Poulan Pro PP19A42 Parts Diagram Overview

When it comes to maintaining your outdoor machinery, having a clear overview of its essential elements is crucial. This knowledge not only helps in effective repairs but also ensures optimal performance of the equipment. Understanding how each component works together can make a significant difference in the longevity and reliability of your tools.

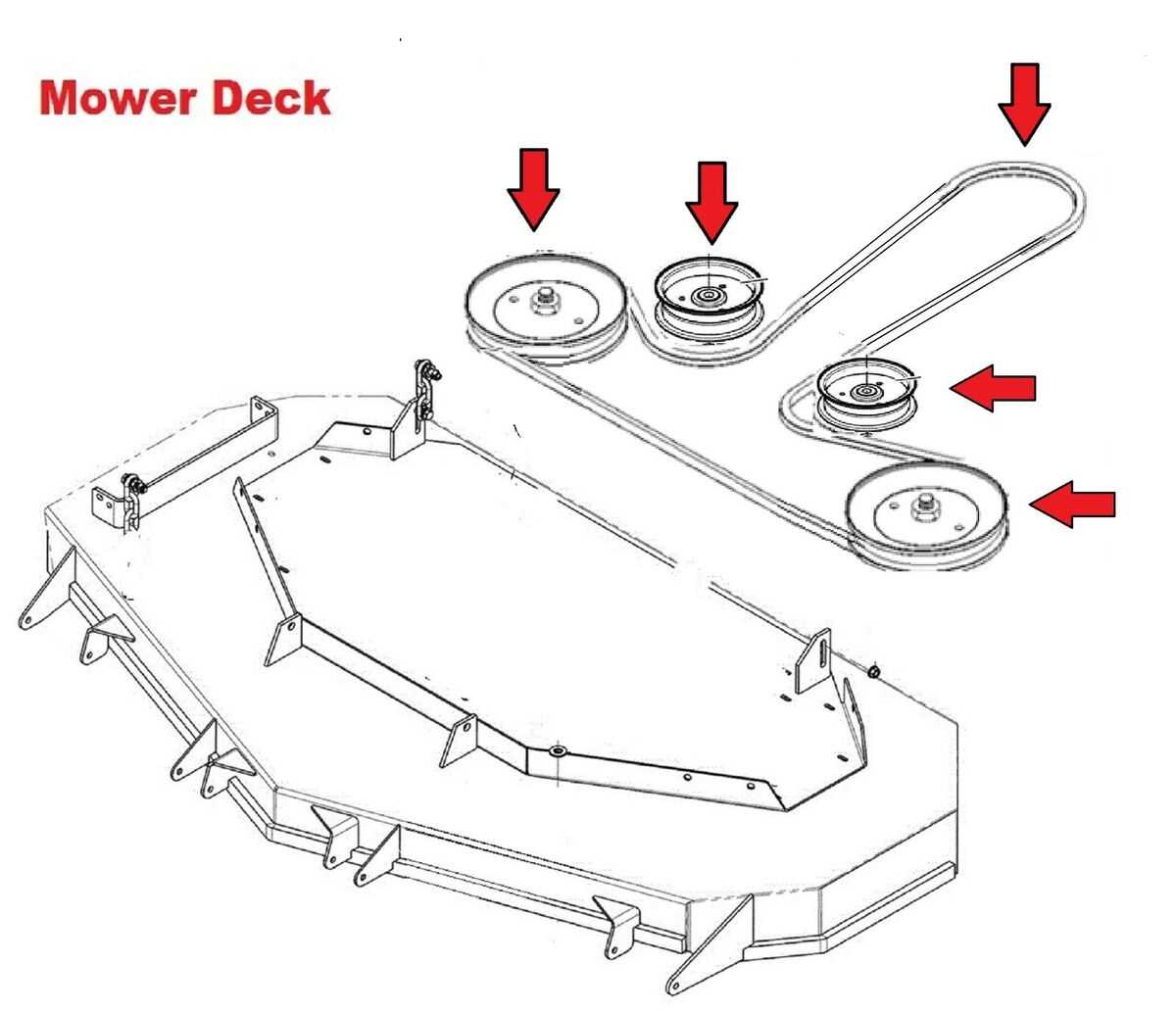

Visual representations play a vital role in comprehending the intricate details of your machinery. They provide an accessible way to identify each part and its function, allowing users to navigate through their equipment with ease. Whether you’re troubleshooting a problem or performing routine maintenance, having a reference guide can streamline the process and enhance your confidence in handling repairs.

In this section, we will delve into the various segments that comprise your lawn care tools. By breaking down the intricate assembly, you will gain valuable insights that can assist you in selecting the right components when the need for replacements arises. An informed approach to understanding these structures can lead to better care and more efficient operation.

