Understanding the Hayward Power-Flo Matrix Parts Diagram

In the realm of aquatic maintenance, comprehending the intricate components of filtration systems is crucial for optimal performance. Each element plays a pivotal role in ensuring that water remains clear and safe for recreational activities. Familiarity with these pieces not only aids in effective troubleshooting but also enhances the overall efficiency of the setup.

Visual representation of these components can greatly assist users in identifying and resolving issues. By breaking down the assembly into manageable sections, one can easily navigate the various elements involved. This approach simplifies the understanding of how each part interacts within the system, allowing for informed decisions regarding repairs or upgrades.

Moreover, a clear depiction serves as an invaluable reference for both novices and seasoned professionals alike. It empowers users to maintain their equipment proactively, ensuring longevity and reliability. Embracing this knowledge ultimately contributes to a more enjoyable and hassle-free experience in maintaining your aquatic environment.

Understanding Hayward Power-Flo Matrix

This section aims to provide clarity on the intricacies of a particular model of pool equipment, focusing on its essential components and how they interact to ensure optimal performance. A comprehensive understanding of these elements is crucial for effective maintenance and troubleshooting.

Key Components and Their Functions

Each element within this equipment plays a vital role in maintaining water circulation and filtration. Familiarity with these components can enhance both longevity and efficiency.

| Component | Function |

|---|---|

| Pump | Circulates water throughout the pool system. |

| Filter | Removes debris and contaminants from the water. |

| Valves | Regulate water flow direction and pressure. |

| Strainer | Catches larger particles before they enter the pump. |

Maintenance Tips

Regular inspection and upkeep of these components can prevent common issues and enhance the overall effectiveness of the system. Paying attention to signs of wear and promptly addressing them can save time and resources in the long run.

Components of Power-Flo Matrix System

The efficient functioning of any water circulation setup relies on various integral elements. Understanding these components is essential for maintaining optimal performance and ensuring longevity. Each part plays a unique role, contributing to the overall effectiveness of the system.

Key Elements

- Filter Unit: This component removes debris and impurities from the water, promoting cleanliness and clarity.

- Pump: Responsible for moving water through the system, ensuring consistent flow and pressure.

- Valves: These regulate the water flow, allowing for adjustments based on specific needs.

- Plumbing Connections: Essential for linking various parts, these connections must be secure to prevent leaks.

Additional Accessories

- Skimmers: These collect surface debris, enhancing the overall filtration process.

- Return Fittings: Designed to direct clean water back into the pool or body of water, facilitating circulation.

- Drainage Systems: Important for maintaining water levels and preventing overflow.

- Maintenance Tools: Various tools assist in the upkeep and repair of the system, ensuring longevity.

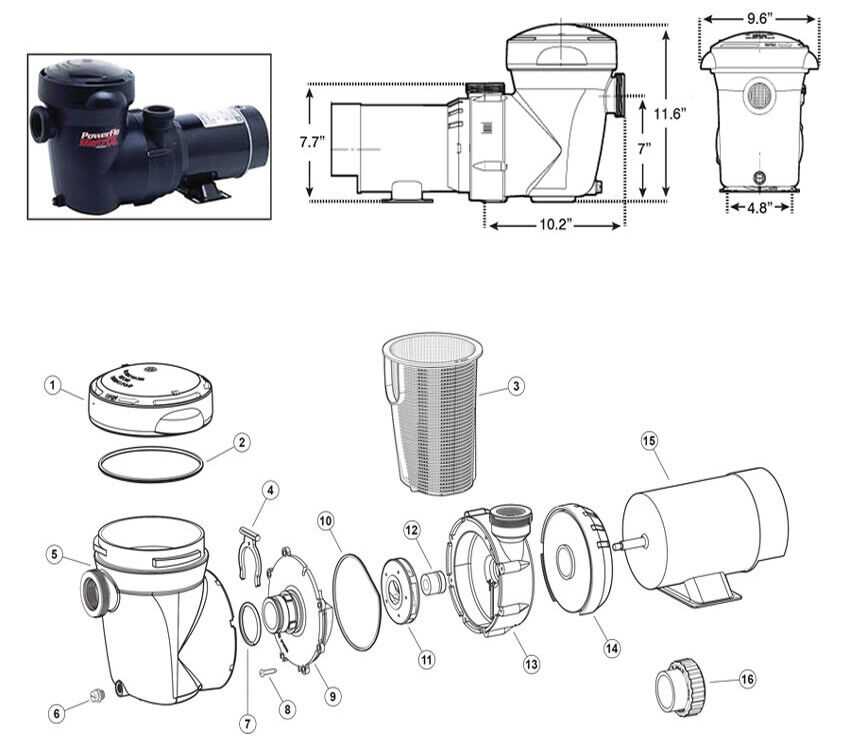

Visual Guide to Parts Diagram

This section provides an insightful overview of the components and their relationships within a specific system. Understanding these elements is crucial for effective maintenance and troubleshooting. By examining the layout and connections, users can gain clarity on how each piece functions and interacts with others.

