Parts Diagram for 2006 Polaris Ranger 700 XP

Understanding the intricate layout of a utility vehicle’s components is essential for both maintenance and performance enhancement. This guide delves into the essential elements that make up these powerful machines, offering insights into their construction and functionality. By familiarizing oneself with the various assemblies and mechanisms, operators can ensure that their vehicles operate at peak efficiency.

Clarity and precision in identifying each segment can greatly enhance the troubleshooting process. Whether it’s routine upkeep or addressing specific issues, knowing where each part resides and how it interconnects is invaluable. This knowledge not only aids in timely repairs but also empowers owners to undertake modifications and upgrades with confidence.

Moreover, exploring the detailed schematic representations of these vehicles allows for a deeper appreciation of engineering ingenuity. The design intricacies reflect the combination of advanced technology and practical application, making it crucial for enthusiasts and technicians alike to engage with this information thoroughly. An informed approach to understanding vehicle architecture is the first step towards optimizing performance and ensuring longevity.

Understanding the Polaris Ranger 700 XP

This section aims to provide a comprehensive overview of a well-regarded utility vehicle, highlighting its features, functionality, and maintenance considerations. With a strong reputation in the off-road community, this model has been engineered to tackle a variety of tasks while ensuring a reliable and enjoyable experience for users.

Key attributes of this robust utility vehicle include:

- Performance: Equipped with a powerful engine that delivers impressive torque and acceleration, making it suitable for both work and recreation.

- Durability: Constructed with high-quality materials, designed to withstand rugged conditions and heavy use.

- Versatility: Capable of handling a range of attachments and accessories, allowing users to customize it for different applications.

Understanding the essential components of this vehicle can enhance the ownership experience. Here are the critical systems to be familiar with:

- Engine System: This includes the powertrain, fuel system, and cooling components, all of which work in harmony to ensure optimal performance.

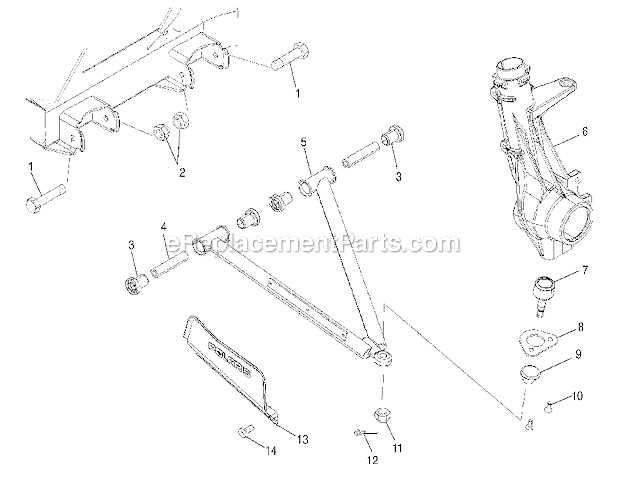

- Suspension System: Essential for maintaining stability and comfort, this system absorbs shocks from uneven terrain.

- Braking System: A reliable braking mechanism is crucial for safety, providing responsive stopping power under various conditions.

Regular maintenance is vital for the longevity and functionality of this vehicle. Consider the following tips:

- Perform routine oil changes to keep the engine running smoothly.

- Inspect the tires regularly for wear and proper inflation.

- Check the braking system frequently to ensure reliable performance.

By familiarizing yourself with these aspects, you can maximize the utility and enjoyment of this impressive off-road machine.

Key Features of the 2006 Model

This model stands out in its category due to a combination of durability, versatility, and advanced engineering. Designed for both work and recreational use, it offers a seamless balance of power and efficiency. Users can expect remarkable performance in various terrains, making it a reliable choice for outdoor enthusiasts and professionals alike.

| Feature | Description |

|---|---|

| Engine Performance | Equipped with a robust engine that delivers impressive torque and horsepower, ensuring optimal performance in demanding conditions. |

| Transmission System | Features an advanced transmission system that allows for smooth shifting, providing better handling and control during operation. |

| Suspension | The sophisticated suspension system enhances stability and comfort, enabling a smoother ride over rough terrains. |

| Cargo Capacity | Designed with ample cargo space, allowing for the transport of heavy loads and equipment with ease. |

| Safety Features | Incorporates essential safety elements such as roll bars and seat belts, ensuring user protection during use. |

The overall design reflects a commitment to quality and performance, making this model a preferred choice for various applications. With its innovative features, it addresses the needs of users seeking reliability and efficiency in a powerful package.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of machinery. They offer a detailed view of how various elements interact within a system, making it easier for users to identify necessary replacements or repairs. This clarity not only aids in efficient maintenance but also enhances the overall performance and longevity of the equipment.

