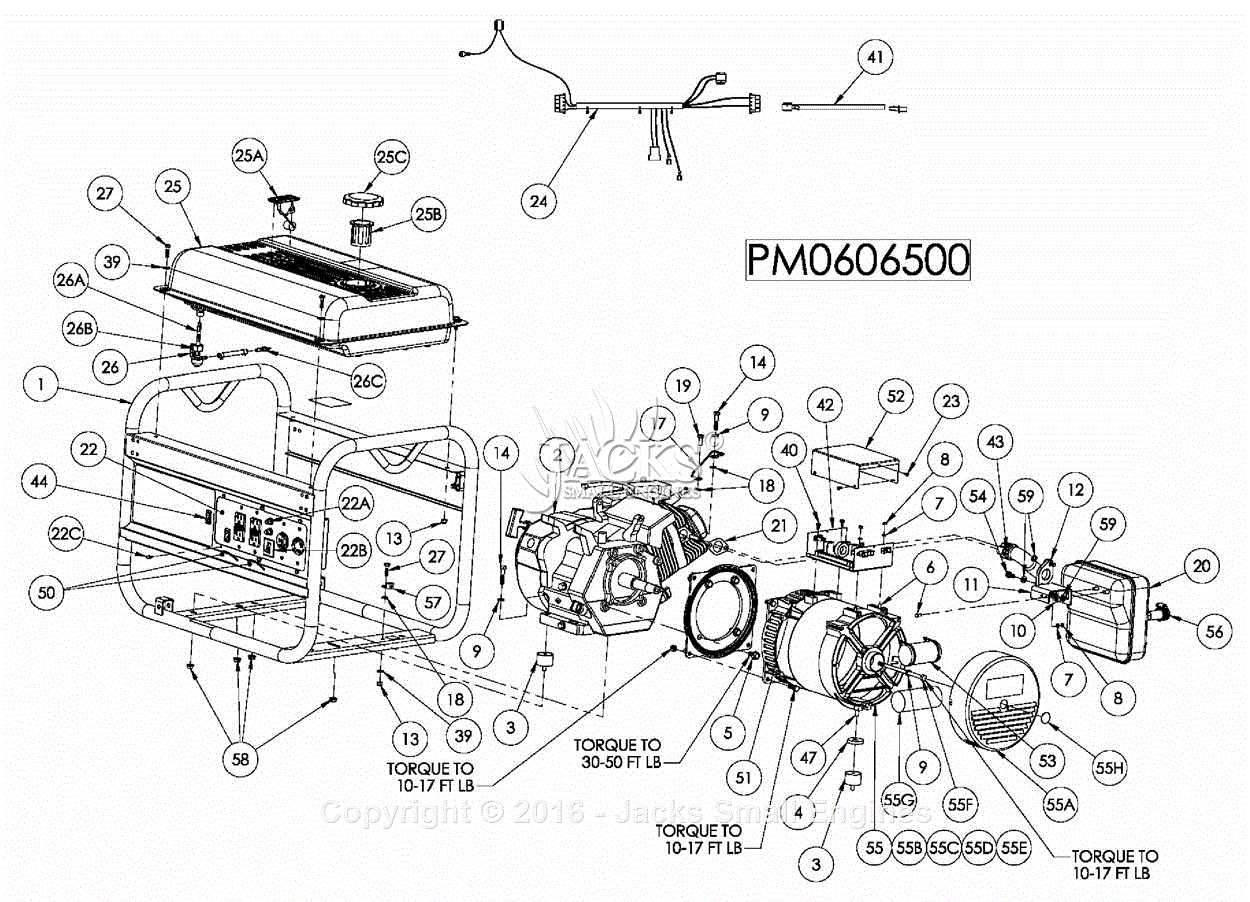

Coleman Powermate 6250 Parts Diagram Overview

In the realm of portable energy solutions, ensuring the longevity and efficiency of your device is paramount. A thorough comprehension of the internal structure and components can greatly enhance your ability to maintain and troubleshoot your equipment. This guide aims to elucidate the essential elements that comprise a typical generator model, providing valuable insights into their functions and interconnections.

