Poulan P3314 Parts Diagram Overview

In the world of outdoor machinery, grasping the intricate details of a tool’s construction is vital for both maintenance and repair. Each unit consists of various elements that work in harmony to deliver optimal performance. Familiarizing oneself with these components enhances the user experience and extends the life of the device.

Whether you’re a seasoned professional or a weekend warrior, knowing how to identify and understand the different sections of your machine can significantly improve its functionality. This knowledge empowers users to troubleshoot issues effectively, ensuring that every task can be accomplished with ease and confidence.

In this article, we will delve into the specific layout and relationships among the crucial parts of your equipment. By breaking down each segment, you’ll gain valuable insights into how these elements contribute to the overall operation, making your maintenance routines more efficient and effective.

Poulan P3314 Parts Overview

This section provides an insight into the various components that make up a specific model of equipment. Understanding these elements is essential for maintenance, repair, and optimization of performance. Each part plays a vital role in ensuring the overall functionality and longevity of the machine.

Key Components

Among the crucial elements are the motor assembly, cutting mechanism, and fuel system. Each part is designed to work seamlessly together, contributing to efficient operation. Regular inspection of these components can prevent potential issues and enhance the equipment’s efficiency.

Maintenance Tips

To ensure longevity, it is important to regularly clean and replace worn-out elements. Keeping an eye on the condition of each component can significantly reduce the risk of malfunctions. Adopting a proactive maintenance routine ultimately leads to better performance and extended lifespan.

Understanding the Poulan P3314 Model

This section delves into the features and functionalities of a popular outdoor power tool, focusing on its components and operational mechanisms. By gaining insight into its structure, users can enhance their experience and ensure effective maintenance.

The model is designed for efficiency and ease of use, making it suitable for both novice and experienced users. Here are some key aspects to consider:

- Engine Performance: The heart of the device provides robust power for various tasks.

- Cutting Mechanism: Innovative design allows for precise and clean cuts.

- Durability: Built with high-quality materials to withstand tough conditions.

- User-Friendly Features: Lightweight and ergonomic design for comfortable handling.

Understanding these elements not only helps in maximizing the tool’s potential but also aids in troubleshooting common issues. Regular maintenance and familiarity with its components can significantly prolong its lifespan.

- Regularly check and replace the spark plug.

- Keep the cutting edge sharp for optimal performance.

- Ensure that fuel is fresh to prevent engine problems.

- Inspect and clean air filters regularly.

By focusing on these areas, users can maintain the efficiency and reliability of their equipment, making outdoor tasks more manageable and enjoyable.

