

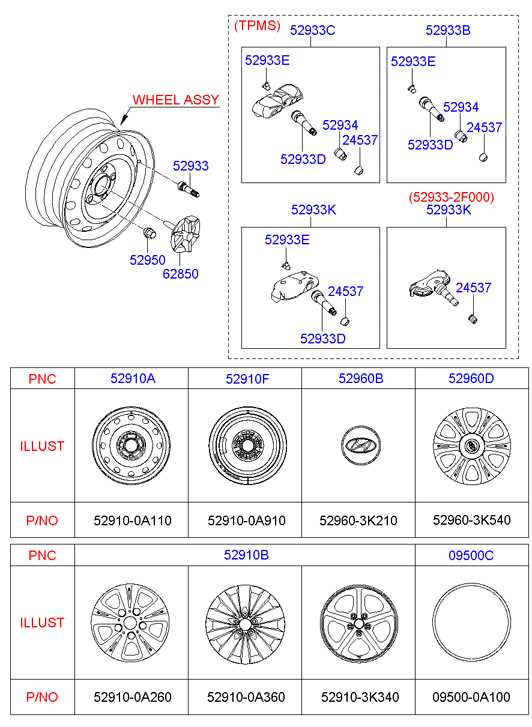

Bead: Ensuring Secure Fit to Rims

The bead is a crucial element in maintaining a stable connection between the wheel and the tire. This component ensures that the assembly remains intact under various conditions, allowing for optimal performance and safety during operation.

A properly designed bead provides a reliable seal that helps to prevent air loss and maintain the desired pressure within the assembly. Understanding its importance can lead to improved handling and durability.

- Functionality: The bead’s primary role is to create a tight fit against the rim, preventing any displacement.

- Materials: Beads are typically constructed from robust materials to withstand the forces experienced during use.

- Installation: Proper fitting of the bead during installation is essential for achieving the best performance and safety.

To ensure the longevity and effectiveness of this component, regular inspections and maintenance should be carried out. Recognizing potential wear or damage can significantly enhance overall safety.