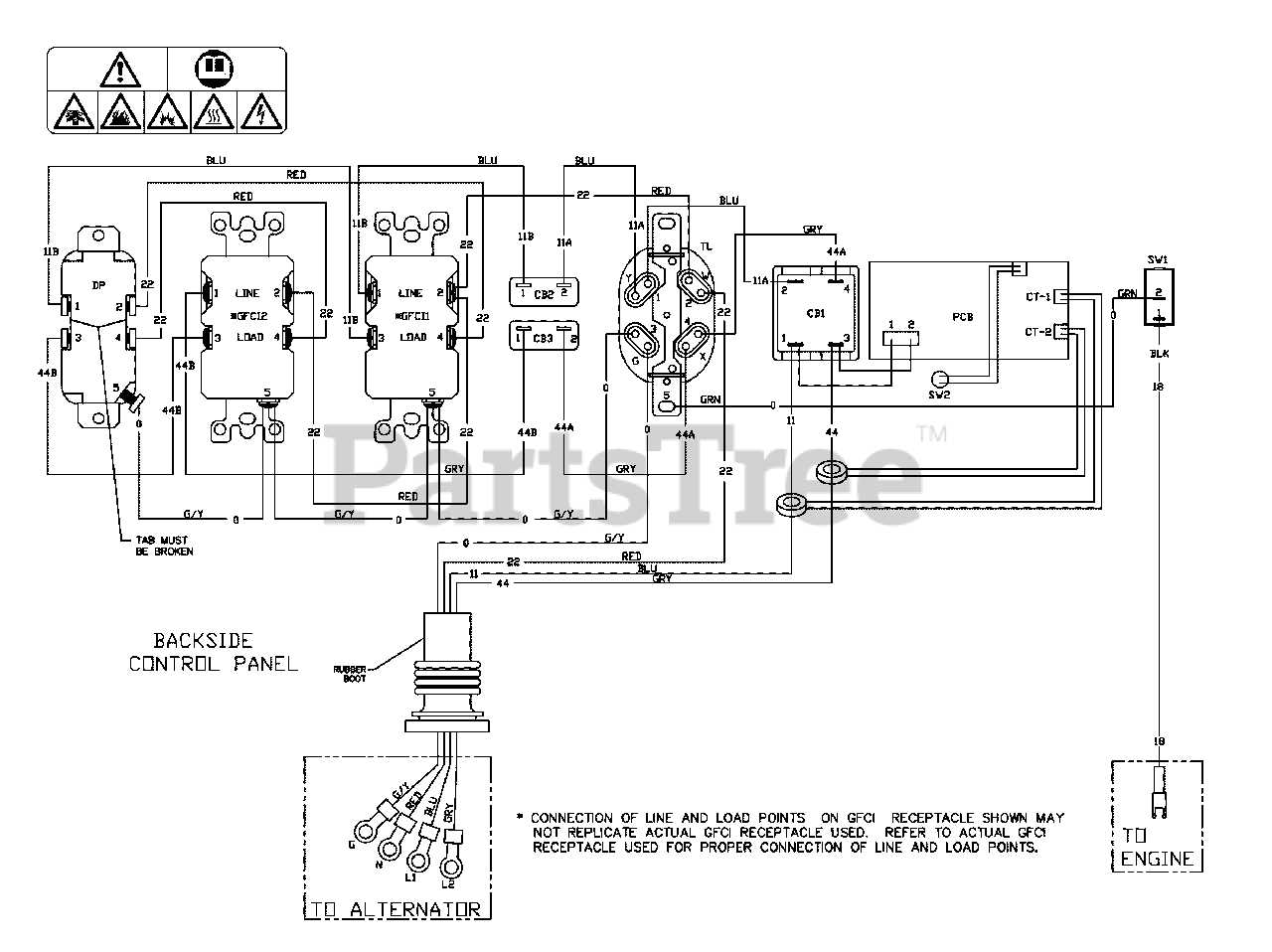

When delving into the intricacies of any power-producing apparatus, having a visual reference can significantly aid in grasping how different components work together. By exploring a schematic representation, users can better identify critical elements, leading to more informed maintenance decisions. This knowledge not only fosters a deeper appreciation of the machinery but also empowers owners to tackle potential issues with confidence.

