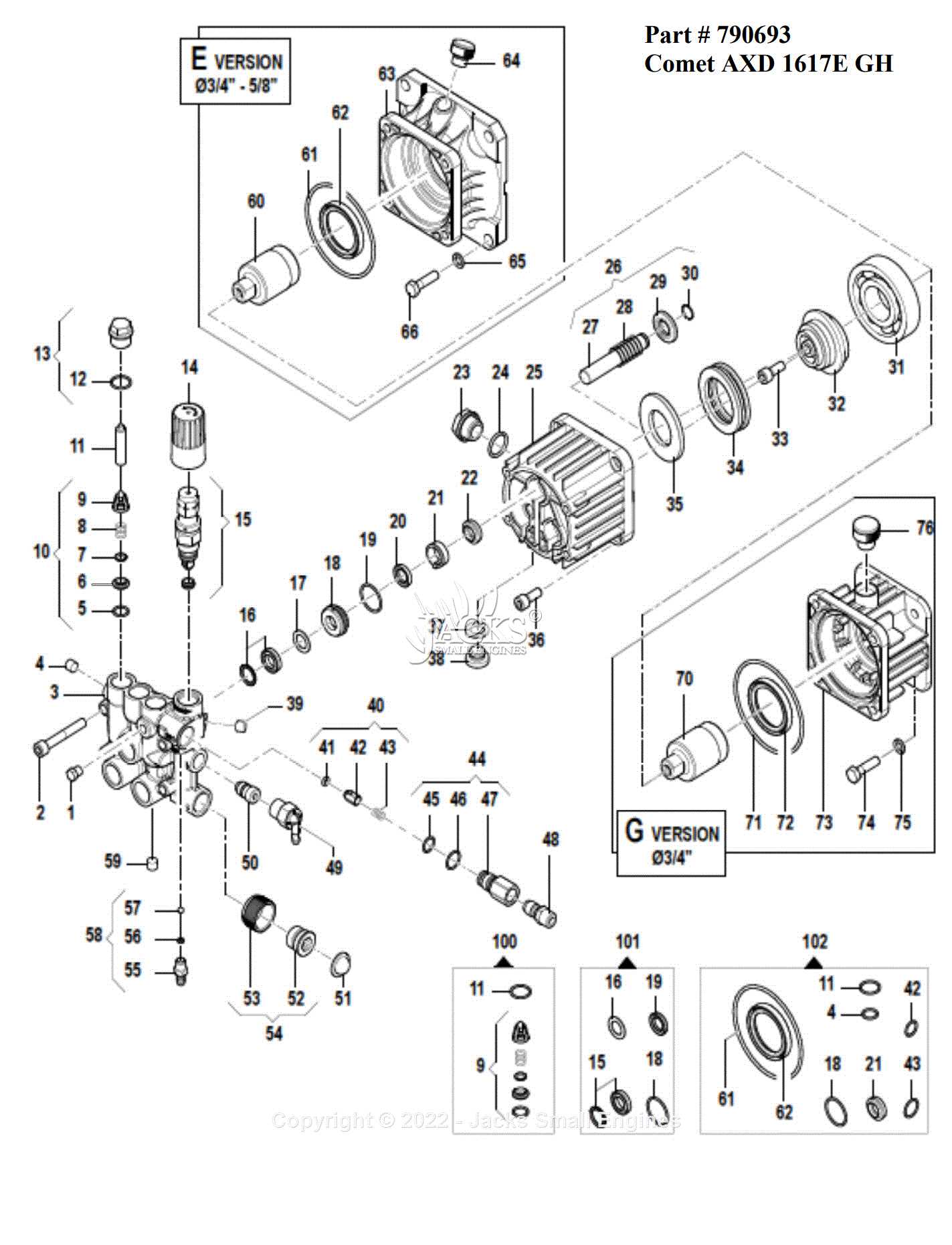

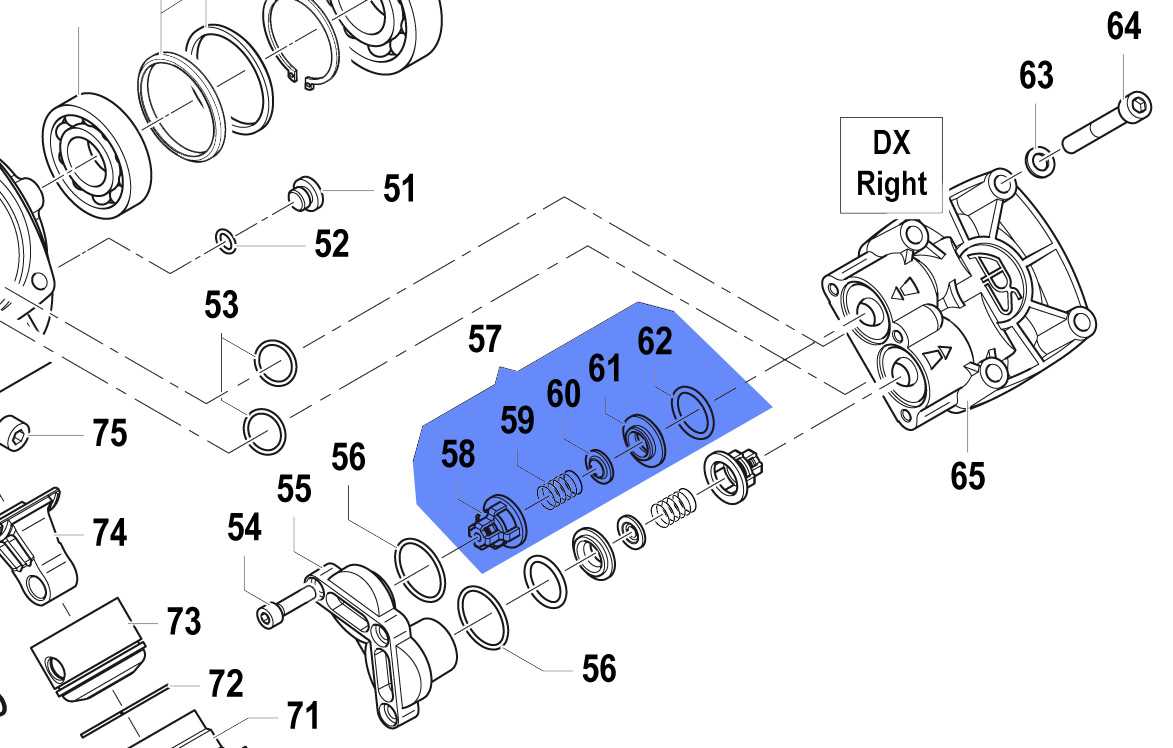

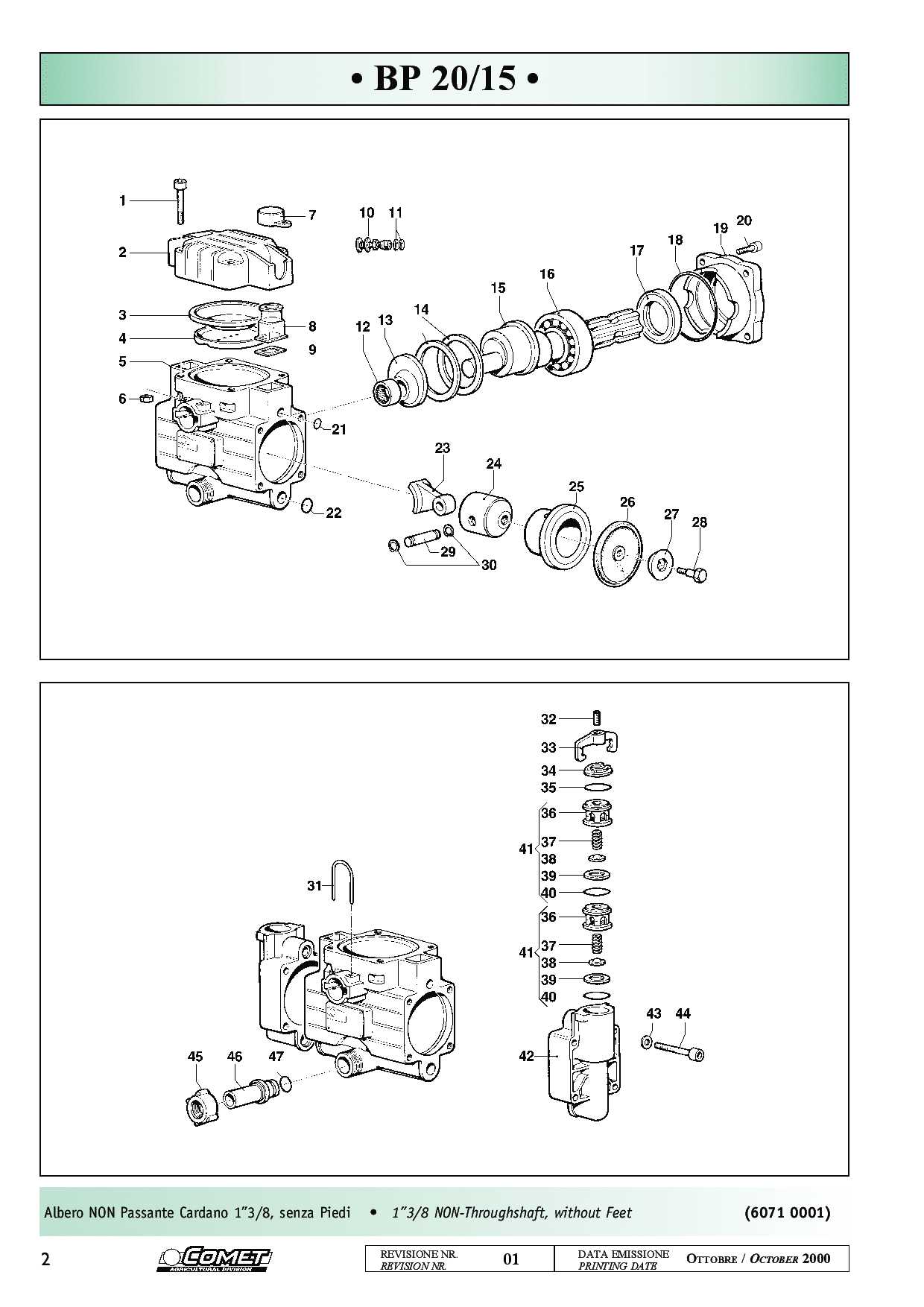

Comet Pump Parts Diagram for Easy Reference

In the realm of fluid mechanics, grasping the intricacies of various equipment is essential for optimal performance. A comprehensive exploration of individual elements reveals their roles and interconnections, enhancing overall functionality. By visualizing these components, one can appreciate the engineering behind effective fluid transfer systems.

Every system is a harmonious blend of mechanics and design, where each element contributes to the efficiency and reliability of the entire apparatus. This examination provides insight into how these intricate devices operate, paving the way for improved maintenance and troubleshooting. Such knowledge empowers users to address issues swiftly and ensure prolonged service life.

Delving deeper into the arrangement of these crucial elements allows for a clearer understanding of their ultimate purpose. Whether in industrial applications or domestic use, knowing the configuration and functionality of each part is key to achieving optimal results. Through this detailed look, one can uncover the principles that drive success in fluid management systems.

