Yth2454 Parts Diagram and Components Overview

When maintaining a lawn tractor, it is essential to have a clear understanding of how different mechanisms work together. A thorough look at its key elements helps in ensuring that everything operates smoothly and efficiently. Knowing how various sections are interconnected can also simplify the process of identifying any issues that may arise over time.

Comprehensive knowledge of the machinery’s framework allows for better decision-making when it comes to repairs or replacements. Recognizing the functions of individual components ensures the overall performance remains optimal, avoiding any unnecessary downtimes during critical periods of use.

Moreover, having a detailed overview of the internal systems and modules provides valuable insight

Overview of Yth2454 Components

This section provides a clear understanding of the essential elements that make up the machine. Each individual component plays a vital role in ensuring smooth functionality and operational efficiency. By examining these elements, users can gain insight into how the equipment operates and maintain it effectively.

Main Structural Elements

- Frame and Chassis: The core structure that supports all mechanical and functional parts, ensuring durability and stability during operation.

- Transmission System: Responsible for power delivery and motion control, this system enables smooth performance under various conditions.

- Steering Mechanism: Ensures precise control and maneuverability, allowing for easy handling and navigation in different environments.

Functional Systems

- Engine Unit: The power source that drives the machine, delivering the necessary force to complete tasks efficiently.

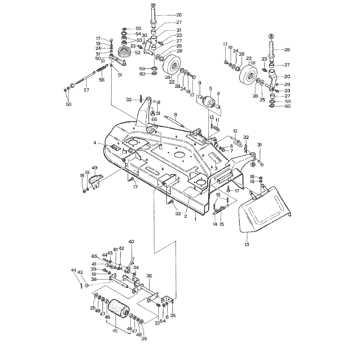

Detailed Engine Parts Breakdown

In this section, we explore the various components that make up the heart of the machine, focusing on the intricacies of its internal mechanisms. Understanding these elements is crucial for maintaining performance and addressing any issues that may arise during operation.

Main Internal Components

The core of the engine consists of several key elements designed to work in harmony. These include the main unit responsible for combustion, a system that ensures smooth power transmission, and the necessary regulators to control speed and efficiency.

Key Functional Elements

Below is a summary of the main functional elements involved in ensuring the engine operates

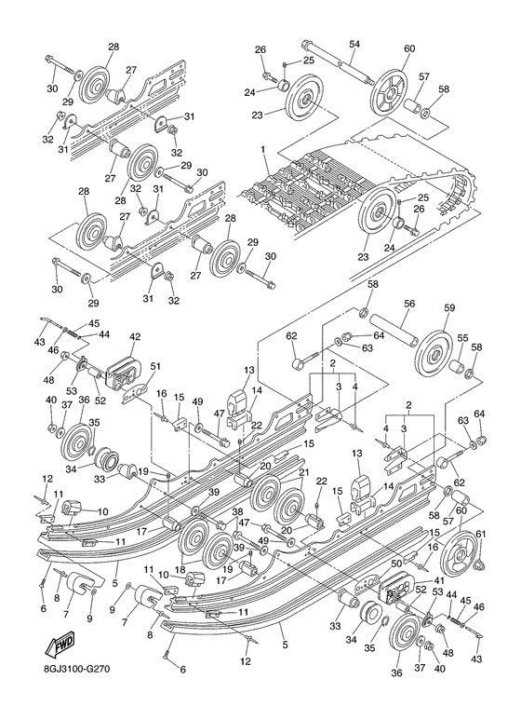

Transmission System Components

The transmission system plays a crucial role in transferring power from the engine to the wheels, ensuring the efficient operation of any machine. By converting the engine’s energy into movement, the transmission system allows the vehicle to adjust its speed and power based on the demands of the terrain or task at hand.

Main Elements

The primary components of a transmission system include various mechanical and hydraulic elements that work together to ensure smooth transitions between gears. These elements include a gearbox, which adjusts speed ratios, and a clutch, responsible for engaging or disengaging power flow. Other vital components are shafts and bearings, which ensure the proper alignment and rotation of internal mechanisms.

Supporting Mechanisms

In addition to the main

Cutting Deck Assembly Diagram

The structure responsible for handling the cutting mechanism is a crucial component of the entire setup. It ensures efficient performance and smooth functioning, allowing for optimal operation when maintaining green spaces. Below, you will find a breakdown of the key elements involved in the assembly of this structure.

