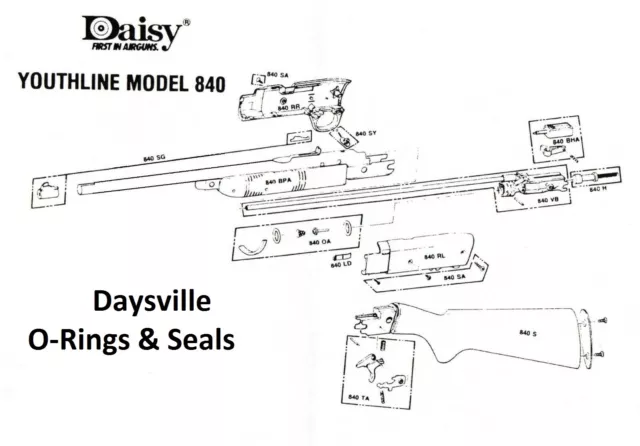

Daisy Powerline 856 Parts Breakdown

When maintaining or repairing air rifles, it is essential to have a clear overview of the internal structure and individual mechanisms. A well-organized schematic helps enthusiasts and technicians navigate through the complex arrangement of elements, ensuring a smoother and more efficient process of replacement or adjustment.

Each piece plays a crucial role in the overall functionality of the rifle. Identifying key components and understanding their interconnectedness allows for precise troubleshooting and upkeep. Whether you’re looking to enhance performance or restore an older model, having a detailed map of the internal system is indispensable.

In this guide, we will explore the various elements that form the core of air rifles. From trigger assemblies to barrel sections, every element will be examined, providing a thorough understanding of how these intricate devices work together.

Overview of Daisy Powerline 856 Components

The internal structure of this air rifle consists of various essential elements that contribute to its overall functionality. Each element plays a crucial role in ensuring efficient performance, from the external frame to the internal mechanisms that operate the firing process. This overview will guide you through the primary components that make up the system.

- Barrel assembly: This part is responsible for guiding the projectile and ensuring accurate shots.

- Compression chamber: This section builds the necessary air pressure for launching the pellet.

- Trigger mechanism: The device that activates the firing sequence when pulled.

- Stock and grip: Provides support and stability for better control during operation.

- Pump lever: Enables the user to manually increase air pressure before firing.

Each of these components is designed to work together, resulting in a precise and reliable shooting experience.

Key Parts of the Daisy Powerline 856

The functioning of this air-powered model relies on several crucial elements that work together to ensure precision and durability. These essential components not only enhance performance but also contribute to the longevity and reliability of the unit.

- Barrel – The central tube through which the projectiles are fired, designed for accuracy and consistency.

- Pump Mechanism – A crucial system that allows for air compression, essential for creating the necessary pressure for operation.

- Trigger Assembly – The responsive control that releases the compressed air, resulting in the discharge of the ammunition.

- Stock and Grip – Provides a sturdy and ergonomic hold for better control and stability during usage.

- Sights – Aiming tools that assist in improving accuracy by aligning the target with the path of the projectile.

- Barrel Assembly: The barrel is designed to guide the projectile accurately. Inside, grooves help in maintaining stability and accuracy during firing.

- Piston and Spring Mechanism: The spring-loaded piston generates the necessary pressure to propel the projectile. It is crucial for generating the necessary force for consistent operation.

- Trigger System: The trigger engages the firing sequence by releasing the compressed spring. Proper tension adjustment ensures safety and functionality.

- Air Compression Chamber: This chamber compresses air as the piston moves, building up the pressure required for the firing process.

- Trigger Lever: The lever is responsible for initiating the firing sequence by releasing the sear when pulled.

- Sear: This part holds the firing mechanism in place until the trigger is engaged.

- Spring: Provides the necessary tension to reset the trigger after each shot, ensuring smooth cycling.

Internal Mechanism Breakdown

The internal components of this air rifle are engineered for precision and reliability. Each part works in harmony to ensure smooth operation, providing a balance between durability and performance. Understanding how these elements interact is key to maintaining the device in optimal condition.

Each of these mechanisms requires regular inspection and upkeep to maintain the air rifle’s functionality. A clear understanding of how they function individually and together is essential for troubleshooting and efficient maintenance.

Understanding the Trigger Assembly

The trigger mechanism plays a crucial role in ensuring the safe and reliable function of the device. This section focuses on how the components within the trigger system interact to provide a smooth and controlled operation. Proper understanding of this mechanism allows for better maintenance and troubleshooting when necessary.

Key Components of the Trigger Mechanism

How the Trigger System Works

- When the trigger is pulled, the lever moves, disengaging the sear.

- The release of the sear allows the firing pin to move forward, initiating

Barrel and Muzzle Construction

The structure of the barrel and muzzle plays a crucial role in determining the overall performance and accuracy of an air rifle. This section explores how these components are designed to enhance precision, stability, and durability. By understanding the engineering behind these elements, it becomes easier to appreciate how they contribute to a reliable and consistent shooting experience.

Component Material Function Barrel Steel or Alloy Provides the path for the projectile, ensuring straight and accurate trajectory Muzzle Reinforced Metal Supports stabilization of the projectile as it exits the barrel, minimizing deviation Stock and Frame Specifications

The components of a firearm’s stock and frame play a crucial role in its overall performance and usability. Understanding these elements can enhance the shooting experience and ensure optimal handling during use. This section outlines the key specifications associated with these vital components.

