Understanding the Parts Diagram for Zd-dubb-2ldc-3ppx

In the realm of advanced machinery, comprehending the intricate arrangements and components is crucial for effective operation and maintenance. This section aims to explore the essential elements that contribute to the overall functionality of these systems, shedding light on their design and organization.

By breaking down the various components into manageable sections, users can better appreciate how each part interacts within the larger framework. Clarity in understanding these relationships not only enhances operational efficiency but also facilitates troubleshooting when issues arise.

As we delve into the specifics, we will uncover the ultimate connections and functions that define the effectiveness of this machinery, providing valuable insights for both novices and seasoned professionals alike.

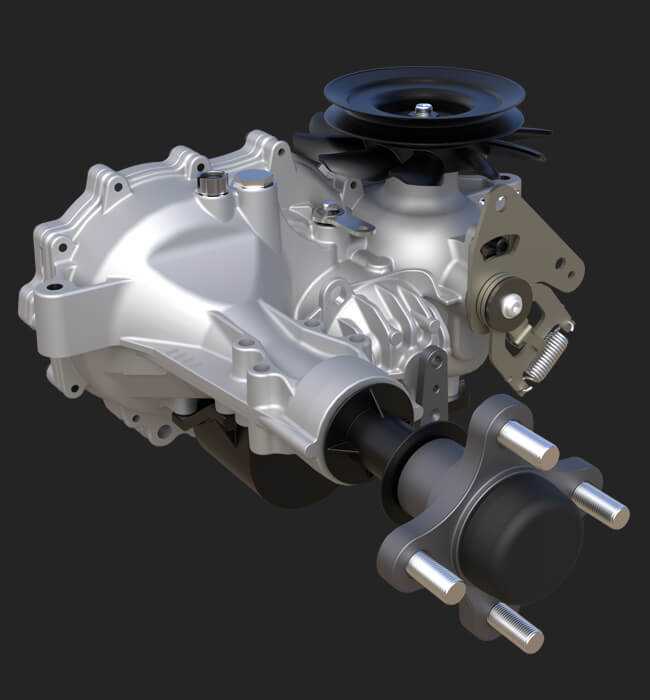

Understanding the Zd-dubb-2ldc-3ppx Model

This section aims to provide a comprehensive overview of a complex system, highlighting its components and their interrelations. By exploring the intricacies of this model, one can appreciate its functionality and the underlying principles that govern its operation.

Key Features and Functionality

The model is characterized by its innovative design, which enhances efficiency and performance. Each element plays a crucial role, contributing to the overall effectiveness of the system. Understanding these features can significantly impact how one utilizes the model in practical applications.

Applications and Implications

In various fields, the utilization of this framework has shown remarkable results. Exploring its implications allows users to unlock new possibilities and optimize their approaches, ultimately leading to superior outcomes in their respective domains.

