Understanding the Wagner Procoat Parts Diagram for Optimal Performance

In the realm of industrial machinery, a clear representation of components is crucial for efficient operation and maintenance. Such illustrations serve as invaluable tools, offering insights into the intricate relationships between various elements. By grasping these layouts, users can ensure optimal functionality and prolong the lifespan of their equipment.

When exploring the configuration of specific mechanisms, it’s essential to recognize the roles each section plays within the overall system. Knowledge of these arrangements not only aids in troubleshooting but also enhances the ability to make informed decisions regarding repairs and upgrades.

Furthermore, delving into detailed schematics enables technicians and operators to communicate effectively about issues and solutions. This understanding fosters a proactive approach to machinery care, ultimately leading to improved performance and reliability.

Understanding Wagner Procoat Parts

Familiarity with the various components of spray equipment is essential for optimal performance and maintenance. Each element plays a critical role in ensuring efficiency and longevity, making it important to grasp their functions and interconnections.

Key Components and Their Functions

The functionality of any spray system relies on specific elements, each designed for a particular task. Recognizing how these components work together can enhance both the user experience and the overall effectiveness of the equipment.

| Component | Function |

|---|---|

| Motor | Drives the pump to generate pressure. |

| Pump | Moves the material from the container to the nozzle. |

| Nozzle | Atomizes the fluid for an even spray pattern. |

| Hose | Connects the pump to the nozzle, facilitating fluid transport. |

| Container | Holds the material to be sprayed. |

Maintenance Tips

Regular upkeep of these components can prevent malfunctions and prolong the lifespan of the equipment. Ensure that all parts are cleaned after use, check for wear and tear, and replace any damaged items promptly to maintain optimal performance.

Overview of Procoat Technology

This section explores advanced coating methodologies that enhance surface application processes, providing efficiency and durability. Such innovations are essential for achieving superior results in various industries, significantly improving the user experience and performance outcomes.

Key Features

The technology encompasses several critical attributes that contribute to its effectiveness. These include precision application, versatility across materials, and ease of maintenance. Understanding these features allows users to maximize the benefits in practical settings.

Applications

These advanced coating techniques find use in multiple sectors, from automotive to consumer goods. Their adaptability ensures that they meet the specific demands of different environments and applications.

