2012 Polaris RZR 800 Parts Breakdown

Understanding the intricate structure of a vehicle’s assembly is crucial for both enthusiasts and mechanics. Each element, no matter how small, plays a pivotal role in ensuring the smooth operation and longevity of the machine. By exploring various components, it becomes easier to recognize how they function together, creating a seamless driving experience.

Knowing where each mechanical element fits and how it contributes to the overall performance can simplify maintenance and repairs. By diving deeper into the layout of different systems, users can enhance their knowledge of the machine’s framework, making repairs and upgrades more efficient.

This guide offers a detailed look into the essential elements of the machine’s configuration, providing clarity on the connections and roles of various pieces. Such insights allow for easier troubleshooting and maintenance, ensuring the vehicle remains in optimal condition.

Overview of Key Components

The machine consists of several essential elements that ensure its proper functioning. These components work together to deliver performance, safety, and stability in various terrains. Understanding the primary elements is crucial for maintaining and optimizing the vehicle’s overall capabilities.

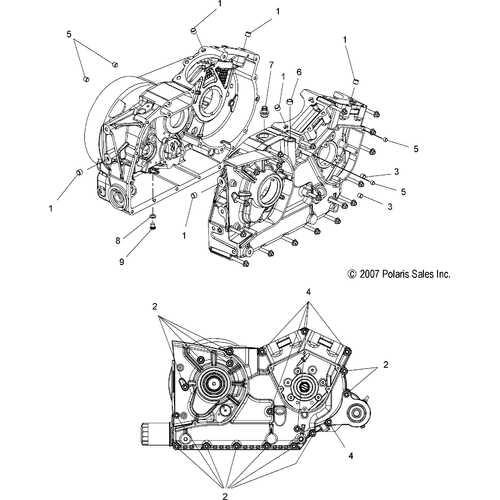

Engine and Transmission

The power unit is the heart of the machine, providing the necessary energy for all operations. Paired with a reliable transmission system, it ensures smooth power delivery and control. Regular maintenance of these parts can significantly improve the efficiency and longevity of the vehicle.

Suspension and Braking System

A well-designed suspension setup ensures stability and comfort, even on rough surfaces. Together with a responsive braking mechanism, it allows for secure handling and maneuverability. Paying attention to these components is essential for both performance and safety, ensuring the best riding experience.

Engine and Transmission Layout

The layout of the power unit and the drivetrain is a critical factor in ensuring smooth operation and performance. Understanding how these components are arranged and connected helps in identifying the key aspects of vehicle mechanics, enhancing overall functionality and driving dynamics.

Engine Structure

The motor is designed to provide maximum efficiency, with its various elements strategically positioned for optimal airflow and cooling. This configuration not only ensures proper combustion but also contributes to the durability of the entire system, reducing strain on critical parts during use.

Transmission Placement

The drivetrain is integrated seamlessly with the motor to allow smooth gear shifting and power transfer. Its strategic positioning ensures minimal energy loss while delivering consistent torque to the wheels. This setup is vital for maintaining vehicle control and stability in various driving conditions.

Suspension and Steering System Breakdown

The suspension and steering system is essential for ensuring smooth movement and control. These interconnected components are designed to absorb shocks, manage weight distribution, and allow for precise handling. In this section, we will examine the key elements that contribute to a well-functioning system.

Key Components of the Suspension

- Shocks and Springs – These elements absorb impacts from uneven terrain, maintaining vehicle stability.

- Control Arms – They connect the wheels to the frame, ensuring the proper movement of the suspension.

- Stabilizer Bars – Reduce body roll during turns, improving overall handling.

Steering Mechanism Overview

The steering mechanism provides the driver with control over direction. It operates in sync with the suspension to maintain proper alignment and responsiveness.

- Steering Rack – Transfers the driver’s input to the wheels, allowing for accurate directional changes.

- Tie Rods – Ensure the wheels respond to the steering input, connecting the steering rack to the hubs.

- Knuckles – Act as pivot points for the steering and suspension, contributing to turning efficiency.

By maintaining these components, the system ensures smooth operation, safety, and performance under various conditions.