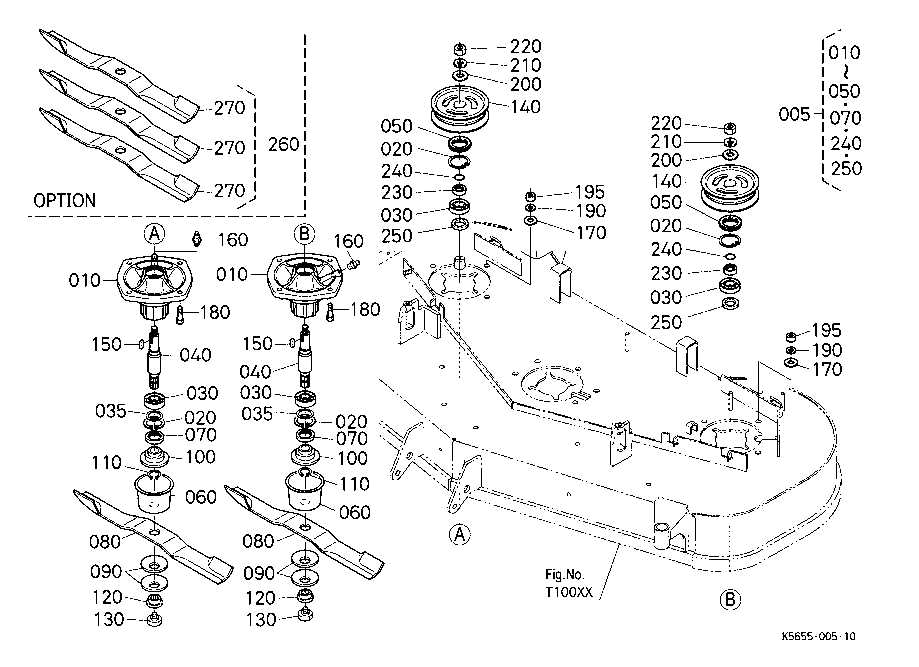

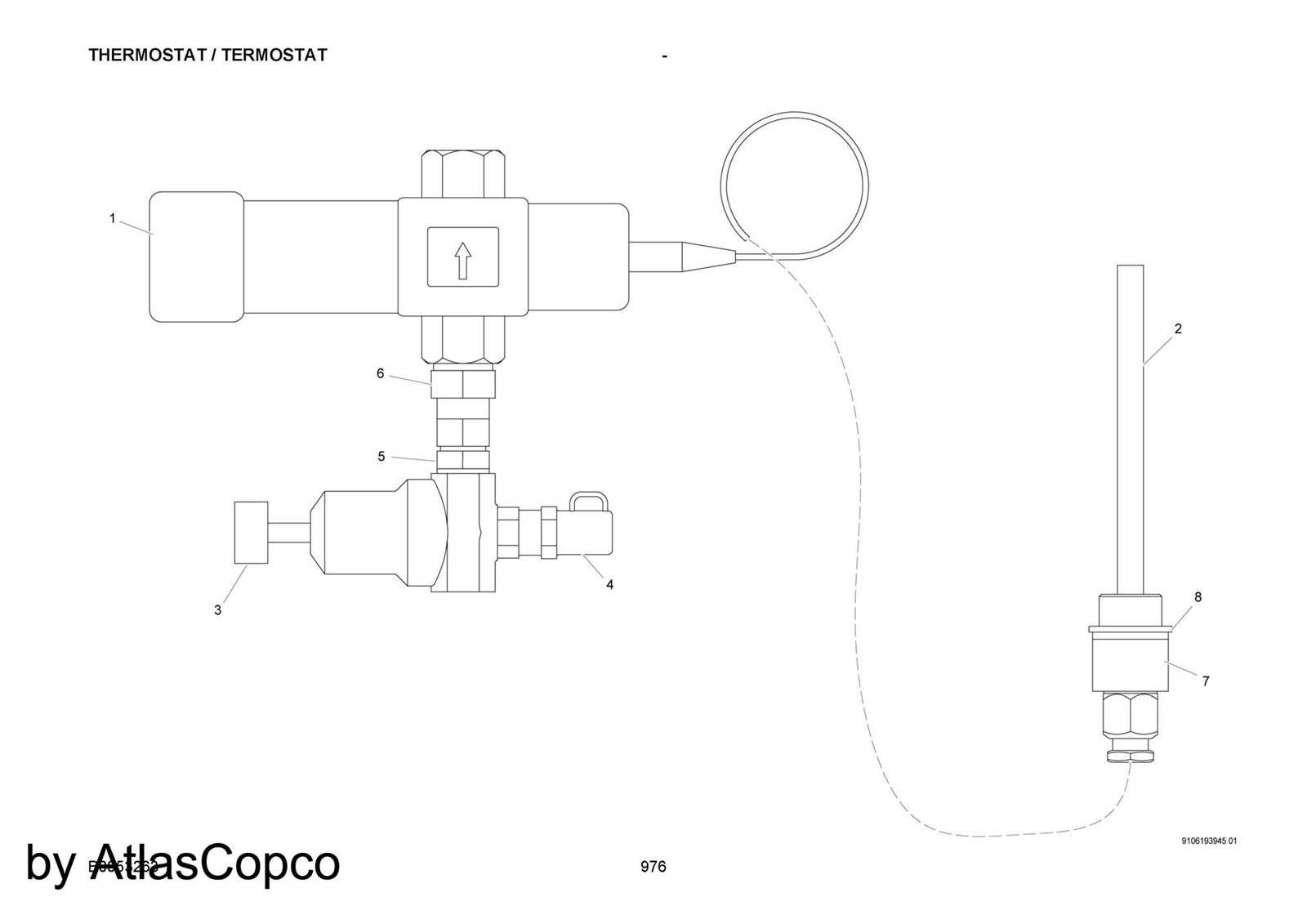

Key Features of the Parts Diagram

This section explores essential attributes of the visual representation that assists in understanding component relationships and functionalities. It serves as a vital resource for both novice and experienced users, facilitating efficient assembly and maintenance.

- Clarity: Provides a clear visual layout of components, making it easy to identify each element.

- Organization: Arranged logically, helping users navigate through complex systems.

- Labeling: Each part is clearly labeled, ensuring accurate identification and reducing errors.

- Interconnectivity: Illustrates how components interact, enhancing understanding of overall functionality.

- Reference: Serves as a handy guide for troubleshooting and repairs, promoting efficiency.

Ultimately, these features contribute to a comprehensive understanding, allowing users to delve deeper into the mechanics involved.

Components Breakdown for Optimal Function

Understanding the individual elements that contribute to a system’s performance is crucial for achieving efficiency and reliability. Each component plays a significant role in the overall functionality, and a thorough examination of these elements can lead to improved operation and longevity. By analyzing how these parts interact, one can identify potential enhancements or necessary adjustments.

| Component | Description | Functionality |

|---|---|---|

| Element A | Main drive unit | Provides the core motion needed for operation. |

| Element B | Support structure | Stabilizes the system and absorbs shocks. |

| Element C | Control module | Manages operations and ensures optimal performance. |

| Element D | Power source | Supplies the necessary energy for operation. |

| Element E | Feedback sensor | Monitors performance and provides data for adjustments. |

By examining these individual units, one can achieve a comprehensive understanding of the system’s dynamics, enabling targeted improvements that enhance overall efficiency and reliability.

Importance of Accurate Diagram Interpretation