Below is a representation of the essential elements, which can assist in identifying parts and their placements for better operational efficiency.

| Component | Description | Function |

|---|---|---|

| Element A | Main filtration unit | Removes debris and contaminants |

| Element B | Inlet pipe | Channel for water entry |

| Element C | Outlet pipe | Path for filtered water exit |

| Element D | Motor | Powers the circulation |

| Element E | Control panel | Regulates system operations |

Utilizing this visual guide enhances comprehension, facilitating easier repairs and adjustments. Familiarity with each component’s role allows for informed decisions and efficient handling of the equipment.

Importance of Each Component

Understanding the significance of individual elements within a system is crucial for maintaining optimal performance and ensuring longevity. Each part plays a specific role that contributes to the overall efficiency and functionality of the apparatus. Neglecting any single component can lead to decreased performance or even system failure.

Functional Roles

Each element serves a distinct purpose, whether it be facilitating the flow of fluids, filtering debris, or regulating pressure. For instance, the filtration unit is essential for keeping the water clean and clear, while the motor ensures that the circulation process is efficient. Recognizing these functional roles helps users appreciate how interdependent these components are.

Maintenance and Longevity

Regular maintenance of each component not only extends the lifespan of the entire system but also enhances its effectiveness. Components that are well-cared for will function better, reducing the risk of costly repairs. Understanding the importance of each part encourages proactive maintenance practices, ensuring that every element is in optimal working condition.

Common Issues with Power-Flo Parts

When it comes to pool maintenance equipment, various challenges can arise that affect performance and reliability. Identifying and understanding these frequent problems is essential for ensuring the longevity and efficiency of the system. Below, we explore some typical concerns that users may encounter.

Leaks and Seal Failures

One of the most prevalent issues is the occurrence of leaks. These can stem from worn-out seals or gaskets, leading to significant water loss and reduced efficiency. Regular inspections are crucial to catch these problems early. Replacing damaged components promptly can help maintain optimal operation.

Clogging and Debris Buildup

Another common complication involves clogging, which often results from debris accumulation within the system. This can hinder flow and decrease overall effectiveness. Regular cleaning and maintenance, including filter replacement, are vital to prevent these blockages and ensure smooth operation.

How to Identify Replacement Parts

Identifying components that need to be replaced can be a straightforward process if approached methodically. Understanding the layout and function of each piece is essential for ensuring proper maintenance and operation of your equipment. This guide will help you navigate the necessary steps to pinpoint which items require attention.

Begin by examining the user manual that accompanies your device. Manuals typically include detailed descriptions of the components, specifications, and sometimes visual references that can aid in identification. If the manual is unavailable, you may find similar information on the manufacturer’s website or by contacting customer support.

Next, conduct a visual inspection of the unit. Look for signs of wear, damage, or any irregularities that may indicate a malfunctioning component. Taking note of any unusual sounds or performance issues can also help narrow down the possibilities.

To assist in your identification process, refer to the table below, which outlines common signs and their corresponding components:

| Symptom | Potential Component |

|---|---|

| Leaks or dripping | Seals or gaskets |

| Noisy operation | Bearings or motor |

| Poor performance | Filters or impellers |

| Overheating | Cooling system parts |

Once you have gathered all relevant information, you can confidently proceed to acquire the necessary replacements. Whether through online retailers, local suppliers, or direct from the manufacturer, ensuring you have the right components is key to restoring functionality.

Maintenance Tips for Longevity

Ensuring the prolonged efficiency of your equipment requires a proactive approach to upkeep and care. Regular maintenance not only enhances performance but also extends the lifespan of the unit, reducing the likelihood of unexpected failures and costly repairs.

1. Regular Inspections: Schedule routine checks to identify wear and tear. Look for signs of damage or corrosion that may indicate underlying issues.

2. Cleanliness is Key: Keep the unit free from debris and dirt. Regularly clean filters and other accessible components to maintain optimal flow and prevent blockages.

3. Lubrication: Apply suitable lubricants to moving parts as recommended by the manufacturer. This reduces friction and minimizes wear, ensuring smooth operation.

4. Monitor Water Chemistry: Regularly test and balance the water chemistry to prevent damage from corrosive elements. Proper levels can prevent scaling and enhance overall performance.

5. Seasonal Preparation: Before winter or extended downtime, ensure that the system is properly drained and winterized to avoid freeze damage.

6. Follow Manufacturer Guidelines: Adhere to the maintenance schedule provided in the user manual. Specific recommendations can significantly impact the longevity and efficiency of the device.

By implementing these practices, you can enhance the durability of your equipment, ensuring it operates effectively for years to come.

Installation Process for New Parts

When it comes to upgrading or replacing components in your system, following a systematic approach is essential for ensuring optimal performance and longevity. This section outlines the necessary steps to effectively install new elements, making the process seamless and efficient.

Preparation Steps

- Gather all required tools and materials to avoid interruptions.

- Refer to the user manual for specific instructions related to your model.

- Ensure that the system is turned off and disconnected from the power source.

Installation Steps

- Remove the old components carefully, noting the arrangement for reference.

