Understanding the Powermore 140cc Parts Diagram for Efficient Repairs

In the world of small engines, comprehending the intricate assembly of various elements is crucial for both enthusiasts and professionals. This knowledge not only aids in effective maintenance but also enhances performance and longevity. By exploring the structural arrangement of these components, users can gain valuable insights into their functionality and interrelationships.

Every engine consists of numerous parts, each serving a specific purpose that contributes to the overall efficiency and operation. Understanding how these elements fit together can simplify troubleshooting and repairs. A clear representation of this assembly allows for easier identification of individual components, promoting a more streamlined approach to engine care.

Whether you are looking to replace a faulty piece or simply want to familiarize yourself with the mechanics, visual aids can be incredibly beneficial. They provide a comprehensive view, enabling a deeper appreciation for the design and engineering behind these powerful machines. By delving into the layout, one can uncover the secrets to optimal performance and durability.

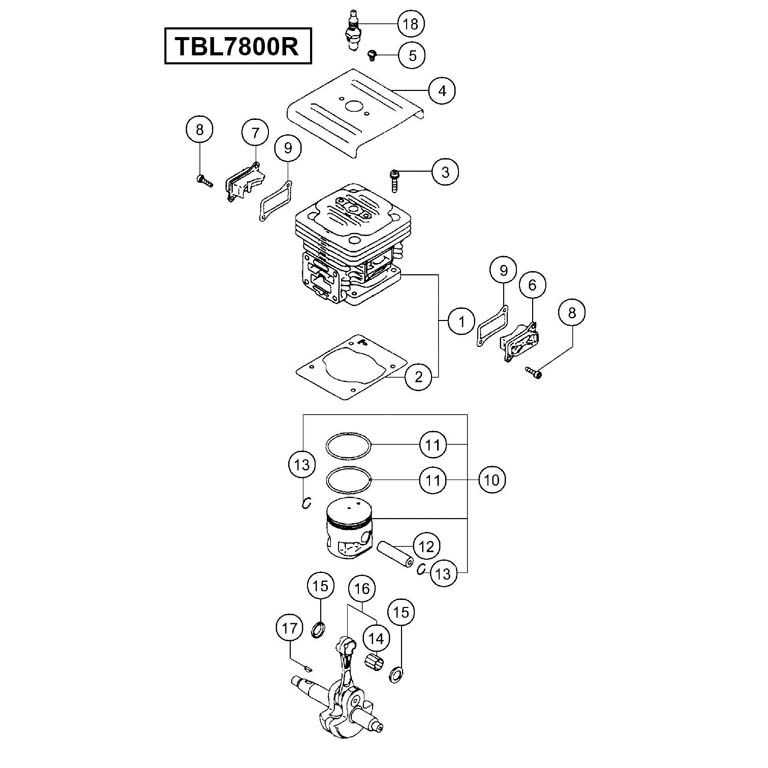

Understanding Powermore 140cc Engine

This section explores the intricacies of a popular small engine commonly used in various outdoor equipment. Gaining insight into its components and functionality can enhance performance and maintenance practices.

- Design: The construction of the engine allows for efficient power generation.

- Components: Key elements include the crankshaft, cylinder, and carburetor, each playing a crucial role.

- Performance: Understanding the mechanics can lead to better operational efficiency and longevity.

By delving into these aspects, users can maximize their equipment’s potential and ensure optimal functioning over time.