Main Components

The assembly consists of several interconnected elements, each playing an essential role in ensuring the stability and effectiveness of the cutting system. These include various support elements, blade holders, and adjustment features that contribute to the overall alignment and performance of the cutting mechanism.

Component Breakdown

Component Name Function Blade Responsible for cutting grass efficiently. Spindle Holds the blade and allows for rotational movement. Electrical System and Wiring

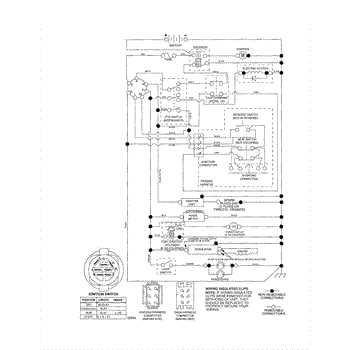

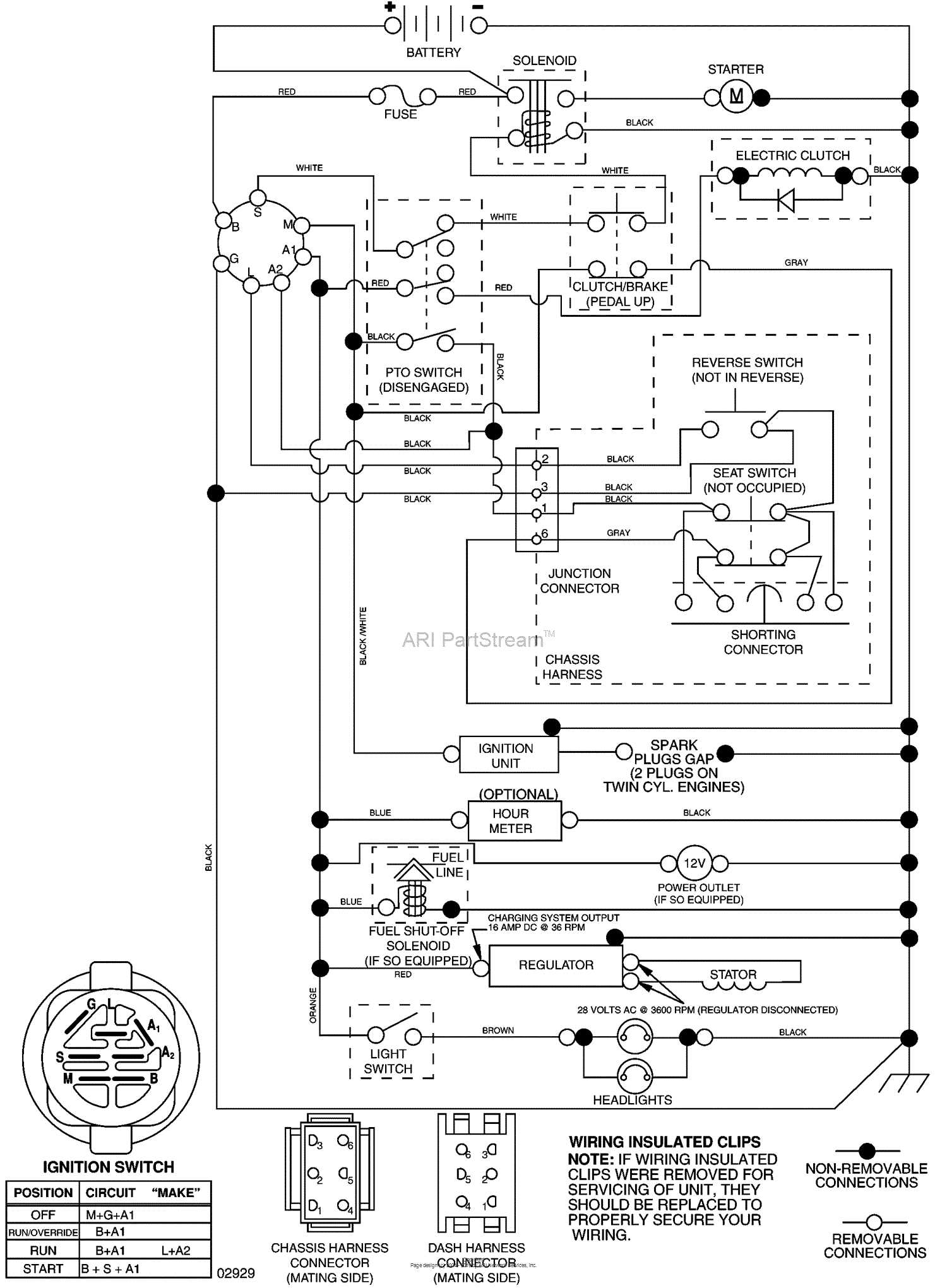

The electrical setup is an essential component that ensures proper functionality and safe operation. It connects key elements and supports the efficient performance of the entire mechanism. Proper maintenance and understanding of the system help in preventing issues that could disrupt the operation.