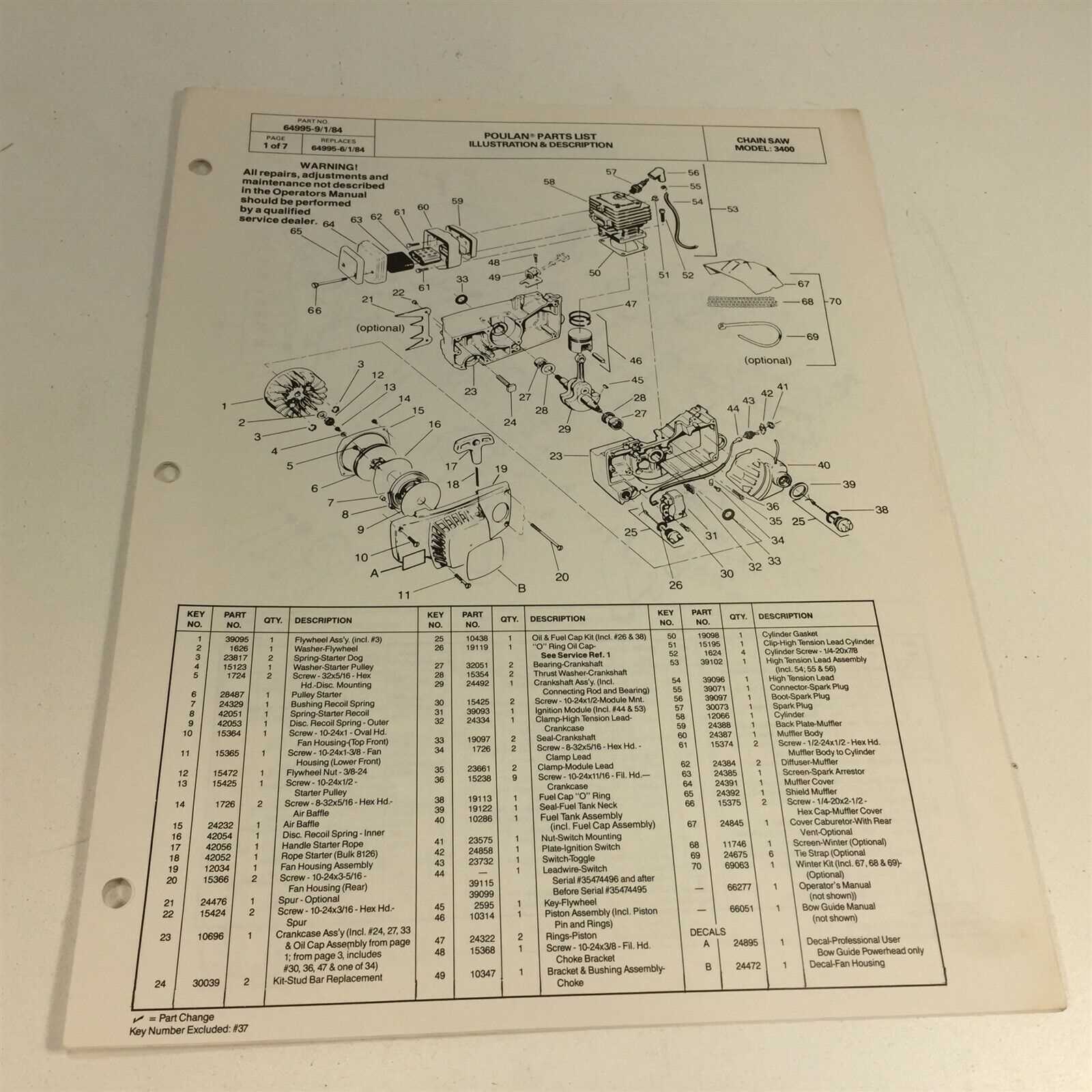

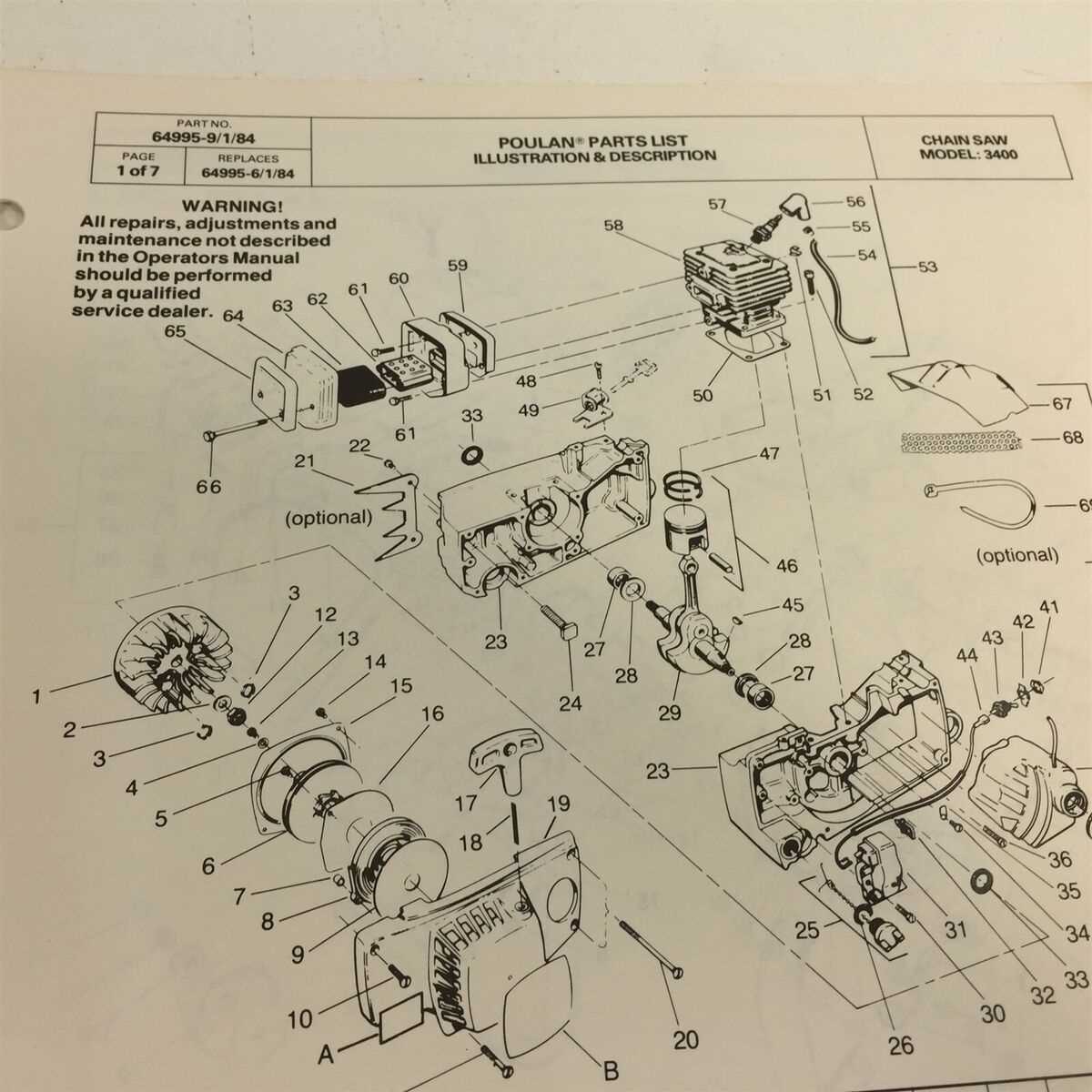

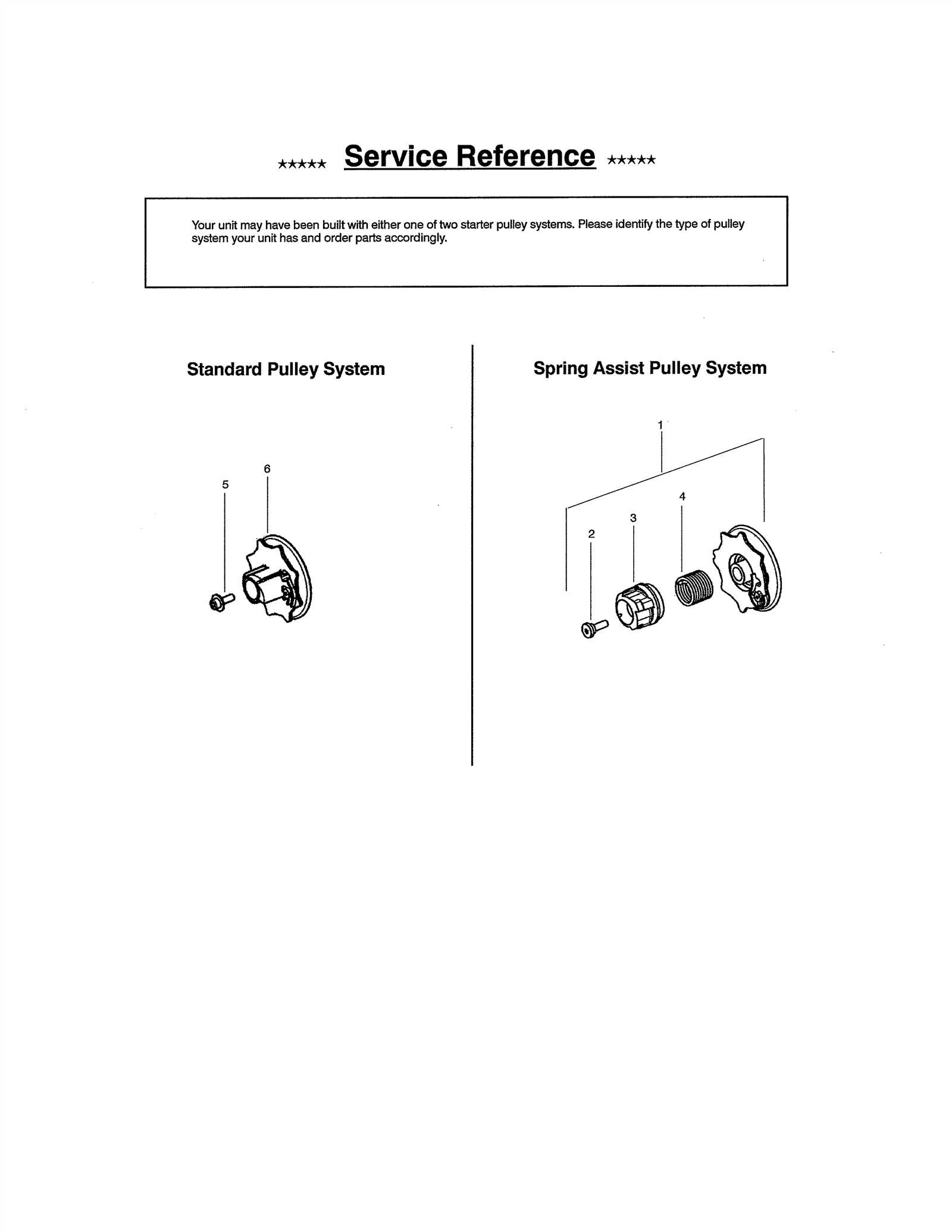

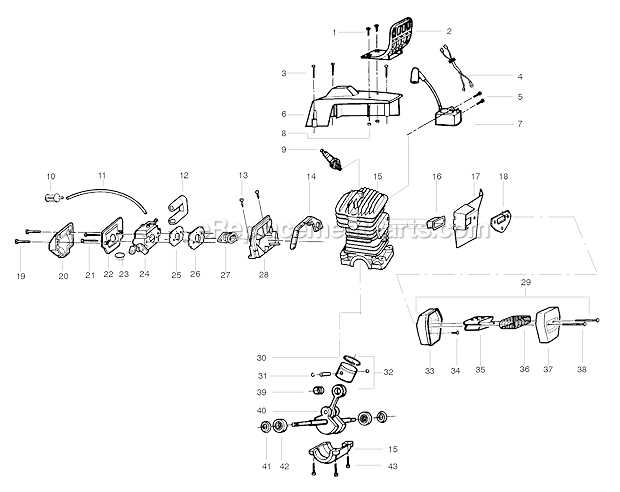

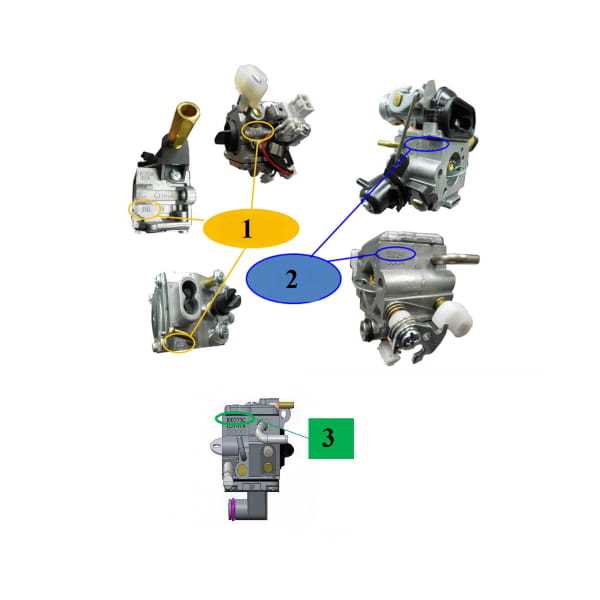

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They offer clarity and enhance understanding, making it easier for users to identify and work with individual elements. By providing a clear layout, these illustrations simplify the process of troubleshooting and reassembly.

Here are some key reasons why these visual aids are essential:

- Enhanced Understanding: They break down complex systems into manageable parts, facilitating a clearer comprehension of how everything fits together.

- Efficient Troubleshooting: Identifying faulty components becomes straightforward, allowing for quicker diagnosis and repair.

- Streamlined Repairs: Users can locate specific items easily, reducing downtime during maintenance tasks.

- Accurate Reassembly: Ensuring that each piece is returned to its correct position helps maintain the integrity and functionality of the equipment.

- Guidance for Replacement: They assist in sourcing the correct replacements, minimizing the risk of errors.