| Feature | Benefit |

|---|---|

| Precision | Minimizes waste and enhances finish quality |

| Versatility | Applicable to various surfaces and materials |

| Durability | Increases longevity of the coated items |

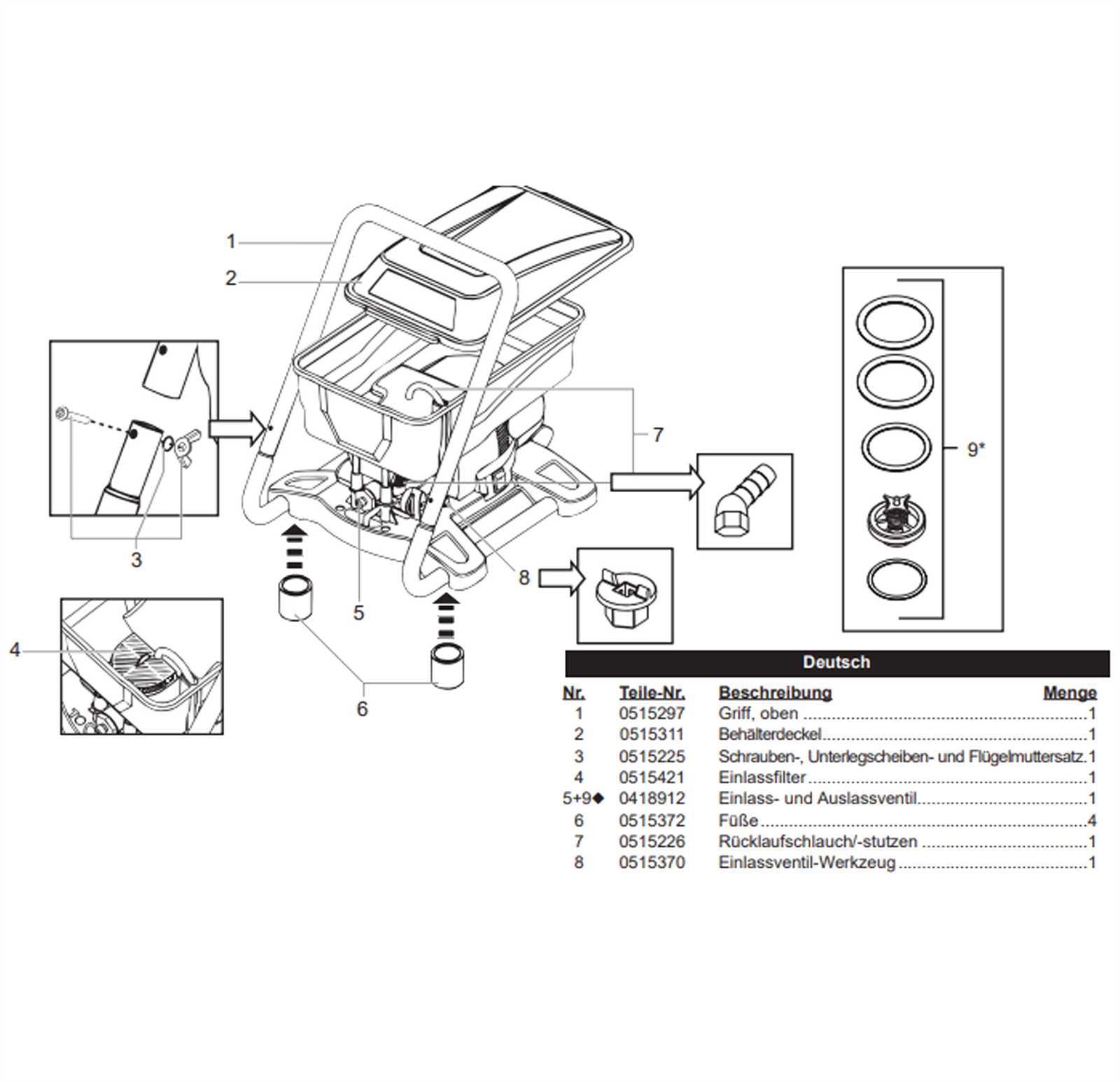

Key Components of Wagner Systems

Understanding the essential elements of coating machinery is crucial for optimal performance and efficiency. These systems are designed to ensure precision and reliability in various applications, making it important to recognize the main components that contribute to their functionality.

| Component | Description |

|---|---|

| Pump | The heart of the system, responsible for moving materials through the machinery. |

| Hose | Flexible tubing that transports the mixture from the pump to the application nozzle. |

| Nozzle | Directs and atomizes the coating material, ensuring an even application on the surface. |

| Filter | Prevents debris from clogging the system, ensuring smooth operation and high-quality results. |

| Control Unit | Regulates the operation of the entire system, allowing for adjustments in pressure and flow rate. |

Each of these components plays a vital role in achieving consistent and effective results, highlighting the importance of maintenance and understanding their functionality for successful coating processes.

Benefits of Procoat Equipment

Utilizing advanced spraying machinery can significantly enhance efficiency and quality in various applications. These tools offer a range of advantages that can elevate both professional and personal projects.

Enhanced Efficiency

- Faster application process, reducing overall project time.

- Consistent spray patterns ensure uniform coverage.

- Minimized waste of materials, leading to cost savings.

Improved Quality

- High precision in finishing, resulting in a polished look.

- Capability to handle diverse materials for versatile use.

- Durability of coatings, extending the lifespan of surfaces.

Common Issues with Procoat Parts

When dealing with spray equipment components, users often encounter various challenges that can hinder performance and efficiency. Understanding these common pitfalls is essential for maintaining optimal functionality and prolonging the lifespan of the equipment.

Frequent Problems

Several issues can arise, including clogging, leaks, and inconsistent flow rates. These complications not only disrupt the painting process but can also lead to costly repairs if not addressed promptly.

Preventative Measures

Implementing regular maintenance and monitoring can significantly reduce the occurrence of these issues. Users should stay vigilant and adopt best practices to ensure seamless operation.

| Issue | Symptoms | Solutions |

|---|---|---|

| Clogging | Poor spray pattern | Regular cleaning and filtration |

| Leaks | Visible fluid escaping | Check seals and connections |

| Inconsistent Flow | Uneven coating | Adjust pressure settings |

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment involves a proactive approach to care and upkeep. Regular maintenance not only extends the lifespan of your machinery but also enhances performance, preventing costly repairs and downtime. Here are some essential tips to help you keep your tools in top condition.

Regular Inspections

Conduct routine checks to identify any signs of wear and tear. Look for unusual noises, vibrations, or leaks that could indicate underlying issues. Early detection is key to preventing more significant problems in the future.

Proper Cleaning

Keeping your equipment clean is crucial. After each use, remove dust and debris to prevent buildup that can hinder performance. Use appropriate cleaning agents and methods, ensuring that all components are free from contaminants that could affect functionality.