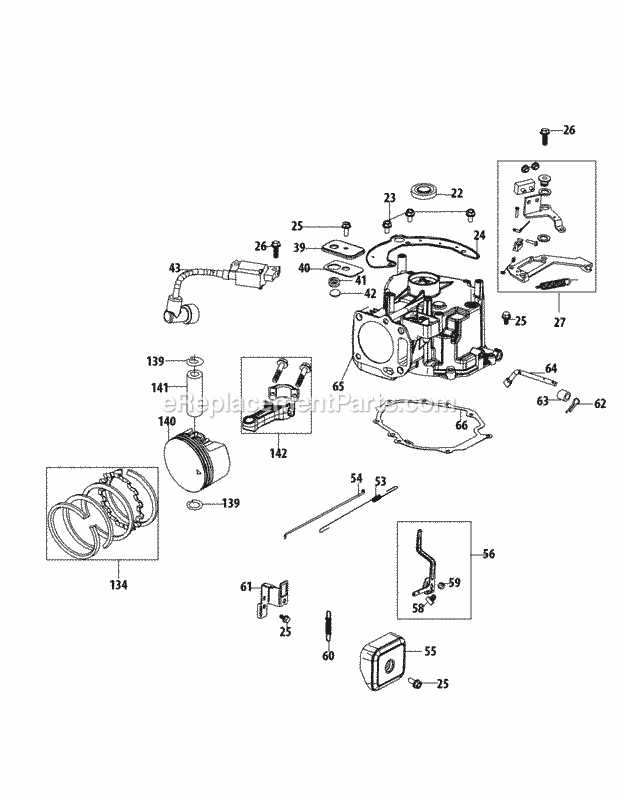

Key Components of Powermore 140cc

This section explores the essential elements that contribute to the functionality and efficiency of small engine systems. Understanding these components is crucial for maintenance and troubleshooting, ensuring optimal performance in various applications.

| Component | Description |

|---|---|

| Cylinder | Houses the combustion process, allowing for the generation of power. |

| Piston | Moves up and down within the cylinder, compressing the fuel-air mixture. |