Facilitating Maintenance

One of the primary benefits of visual representations is the assistance they provide during maintenance tasks. By showcasing the layout of different components, users can easily locate specific elements that require attention. This efficiency minimizes downtime and ensures that machinery remains in optimal working condition.

Aiding in Troubleshooting

Visual aids are invaluable for diagnosing issues within complex systems. When a malfunction occurs, having a clear overview of the arrangement of elements allows for quicker identification of the root cause. This leads to faster resolutions, reducing the time and resources spent on repairs.

| Benefit | Description |

|---|---|

| Efficiency | Speeds up the maintenance process by clearly showing where parts are located. |

| Clarity | Provides a straightforward view of component relationships and functions. |

| Cost-Effectiveness | Reduces the likelihood of unnecessary repairs and replacements. |

| Training Tool | Serves as an educational resource for new technicians to understand machinery better. |

Common Issues with the Ranger 700 XP

Owners of utility vehicles often encounter a variety of challenges that can affect performance and reliability. Understanding these common problems is essential for maintaining optimal functionality and ensuring a smooth riding experience. Addressing these issues promptly can prevent further complications and enhance the longevity of the machine.

Mechanical Problems

One of the primary concerns for users involves mechanical components that may wear out or fail over time. Regular inspection and maintenance are crucial in mitigating these risks. Key areas to monitor include the transmission, suspension system, and engine components. Failure in these systems can lead to significant performance degradation.

Electrical Failures

Another frequent issue arises from electrical systems, which can become problematic due to corrosion or faulty connections. Battery performance can diminish, resulting in starting difficulties. Additionally, wiring harnesses may suffer from wear and tear, leading to intermittent electrical failures. Regular checks can help identify these issues early on.

| Issue | Description | Recommended Action |

|---|---|---|

| Transmission Slippage | Loss of power during acceleration or difficulty shifting gears. | Inspect fluid levels and replace filters regularly. |

| Overheating | Excessive engine heat leading to performance loss or shutdown. | Check coolant levels and inspect the radiator for blockages. |

| Battery Drain | Inability to start the engine due to insufficient power. | Test the battery regularly and replace if necessary. |

| Steering Issues | Difficulty in steering or unusual noises while turning. | Examine steering components for wear and lubricate as needed. |

Finding OEM Replacement Parts

When it comes to maintaining the performance and reliability of your vehicle, sourcing high-quality components is essential. Original Equipment Manufacturer (OEM) replacements ensure that you receive parts designed specifically for your model, promoting optimal functionality and longevity. These components adhere to the same standards as those initially installed, providing peace of mind for any enthusiast or owner.

Why Choose OEM Components?

Opting for OEM components offers several advantages. Firstly, these items are manufactured to precise specifications, ensuring compatibility and seamless integration. Additionally, OEM replacements often come with warranties, which can safeguard your investment. Furthermore, using original parts can help maintain the resale value of your vehicle, as potential buyers often look for models that have been properly serviced with genuine components.

Where to Locate OEM Components

Finding authentic replacements can be straightforward if you know where to look. Authorized dealers are a reliable source, providing access to a full range of components tailored for your specific vehicle. Online platforms dedicated to automotive parts also feature extensive catalogs, often with user reviews that can assist in making informed choices. Additionally, engaging with local mechanics who specialize in your vehicle’s brand can provide insights and recommendations for trusted suppliers.

