Comprehensive Guide to White 508 Plow Parts Diagram

The efficiency and functionality of agricultural machinery heavily rely on the intricate network of its various elements. Recognizing how these pieces interconnect is essential for optimal performance and longevity. This section aims to illuminate the essential constituents that contribute to the overall operation of such machinery.

By exploring the specific arrangements and functions of these components, operators can ensure seamless maintenance and repair. Familiarity with each section allows for informed decision-making and enhanced productivity on the field.

Whether you are a seasoned user or a newcomer, grasping the layout and purpose of these critical elements will empower you to tackle challenges effectively. Delving into this subject reveals not just the mechanics but also the ultimate potential of your equipment.

Understanding White 508 Plow Functionality

This section explores the mechanics and operation of a specific type of snow removal implement, highlighting its essential components and overall effectiveness in various conditions.

Key features include:

- Robust construction for durability.

- Adjustable angles for optimal performance.

- Efficient material management for improved workflow.

The following elements contribute significantly to its functionality:

- Design: A streamlined structure that enhances maneuverability.

- Material: High-grade substances that withstand harsh conditions.

- Compatibility: Seamless integration with a variety of machinery.

Understanding these aspects allows users to maximize the implement’s potential and efficiency in clearing snow and debris.

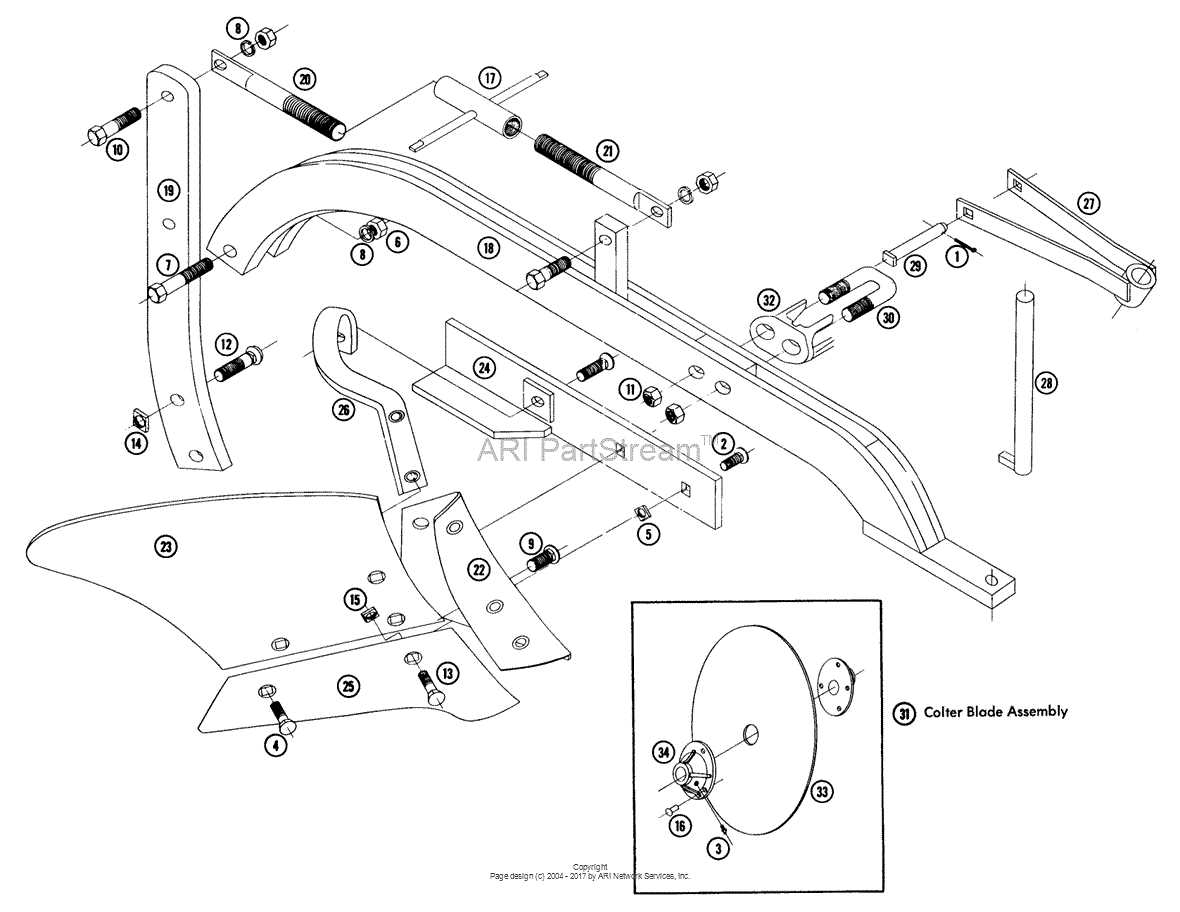

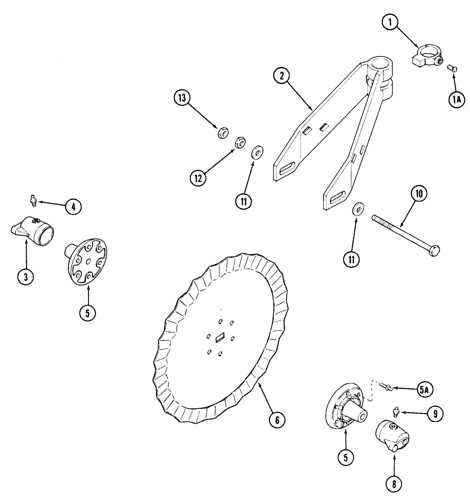

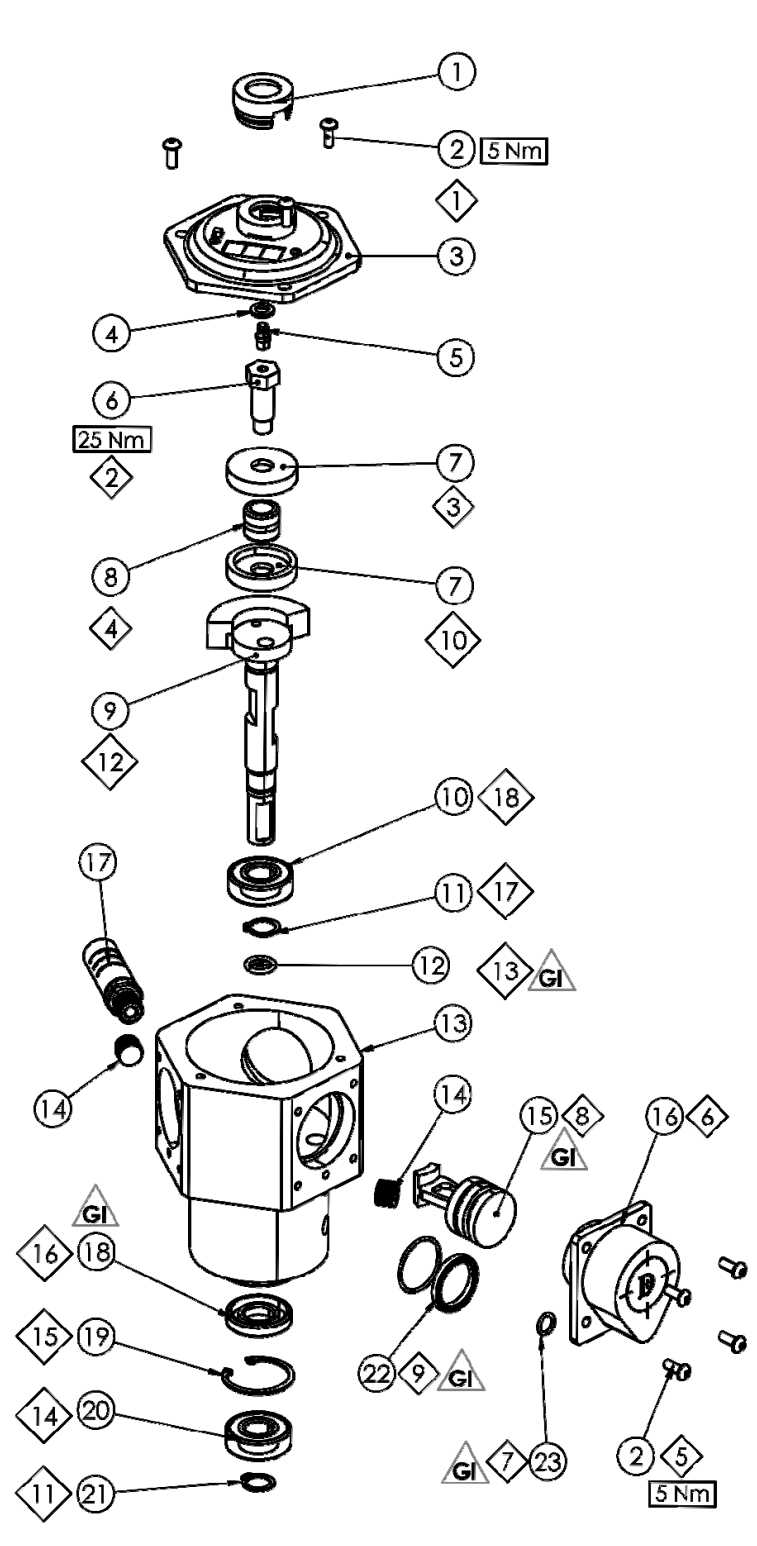

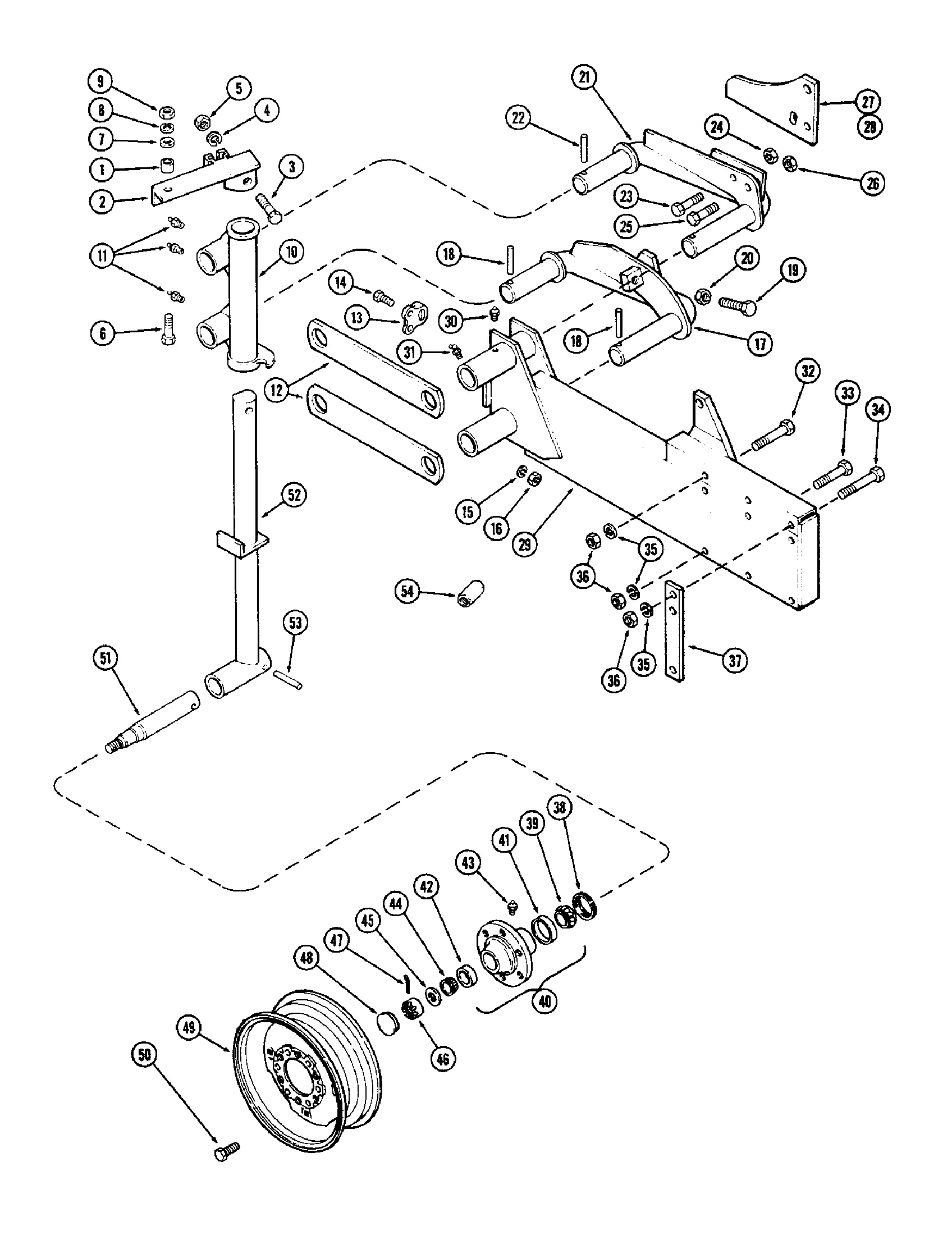

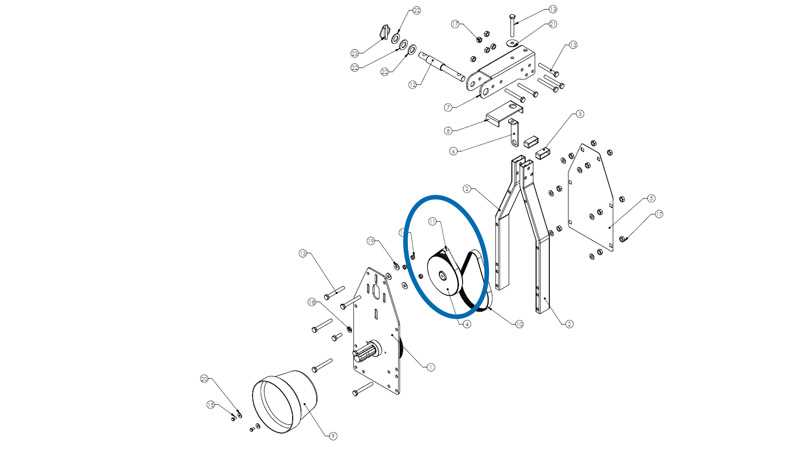

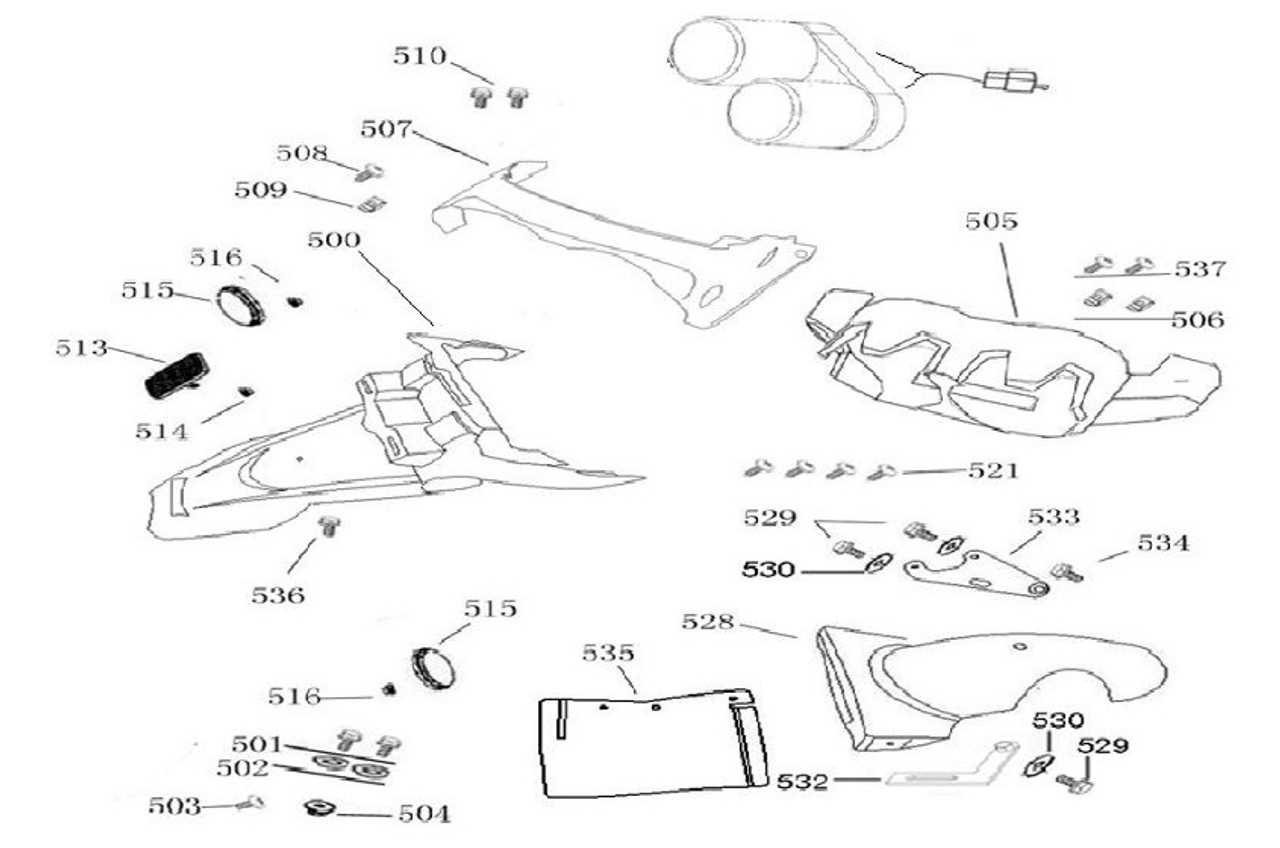

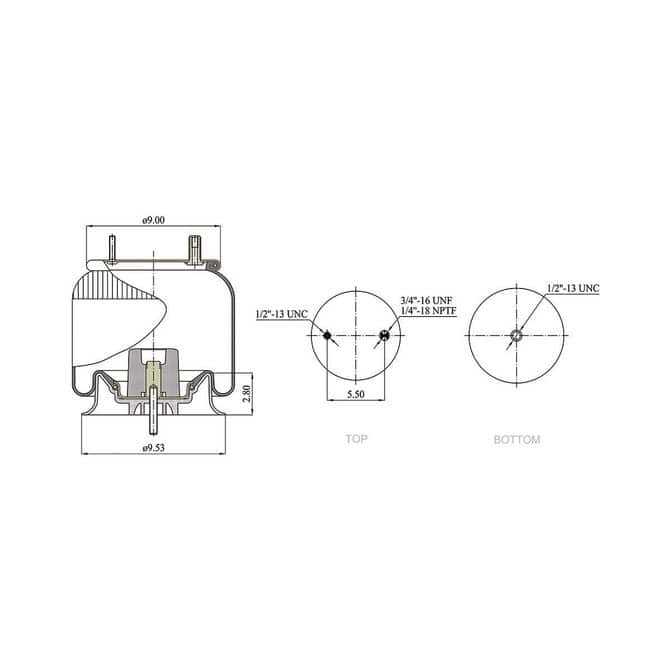

Key Components of the Plow System

This section explores the essential elements that contribute to the effective operation of snow clearing equipment. Understanding these components is crucial for maintenance and optimal performance during harsh winter conditions.

1. Blade Assembly

The blade assembly is the primary functional unit responsible for cutting through snow and ice. Its design ensures efficient snow removal, while the material used often enhances durability and resistance to wear.

2. Mounting Mechanism

The mounting mechanism plays a vital role in securing the blade to the vehicle. A robust and adjustable setup allows for proper alignment and stability, ensuring the implement can withstand various driving conditions while performing its task.

Importance of Accurate Diagrams

Precise visual representations play a crucial role in various industries, ensuring efficiency and clarity in processes. These illustrations serve as essential tools for understanding complex systems, facilitating effective communication among professionals, and supporting troubleshooting efforts. Without accurate visuals, the likelihood of errors and misinterpretations significantly increases, potentially leading to costly mistakes.

Enhancing Understanding

Detailed visuals help individuals grasp intricate concepts and components. They break down complicated machinery into understandable sections, making it easier to identify and analyze each part. This clarity promotes better decision-making and fosters confidence among users.

- Facilitates training for new personnel

- Assists in identifying specific components quickly

- Supports maintenance and repair efforts

Streamlining Processes

When professionals have access to accurate representations, it streamlines workflow and enhances productivity. Clear visuals minimize the time spent searching for information, allowing teams to focus on their tasks effectively.

- Reduces downtime during maintenance

- Improves collaboration across departments

- Ensures compliance with safety standards

In conclusion, the significance of well-crafted visual aids cannot be overstated. They are integral to successful operations and help maintain the integrity of complex systems.