| Crankshaft | Converts linear motion from the piston into rotational energy. |

| Valves | Regulate the intake of fuel and the expulsion of exhaust gases. |

| Carburetor | Mixes air and fuel in the correct ratio for combustion. |

| Ignition System | Generates the spark needed to ignite the fuel-air mixture. |

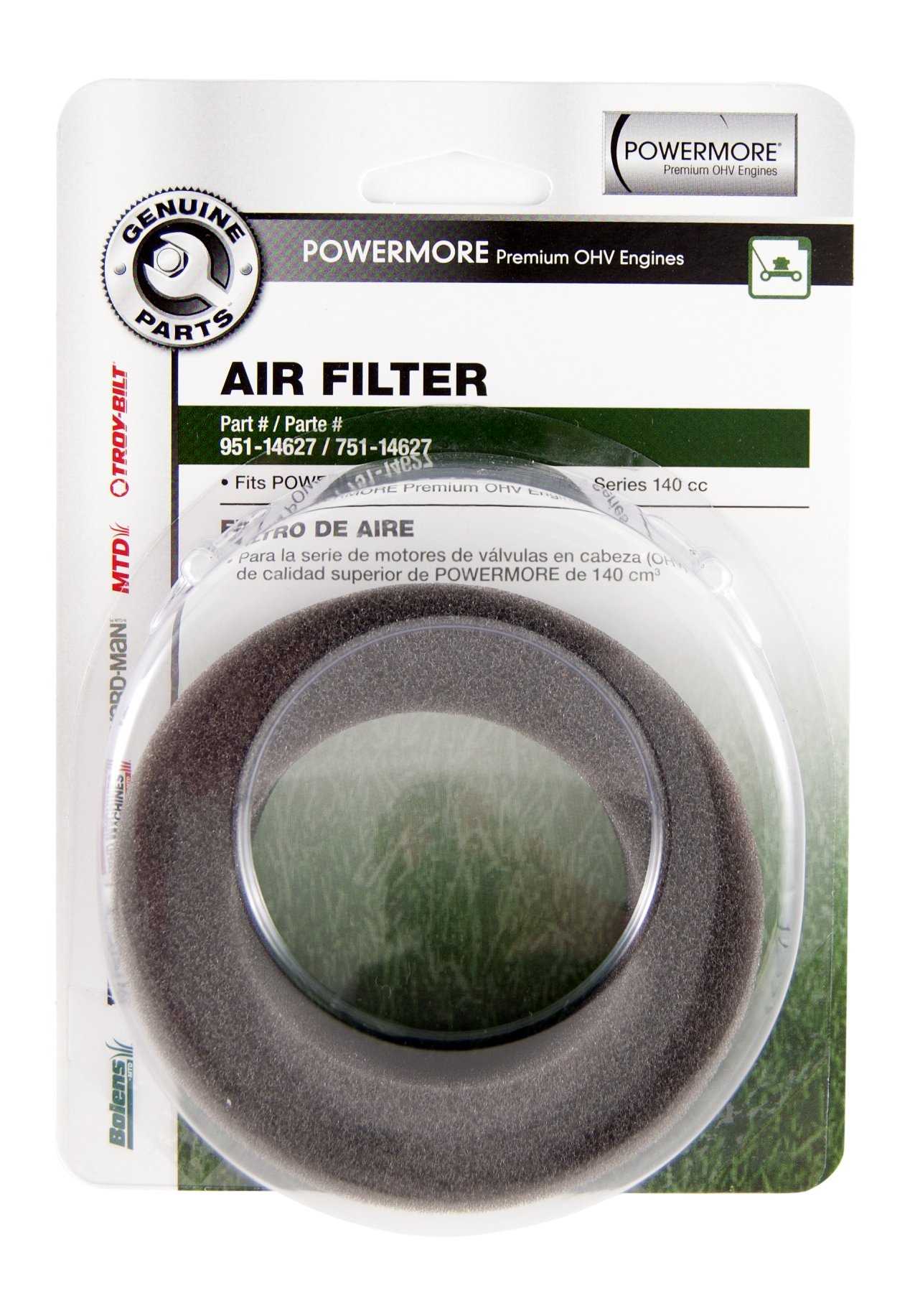

Benefits of Using Original Parts

When it comes to maintaining equipment, opting for authentic components offers numerous advantages that enhance performance and longevity. These elements are designed specifically for compatibility and reliability, ensuring seamless integration with existing systems.

Quality Assurance: Original components are manufactured to stringent standards, guaranteeing durability and effective functionality. This leads to fewer malfunctions and costly repairs.

Optimal Performance: Using genuine parts ensures that the machinery operates at its highest potential. They are engineered to work harmoniously, resulting in improved efficiency and output.

Warranty Protection: Many manufacturers provide warranties on their authentic components, offering peace of mind. This safeguard can cover potential issues, reducing financial risk.

Enhanced Safety: Genuine components are designed with safety in mind, minimizing risks associated with inferior substitutes. This contributes to a safer working environment for users.

Long-term Cost Savings: While authentic components may have a higher initial cost, their reliability often leads to reduced maintenance expenses over time. Investing in quality can save money in the long run.

Common Issues with Powermore Engines

Small engines are widely used in various outdoor equipment, and while they are generally reliable, they can encounter several common challenges. Understanding these issues can help users maintain their machines more effectively and prolong their lifespan. Below are some typical problems that users may face, along with potential solutions.

Fuel-Related Problems

One of the most frequent issues is fuel-related complications. Stale or contaminated fuel can lead to poor performance, causing the engine to stall or fail to start. It’s crucial to use fresh fuel and to store it properly. Additionally, clogged fuel filters or lines can restrict the flow, so regular maintenance and inspection are recommended to ensure optimal operation.

Overheating and Lubrication Issues

Overheating is another concern, often resulting from inadequate cooling or lubrication. Lack of proper oil can lead to friction and severe engine damage. Users should regularly check oil levels and replace oil as needed. Ensuring that air filters are clean and cooling fins are free from debris can also help maintain a suitable operating temperature.

Addressing these common issues promptly can significantly enhance the performance and longevity of small engines. Regular maintenance and attention to detail are key to preventing problems before they arise.

Where to Find Replacement Parts

Locating suitable components for your equipment can be essential for maintaining its performance and longevity. Whether you’re conducting repairs or upgrades, knowing where to search for these items can save you time and ensure you get quality replacements. Various resources are available, both online and offline, to assist in your quest for the right items.