Poulan Pro PP19A42 Overview

This model is designed for those seeking a reliable and efficient solution for their outdoor maintenance needs. It combines robust engineering with user-friendly features, making it an excellent choice for both novice and experienced users. Its innovative design ensures optimal performance, allowing for effective grass cutting and yard care.

With a powerful engine and a durable build, this equipment is tailored to tackle various tasks with ease. The intuitive controls and adjustable settings enhance usability, providing a seamless experience. Additionally, it incorporates advanced technology aimed at improving efficiency while minimizing environmental impact.

Overall, this machine stands out for its blend of power, versatility, and practicality. Whether managing a small garden or a larger lawn, it delivers consistent results, making outdoor work more manageable and enjoyable.

Key Features of the Model

This model stands out for its innovative design and robust functionality, making it an excellent choice for various landscaping tasks. With a combination of power and efficiency, it is engineered to meet the needs of both residential and professional users.

Durable Construction

The build quality is a significant aspect of this unit. It features a sturdy frame that ensures longevity and withstands rigorous use. The materials used are selected to resist wear and tear, providing reliability over time.

Enhanced Performance

Equipped with a high-performance engine, this model delivers impressive power, allowing for smooth operation even in challenging conditions. The engine’s efficiency contributes to reduced fuel consumption, making it an environmentally friendly option. Additionally, advanced cutting technology ensures precision and effectiveness, making every task easier to handle.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate workings of machinery. They serve as essential tools for both professionals and enthusiasts, facilitating a deeper comprehension of how each element interacts within a system. By providing a clear layout, these illustrations simplify the process of maintenance, repair, and assembly.

Moreover, having a comprehensive visual guide aids in the identification of specific pieces, ensuring that replacements are accurate and efficient. This ultimately leads to improved performance and longevity of the equipment. For users, this means less frustration and more successful outcomes when addressing mechanical issues.

In summary, such visual aids are indispensable for anyone looking to delve into the mechanics of devices, making troubleshooting and upkeep a more streamlined process.

Common Issues and Repairs

When maintaining outdoor equipment, users often encounter various challenges that may hinder performance. Understanding these common problems and their solutions can significantly improve the longevity and efficiency of your machinery. This section explores frequent malfunctions and effective repair strategies to keep your equipment running smoothly.

Frequent Problems

- Engine Starting Issues

- Ineffective Cutting Performance

- Fuel Leaks

- Excessive Vibration

- Difficulty in Maneuvering

Repair Solutions

- Engine Starting Issues: Check the spark plug for wear and replace it if necessary. Ensure the fuel is fresh and properly mixed.

- Ineffective Cutting Performance: Sharpen or replace the cutting blade. Inspect the height adjustment settings for proper alignment.

- Fuel Leaks: Inspect hoses and connections for damage or loose fittings. Replace any worn-out parts immediately.

- Excessive Vibration: Tighten all bolts and screws. Check for any imbalances in the cutting blade or wheels.

- Difficulty in Maneuvering: Ensure that wheels are not obstructed. Lubricate moving parts to enhance mobility.

Regular maintenance and prompt repairs can help mitigate these issues, ensuring your outdoor equipment remains in optimal condition for any task.

Identifying Parts by Number

Understanding how to recognize components by their numerical identifiers is essential for efficient maintenance and repairs. Each element typically has a unique code that facilitates the ordering and replacement process, ensuring compatibility and functionality. Familiarity with these identifiers can significantly streamline any repair project, allowing for quicker resolutions and enhanced performance.

Importance of Numerical Identification

Numerical identification serves as a universal language among technicians and hobbyists alike. It eliminates confusion by providing a clear reference point for each component, regardless of the manufacturer. This system not only aids in locating specific items but also helps in verifying the authenticity and quality of replacements, ensuring that the equipment operates at its best.

How to Locate Identification Numbers

Identification numbers can usually be found on the component itself, often stamped or printed in a visible location. Consulting the user manual or official resources can also yield valuable information regarding the exact locations of these identifiers. By taking the time to familiarize oneself with this process, users can make informed decisions, ultimately prolonging the life of their equipment and enhancing its reliability.

Where to Find Replacement Parts

Locating the necessary components for your equipment can be essential for its optimal performance. Fortunately, there are various avenues to explore when seeking out suitable replacements.

- Online Retailers: Websites specializing in outdoor tools often have extensive catalogs.

- Local Dealers: Authorized distributors can provide genuine components and expert advice.

- Second-hand Markets: Platforms like eBay or Craigslist may have used parts at lower prices.

- Manufacturer Websites: Directly visiting the manufacturer’s site can lead to finding the right components.

- Community Forums: Engaging in online communities can offer recommendations and resources from fellow users.

By exploring these options, you can delve deeper into finding the ultimate replacement for your needs.

Tools Needed for Repairs

Proper maintenance and repair require a specific set of instruments to ensure efficiency and safety. Utilizing the right tools can make tasks smoother and enhance the overall repair experience.