Understanding complex visuals is crucial in any technical field, as it directly impacts the efficiency and effectiveness of tasks. The ability to accurately decipher these illustrations ensures that individuals can carry out their responsibilities with confidence and precision. Misinterpretation can lead to errors, delays, and unnecessary complications, making clarity essential in any documentation.

Clarity in Communication: Effective visuals serve as a universal language, bridging gaps between various expertise levels. When individuals can correctly interpret these representations, they can communicate ideas more clearly and collaborate more effectively. This fosters a better working environment and minimizes misunderstandings.

Enhanced Problem-Solving: Accurate understanding of schematics allows for quicker identification of issues and solutions. When professionals grasp the intricacies of a visual representation, they can troubleshoot with greater efficiency, leading to timely resolutions and improved productivity.

Training and Skill Development: For newcomers in a field, mastering the interpretation of technical visuals is a fundamental skill. Comprehensive understanding not only builds confidence but also equips individuals with the tools necessary for career advancement. As they gain experience, their ability to analyze and apply this knowledge will grow, contributing to their overall success.

Quality Assurance: In any industry, the stakes are high when it comes to maintaining standards. Accurate comprehension of illustrations directly correlates with quality control, ensuring that all components function harmoniously. This not only preserves the integrity of the work but also enhances safety and reliability.

In summary, the significance of precise interpretation cannot be overstated. It is foundational to successful outcomes, fostering communication, enhancing problem-solving capabilities, and promoting ongoing professional development.

Common Issues in Assembly and Repair

When undertaking the task of assembling or repairing complex equipment, various challenges may arise. These hurdles can stem from miscommunication, inadequate tools, or a lack of familiarity with specific components. Understanding common problems can significantly streamline the process and enhance efficiency.

Frequent Challenges

- Misalignment: Components may not fit together properly, leading to operational issues.