- Material: The stock and frame can be constructed from various materials, including wood, synthetic polymers, and metals. Each material offers distinct advantages in terms of durability, weight, and aesthetics.

- Length: The length of the stock influences the shooter’s comfort and control. A properly sized stock is essential for achieving accurate aiming and consistent shooting.

- Width: The width of the frame affects the grip and overall handling of the firearm. A comfortable grip is important for maintaining stability during firing.

- Weight: The weight distribution between the stock and frame impacts maneuverability. A well-balanced firearm can enhance shooting accuracy and reduce fatigue during prolonged use.

Attention to these specifications is essential for selecting or modifying a firearm to suit individual preferences and needs. By considering these factors, users can achieve improved performance and enjoyment in their shooting endeavors.

Pump and Compression System Details

The pump and compression system plays a crucial role in the functionality of air-powered devices, providing the necessary force to propel projectiles. This section will delve into the essential components and their interactions, highlighting how each part contributes to the overall performance and efficiency of the mechanism.

Core Components of the System

At the heart of the compression system lies the pump, designed to compress air effectively. This element typically consists of a cylinder and piston assembly, which work in tandem to create high-pressure air. As the piston moves within the cylinder, it compresses the air, storing energy that will later be released to propel the projectile.

Maintenance Considerations

Regular maintenance of the pump and compression system is vital for optimal performance. Ensuring that seals are intact and free from wear can prevent air leaks, which would compromise the system’s efficiency. Additionally, lubricating moving parts can reduce friction and extend the lifespan of the components, ultimately enhancing the device’s reliability.

Sights and Accuracy Adjustments

Achieving precision in shooting requires a comprehensive understanding of aiming devices and their adjustments. Properly configured sights play a crucial role in enhancing target acquisition and improving overall accuracy. This section explores the various types of aiming mechanisms available and the methods to fine-tune them for optimal performance.

The alignment of the sights is fundamental to ensuring accurate shots. Adjustments may include elevation and windage settings, which help compensate for external factors such as distance and environmental conditions. Familiarizing oneself with the specific features of the aiming device can significantly enhance the user’s ability to hit targets consistently.

Regular practice and familiarity with the adjustments not only improve shooting skills but also build confidence. By understanding how to manipulate the sight settings effectively, users can adapt to different shooting scenarios and maintain accuracy under various conditions.

Air Compression Chamber Functionality

The air compression chamber is a critical component in pneumatic mechanisms, serving a vital role in the propulsion of projectiles. This section explores how this chamber operates and its significance in enhancing the performance of the device.

In essence, the air compression chamber facilitates the conversion of energy into kinetic force. It achieves this through a series of processes that involve air intake, compression, and subsequent release. The following points outline its key functionalities:

- Air Intake: The chamber allows ambient air to enter, preparing for the compression cycle.

- Compression Process: As the mechanism cycles, the air within the chamber is compressed, increasing its pressure and density.

- Energy Storage: The compressed air acts as a reservoir of potential energy, ready to be converted into motion.

- Force Generation: Upon release, the high-pressure air expands rapidly, propelling the projectile with significant force.

Understanding the functionality of the air compression chamber is essential for comprehending the overall efficiency and effectiveness of pneumatic systems. Proper maintenance and design considerations are crucial to ensuring optimal performance.

Repair and Replacement Tips

Maintaining the functionality of your equipment is crucial for optimal performance. Understanding the methods for repair and replacement can significantly extend the lifespan of your device. This section will provide useful insights into common practices and essential considerations when addressing issues that may arise during use.

Common Issues and Solutions

Several frequent problems can occur with devices, and knowing how to troubleshoot them can save time and effort. Here are some typical issues and their corresponding solutions:

Issue Recommended Action Decreased Accuracy Check and clean the internal mechanisms; recalibrate as necessary. Inconsistent Power Inspect the battery and connections; replace batteries if needed. Physical Damage Evaluate the extent of damage and replace any broken components. Malfunctioning Trigger Examine the trigger assembly for obstructions; lubricate if necessary. Maintenance Best Practices

Regular maintenance is vital to prevent issues from arising. Adopting a routine can enhance the reliability of your device. Consider the following best practices:

- Clean the exterior and interior components periodically.

- Store in a dry and safe environment to avoid rust or corrosion.

- Keep track of wear and tear; replace worn parts promptly.

Maintenance Advice for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your equipment. By following a few simple guidelines, you can enhance performance and prevent premature wear. Regular maintenance not only preserves functionality but also ensures safety during use.

- Regular Cleaning: Keep your device clean by removing dirt and debris after each use. This prevents buildup that can affect performance.

- Inspect Components: Periodically check all parts for signs of wear or damage. Addressing issues early can prevent more significant problems later.

- Lubrication: Apply appropriate lubricants to moving parts as needed to minimize friction and maintain smooth operation.

- Store Properly: When not in use, store the equipment in a cool, dry place to protect it from environmental factors that can cause deterioration.

- Follow Manufacturer Guidelines: Always adhere to the recommendations provided in the user manual for optimal care and maintenance procedures.

Implementing these practices will help extend the functionality and efficiency of your equipment, ensuring it remains in good condition for many years.