- Wrenches: Essential for loosening or tightening various components.

- Screwdrivers: A variety of types is needed for different screws.

- Pliers: Useful for gripping and manipulating small parts.

- Socket Set: Provides versatility for various bolt sizes.

- Fuel Stabilizer: Helps maintain engine performance during storage.

Having these essential tools at hand will ultimately streamline the repair process and contribute to successful outcomes.

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your equipment requires consistent care and attention. By implementing regular maintenance practices, you can significantly extend the lifespan and functionality of your tools, reducing the risk of unexpected breakdowns.

| Tip | Description |

|---|---|

| Regular Cleaning | Remove dirt and debris after each use to prevent buildup that can cause damage. |

| Check Fluids | Ensure oil and fuel levels are adequate and change them as recommended to maintain performance. |

| Inspect Components | Regularly examine all parts for wear and tear, replacing any that show signs of damage. |

| Sharpen Blades | Keep cutting edges sharp to ensure efficient operation and reduce strain on the engine. |

| Store Properly | Store in a dry, protected area to prevent rust and deterioration during off-seasons. |

Understanding the Assembly Process

The assembly process is a crucial aspect of ensuring that mechanical devices function efficiently and reliably. It involves the systematic arrangement and connection of various components, each playing a significant role in the overall operation. A clear understanding of this procedure not only enhances productivity but also minimizes errors and enhances safety during operation.

In order to grasp the intricacies of the assembly, it’s essential to break down the components involved and their respective functions. Each part must be accurately placed and secured to guarantee optimal performance. The following table outlines the typical stages of assembly along with key considerations:

| Stage | Description | Key Considerations |

|---|---|---|

| Preparation | Gathering all necessary components and tools. | Ensure all items are present and in good condition. |

| Arrangement | Organizing components in a logical order for assembly. | Follow the layout to avoid confusion during assembly. |

| Assembly | Connecting parts according to the specified procedure. | Use appropriate tools and techniques to secure connections. |

| Testing | Checking the assembled unit for functionality. | Conduct tests to verify performance meets standards. |

| Finalization | Completing any final adjustments and ensuring quality control. | Inspect for any defects and make necessary corrections. |

By following a structured approach to assembly, one can significantly improve the reliability of the final product, ensuring it operates as intended. Attention to detail at each stage is paramount to achieving a high-quality assembly.

Frequently Asked Questions

This section aims to address common inquiries related to the maintenance and repair of lawn equipment. Understanding these aspects can enhance user experience and prolong the lifespan of your machinery.

What should I do if I can’t find a specific component?

If a particular piece is elusive, consider checking online retailers or contacting the manufacturer for guidance. Additionally, local repair shops may have access to the parts you need.

How can I ensure proper installation of replacement items?

Refer to the user manual for detailed instructions on installation. Watching tutorial videos can also be helpful, providing visual guidance for a more straightforward process.

User Reviews and Experiences

This section explores the insights and feedback from users who have interacted with a specific outdoor power tool. Their testimonials highlight a variety of perspectives, from reliability and ease of use to maintenance challenges and performance issues. By delving into these experiences, potential buyers can gain a clearer understanding of what to expect.

Many users have praised the overall functionality and effectiveness of the equipment. They often mention how it meets their needs for lawn care and other outdoor tasks, making their work easier and more efficient. Several reviews indicate satisfaction with the machine’s durability, noting that it withstands various weather conditions without significant wear.

However, some users have encountered difficulties, particularly related to assembly and parts replacement. Common concerns include the availability of replacement components and the complexity of the user manual. These reviews serve as valuable feedback for potential purchasers to consider before making a decision.

Comparing with Similar Models

When evaluating a particular outdoor power equipment model, it is essential to consider how it stacks up against its counterparts. This comparison can highlight distinct features, performance metrics, and overall value, helping potential users make informed decisions tailored to their specific needs.

Key Features and Performance

Examining key attributes such as engine capacity, cutting width, and ease of maintenance provides insight into the equipment’s effectiveness. While some models may excel in power, others might prioritize user-friendliness, ultimately impacting the selection process.

Cost-Effectiveness and Durability

Understanding the pricing structure and longevity of similar machines is crucial. A higher initial investment might yield better durability and performance over time, making it a more favorable option for users who seek long-term reliability and efficiency.

Contacting Customer Support

When encountering issues with your equipment, reaching out for assistance can be crucial for a swift resolution. Customer support serves as a vital resource, providing guidance and solutions tailored to your specific needs. It’s essential to know the best methods to get in touch for effective communication.

Methods of Contact

You can typically connect through various channels such as phone, email, or live chat. Each option offers unique advantages, so choose the one that best fits your situation. Ensure you have all relevant information handy to streamline the process.

What to Expect