Furthermore, understanding each segment’s role within the larger system is vital for optimizing performance and preventing unnecessary wear. Whether you are a seasoned technician or a casual user, familiarizing yourself with the internal makeup of your generator will ensure that you can address problems swiftly and effectively. Let’s embark on a journey to decode the essential features that keep your power source running smoothly.

Understanding Coleman Powermate 6250

This section delves into the essential components and features of a widely used portable energy generator. It offers insights into its design and functionality, highlighting the importance of each element in ensuring reliable performance.

Key Features

- Power output capabilities for various applications

- Fuel efficiency and runtime considerations

- Mobility and ease of transportation

- User-friendly controls and indicators

Components Breakdown

- Engine: The heart of the generator, providing necessary power.

- Fuel system: Essential for operation, affecting performance and maintenance.

- Electrical system: Converts mechanical energy into usable electricity.

- Chassis: Provides structural support and enhances portability.

Understanding these aspects is crucial for optimal usage and maintenance, ensuring longevity and reliability for users in diverse scenarios.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding and maintaining machinery. They provide a clear and organized view of each element, facilitating repairs, replacements, and upgrades. These illustrations are essential tools for both professionals and DIY enthusiasts alike, ensuring that tasks are completed efficiently and correctly.

Benefits of Visual Representations

- Clarity: Detailed images eliminate confusion, allowing users to identify specific pieces quickly.

- Guidance: Step-by-step visuals can guide users through complex assembly or disassembly processes.

- Organization: Clear layouts help in categorizing components, making it easier to find what’s needed.

- Efficiency: Reduced downtime occurs when users can swiftly locate and replace faulty items.

Enhancing Knowledge and Skills

- Understanding the functionality of each element improves overall competence in handling equipment.

- Familiarity with visual aids boosts confidence in troubleshooting issues.

- Learning from these guides can cultivate a deeper appreciation for the mechanics involved.

In summary, having access to well-crafted visual resources not only simplifies maintenance tasks but also empowers individuals to engage more deeply with their equipment, enhancing both their skills and confidence in handling repairs.

Common Issues with Coleman Powermate

Many users encounter several frequent problems when operating their portable energy generators. Understanding these issues can enhance reliability and performance. Common challenges range from mechanical failures to electrical malfunctions, affecting the overall efficiency of the unit.

One typical problem involves starting difficulties. Generators may fail to ignite due to various factors, including battery issues, fuel quality, or even environmental conditions. Ensuring proper maintenance and using high-quality fuel can often resolve these concerns.

Another common issue is related to power output. Users may experience fluctuations or insufficient voltage, which can stem from overloaded circuits or internal component failures. Regular inspection of the electrical system and avoiding overloads can help mitigate this risk.

Additionally, noise and vibration problems can arise, which may indicate loose parts or unbalanced components. Tightening screws and ensuring proper alignment can reduce these disturbances, improving user experience.

Lastly, fuel leaks pose a significant safety risk. Regularly checking for cracks in fuel lines or seals can prevent hazardous situations and enhance the longevity of the generator.

Key Components of the Generator

Understanding the essential elements of a power generator is crucial for both operation and maintenance. Each component plays a significant role in ensuring the unit functions efficiently and reliably. Familiarity with these parts can aid users in troubleshooting issues and performing routine upkeep.