- Incorrect Fastening: Using the wrong type or size of fasteners can compromise structural integrity.

- Overlooking Instructions: Neglecting to follow provided guidelines can result in mistakes that are costly to rectify.

- Inadequate Tools: Insufficient or inappropriate tools can hinder progress and affect the quality of the assembly.

Solutions and Best Practices

- Ensure all components are inspected for damage before starting.

- Double-check alignment before securing parts.

- Refer to manuals or guides consistently throughout the process.

- Invest in quality tools that are suited for the task at hand.

By being aware of these potential issues and implementing effective solutions, the assembly and repair process can be executed with greater precision and success.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. By following a few essential guidelines, you can enhance the lifespan and performance of your machinery, ultimately reducing costs and preventing unexpected breakdowns.

Regular Inspections

Conduct frequent checks to identify wear and tear. Look for signs of damage or corrosion that could lead to bigger issues if not addressed promptly.

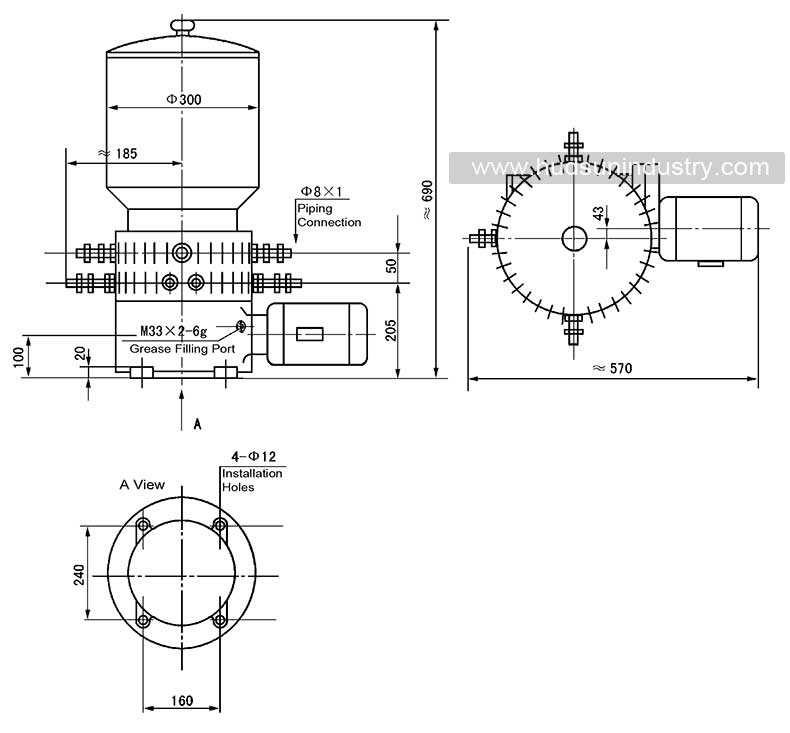

Proper Lubrication

Keep all moving components well-lubricated to minimize friction and heat generation. This practice not only improves functionality but also extends the life of critical elements.

Tools Required for Efficient Work

To achieve optimal performance in any task, it is essential to have the right instruments at hand. The selection of appropriate tools not only enhances productivity but also ensures precision and quality in the results obtained.

Firstly, consider basic hand tools such as wrenches and screwdrivers, which are fundamental for a variety of tasks. Additionally, power tools like drills and saws can significantly speed up processes and reduce manual effort.

Moreover, ensuring that safety equipment is readily available cannot be overstated, as it protects users from potential hazards. Investing in high-quality, well-maintained tools will ultimately lead to a more efficient workflow.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components and their functionalities. Understanding these elements is crucial for effective maintenance and operation.

What should I consider when selecting components?

It’s essential to evaluate compatibility, quality, and performance specifications to ensure optimal functionality.

How can I identify a malfunctioning element?

Signs of wear, unusual noises, or performance issues often indicate that a component may need attention or replacement.

Where can I find reliable information about specific components?

Consulting manufacturer manuals, reputable online resources, and community forums can provide valuable insights.

