Understanding the Genie Powerlift 900 Parts Diagram

In the realm of aerial equipment, having a clear grasp of the various elements that contribute to functionality is crucial for both maintenance and operational efficiency. Each segment plays a pivotal role in ensuring safe and reliable performance, which is essential for achieving optimal results in any lifting operation.

To facilitate a comprehensive understanding, it is beneficial to explore the intricate design and arrangement of these components. By delving into their interrelationships and functions, users can gain valuable insights that enhance both troubleshooting and repair processes.

Moreover, recognizing how each piece interacts within the larger assembly can lead to improved decision-making when it comes to upgrades and replacements. This knowledge ultimately empowers operators to maintain peak performance and extend the lifespan of their equipment.

Understanding Genie Powerlift 900 Components

This section aims to provide a comprehensive overview of the various elements that contribute to the efficient functioning of this lifting mechanism. Each component plays a vital role in ensuring safety, reliability, and optimal performance, making it essential to familiarize oneself with their functions and interrelationships.

Main Elements

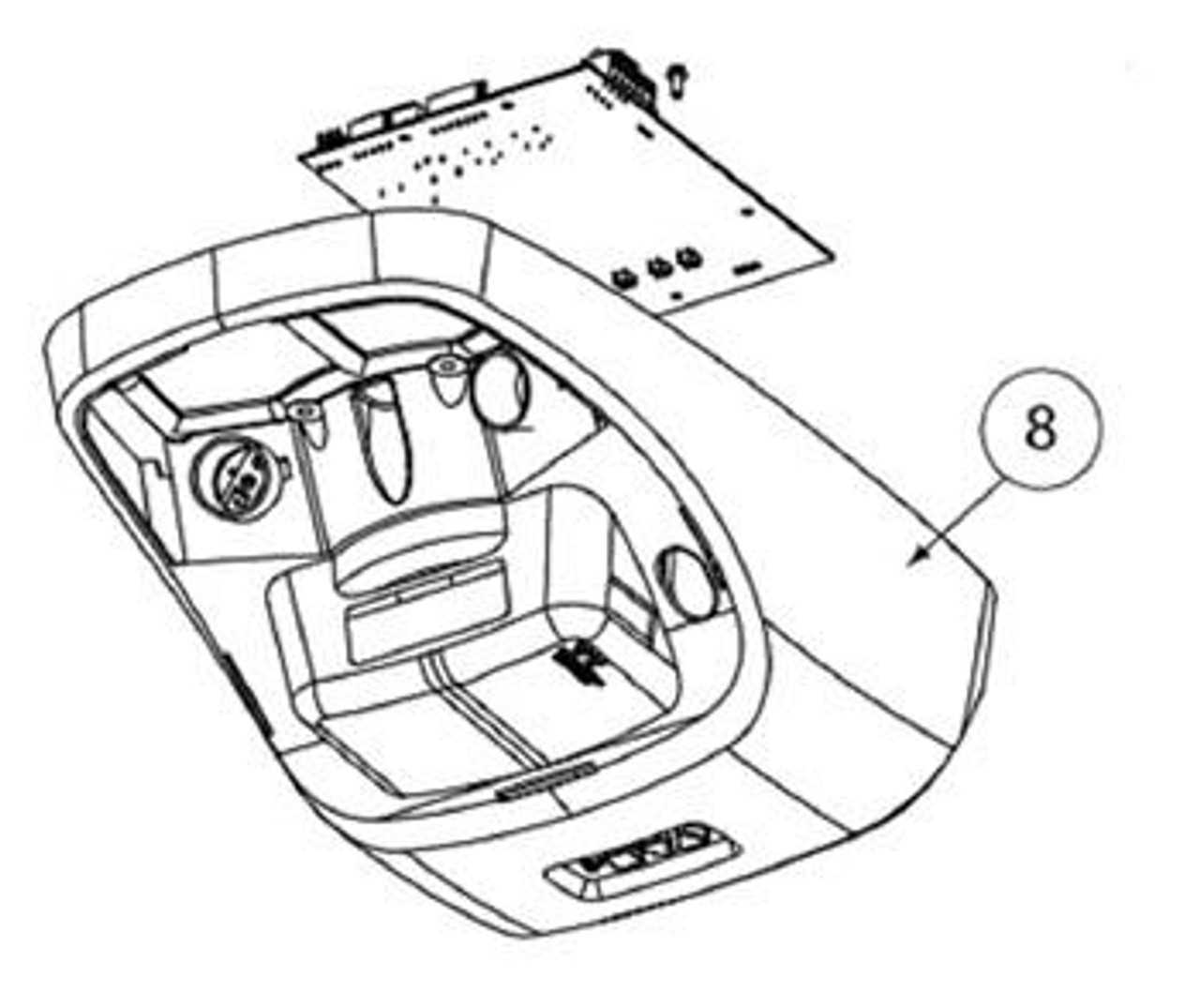

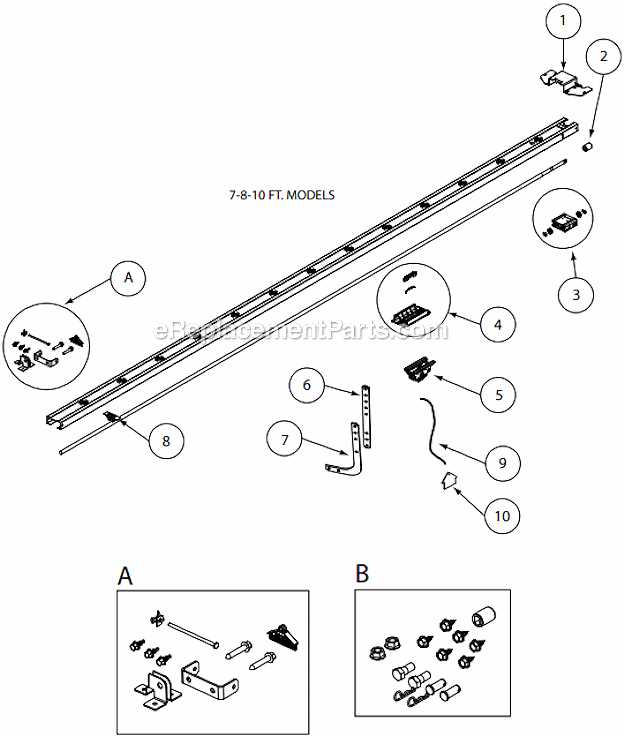

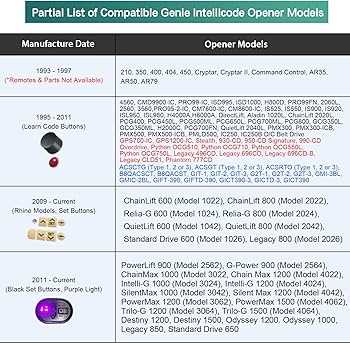

This section provides an insight into the exceptional attributes that enhance the functionality and efficiency of the lifting equipment. Users can benefit from a range of advanced features designed for optimal performance and safety. Understanding the intricacies of mechanical systems is crucial for efficient maintenance and repair. Visual representations of components provide a clear view of how different elements interact, enabling users to diagnose issues swiftly and accurately. These illustrations serve as essential tools for both professionals and DIY enthusiasts, enhancing comprehension and facilitating effective troubleshooting. Visual aids play a significant role in clarifying complex structures. By breaking down assemblies into individual elements, users can gain insights into the functionality and placement of each component. This clarity not only boosts confidence in handling repairs but also minimizes the risk of errors during reassembly. Access to detailed representations can significantly streamline the upkeep process. When users are equipped with accurate visuals, they can identify required replacements or adjustments quickly. This efficiency reduces downtime and enhances the overall performance of the equipment. In any mechanical system, certain challenges can arise that impact performance and efficiency. Understanding these frequent complications is essential for effective troubleshooting and maintenance. Below are some of the most commonly encountered problems, along with their potential causes and solutions. Understanding an assembly illustration is crucial for effective maintenance and repair. These visual representations provide insight into component relationships and facilitate troubleshooting. Regular upkeep of equipment requires a selection of fundamental instruments that ensure efficiency and longevity. Having the right tools not only simplifies the process