Wiring layout is designed to interconnect various elements, ensuring smooth communication between them. Each wire serves a unique purpose, with some dedicated to power delivery and others to control signals. Proper isolation of wires prevents interference and ensures a longer lifespan for the components.

Regular checks of the connections are necessary to identify any wear or potential risks. By keeping an eye on the condition of the system, users can avoid unexpected malfunctions and maintain reliability.

Steering Mechanism Parts Layout

The steering mechanism is a crucial component of any vehicle, facilitating the control and direction of motion. Understanding the arrangement of its components is essential for effective maintenance and troubleshooting. Each element plays a significant role in ensuring smooth operation and responsiveness.

In this section, we will explore the various elements involved in the steering system, highlighting their functions and interrelations. Below is a detailed breakdown of the key components:

- Steering Wheel: The primary interface for the driver, allowing for directional control.

- Steering Column: Connects the steering wheel to the mechanism, providing support and housing for controls.

- Universal Joints: Facilitate the transfer of motion at varying angles, enhancing flexibility.

- Rack and Pinion: A critical component that translates the rotational motion of the wheel into linear movement.

- Power Steering Pump: Assists in reducing the effort needed to turn the wheel, enhancing maneuverability.

- Linkages: Connect various parts of the steering system, transmitting motion efficiently.

- Steering Knuckles: Allow the wheels to pivot, enabling turns and directional changes.

Each of these elements contributes to the overall functionality of the steering mechanism, ensuring safe and precise navigation on the road.

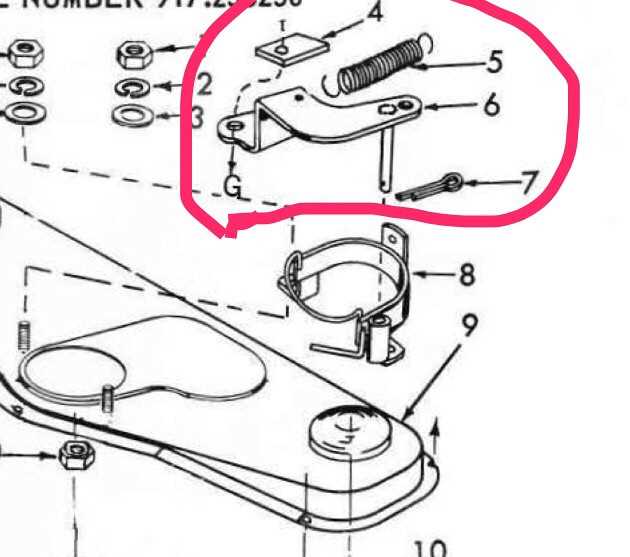

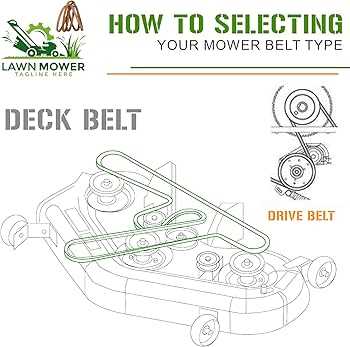

Blade and Belt Arrangement

The configuration of cutting elements and the associated drive mechanisms is crucial for the efficient operation of lawn maintenance equipment. Proper alignment and installation of these components ensure optimal performance and longevity of the machine.

In this section, we will explore the various aspects of blade and belt placement:

- Blade Positioning: The correct positioning of the cutting blades is vital for achieving a uniform cut. Blades must be installed at the appropriate angle to facilitate effective grass trimming.

- Belt Routing: The drive belt’s routing should be carefully planned to ensure smooth power transmission from the engine to the cutting mechanism. Incorrect routing can lead to wear and inefficiency.

- Adjustment Mechanisms: Many machines feature adjustment systems that allow users to modify blade height and tension. Proper adjustments help maintain the desired cutting quality and extend component life.