Common Issues with White 508 Parts

When operating heavy machinery, various components may encounter challenges that affect performance and efficiency. Understanding these common complications is essential for timely maintenance and repairs, ultimately enhancing the longevity of the equipment.

| Issue | Description |

|---|---|

| Wear and Tear | Components can degrade over time, leading to decreased functionality. |

| Corrosion | Exposure to moisture and harsh environments can result in rust and damage. |

| Improper Alignment | Misalignment can cause uneven wear and affect operational efficiency. |

| Hydraulic Issues | Leaks or pressure drops can hinder performance and lead to system failures. |

| Electrical Failures | Faulty wiring or connections can interrupt functionality and cause breakdowns. |

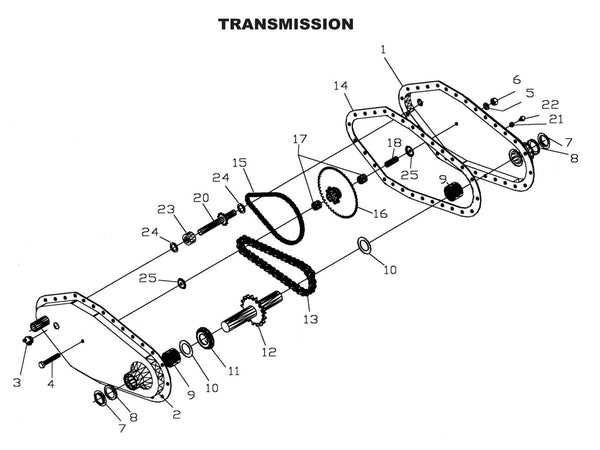

Identifying Replacement Components

When it comes to maintaining equipment, understanding the necessary elements for replacement is crucial. Identifying the right components ensures optimal functionality and longevity of machinery.

To accurately determine which elements need to be replaced, consider the following steps:

- Consult the manufacturer’s manual for specific details.

- Inspect the equipment for wear and tear signs.

- Cross-reference with a comprehensive catalog for compatibility.

Key components to focus on may include:

- Blades

- Bearings

- Mounting brackets

- Drive chains

- Hydraulic hoses

By delving into these areas, one can ensure that the ultimate choices made for replacements are both accurate and efficient, thus enhancing overall performance.

Maintenance Tips for Longevity

Ensuring the durability and performance of your agricultural machinery requires a strategic approach to upkeep. Regular maintenance not only enhances efficiency but also extends the lifespan of your equipment, reducing the likelihood of unexpected breakdowns and costly repairs.

To achieve optimal performance, follow these essential maintenance practices:

| Tip | Description |

|---|---|

| Regular Inspection | Conduct routine checks to identify wear and tear early. Pay close attention to moving components and connections. |

| Lubrication | Apply appropriate lubricants to critical parts to minimize friction and prevent rust, ensuring smooth operation. |

| Cleaning | Keep equipment clean to prevent dirt buildup, which can affect performance and lead to premature wear. |

| Storage | Store machinery in a dry, sheltered area to protect it from environmental factors that can cause damage. |

| Follow Manufacturer Guidelines | Adhere to the recommended maintenance schedule provided by the manufacturer to ensure all necessary tasks are completed timely. |

By implementing these maintenance strategies, you can significantly enhance the reliability and longevity of your machinery, ensuring it remains a valuable asset for years to come.

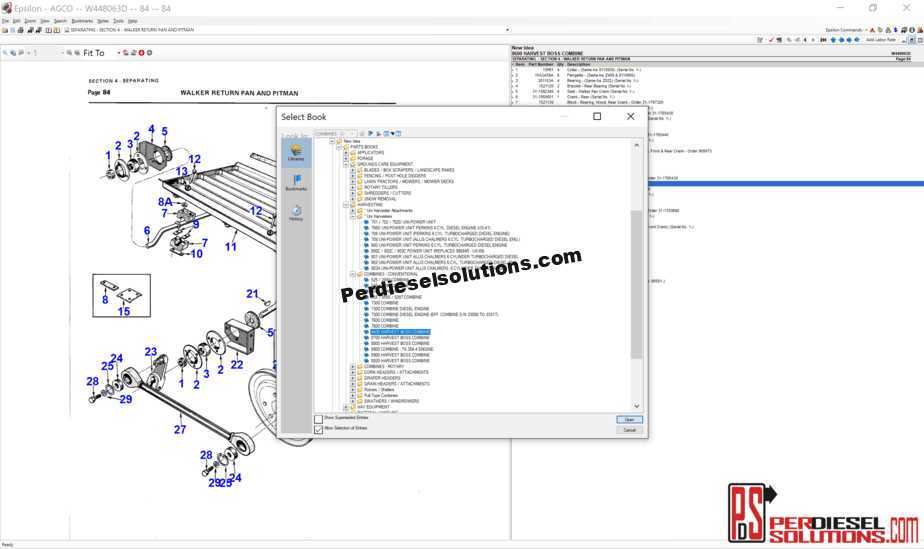

Where to Find Parts Diagrams

Locating visual guides for equipment components can significantly enhance maintenance and repair efforts. Various resources are available to help users access these valuable illustrations effectively.