In conclusion, visual guides are invaluable tools for anyone involved in the upkeep of mechanical systems, ensuring that processes are efficient and effective.

Key Components of the P3314 Chainsaw

Understanding the essential elements of a chainsaw is crucial for optimal performance and maintenance. Each part plays a significant role in ensuring that the tool operates efficiently, allowing users to tackle various cutting tasks with ease. This overview highlights the main components that contribute to the functionality and reliability of this powerful device.

Engine and Power System

The engine serves as the heart of the chainsaw, providing the necessary power to drive the chain. Equipped with a robust combustion system, it transforms fuel into kinetic energy, enabling smooth and effective cuts. Additionally, the ignition system ensures that the engine starts reliably and runs consistently, maintaining the ideal speed for various applications.

Cutting Mechanism

The cutting assembly comprises the chain, guide bar, and sprocket, which work together to deliver precise and swift cutting action. The chain, made of durable metal links, wraps around the guide bar and rotates at high speeds, allowing for effortless slicing through wood. The sprocket connects the chain to the engine, ensuring that power is efficiently transferred for optimal performance.

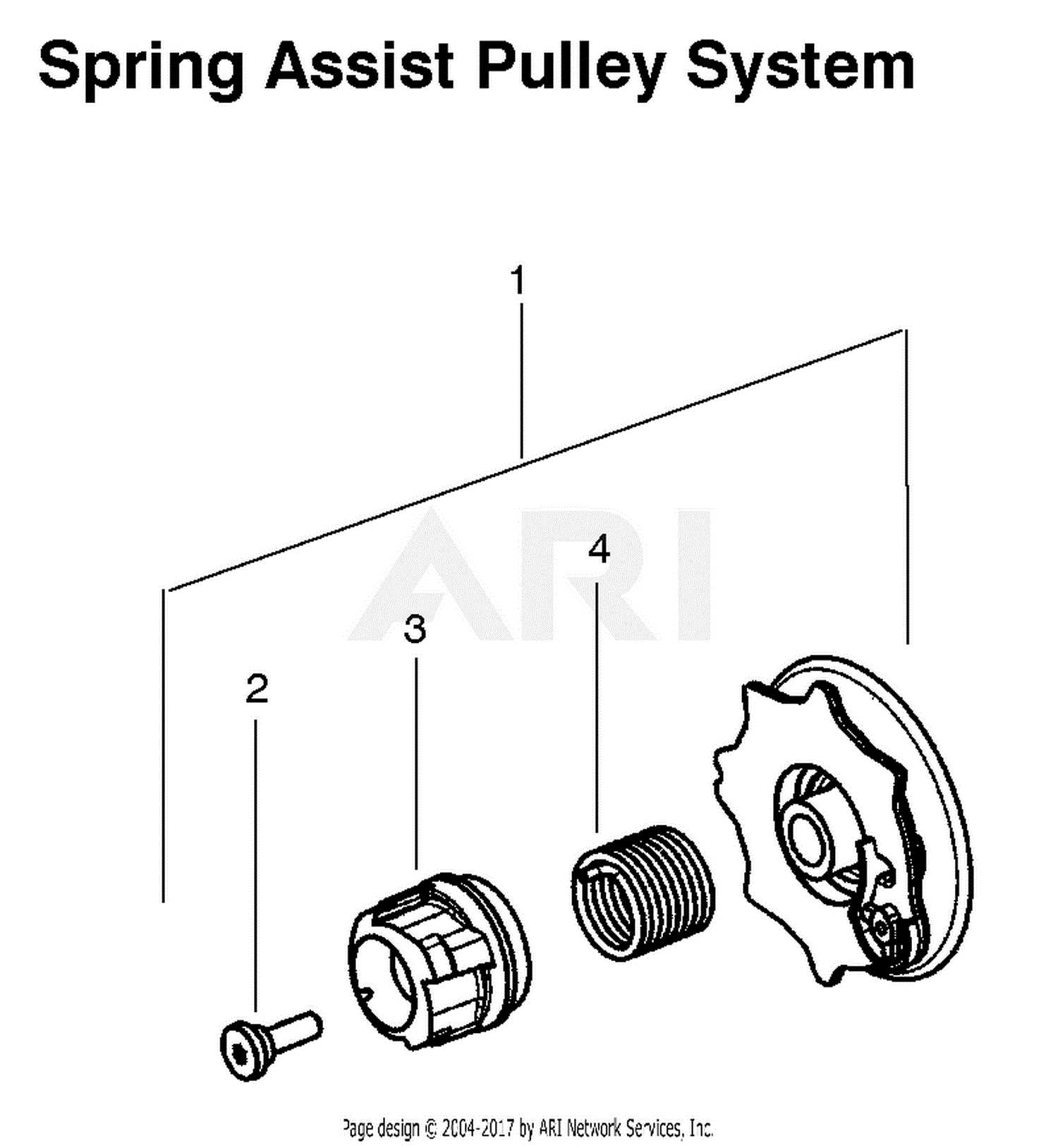

How to Read Parts Diagrams

Understanding schematics is essential for effective maintenance and repair. These visual guides help identify components and their relationships, ensuring that you can assemble or disassemble devices efficiently. By familiarizing yourself with the layout, you can streamline your repair process and avoid potential pitfalls.

Identifying Key Components

Begin by locating the main elements within the schematic. Each item is typically labeled with a reference number, which corresponds to a list detailing specifications or descriptions. Recognizing these labels will enable you to pinpoint the necessary components quickly.

Understanding Relationships and Assembly

Pay attention to how parts connect and interact. Arrows and lines often indicate relationships and assembly order. This understanding will guide you in proper installation and troubleshooting, ensuring everything fits together seamlessly.

| Label | Description |

|---|---|

| 1 | Main Body |

| 2 | Motor Assembly |

| 3 | Fuel Tank |

Identifying Replacement Parts Easily

Understanding how to locate and select the right components for your equipment can significantly enhance its longevity and performance. This section outlines effective strategies to simplify the identification process for necessary items, ensuring that maintenance and repairs are handled efficiently.

Utilizing Online Resources

- Search for model specifications on manufacturer websites.