Online Retailers and Marketplaces

The internet is a treasure trove of options. E-commerce platforms host a wide array of suppliers, offering everything from original components to compatible alternatives. Websites such as eBay and Amazon frequently have listings that cater to various needs. Additionally, specialized websites focusing on outdoor equipment often provide detailed catalogs and user reviews, helping you make informed decisions.

Local Stores and Repair Shops

Visiting nearby hardware stores or specialized repair shops can also yield positive results. These establishments often stock essential items and can provide expert advice. Engaging with local technicians might lead you to reliable sources or even used components that are still in great condition. Building relationships with these professionals can enhance your ability to find what you need in the future.

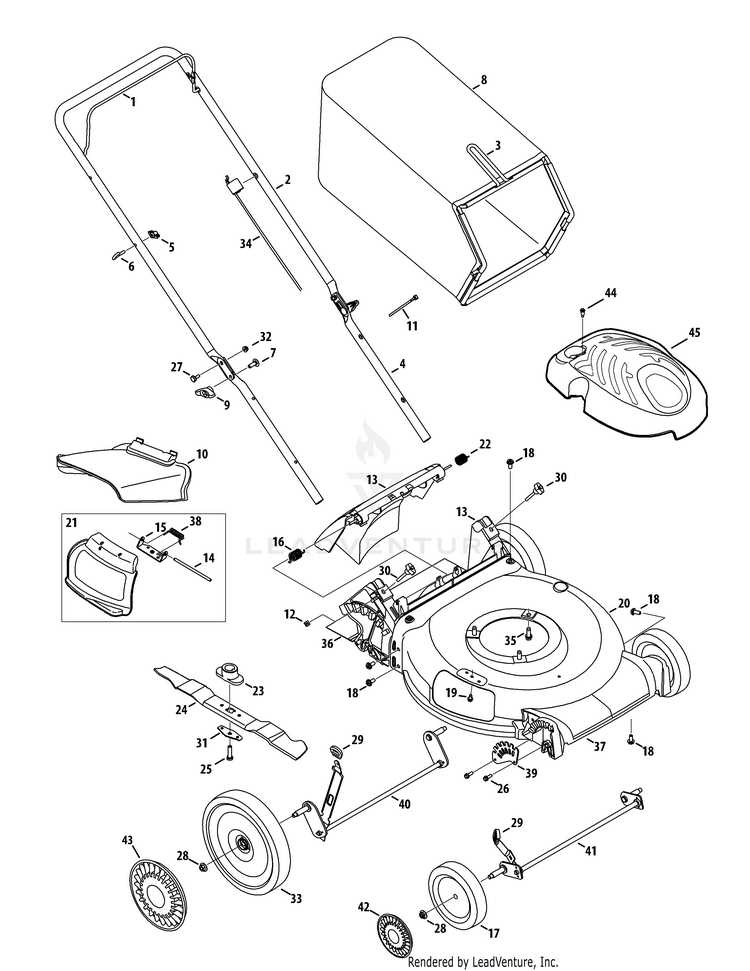

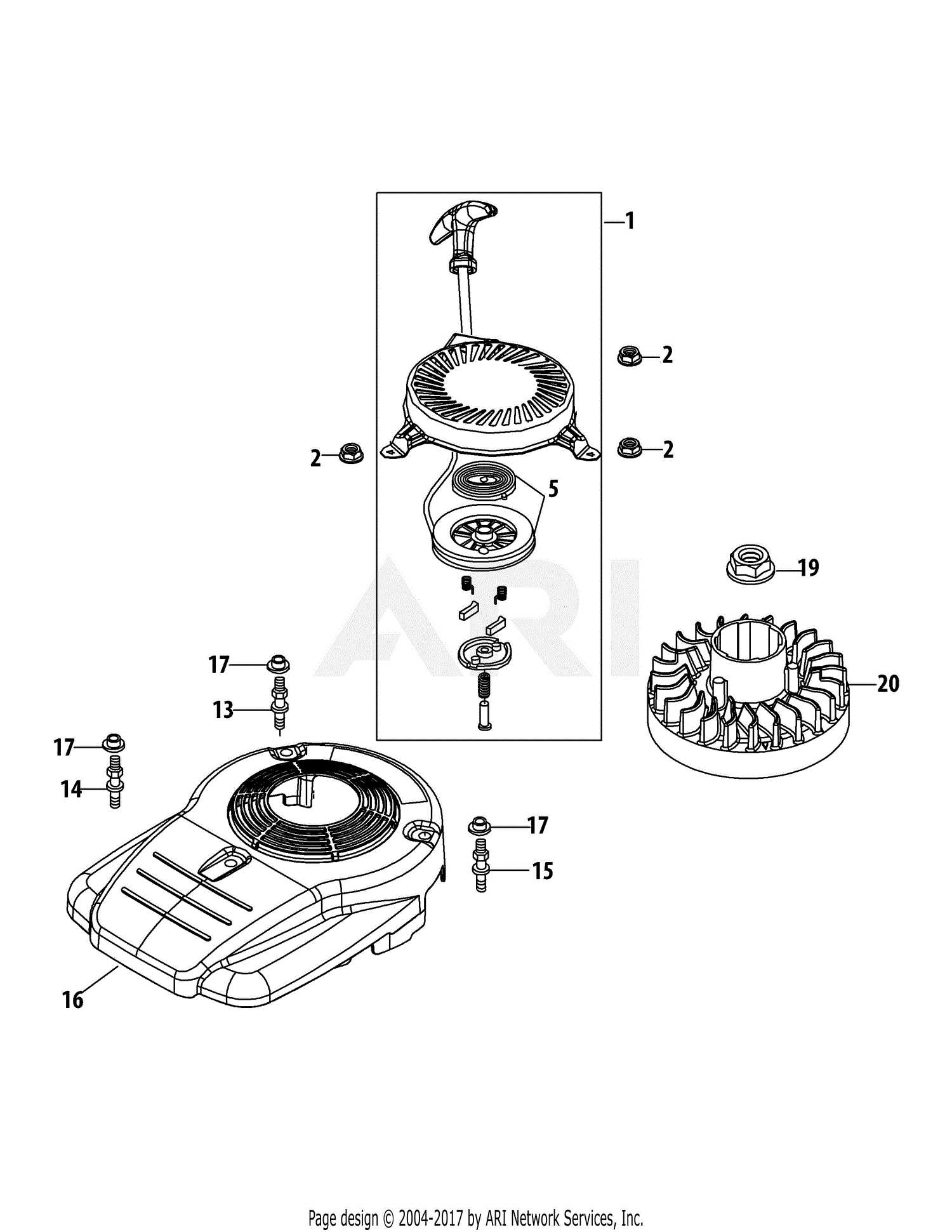

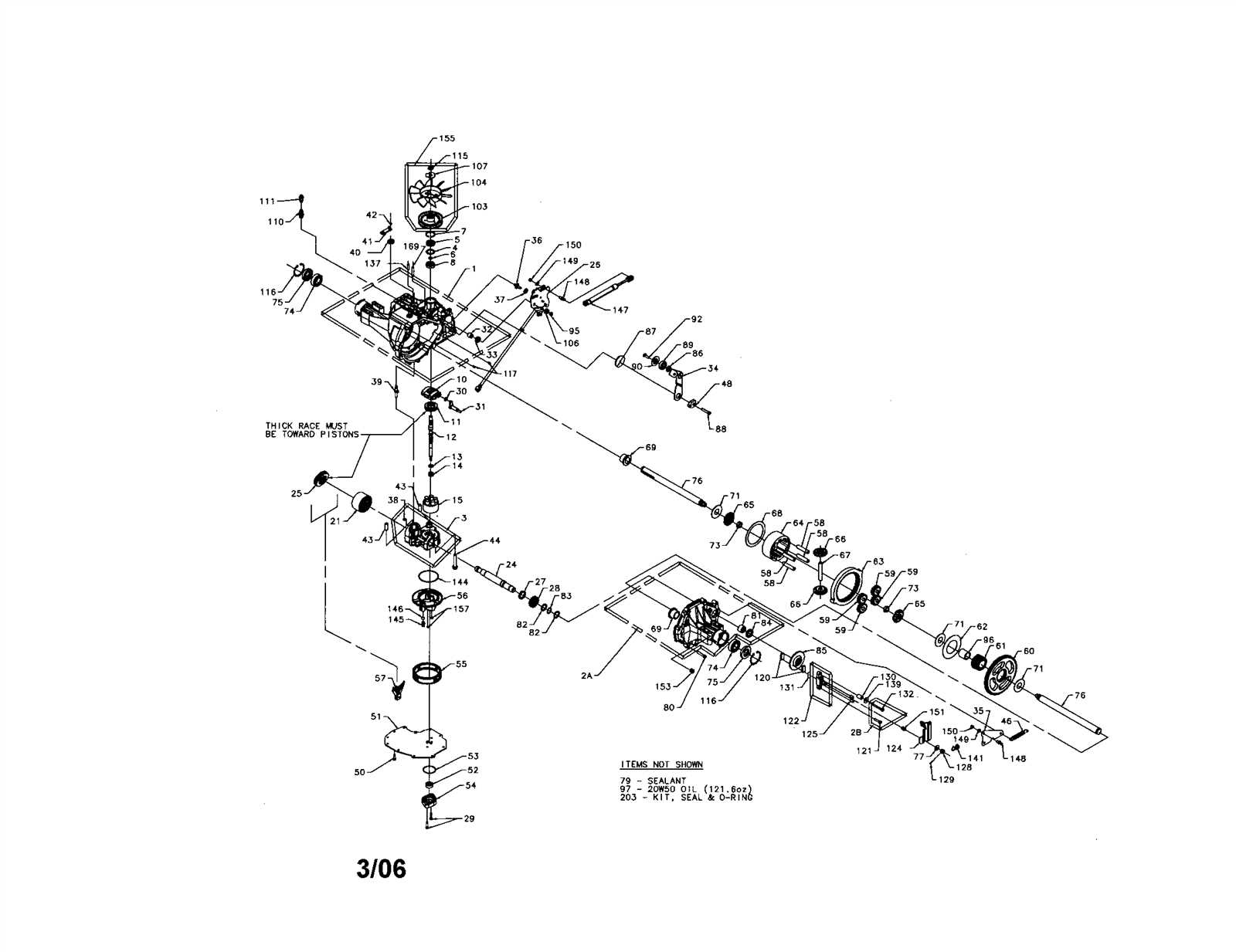