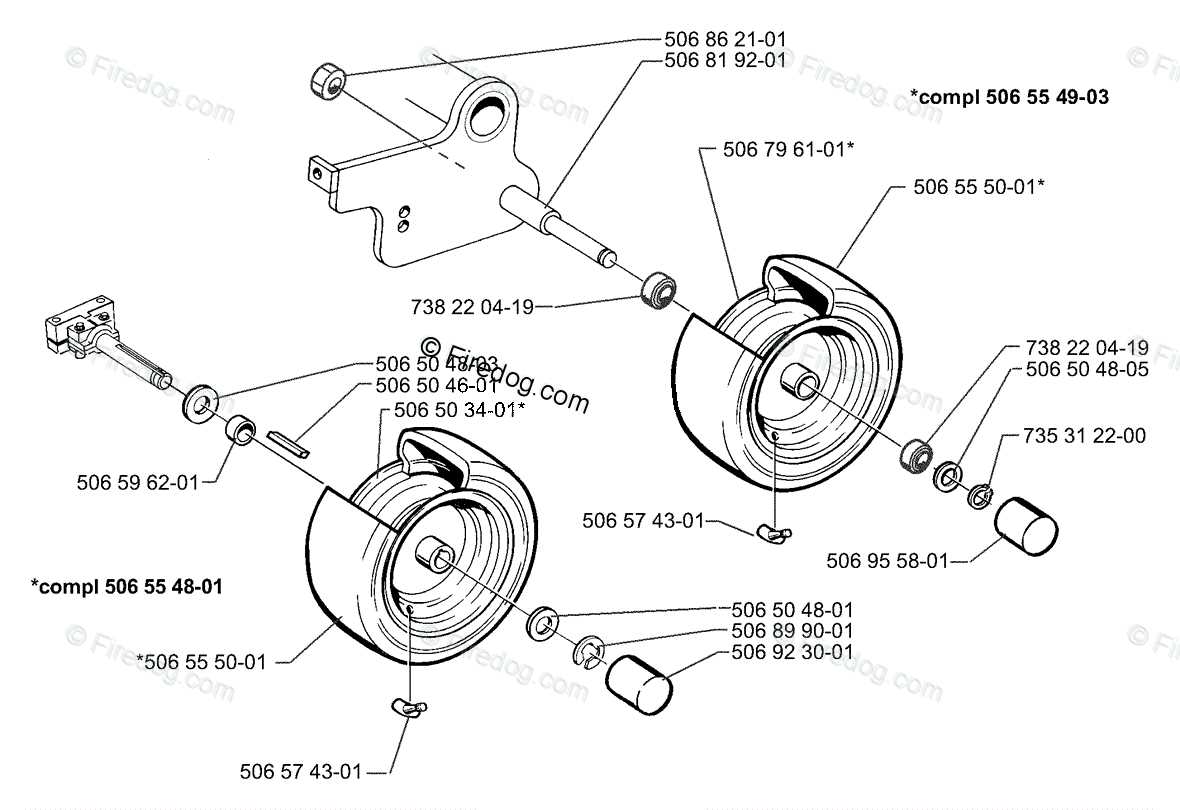

Tyre Belt System for Durability

The durability of a vehicle’s outer covering is essential for optimal performance and safety on the road. One crucial component in enhancing this longevity is the belt system, which provides structural integrity and strength. This system plays a significant role in distributing forces and maintaining shape during operation, ensuring the outer layer can withstand various driving conditions.

Key Elements of the Belt Structure include a combination of materials that work together to resist wear and tear. These elements contribute to the overall robustness of the outer layer, allowing it to endure the rigors of everyday use. By utilizing advanced technology in manufacturing, the belt system effectively reduces the risk of damage from impacts and abrasions.

Maintenance Tips are vital to ensure the longevity of the belt system. Regular inspections and timely replacements can prevent potential failures that might compromise the vehicle’s performance. Understanding the wear patterns and knowing when to address issues can significantly enhance the lifespan of the outer covering, leading to improved safety and efficiency on the road.

Influence of Shoulder on Cornering Grip

The shoulder region of a wheel plays a crucial role in how effectively a vehicle can navigate corners. This area directly impacts the contact patch, which is vital for maintaining traction during turns. Understanding the dynamics of this section helps in optimizing performance and ensuring stability while cornering.

Several factors contribute to the effectiveness of the shoulder in providing grip:

- Shape and Design: The contour of the shoulder influences how weight is distributed during cornering, affecting the level of contact with the surface.

- Material Composition: The materials used in this region can enhance grip and durability, allowing for better performance under various conditions.

- Angle and Inclination: The angle at which the shoulder meets the surface can determine the extent of traction available, particularly during sharp turns.

- Wear Patterns: Understanding how the shoulder wears over time provides insights into performance and can indicate necessary adjustments to enhance grip.

In summary, the shoulder’s characteristics are integral to cornering performance. By examining these factors, manufacturers can create designs that improve handling and safety.

How Tyre Ply Affects Flexibility

The construction of a vehicle’s outer covering significantly influences its ability to bend and adapt to various surfaces. The arrangement and composition of the layers within the casing play a crucial role in determining how well it can absorb shocks and maintain contact with the ground. This aspect is vital for performance, safety, and overall driving experience.

Understanding the Structure

The arrangement of fibers and materials in the layers contributes to the overall behavior of the outer covering. A design that incorporates multiple layers can enhance resilience, allowing for better performance during dynamic maneuvers. Conversely, a simpler configuration may offer more flexibility but at the expense of durability.

Impact on Performance

Flexibility directly influences traction and handling. A more adaptable structure can better conform to uneven surfaces, enhancing grip and control. On the other hand, excessive flexibility may lead to instability, especially during high-speed turns. Therefore, striking a balance between rigidity and pliability is essential for optimal performance.