- Manufacturer Websites: Official sites often provide comprehensive resources, including illustrations and technical documents.

- Online Retailers: E-commerce platforms specializing in machinery parts frequently offer detailed visuals to assist buyers.

- Forums and Community Groups: Engaging with online communities can yield shared resources and insights from fellow enthusiasts.

- Service Manuals: Purchasing or downloading service manuals can provide in-depth diagrams and descriptions.

Exploring these avenues can ultimately streamline the process of identifying and sourcing necessary components for any machinery.

How to Read Diagrams Effectively

Understanding visual representations is crucial for grasping complex information quickly. By mastering the art of interpreting these illustrations, you can enhance your problem-solving skills and streamline maintenance tasks.

Here are some tips to help you decode visual guides:

- Familiarize Yourself with Symbols: Each representation often uses specific symbols. Learn their meanings to avoid confusion.

- Identify Sections: Break down the illustration into sections. This approach makes it easier to focus on individual components.

- Follow the Flow: Understand the directional cues within the guide. This can reveal how parts interact with one another.

With practice, you’ll become proficient at interpreting these resources, leading to improved efficiency in your tasks.

Comparison with Other Plow Models

When evaluating various agricultural implements designed for soil management, it’s essential to understand how different models stack up against each other. Each version brings unique features and specifications that cater to specific farming needs, influencing efficiency, durability, and overall performance. This analysis provides insight into the distinctions and similarities among popular alternatives.

| Model | Weight | Working Width | Depth Adjustment | Price Range |

|---|---|---|---|---|

| Model A | 1,200 lbs | 10 ft | Manual | $3,500 – $4,000 |

| Model B | 1,400 lbs | 12 ft | Hydraulic | $4,200 – $4,700 |

| Model C | 1,100 lbs | 9 ft | Manual | $3,000 – $3,500 |

| Model D | 1,500 lbs | 11 ft | Hydraulic | $4,800 – $5,300 |

This table highlights key specifications, allowing potential buyers to make informed choices based on their specific requirements. Factors such as weight, working width, and adjustment mechanisms can significantly affect usability and effectiveness in the field. Understanding these aspects helps in selecting the right implement for optimal agricultural results.

Benefits of Upgrading Components

Enhancing machinery with modern components can lead to significant improvements in performance, efficiency, and longevity. Upgrading ensures that equipment operates at its best, minimizing downtime and maximizing productivity.

Improved Efficiency

Newer components often feature advanced technology, which can streamline operations and reduce energy consumption. This results in cost savings and a lower environmental impact.

Enhanced Durability

Modern parts are typically designed with superior materials, providing greater resistance to wear and tear. This translates to less frequent replacements and reduced maintenance costs over time.

| Benefit | Description |

|---|---|

| Increased Performance | Upgraded components can enhance overall functionality and responsiveness. |

| Cost Savings | Efficiency improvements lead to lower operating costs and maintenance expenses. |

| Extended Lifespan | Modern materials ensure greater durability and longevity of machinery. |

DIY Repairs vs. Professional Help

When it comes to maintaining equipment, the decision between handling repairs yourself or seeking expert assistance can be crucial. Each approach has its own set of advantages and drawbacks that can significantly impact both time and cost.

| Aspect | DIY Repairs | Professional Help |

|---|---|---|

| Cost | Generally lower; only materials needed | Higher; includes labor fees |

| Time | Can take longer, especially without experience | Often quicker due to expertise |

| Skill Level | Requires some knowledge and tools | Handled by trained professionals |

| Quality of Work | Varies; may depend on personal skill | Typically high, with guarantees |

Resources for Plow Enthusiasts

For those passionate about snow removal equipment, finding reliable information and tools is essential. A wealth of resources exists to support hobbyists and professionals alike in maintaining and enhancing their machinery.

Online Communities

- Forums: Engage with fellow enthusiasts to share tips and experiences.

- Social Media Groups: Join platforms where discussions on equipment and modifications thrive.

Repair Manuals and Guides

- Manufacturer Websites: Access official documentation for detailed specifications.

- DIY Blogs: Explore step-by-step tutorials created by other users.