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repairs. These illustrations provide a comprehensive view of components and their relationships, enabling users to identify and locate specific elements quickly.

To navigate these visuals successfully, consider the following steps:

- Familiarize Yourself with Symbols: Each graphic uses unique representations for various parts. Learning these will help you decode the information efficiently.

- Identify the Key: Look for a legend or key that explains the symbols and numbering used in the schematic.

- Follow the Flow: Understand how components interact by tracing connections and paths throughout the illustration.

- Note Groupings: Parts are often categorized into sections. Pay attention to these groupings for easier identification.

- Cross-reference with Lists: Use accompanying lists or descriptions to verify part names and numbers as needed.

By mastering these techniques, you can efficiently navigate and interpret these vital resources for your repair needs.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires regular attention and care. By following a systematic approach to upkeep, you can prevent premature wear and enhance performance, ultimately saving time and resources.

Regular Inspections

Conduct routine checks to identify any signs of wear or damage. Look for loose components, leaks, or unusual noises, as early detection can mitigate larger issues down the line.

Cleanliness and Lubrication

Keep the machinery clean and free from debris. Regularly apply suitable lubricants to moving parts to reduce friction and enhance efficiency. Proper maintenance practices will contribute significantly to the longevity of your equipment.

Tools Needed for Repairs

When it comes to performing maintenance or fixing mechanical equipment, having the right tools is essential for achieving optimal results. The correct instruments not only streamline the process but also enhance safety and efficiency. Below are some indispensable tools that will aid in your repair endeavors.