Regular maintenance of both the cutting elements and the drive systems is essential for ensuring that the equipment operates efficiently. Checking for wear and tear on belts and blades can prevent costly repairs and enhance overall performance.

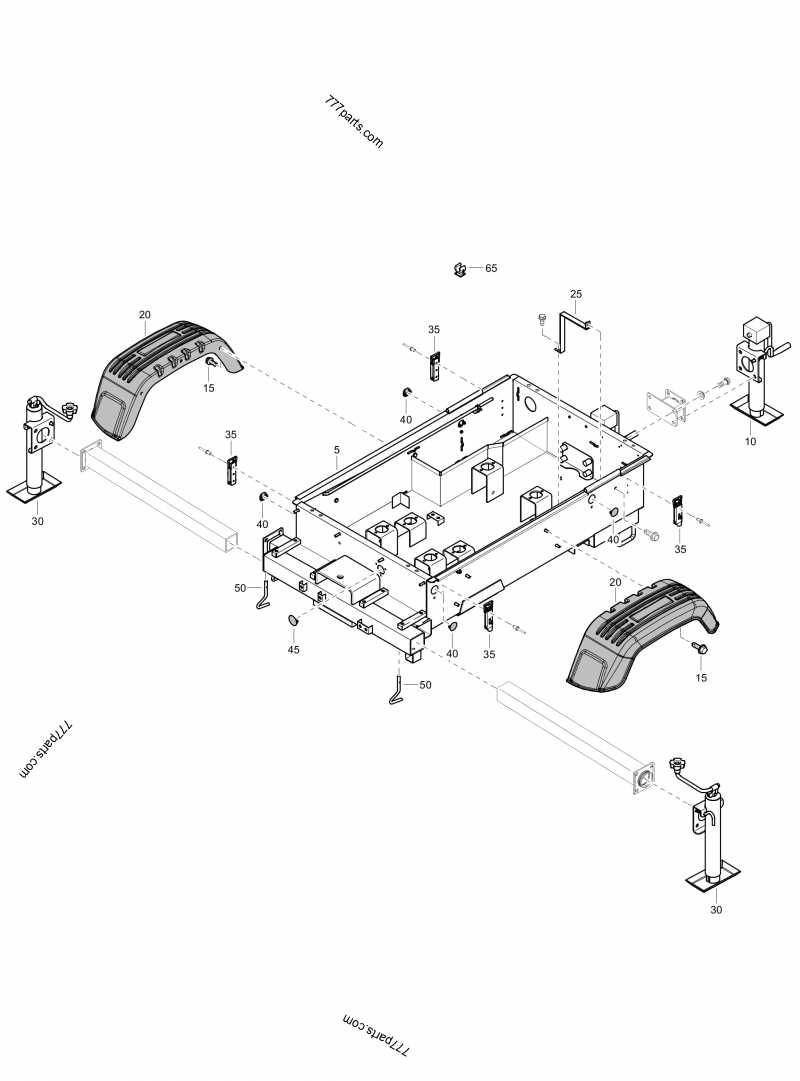

Chassis and Frame Components

The structural foundation of any vehicle is crucial for ensuring stability and support. This section explores the essential elements that contribute to the overall integrity of the framework. Understanding these components is vital for maintaining performance and safety.

Typically, the framework is designed to bear the weight of the machine while providing a secure attachment point for various mechanisms. Each component plays a significant role in enhancing durability and handling.

Component Description Function Frame The main structure that supports the vehicle’s weight and components. Provides rigidity and strength. Suspension System of springs and dampers that connects the frame to the wheels. Ensures stability and comfort during operation. Subframe A secondary structure attached to the main frame for additional support. Distributes load and enhances rigidity. Crossmember Horizontal structural element that reinforces the frame. Increases strength and resists twisting. Mounts Devices used to secure various components to the frame. Isolate vibrations and support components. Fuel System Structure

The fuel system plays a crucial role in ensuring efficient engine performance by managing the delivery of fuel. This intricate assembly comprises various components that work harmoniously to store, filter, and transport fuel to the engine, enabling optimal combustion.

Key Components

Essential elements of the fuel system include the fuel tank, which serves as the storage reservoir, and the fuel pump, responsible for transferring fuel to the engine. Additionally, filters are implemented to remove impurities, ensuring that only clean fuel reaches the combustion chamber. Each part is vital for maintaining the overall functionality and longevity of the engine.