- Explore forums and communities for shared insights and recommendations.

- Access instructional videos that demonstrate replacement processes.

Organizing Information

- Keep a log of component numbers and descriptions for future reference.

- Create a visual reference by taking pictures of disassembled parts.

- Label each component during disassembly to avoid confusion.

Common Issues and Solutions

In any mechanical device, certain problems tend to arise frequently, affecting performance and usability. Understanding these common challenges and their remedies can enhance the longevity and efficiency of the equipment. This section explores typical issues encountered and offers practical solutions to address them effectively.

Engine Performance Problems

One of the most prevalent issues involves engine malfunction, which may manifest as difficulty starting or irregular running. Regular maintenance is crucial to prevent these issues. Ensure that the fuel is fresh and the air filter is clean. Additionally, check the spark plug for wear and replace it if necessary to restore optimal function.

Cutting Efficiency

Decreased cutting performance can occur due to dull blades or improper tension. Sharpening the blades or adjusting their tension can significantly improve cutting efficiency. It is advisable to inspect the cutting components regularly to ensure they are in good condition, as this not only enhances performance but also ensures safety during operation.

Where to Find Parts Diagrams

Locating detailed illustrations of components for various equipment can significantly simplify repair and maintenance tasks. Such visuals not only assist in identifying individual elements but also provide crucial information on assembly and disassembly processes. Here are several effective resources for accessing these valuable references.

Online Resources

- Manufacturer Websites: Official sites often feature dedicated sections for user manuals and component layouts.

- Repair Forums: Communities focused on repairs frequently share links to illustrations and discuss their experiences.

- Online Retailers: E-commerce platforms selling replacement items usually have accompanying visuals to aid in identification.

Physical Resources

- Local Repair Shops: Professionals can provide printed versions or direct you to reliable sources.

- Libraries: Many libraries maintain archives of repair manuals that include detailed sketches.

- Service Centers: Authorized service centers often have access to comprehensive documentation.

Ordering Genuine Poulan Parts

When maintaining outdoor equipment, obtaining authentic components is crucial for optimal performance and longevity. Sourcing high-quality items ensures compatibility and reliability, minimizing the risk of future issues. This section guides you through the process of acquiring the right pieces for your machinery.