Engine: The heart of the generator, this component converts fuel into mechanical energy. Its performance directly affects the output and efficiency of the entire system.

Alternator: This unit is responsible for transforming mechanical energy from the engine into electrical energy. The quality of the alternator impacts the stability and reliability of the electrical output.

Fuel System: This includes the fuel tank, lines, and filter. A well-maintained fuel system ensures that the generator runs smoothly and efficiently by providing a consistent supply of fuel.

Control Panel: This interface allows users to monitor and manage the generator’s operation. It typically includes meters for voltage and frequency, as well as switches and indicators for status alerts.

Cooling System: Effective temperature regulation is vital to prevent overheating. This system often includes fans or liquid cooling mechanisms to maintain optimal operating conditions.

Chassis: The framework that supports all components, providing stability and protection. A robust chassis contributes to the overall durability and portability of the generator.

By recognizing these key components, users can better appreciate how each part contributes to the overall functionality of the generator, leading to more effective use and maintenance.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as guides, enabling users to identify and locate various elements within a machine or device. By familiarizing oneself with the layout and symbols used, one can streamline the process of troubleshooting and ordering replacements.

Start with the Legend: Most illustrations include a key that defines the symbols and notations. This legend is crucial for grasping the meaning behind each icon, allowing for accurate interpretation of the drawing.

Identify the Sections: Components are often grouped by functionality or location. Recognizing these sections helps in understanding how different parts interact and where specific items are situated within the overall assembly.

Follow the Flow: Many representations are designed to show the relationship between various elements. Observing the flow can provide insight into how the machine operates, highlighting the sequence in which parts work together.

Cross-reference with Manuals: To enhance comprehension, it’s beneficial to consult accompanying documentation. Manuals often provide additional context, such as installation instructions or troubleshooting tips, which can be invaluable when deciphering the illustration.

Practice Makes Perfect: The more frequently you work with these visual aids, the more adept you will become at reading them. Regular exposure will enhance your ability to quickly locate components and understand their functions within a system.

Replacement Parts Availability

When maintaining or repairing machinery, ensuring access to the necessary components is crucial for optimal performance. Availability of these items can significantly influence the efficiency and longevity of your equipment.

Several factors can affect the accessibility of replacement components:

- Manufacturer Support: Reliable manufacturers often provide extensive catalogs, making it easier to find what you need.

- Aftermarket Options: Third-party suppliers can offer alternative solutions, often at competitive prices.

- Online Retailers: E-commerce platforms have made it simpler to source items, providing customer reviews and competitive pricing.

- Local Stores: Brick-and-mortar shops may carry essential items, allowing for quick access without shipping delays.

To enhance your search, consider these strategies:

- Check official websites for parts listings and specifications.

- Explore online marketplaces for used or refurbished options.

- Join community forums or groups focused on your equipment to gain insights and recommendations.

- Keep an eye on seasonal sales and promotions to save on costs.

By understanding the landscape of component availability, you can ensure your equipment remains functional and efficient for years to come.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. By adopting a proactive maintenance routine, you can extend the lifespan of your machinery and enhance its performance. This section provides essential strategies to keep your unit running smoothly for years to come.

Regular Inspection

Frequent checks on your device can help identify potential issues before they escalate. Look for signs of wear, loose connections, or any unusual noises during operation. Addressing these problems early can prevent costly repairs and downtime.

Proper Storage

When not in use, ensure your equipment is stored in a dry, protected area. Excess moisture can lead to rust and corrosion, while exposure to extreme temperatures may affect internal components. Utilizing a cover can further shield it from dust and debris.

Finding OEM vs Aftermarket Parts

When it comes to sourcing replacement components for your equipment, understanding the difference between original equipment manufacturer (OEM) and alternative options is crucial. OEM products are crafted by the same manufacturer that produced the original item, ensuring compatibility and adherence to specific quality standards. On the other hand, aftermarket alternatives are created by different companies, often at a lower cost, but may vary in quality and performance.