Electrical System Overview

The electrical setup in modern off-road vehicles is essential for managing various components and ensuring smooth operation. Understanding the wiring and power distribution is crucial for efficient maintenance and troubleshooting of these machines.

Below is a breakdown of the key components involved in the electrical system:

- Battery: The primary power source, responsible for supplying energy to all electrical parts when the engine is off.

- Alternator: This device recharges the battery while the engine is running and powers the vehicle’s electrical systems.

- Fuses and Relays: These components protect the electrical circuits by interrupting power during overloads, ensuring safety.

- Ignition System: Controls the starting process by generating the necessary voltage to ignite the engine.

- Wiring Harness: A network of wires connecting all electrical components, ensuring proper communication and power flow.

Maintaining these elements is key to ensuring the longevity and reliability of the vehicle’s performance in various conditions.

Cooling System Parts Arrangement

The cooling system is essential for maintaining the optimal temperature of the engine, ensuring efficient performance and longevity. Understanding how the components of this system are structured can help with proper maintenance and troubleshooting. Each element is carefully positioned to regulate airflow and coolant circulation, preventing overheating during operation.

Key Components in the Cooling System

The cooling system consists of several interconnected elements that work together to manage temperature. The radiator is central to the setup, dispersing heat through fluid exchange. Coolant flows through the system, moving from the engine to the radiator, where it is cooled by airflow. A thermostat helps regulate the coolant’s flow based on the engine’s temperature, ensuring it stays within the safe range.

Flow and Circulation

Fluid movement in the cooling system is managed by the water pump, which pushes coolant throughout the engine and into the radiator. Hoses connect these parts, ensuring smooth circulation. This coordinated process helps maintain the engine’s temperature even during intensive usage.

Braking Mechanism and Components

The braking system is crucial for the safe operation of any vehicle, as it ensures control and stability during movement. Understanding the various elements that make up this system can help in maintaining optimal performance and addressing any potential issues. This section delves into the essential components and their roles within the braking mechanism.

Key Elements of the Braking System

- Brake Pads: These components create friction against the brake rotors to slow down or stop the vehicle.

- Brake Rotors: Also known as discs, these circular metal pieces are attached to the wheels and work in conjunction with the brake pads.

- Calipers: These devices house the brake pads and are responsible for applying pressure to them against the rotors.

- Master Cylinder: This component generates hydraulic pressure when the brake pedal is pressed, facilitating the operation of the braking system.

- Brake Lines: These tubes carry brake fluid from the master cylinder to the calipers, enabling the transmission of pressure.

- Brake Fluid: A specialized hydraulic fluid that transfers force within the braking system, allowing for effective braking action.

Functionality and Maintenance

The effectiveness of the braking mechanism relies on the seamless interaction of its components. Regular inspection and maintenance are vital to ensure all parts are functioning properly. Signs of wear, such as decreased responsiveness or unusual noises, should be addressed promptly to avoid compromising safety.

Chassis and Frame Structure

The foundation of any off-road vehicle plays a critical role in its performance, durability, and overall stability. This section delves into the essential components and design elements that constitute the framework of these rugged machines. A well-engineered structure ensures optimal handling and supports various attachments, providing a seamless driving experience over diverse terrains.

Key Components of the Framework

- Main Frame: The core structure that supports all other components and provides rigidity.

- Subframe: Secondary structure designed to hold specific parts like the engine and suspension, enhancing stability.

- Crossmembers: Reinforcements that distribute loads and increase the overall strength of the framework.

- Mounting Points: Designated locations for attaching essential elements such as the suspension and drivetrain.

Materials Used in Construction

The materials selected for the construction of the chassis significantly impact weight, strength, and resistance to wear. Commonly used materials include:

- Steel: Known for its durability and strength, often used in main structural elements.

- Aluminum: Lightweight and resistant to corrosion, used in components where weight reduction is crucial.

- Composite Materials: Increasingly popular for specific applications due to their lightweight and high-strength properties.

Fuel System Assembly

The fuel system is a vital component of any off-road vehicle, responsible for delivering the necessary fuel to the engine for optimal performance. This assembly encompasses several elements that work together to ensure efficient fuel management, contributing to the overall functionality and reliability of the machine.