Lubrication is another vital aspect. Regularly apply suitable oils or greases to moving parts, ensuring smooth operation. Follow the manufacturer’s recommendations regarding the frequency and type of lubricants to use.

Finally, always adhere to the manufacturer’s guidelines for maintenance schedules. By committing to a consistent upkeep routine, you will enhance the longevity of your machinery and ensure reliable performance for years to come.

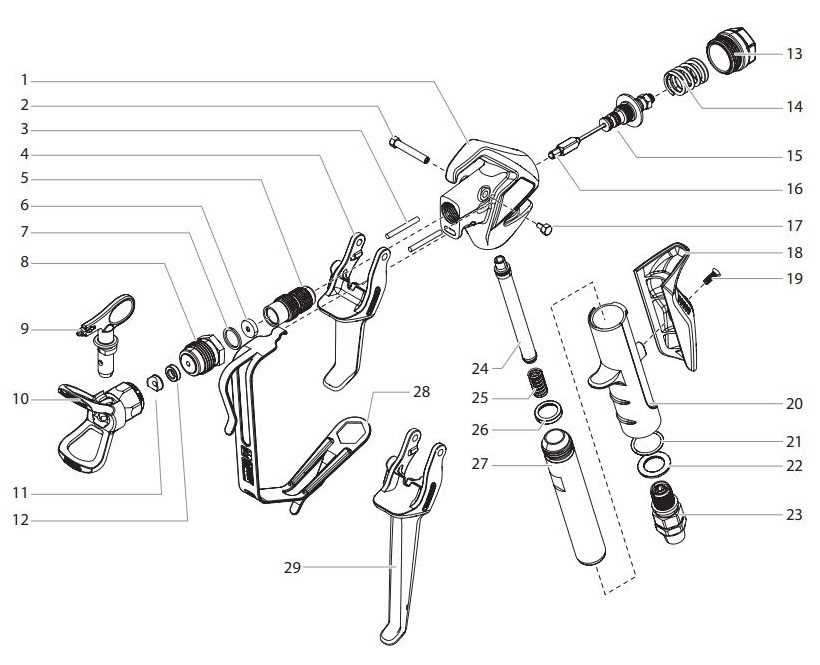

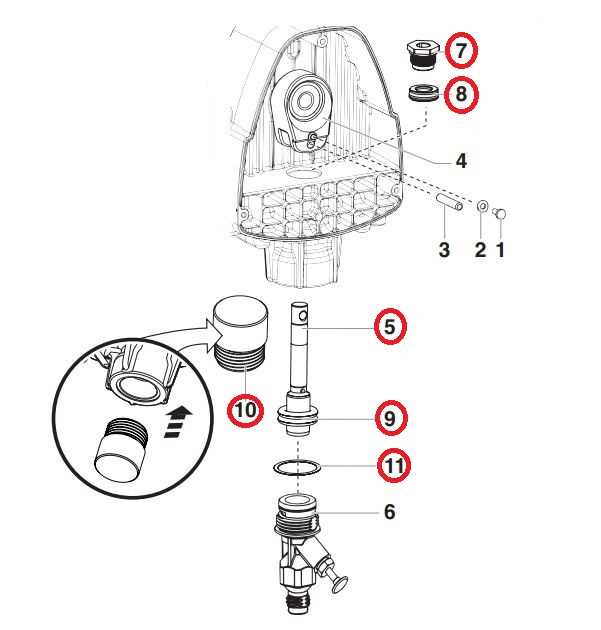

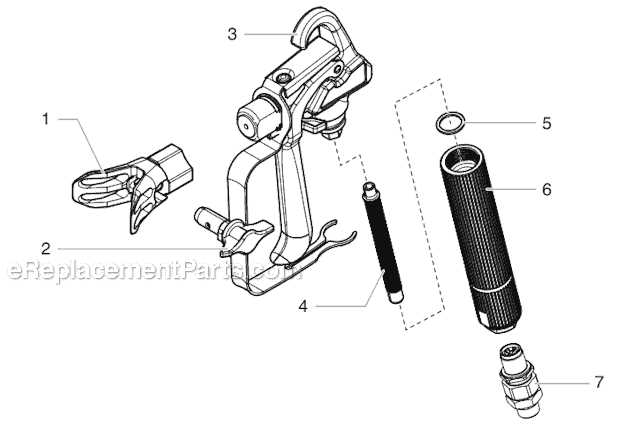

How to Identify Parts Diagrams

Recognizing the intricate layouts of components is essential for effective maintenance and repair. Understanding these visual representations allows users to pinpoint specific elements, facilitating a smoother workflow. Each illustration typically provides a systematic overview, breaking down complex machinery into manageable segments.