Choosing the right type of component depends on various factors, including budget, intended use, and the importance of warranty coverage. It is essential to evaluate both options carefully to make an informed decision that aligns with your needs.

| Criteria | OEM | Aftermarket |

|---|---|---|

| Quality | High, meets manufacturer standards | Varies, not always guaranteed |

| Cost | Generally higher | Often lower |

| Compatibility | Perfect fit for specific models | May not fit all models perfectly |

| Warranty | Usually covered | Varies, may lack coverage |

| Availability | Limited to manufacturer | Widely available from various sources |

In summary, weighing the benefits and drawbacks of each option will guide you toward the most suitable choice for your specific application. Conduct thorough research and consider reaching out to experts for advice when needed.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to restoring functionality to your equipment. By following each step meticulously, you can diagnose issues effectively and implement necessary repairs with confidence.

- Gather Necessary Tools:

- Screwdrivers (flathead and Phillips)

- Wrenches and pliers

- Replacement components as needed

- Safety goggles and gloves

- Read the Manual: Familiarize yourself with the user manual to understand the layout and specifications of your device.

- Perform Visual Inspection:

- Check for any visible damage or wear.

- Look for loose connections or frayed wires.

- Identify the Problem: Determine the specific malfunction. Is it electrical, mechanical, or a combination of both?

- Disassemble the Unit: Carefully remove any outer casing or covers, noting the placement of screws and components.

- Test Individual Parts:

- Use a multimeter for electrical components.

- Inspect mechanical parts for obstructions or damage.

- Replace Faulty Components: If any parts are damaged, replace them with compatible alternatives. Ensure a proper fit and connection.

- Reassemble the Equipment: Carefully put everything back in place, ensuring that all screws and components are securely fastened.

- Conduct a Final Test: Power on the device to verify that it operates as intended. Monitor for any unusual sounds or behaviors.

By following these steps, you can effectively troubleshoot and repair your machinery, ensuring longevity and optimal performance.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is crucial to prioritize safety to prevent accidents and ensure a smooth workflow. Proper precautions not only protect the individual performing the repairs but also safeguard surrounding equipment and property. Adhering to established guidelines can significantly reduce the risk of injuries and enhance the overall effectiveness of the repair process.

Essential Safety Measures

Before starting any repair work, it is important to wear appropriate personal protective equipment (PPE). This includes gloves, safety goggles, and, if necessary, hearing protection. Ensuring that the workspace is well-ventilated and free from clutter can help minimize hazards. Additionally, familiarize yourself with the tools and components you will be using to avoid mishandling and accidents.

Electrical and Fuel Safety

For tasks involving electrical components or fuel systems, always disconnect power sources and drain any fluids before proceeding. Use insulated tools when dealing with electrical parts to prevent shock. When handling fuel, store it in approved containers and avoid working near open flames or sparks. These precautions are vital in maintaining a safe working environment and preventing potential fire hazards.

Where to Purchase Replacement Parts

Finding the right components for your equipment can enhance its longevity and performance. Whether you’re seeking to replace a worn-out element or upgrade functionality, knowing where to look is essential.

Here are several reliable sources for acquiring the necessary components:

- Authorized Dealers: Start with official retailers who specialize in your brand. They often carry a wide range of components tailored to specific models.

- Online Marketplaces: Websites like Amazon or eBay offer numerous listings. Be sure to check seller ratings and reviews for reliability.

- Local Hardware Stores: Many community stores stock general components and may even assist in ordering specific items.

- Specialty Shops: Some stores focus exclusively on equipment and can provide expert advice alongside their inventory.

- Manufacturer’s Website: Directly visiting the brand’s website can often lead you to a section dedicated to components, including diagrams and specifications.

Always ensure that you verify compatibility with your specific model before making a purchase to avoid any mismatches. Comparing prices and checking for warranties can also provide added peace of mind.