- Clean the area to eliminate any debris or residue that may hinder the new installation.

- Align the new components according to the manufacturer’s specifications.

- Securely attach the new elements, making sure all fittings are tight to prevent leaks.

- Reconnect the system to the power source and perform a test run to ensure proper functionality.

Following these guidelines will help ensure a successful installation, enhancing the overall efficiency of your equipment.

Comparing Power-Flo Matrix Models

When exploring different models of filtration systems, it’s essential to understand their unique features and capabilities. Each version offers distinct advantages, catering to various needs in water management and pool maintenance. Analyzing these differences can help users make informed decisions about which system best suits their requirements.

Model Variations can include differences in flow rates, efficiency levels, and design configurations. Some models are optimized for larger installations, while others are designed for compact spaces. This versatility allows for tailored solutions depending on the specific environment and usage demands.

Performance Metrics such as energy consumption and maintenance frequency also play a crucial role in the comparison. Users should consider how often they will need to service each model and what the energy costs will look like over time. A model that is efficient in performance may lead to long-term savings, making it a wise investment.

Ultimately, choosing between these systems involves evaluating personal preferences, budget constraints, and intended usage. By comparing the features and specifications of each variant, users can identify the most suitable option for their needs, ensuring optimal functionality and satisfaction.

Cost Factors for Replacement Parts

When it comes to the maintenance of pool equipment, understanding the financial implications of substituting components is essential. Various elements influence the overall expenses, which can impact budgeting and long-term planning for pool owners.

Quality and Brand

The choice of manufacturer can significantly affect the price of components. Higher-quality brands often command a premium, yet they may offer enhanced durability and performance. Conversely, opting for generic or lesser-known brands might reduce initial costs, but this can lead to increased frequency of replacements in the long run.

Availability and Sourcing

Accessibility of specific items can also play a crucial role in determining expenses. Components that are readily available from multiple suppliers tend to be more competitively priced. However, rare or specialized items may incur higher costs due to limited supply and potential shipping fees. Additionally, local sourcing may save on shipping costs and expedite the replacement process.

Where to Buy Genuine Parts

Finding authentic components for your equipment is crucial for maintaining performance and longevity. Quality materials ensure that your system operates smoothly, reducing the risk of breakdowns and enhancing efficiency. Here are some reliable sources for purchasing these essential items.

- Authorized Dealers: Visit certified retailers that specialize in pool and spa supplies. They often carry a comprehensive selection of original components.

- Official Websites: Many manufacturers have online stores where you can directly purchase genuine items. This option often provides the most up-to-date inventory.

- Local Hardware Stores: Some local stores may stock authentic parts. Always verify their reputation and check if they are recognized by the manufacturer.

- Online Marketplaces: Websites such as Amazon or eBay can be convenient, but ensure that you are buying from a reputable seller with verified listings.

- Specialty Shops: Look for stores that focus specifically on swimming pool maintenance and repair. They typically have expert staff who can guide you to the right products.

Prioritize sourcing your components from trusted outlets to ensure you receive quality items that meet industry standards. This approach not only guarantees compatibility but also protects your investment over time.

Customer Reviews and Feedback

Understanding user experiences is essential for anyone considering a purchase. Feedback from customers provides valuable insights into product performance, reliability, and overall satisfaction. This section highlights various opinions and evaluations from individuals who have used the equipment, offering a well-rounded perspective.

| Reviewer | Rating | Comment |

|---|---|---|

| John D. | ★★★★☆ | Works efficiently and is easy to maintain. Highly recommend! |

| Emily R. | ★★★☆☆ | Decent performance, but installation was a bit challenging. |

| Michael S. | ★★★★★ | Exceeded my expectations! Great value for the price. |

| Sarah K. | ★★☆☆☆ | Had some issues with durability after a few months. |

| David T. | ★★★★☆ | Customer support was helpful, and the product performs well. |

Overall, the feedback showcases a range of experiences, emphasizing both positive aspects and areas for improvement. This information can assist potential buyers in making informed decisions.

Future Upgrades for Power-Flo Matrix

As the demand for enhanced efficiency and performance in aquatic systems continues to rise, exploring advancements for existing filtration models becomes essential. Innovations in technology can significantly improve user experience and overall functionality. This section discusses potential enhancements that could redefine the effectiveness of current systems.

Key areas for improvement include energy efficiency, ease of maintenance, and enhanced filtration capabilities. By integrating smart technologies, manufacturers can create solutions that not only optimize performance but also offer users greater control and convenience.

| Upgrade Area | Description |

|---|---|

| Energy Efficiency | Incorporating energy-efficient motors and components to reduce power consumption while maintaining performance. |

| Smart Technology | Integration of IoT features for remote monitoring and automated adjustments, enhancing user control. |

| Enhanced Filtration | Development of advanced filtration media to improve water clarity and quality, reducing the need for frequent maintenance. |

| Modular Design | Creating a modular system that allows for easy upgrades and replacements, prolonging the lifespan of the equipment. |

These advancements not only promise improved functionality but also contribute to a more sustainable approach to water management, making future systems more environmentally friendly and user-centric.