Aftermarket Parts vs. OEM Options

When it comes to maintaining and enhancing the performance of your vehicle, the choice between aftermarket components and original equipment manufacturer (OEM) alternatives is crucial. Both options have their unique advantages and drawbacks, making it essential for vehicle owners to understand the distinctions to make informed decisions.

Quality and Reliability

OEM components are specifically designed and tested by the original manufacturer, ensuring a high level of quality and reliability. These parts are often made from superior materials and adhere to strict manufacturing standards. In contrast, aftermarket options can vary widely in quality. While some aftermarket brands offer products that meet or exceed OEM specifications, others may fall short, potentially compromising performance and safety. Therefore, evaluating the reputation of the aftermarket brand is vital before making a purchase.

Cost Considerations

One of the most significant factors influencing the decision between these two types of components is cost. Aftermarket options typically come at a lower price point than their OEM counterparts, which can make them an attractive choice for budget-conscious consumers. However, it’s essential to consider the potential long-term implications of choosing cheaper alternatives. While the initial savings may be appealing, inferior quality could lead to more frequent replacements and additional repair costs down the line.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficient performance of your vehicle. By implementing a consistent maintenance routine, you can prevent premature wear and tear, thus extending the lifespan of various components. This guide outlines key practices that will help you keep your machine in top condition.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Check Oil Levels | Every 25 hours of use | Monitor engine oil and replace it as needed to ensure proper lubrication. |

| Inspect Air Filter | Monthly | Clean or replace the air filter to maintain optimal airflow to the engine. |

| Examine Tire Pressure | Every 2 weeks | Ensure tires are inflated to the recommended pressure for better traction and fuel efficiency. |

| Clean the Chassis | After every use | Remove dirt and debris from the chassis to prevent corrosion and mechanical issues. |

| Check Brake Fluid | Monthly | Inspect brake fluid levels and top off as necessary to maintain braking performance. |

| Lubricate Moving Parts | Every 50 hours of use | Apply lubricant to all moving components to reduce friction and wear. |

Following these maintenance guidelines will not only enhance the performance of your vehicle but also contribute to a safer and more enjoyable experience. Prioritize care and attention to detail, and you will reap the benefits of a reliable machine for years to come.