1. Familiarize Yourself with Symbols: Different graphics use unique symbols to represent various items. Learning these can streamline your identification process.

2. Refer to the Legend: Most visuals include a legend or key. This section is crucial for understanding what each symbol or number signifies.

3. Analyze the Arrangement: Pay attention to how items are organized. Their layout can provide insights into their function and relationship with surrounding components.

4. Use a Reference Guide: Having a reference manual on hand can enhance comprehension, allowing for easier cross-referencing with the visual.

5. Practice Makes Perfect: Regular exposure to these illustrations builds familiarity, making it easier to identify components quickly in future tasks.

By honing these skills, individuals can ultimately improve their ability to navigate complex illustrations and enhance their overall understanding of machinery.

Finding Replacement Parts Efficiently

Locating suitable components for your equipment can be a daunting task. It requires a strategic approach to ensure that the replacement items fit perfectly and function optimally. By employing specific methods, you can streamline the process and minimize downtime.

Researching Options

Begin by gathering as much information as possible about the original items. Check manuals, online resources, and forums where enthusiasts share insights. Knowledge of specifications and compatible models will greatly assist in your search.

Utilizing Reliable Sources

Consider purchasing from authorized dealers or reputable online platforms that specialize in machinery supplies. Always verify the authenticity of the components to avoid subpar substitutes.

| Source Type | Benefits |

|---|---|

| Authorized Dealers | Quality assurance, expert advice |

| Online Marketplaces | Wide selection, customer reviews |

| Local Retailers | Immediate availability, personal assistance |

Exploring Aftermarket Options

When seeking enhancements or replacements for automotive components, many enthusiasts turn to alternative suppliers. These aftermarket choices often provide a range of benefits, including cost-effectiveness and improved performance. Understanding the variety of available options can empower users to make informed decisions that align with their specific needs.

Benefits of Alternative Suppliers

Opting for non-original equipment can lead to substantial savings while also offering superior quality in some cases. Many companies focus on innovation and customer feedback, resulting in products that might outperform their factory counterparts. Additionally, a broader selection allows for customization to better suit individual preferences.

Considerations When Choosing

While exploring these options, it’s crucial to assess quality, compatibility, and warranty terms. Researching customer reviews and seeking recommendations can provide valuable insights. Ultimately, ensuring that the chosen components meet performance expectations and durability standards will lead to a satisfactory experience.

Procoat System Assembly Guidelines

This section offers essential instructions for the effective assembly of a specialized application system. Understanding the intricacies of the components and their interactions will lead to optimal performance and durability. Careful adherence to these guidelines will ensure a smooth installation process and long-lasting results.

Preparation and Tools

Before starting the assembly, gather all necessary tools and materials. A clean workspace enhances efficiency. Make sure to have the following tools on hand: wrenches, screwdrivers, and measuring instruments. Proper preparation is crucial to achieving a seamless assembly.

Step-by-Step Assembly

Begin with the foundational elements, ensuring all parts fit snugly together. Follow the sequence outlined in the accompanying documentation for optimal results. Double-check connections and tighten fasteners to prevent any future leaks or failures. Attention to detail during this stage will yield the best performance.

Comparing Procoat to Competitors

This section explores the distinctions between a leading coating system and its rivals in the market. Understanding these differences can guide consumers in making informed decisions based on their specific needs and preferences.

Key aspects to consider include:

- Performance: Assess how well each option performs in various conditions.

- Durability: Evaluate the longevity of the finishes provided by different brands.

- Ease of Use: Compare user-friendliness and application methods.

- Cost: Consider the price point and value offered by each manufacturer.

Ultimately, choosing the right system involves weighing these factors to determine which best suits individual requirements.

Expert Recommendations for Users

When engaging with specialized equipment, understanding its components and their interrelations is crucial for optimal performance. Users are encouraged to familiarize themselves with the layout and functionality of various elements to ensure effective usage and maintenance.

Prioritize Regular Maintenance

Routine checks on your machinery can prevent minor issues from escalating into major problems. Establish a schedule for inspecting key elements and replace any worn parts promptly. This practice not only extends the lifespan of your equipment but also enhances its efficiency.

Utilize Professional Guidance

Consulting with industry experts can provide valuable insights into the best practices for your specific model. Don’t hesitate to reach out for support or training to improve your operational skills. Leveraging professional knowledge ensures you are utilizing your equipment to its fullest potential.