Where to Find Authentic Components

Start by visiting authorized retailers and service centers, which often carry a comprehensive selection of genuine items. Additionally, exploring online platforms dedicated to equipment can provide a broader inventory, allowing for easy comparison and selection.

Benefits of Choosing Original Items

Investing in original components not only enhances the functionality of your machinery but also preserves its warranty. These items are designed to fit perfectly, reducing the likelihood of mechanical failures. Quality matters, and opting for genuine options will ensure your equipment operates as intended.

Remember to verify the authenticity of the components before making a purchase, as this will safeguard your investment and ensure lasting performance. Proper maintenance begins with the right supplies.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your outdoor power equipment requires regular upkeep and attention. Implementing simple maintenance practices can significantly extend the lifespan of your tools while optimizing their efficiency. Here are some essential tips to keep your machinery in peak condition.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Clean Air Filter | Every 10 hours of use | Remove dirt and debris to enhance airflow and engine performance. |

| Check Spark Plug | Every season | Inspect for wear and replace if necessary to ensure reliable starting and combustion. |

| Inspect Blades | After each use | Sharpen or replace blades to maintain cutting efficiency and prevent strain on the engine. |

| Change Oil | Every 20-25 hours of use | Replace oil to keep the engine lubricated and reduce wear over time. |

| Check Fuel System | Monthly | Inspect fuel lines and filters for leaks or clogs, and replace stale fuel. |

By adhering to these guidelines, you can significantly enhance the durability and performance of your equipment, ensuring that it operates effectively for many years to come.

DIY Repairs: What You Need

Engaging in do-it-yourself repairs can be both rewarding and economical. To successfully tackle these tasks, it’s essential to equip yourself with the right tools and knowledge. This section outlines the fundamental components you will need to ensure your repair project is completed efficiently and effectively.

Tools are the backbone of any repair job. A reliable toolkit should include essential items such as screwdrivers, pliers, and wrenches, which are necessary for handling various fasteners. Additionally, having a quality set of sockets can streamline the process of loosening or tightening bolts.

Moreover, replacement components may be required for your project. Familiarizing yourself with the specifications and types of parts needed will save time and frustration. Always keep a list of potential replacements handy to avoid delays during the repair.

Safety gear is another crucial aspect. Protecting yourself while working is paramount; gloves, goggles, and masks can prevent injuries and ensure a safer working environment. Never underestimate the importance of being well-prepared.

Finally, instructions and resources are invaluable. Whether it’s manuals, online tutorials, or community forums, having access to reliable guidance can make a significant difference in your repair success. Take the time to research and gather as much information as possible before starting your project.

Tools Required for Repairs

Proper maintenance and restoration of outdoor equipment necessitate specific tools to ensure efficiency and accuracy. Having the right instruments not only simplifies the process but also enhances safety and effectiveness. Familiarity with these tools can greatly impact the success of any repair task.

Essential Hand Tools

A variety of hand tools are critical for performing repairs. Wrenches, screwdrivers, and pliers are among the most commonly used items. These tools allow for easy disassembly and reassembly of components, ensuring that every part can be accessed and inspected as needed. Additionally, having a good set of sockets can streamline tasks that involve fasteners of various sizes.

Power Tools and Safety Gear

Power tools can significantly expedite the repair process, making tasks quicker and less labor-intensive. Drills, saws, and grinders are often essential for more complex jobs. Alongside power tools, safety gear such as gloves, goggles, and hearing protection should not be overlooked. Using the right protective equipment is vital to prevent injuries while working with potentially hazardous machinery.

Safety Precautions When Repairing

When engaging in maintenance tasks, adhering to safety measures is essential to prevent accidents and ensure a smooth workflow. Understanding the risks involved and taking proactive steps can significantly enhance personal safety and equipment longevity. Always prioritize protection, as it lays the foundation for successful repairs.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is crucial. This includes safety goggles to shield your eyes from debris, gloves to protect your hands from sharp edges, and sturdy footwear to prevent injuries from falling objects. Additionally, consider using ear protection if operating loud machinery.

Workspace Safety

Maintain a clean and organized workspace to minimize hazards. Ensure that tools are in good condition and stored properly when not in use. Clear any unnecessary items from the area to reduce the risk of tripping or accidents. Always work in a well-lit environment to enhance visibility and concentration.