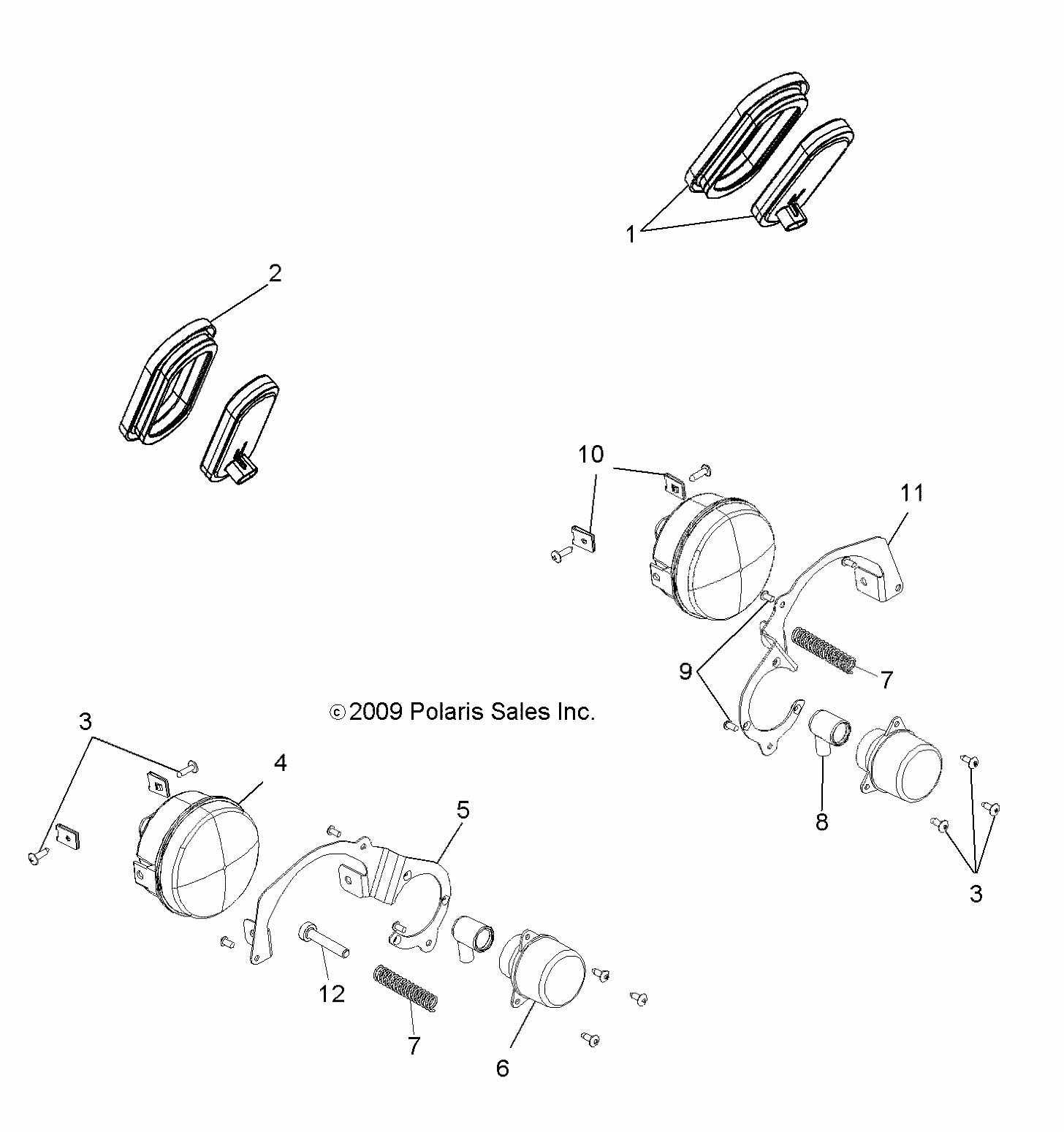

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair tasks. Such illustrations provide a visual breakdown of various elements, showcasing their interconnections and functions. This knowledge can help streamline the identification and ordering of necessary components, ensuring a smoother repair process.

Start by familiarizing yourself with the layout of the illustration. Typically, these representations are organized systematically, allowing for easy navigation through different sections. Look for a legend or key that explains symbols and terminology used in the illustration, as this will enhance your comprehension of the relationships between components.

Next, pay attention to the numbering or labeling system employed in the visual guide. Each element is usually assigned a specific identifier, which corresponds to detailed descriptions or specifications in accompanying documentation. Cross-referencing these identifiers will aid in understanding the purpose and compatibility of each component.

As you examine the visual representation, take note of the arrangement and orientation of parts. This can provide insights into how components fit together during assembly or disassembly. Understanding the layout will help avoid potential mistakes during the repair process and ensure that everything is installed correctly.

Finally, practice interpreting these illustrations by reviewing multiple examples. Gaining experience will improve your ability to quickly analyze different representations, ultimately making you more efficient in your repair tasks. With time, you will become adept at navigating these essential tools for maintenance and repair activities.

Essential Tools for Repairs

Performing maintenance and repairs on utility vehicles requires a well-equipped toolkit to ensure efficiency and effectiveness. The right instruments not only simplify the task but also enhance safety during the repair process. Having a comprehensive set of tools allows one to tackle various issues, from routine maintenance to complex repairs, ensuring the vehicle remains in optimal condition.

Basic Hand Tools

Hand tools form the foundation of any repair toolkit. Essential items include wrenches, screwdrivers, and pliers. These instruments are indispensable for loosening or tightening bolts, fastening components, and handling a variety of other tasks. Socket sets also play a crucial role, offering versatility for accessing different fasteners in tight spaces. Ensuring these tools are of high quality can significantly reduce wear and tear, making repairs smoother and more reliable.

Specialized Equipment

In addition to basic hand tools, some repairs may require specialized equipment. Torque wrenches are vital for applying the correct force to fasteners, preventing damage to components. Diagnostic tools are essential for identifying issues within the vehicle’s systems, allowing for targeted repairs rather than guesswork. Additionally, having a reliable jack and jack stands ensures safe lifting of the vehicle, providing easy access to the underside for maintenance tasks.