Is it necessary to use original components?

While original parts are often recommended for best performance, quality alternatives can also be effective if they meet required standards.

What is the typical lifespan of components?

Lifespans vary based on usage and maintenance, but most elements have recommended service intervals for replacement or inspection.

Comparison with Similar Models

This section explores the distinctions and similarities among various devices in the same category, focusing on their features, functionalities, and user experiences. By examining these comparisons, we can gain insights into which options may best suit specific needs and preferences.

Feature Overview

| Model | Key Features | Price |

|---|---|---|

| Model A | High durability, energy-efficient, user-friendly interface | $150 |

| Model B | Compact design, advanced technology, affordable | $120 |

| Model C | Versatile applications, robust performance, premium materials | $180 |

User Feedback

Customer reviews reveal that while some users prefer the advanced technology of Model B, others appreciate the durability of Model A. Ultimately, user preferences vary based on individual requirements and usage scenarios.

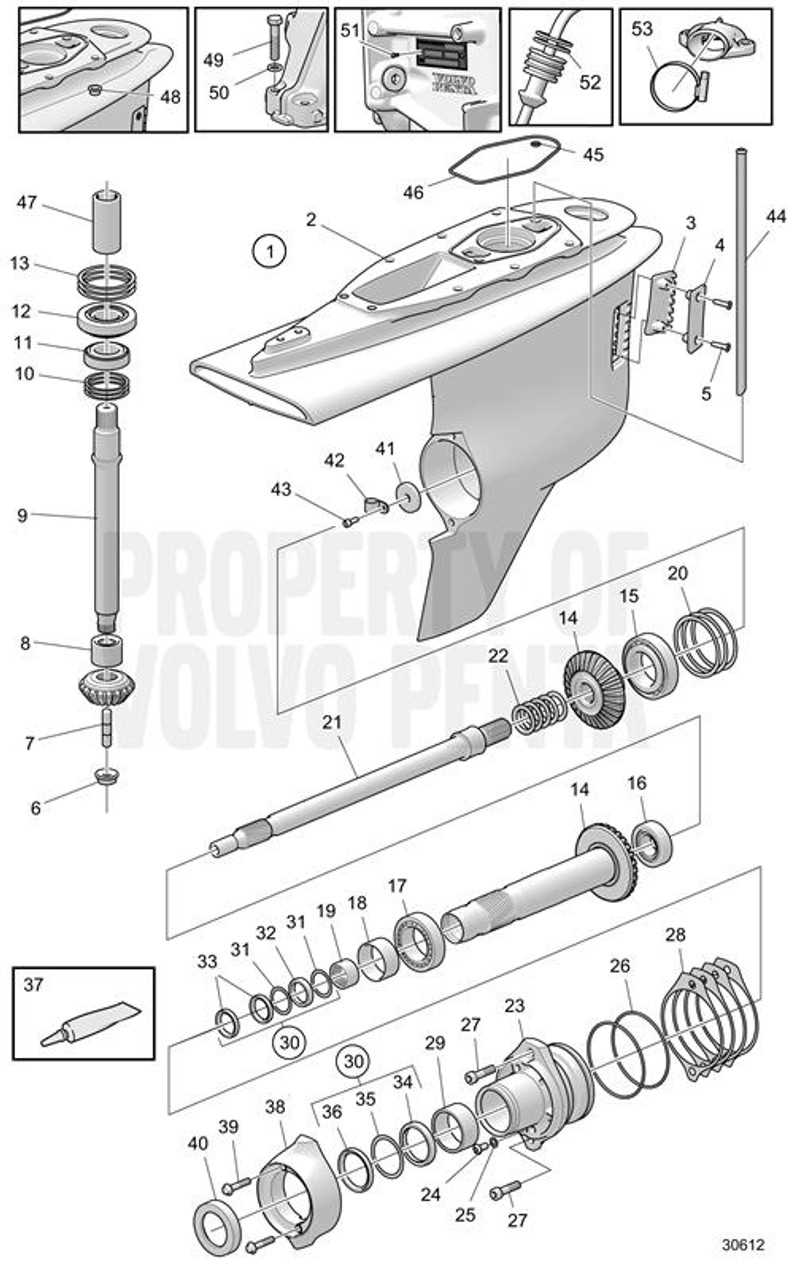

Step-by-Step Assembly Instructions

This section provides a comprehensive guide to successfully bringing together various components of your project. Following these systematic instructions will ensure a smooth assembly process and optimal performance.