Wrenches: A set of wrenches in various sizes is crucial for loosening and tightening nuts and bolts. Consider both standard and metric measurements to cover all possibilities.

Screwdrivers: Having a range of screwdrivers, including flathead and Phillips types, ensures that you can tackle any screws you encounter during disassembly or assembly.

Pliers: Pliers are versatile tools that can grip, twist, and cut wires or small components. A pair of needle-nose pliers is particularly useful for accessing tight spaces.

Socket Set: A socket set provides the ability to work with different sizes of fasteners quickly and effectively. This tool is invaluable for tasks requiring significant torque.

Torque Wrench: This tool ensures that you apply the correct amount of force when tightening bolts, which is vital for maintaining the integrity of assembled parts.

Multimeter: For electrical repairs, a multimeter is essential for measuring voltage, current, and resistance, helping diagnose issues efficiently.

Work Light: Proper lighting is key when working on intricate tasks. A portable work light can illuminate dark areas, allowing for better visibility and accuracy.

Equipping yourself with these essential tools will greatly enhance your ability to perform repairs effectively and with confidence.

Assembly Instructions for Parts

Proper assembly is crucial for optimal performance and longevity of your equipment. Following systematic instructions ensures that every component fits together seamlessly, enhancing functionality.

- Preparation:

- Gather all necessary components and tools.

- Read through the instructions thoroughly before starting.

- Initial Assembly:

- Begin with the base unit, ensuring it is stable.

- Attach the main components as indicated, using appropriate fasteners.

- Connecting Parts:

- Securely connect secondary elements to the main structure.

- Double-check each connection for tightness and alignment.

- Final Checks:

- Inspect all assemblies for any loose connections.

- Test the unit to ensure smooth operation before final use.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when performing maintenance or repair tasks. Adhering to essential guidelines helps prevent accidents and promotes efficiency. It is vital to prepare adequately and remain aware of potential hazards throughout the process.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and other necessary equipment to shield yourself from injuries. |

| Work in a Well-Ventilated Area | Ensure that your workspace has proper airflow to avoid inhaling harmful fumes. |

| Disconnect Power Sources | Always turn off and disconnect power supplies before starting any work to prevent electric shock. |

| Keep Tools Organized | Maintain a tidy workspace to minimize the risk of tripping or misplacing tools. |

| Follow Manufacturer Instructions | Consult manuals and guidelines to ensure correct procedures are followed during repairs. |

Comparing Powermore 140cc with Competitors

This section aims to analyze and contrast a specific engine model with its rivals in the market, focusing on performance, durability, and features. By evaluating these aspects, we can gain insights into what makes this engine stand out or fall short compared to others in its category.

Performance Metrics

- Horsepower output

- Torque delivery

- Fuel efficiency

When comparing performance, key metrics include horsepower and torque, which influence the overall effectiveness of the engine in various applications. Additionally, fuel efficiency plays a crucial role in determining long-term operational costs.

Durability and Build Quality

- Material quality

- Maintenance frequency

- Warranty offerings

Durability is assessed through the materials used in construction and how often maintenance is required. Warranty offerings also reflect the manufacturer’s confidence in their product’s longevity, impacting consumer trust.

Customer Reviews and Experiences

This section explores the diverse experiences and feedback from users who have engaged with a specific engine model. Insights from actual customers provide valuable perspectives on performance, reliability, and overall satisfaction, helping potential buyers make informed decisions.

Positive Feedback

- Many users praise the efficiency of the engine, noting that it performs exceptionally well for various tasks.

- Customers frequently highlight its durability, stating that it withstands rigorous use without significant wear.

- Ease of installation is another common compliment, with several reviewers mentioning straightforward assembly processes.

Challenges Faced

- Some users report difficulties in sourcing specific components, which can lead to longer repair times.

- A few customers experienced issues with noise levels, suggesting a need for quieter operation in residential areas.

- There are mentions of limited support resources, which could enhance the user experience for troubleshooting and maintenance.