but also enhances safety during repairs and servicing. Wrenches are indispensable for loosening and tightening bolts, providing the necessary leverage to perform adjustments with precision. Screwdrivers, in various sizes and types, allow for the secure fastening of components and the ability to access hard-to-reach areas. Multimeters are crucial for electrical diagnostics, helping to measure voltage, current, and resistance. Additionally, lubricants play a vital role in reducing friction, which contributes to the smooth operation of moving parts. Finally, cleaning supplies such as brushes and rags ensure that all surfaces remain free of debris, ultimately prolonging the lifespan of the machinery. Equipping yourself with these essential tools allows for effective maintenance and promotes optimal performance. This section explores essential components that play crucial roles in the operation and efficiency of lifting equipment. Understanding these elements can enhance maintenance and improve overall performance. Each of these elements contributes to the ultimate functionality and reliability of the equipment. Finding components for your equipment can sometimes be a challenge, but there are numerous resources available to help you locate what you need. Whether you require a single item or a complete set, understanding where to search can save you time and ensure you get the right fit. Here are some reliable options for sourcing your necessary components: Additionally, consider exploring forums and community groups related to your equipment type. Fellow users can offer insights and recommendations on where to find specific components or share their experiences with various suppliers. By utilizing these resources, you can efficiently locate the necessary components to keep your machinery running smoothly. This section provides a comprehensive approach to fixing common issues with your lifting mechanism. By following these detailed instructions, you can efficiently address problems, ensuring optimal functionality and longevity of the device. Before beginning any repair, gather the necessary tools and familiarize yourself with the components involved. A clear understanding of the assembly will help streamline the process. By following these steps carefully, you can effectively troubleshoot and repair your lifting device, enhancing its performance and reliability. When undertaking maintenance or repair tasks, ensuring safety is paramount. Proper precautions can prevent accidents and injuries, allowing for a smooth and effective workflow. It is essential to be aware of potential hazards and to take the necessary steps to mitigate risks while working on machinery. Wearing appropriate personal protective equipment (PPE) is crucial. Always use safety goggles to shield your eyes from debris, gloves to protect your hands, and steel-toed boots to safeguard your feet. Additionally, consider using ear protection if the equipment operates at high noise levels. Maintain a clean and organized workspace to minimize hazards. Ensure that tools are stored correctly, and that the area is free from clutter. Proper lighting is also essential, as it enhances visibility and reduces the chance of accidents. Always disconnect power sources before beginning any repair work to prevent unintended operation. Maintaining the longevity of