| Step | Description |

|---|---|

| 1 | Gather all necessary elements and tools required for assembly. |

| 2 | Identify each component and familiarize yourself with their functions. |

| 3 | Begin with the base structure, ensuring all connections are secure. |

| 4 | Attach secondary units following the designated order for stability. |

| 5 | Perform a thorough check of all joints and fasteners for proper alignment. |

| 6 | Test the assembly to confirm functionality and make any necessary adjustments. |

Where to Source Replacement Parts

Finding reliable sources for components is essential for maintaining the functionality of your equipment. Here are several avenues to consider when searching for suitable items:

- Online Retailers: Websites dedicated to selling various goods often carry a wide selection of replacements.

- Manufacturer Websites: Directly visiting the producer’s site can provide specific information and original options.

- Local Hardware Stores: Brick-and-mortar shops may stock essential items, allowing for immediate purchase.

- Specialized Suppliers: Companies focusing on specific types of equipment frequently have hard-to-find components.

- Second-Hand Markets: Platforms offering used goods can yield unique finds at reduced prices.

By exploring these channels, you can ensure access to the necessary replacements effectively.

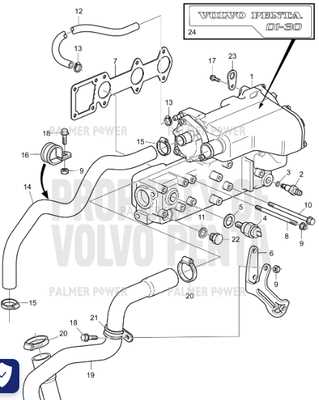

Understanding Electrical Components in Diagrams

Electrical schematics serve as a vital tool for visualizing and comprehending various elements within a circuit. These illustrations encapsulate the relationships and functions of components, providing insights into their operational mechanics. Gaining a deeper understanding of these representations is essential for effective troubleshooting and design.

To navigate these illustrations effectively, one must familiarize themselves with the common elements encountered. Below are key components often represented:

- Resistors: Devices that limit current flow, often depicted as zigzag lines.

- Capacitors: Components that store electrical energy, usually shown as parallel lines or two plates.

- Inductors: Coils of wire that store energy in a magnetic field, typically illustrated as loops or spirals.

- Diodes: Components that allow current to flow in one direction, represented by a triangle pointing to a line.

- Transistors: Semiconductors used for switching or amplification, displayed as a combination of lines and arrows.

Understanding the symbols and their meanings enables one to decode the functionality of the entire system. Each component plays a crucial role, and recognizing their interactions can simplify complex processes.

Additionally, one should consider the following tips when interpreting these visual representations:

- Familiarize yourself with standard symbols: Many resources are available to learn common representations.

- Pay attention to connections: Lines between components indicate how they interact.

- Analyze the flow of current: Understanding the direction can provide insights into the circuit’s purpose.

- Refer to documentation: Often, additional explanations accompany illustrations for clarity.

In summary, mastering the understanding of electrical components in visual layouts is crucial for anyone engaged in electronics. This knowledge not only enhances comprehension but also empowers individuals to innovate and resolve issues effectively.

Expert Recommendations for Users

To optimize your experience with complex systems, it’s crucial to follow guidelines that enhance functionality and durability. Implementing expert advice can prevent issues and ensure smooth operation.

Understanding the System

- Familiarize yourself with the components and their roles.

- Regularly consult the user manual for updates and maintenance tips.

- Identify common pitfalls to avoid in your usage.

Maintenance and Care

- Schedule routine inspections to catch potential problems early.

- Utilize appropriate cleaning methods to preserve component integrity.

- Keep a log of any changes or repairs for future reference.