Operational Mechanism

When the engine is activated, the fuel pump initiates the flow of fuel from the tank through the filters. This process ensures that the engine receives a steady supply of fuel at the correct pressure. The proper functioning of this system is essential for maintaining performance and preventing potential issues related to fuel quality.

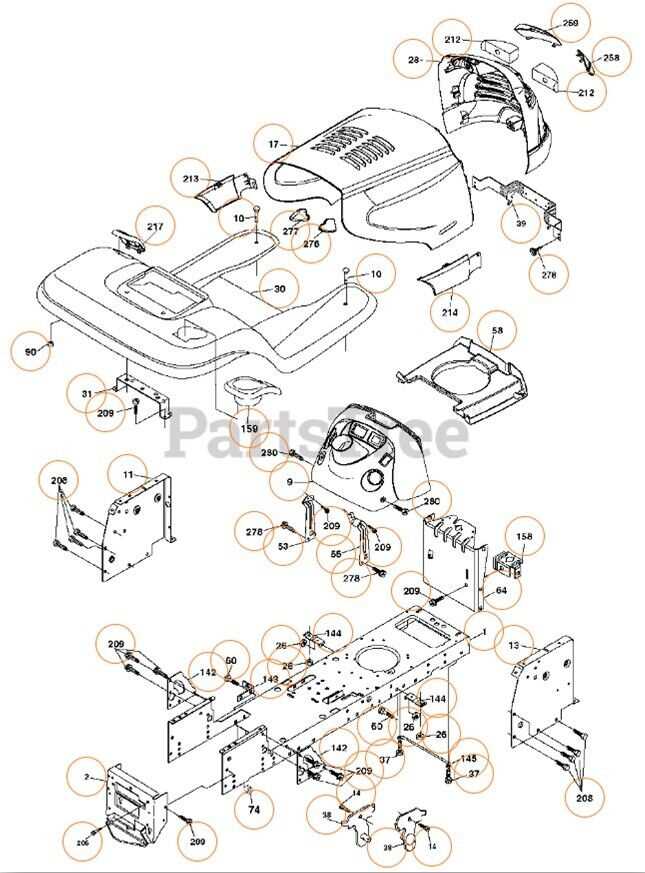

Seat and Control Panel Layout

The arrangement of seating and controls is crucial for the functionality and comfort of the operator. A well-designed setup ensures that all essential elements are easily accessible, promoting efficiency during operation. This section will explore the key features and layout considerations that enhance user experience.

Key Features of the Seating Arrangement

- Ergonomic design for enhanced comfort

- Adjustable seat positioning to accommodate different user heights

- Supportive backrest for improved posture

- Sturdy construction for durability

Control Panel Configuration

- Intuitive layout for easy navigation

- Clearly labeled controls for quick identification

- Strategic placement to minimize movement while operating

- Accessibility for maintenance and adjustments

Exhaust System Components

The exhaust system plays a crucial role in the overall performance and efficiency of an engine. It is designed to guide harmful gases away from the engine and reduce noise, ensuring a smoother operation. Understanding the various elements of this system can help in maintaining and optimizing vehicle performance.

Key elements of the exhaust assembly include the manifold, which collects gases from the engine’s cylinders, and the catalytic converter, responsible for reducing harmful emissions. The muffler further diminishes noise levels, while the exhaust pipes direct the gases safely out of the vehicle.

Additionally, components like the oxygen sensors monitor emissions, providing feedback to the engine control unit for optimal fuel mixture adjustments. Each part works in harmony to ensure that the exhaust system functions efficiently, contributing to both performance and environmental compliance.

Maintenance Parts and Replacement Guide

This section provides essential information for keeping your equipment in optimal condition. Regular upkeep and timely substitutions are crucial for ensuring longevity and performance. By understanding the various components that may require attention, users can effectively manage their maintenance routines.

It is vital to periodically inspect the machine for wear and tear, as well as to identify any items that might need replacement. Creating a schedule for these evaluations can help prevent unexpected breakdowns and improve overall efficiency.

When selecting suitable replacements, consider using original components to ensure compatibility and reliability. Always consult the user manual for specifications and recommendations regarding the best practices for maintenance. Proper handling during replacement is equally important to avoid damage to the equipment.

Implementing these guidelines will not only enhance the performance of your machinery but also extend its operational life, resulting in better productivity and lower long-term costs.