mechanical systems requires consistent care and attention. Implementing preventive measures can significantly enhance performance and reduce the need for costly repairs. Regular Inspections: Schedule routine checks to identify wear and tear early. Look for signs of rust, misalignment, or loose components. Lubrication: Ensure all moving parts are adequately lubricated. This minimizes friction and prolongs the life of essential mechanisms. Environmental Considerations: Protect the device from harsh weather conditions. Store in a dry, sheltered area to prevent damage from moisture and debris. Weight Limit Awareness: Always adhere to the manufacturer’s weight specifications. Overloading can lead to premature failure and increased maintenance costs. Prompt Repairs: Address any issues immediately. Delaying repairs can exacerbate problems, leading to more extensive damage. Enhancing the efficiency and functionality of lifting equipment is crucial for optimal performance. By replacing or improving certain elements, users can significantly boost both safety and operational capability. Implementing modern technologies can lead to remarkable advancements: These upgrades not only extend the lifespan of equipment but also enhance overall productivity. This section aims to address common inquiries related to the operation and maintenance of lifting equipment. Whether you’re a user or a technician, you’ll find valuable insights here.Overview of Powerlift 900 Features

Key Attributes

Additional Benefits

Importance of Parts Diagrams

Enhanced Understanding

Streamlined Maintenance

Benefits

Description

Clarity

Provides a clear view of component relationships.

Efficiency

Facilitates quicker diagnostics and repairs.

Confidence

Empowers users to tackle repairs with assurance.

Reduced Errors

Minimizes mistakes during assembly and disassembly.

Common Issues with Genie Powerlift 900

Issue

Potential Cause

Recommended Solution

Motor Not Running

Power supply failure

Check the power source and connections; replace faulty components.

Inconsistent Movement

Worn gears or chains

Inspect and replace any damaged or worn parts.

Excessive Noise

Lack of lubrication

Apply appropriate lubricant to moving parts.

Overheating

Continuous operation or blockages

Allow the system to cool and check for obstructions.

Control Malfunctions

Faulty wiring or switches

Examine electrical connections and replace any defective components.

How to Read a Parts Diagram

Key Elements to Identify

Steps to Effectively Interpret

Essential Tools for Maintenance

Key Parts and Their Functions

Where to Find Replacement Parts

Step-by-Step Repair Guide

Step

Description

Tools Required

1

Disconnect the power supply to ensure safety during repairs.

None

2

Remove the cover to access internal components.

Screwdriver

3

Inspect the motor and gears for signs of wear or damage.

Flashlight

4

Replace any worn parts as necessary to restore functionality.

Replacement Parts

5

Reassemble the cover securely, ensuring all screws are tightened.

Screwdriver

6

Reconnect the power supply and test the system.

None

Safety Precautions When Repairing

Personal Protective Equipment

Workspace Safety

Tips for Prolonging Lifespan

Upgrading Genie Powerlift 900 Components

Frequently Asked Questions

General Inquiries

Troubleshooting Issues