Key components of the fuel system include the fuel tank, pump, filter, and injectors. Each part plays a crucial role in transporting and regulating fuel flow. Below is a table summarizing these essential elements and their functions:

| Component | Function |

|---|---|

| Fuel Tank | Stores the fuel required for operation. |

| Fuel Pump | Transports fuel from the tank to the engine. |

| Fuel Filter | Removes impurities from the fuel to protect the engine. |

| Fuel Injectors | Delivers precise amounts of fuel into the engine for combustion. |

Understanding the layout and functionality of these components is essential for effective maintenance and troubleshooting, ensuring that the vehicle operates smoothly and efficiently.

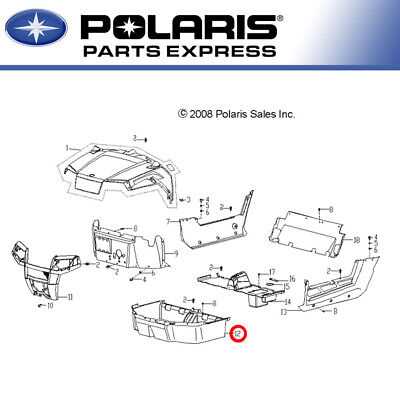

Interior and Dashboard Parts

The cabin of an off-road vehicle is designed for both functionality and comfort, providing drivers and passengers with essential features for an enjoyable ride. Understanding the various components that comprise the interior and dashboard can enhance the overall driving experience, ensuring that all necessary controls and displays are easily accessible and user-friendly.

Dashboard Elements: The dashboard includes vital instruments such as the speedometer, fuel gauge, and temperature indicator, which provide real-time information about the vehicle’s performance. Additionally, controls for lights, wipers, and other essential functions are strategically placed to maximize convenience.

Seating and Storage: The interior space often features ergonomically designed seats that offer support during rough terrains. Furthermore, integrated storage compartments allow for the secure placement of personal items and equipment, contributing to a clutter-free environment.

Understanding the layout and function of these components not only aids in maintenance but also enhances the driving experience by ensuring that all necessary tools are at the driver’s fingertips.

Exhaust System Configuration

The exhaust system plays a crucial role in the performance and efficiency of a vehicle’s engine. Its primary function is to channel exhaust gases away from the engine, ensuring optimal operation and reducing emissions. A well-designed exhaust layout can significantly enhance engine performance, improve fuel efficiency, and contribute to a quieter ride.

In this configuration, various components work in harmony to facilitate the proper flow of gases. The exhaust manifold collects fumes from the engine cylinders and directs them into the exhaust pipes. High-quality materials are essential for durability and to withstand extreme temperatures.

Next, a series of pipes connect to the muffler, which serves to muffle the sound produced by the engine. The placement and design of these elements are vital for achieving the desired sound characteristics and performance levels. Additionally, performance upgrades, such as high-flow catalytic converters and aftermarket mufflers, can further enhance efficiency and power output.

Understanding the intricacies of the exhaust system configuration allows for better maintenance and potential upgrades, leading to improved overall vehicle performance.

Tire and Wheel Specifications

This section provides an overview of the essential attributes and features related to tires and wheels for the off-road vehicle. Understanding these specifications is crucial for ensuring optimal performance, safety, and compatibility with various terrains.

The following points highlight key characteristics to consider when selecting tires and wheels:

- Size: The dimensions of tires and wheels, including width, diameter, and aspect ratio, significantly impact handling and stability.

- Tread Pattern: The design of the tire surface influences traction, grip, and performance on different surfaces such as mud, sand, or gravel.

- Load Capacity: Each tire has a specific load rating that indicates the maximum weight it can support while maintaining safety and performance.

- Material Composition: The materials used in tire and wheel construction can affect durability, weight, and overall performance in rugged conditions.

- Inflation Pressure: Proper tire pressure is essential for maintaining control, comfort, and fuel efficiency during operation.

When selecting tires and wheels, it is important to consult the manufacturer’s recommendations to ensure compatibility with the vehicle’s specifications and to enhance the overall riding experience.