Step-by-Step Repair Process

This section outlines a comprehensive approach to conducting repairs on an all-terrain vehicle. By following a systematic method, you can ensure that every aspect of the maintenance is addressed, leading to a more efficient and effective repair experience. Understanding the structure and functions of various components will aid in identifying issues and implementing solutions.

Step 1: Gather Necessary Tools and Equipment

Before beginning the repair process, collect all essential tools and equipment. This may include wrenches, screwdrivers, pliers, and diagnostic devices. Having everything on hand will save time and prevent unnecessary interruptions during the work.

Step 2: Refer to the Repair Manual

Consult the repair manual specific to your vehicle model. This document contains vital information regarding the assembly, disassembly, and troubleshooting procedures. Familiarize yourself with the instructions and diagrams to understand the layout and connections of various parts.

Step 3: Conduct a Thorough Inspection

Perform a detailed inspection of the vehicle to identify any visible wear, damage, or irregularities. Pay close attention to key components such as the engine, transmission, suspension, and electrical systems. Document any findings to streamline the repair process.

Step 4: Disassemble Affected Components

Carefully disassemble the parts that require attention. Keep track of all screws, nuts, and other fasteners to avoid losing them. It is advisable to take photographs during this stage to aid in reassembly.

Step 5: Replace or Repair Faulty Parts

Based on your inspection, either replace damaged components with new ones or repair them as needed. Ensure that any replacement parts are compatible with your vehicle’s specifications to maintain optimal performance.

Step 6: Reassemble the Vehicle

Once repairs or replacements are complete, begin reassembling the vehicle in reverse order of disassembly. Refer back to the photographs and the repair manual to ensure everything is correctly positioned and secured.

Step 7: Test the Vehicle

After reassembly, conduct a thorough test of the vehicle to ensure all systems are functioning correctly. Check for unusual noises, leaks, or performance issues. If any problems persist, revisit the inspection step to troubleshoot further.

Step 8: Regular Maintenance

Once repairs are completed and the vehicle is operating normally, establish a routine maintenance schedule. Regular checks can prevent future issues and extend the lifespan of your all-terrain vehicle.

Where to Buy Replacement Parts

Finding high-quality components for your utility vehicle can significantly enhance its performance and longevity. Whether you’re looking to repair a malfunctioning mechanism or upgrade specific features, various sources offer reliable options. Knowing where to seek these essential items can save you time and ensure you get the best value for your investment.

Authorized Dealers

One of the most trustworthy sources for acquiring necessary components is through authorized dealerships. These establishments typically carry a wide selection of genuine items, ensuring compatibility and reliability. Furthermore, they often provide knowledgeable staff who can assist in identifying the right components for your specific model.

Online Retailers

The internet has transformed the way enthusiasts shop for vehicle components. Numerous online platforms offer a vast array of options at competitive prices. When choosing an online retailer, ensure they have a solid reputation and provide customer reviews, detailed product descriptions, and return policies to facilitate a smooth purchasing experience.

Community Resources and Forums

Engaging with fellow enthusiasts can greatly enhance your experience and knowledge about maintenance and upgrades. Online communities and discussion platforms provide a wealth of information, shared experiences, and solutions to common issues. Whether you’re looking for advice on specific components or seeking recommendations for modifications, these resources are invaluable for both novice and experienced users.

Popular Online Forums

Several well-established forums cater to enthusiasts of all types of utility vehicles. These platforms allow members to discuss various topics, share tips, and troubleshoot problems collectively.

| Forum Name | Description | Link |

|---|---|---|

| UTV Source | A comprehensive community for utility vehicle owners, offering advice and reviews. | Visit |

| Off-Road Forums | A popular space for off-road enthusiasts to discuss modifications and share stories. | Visit |

| ATV & UTV Forum | A dedicated forum focused on all-terrain vehicles, with sections for troubleshooting and upgrades. | Visit |

Social Media Groups

In addition to forums, various social media platforms host groups where users can connect, ask questions, and share insights. These groups often have members with diverse experiences and can provide quick responses and support.