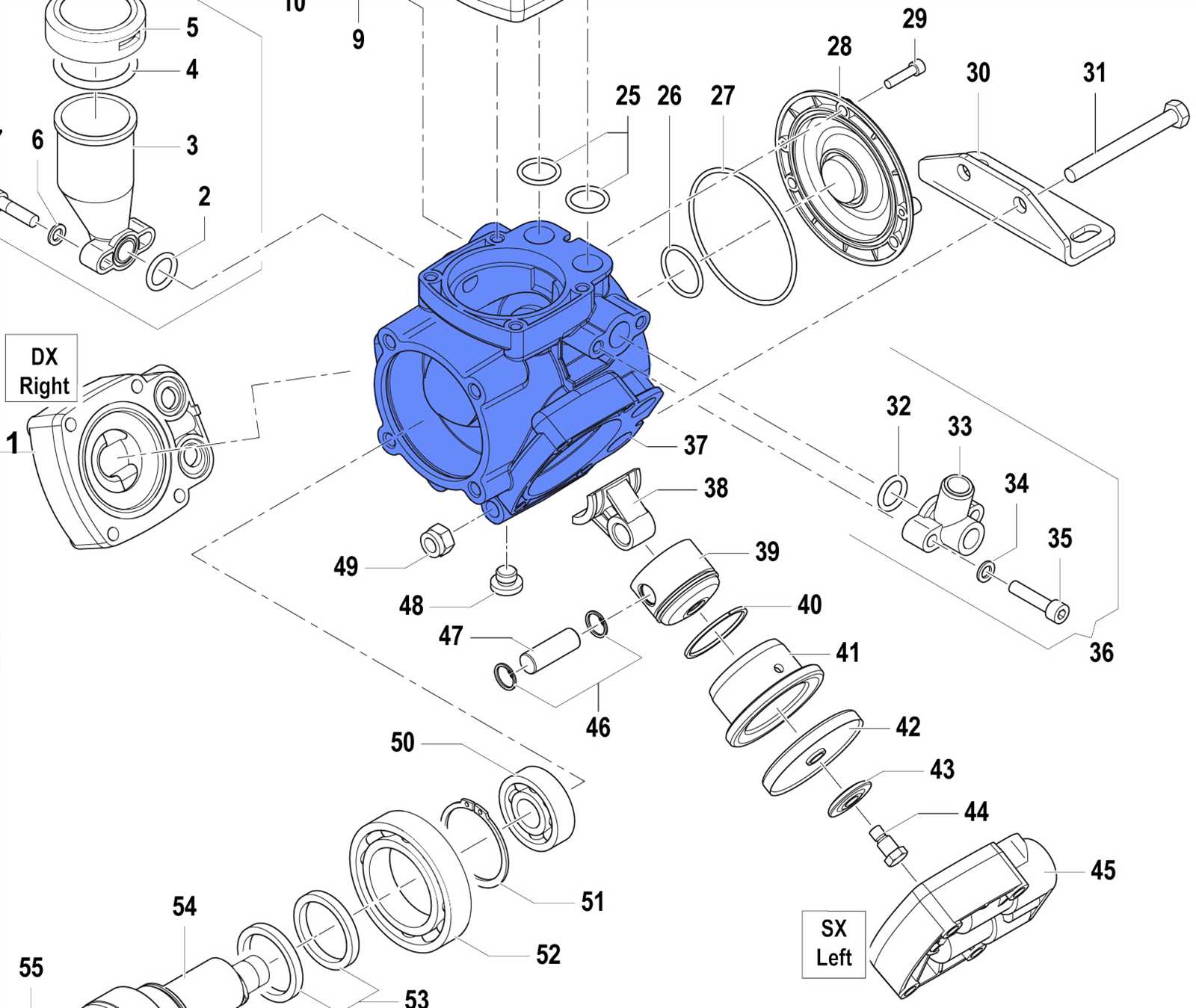

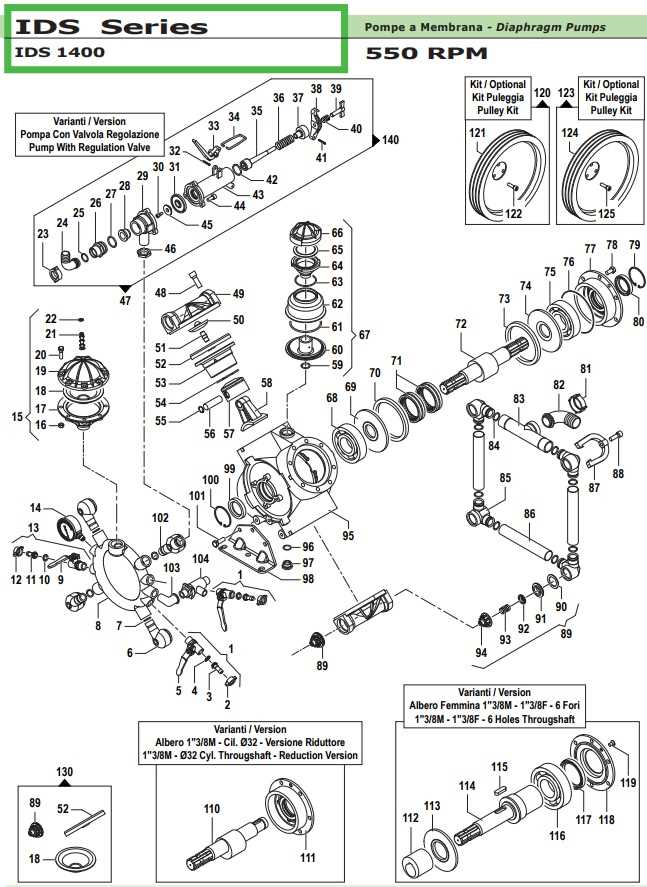

Understanding Comet Pump Components

This section explores the essential elements that constitute a fluid transfer mechanism, focusing on their roles and interconnections. Each component is integral to the overall function, contributing to efficiency and reliability in operation.

| Component | Description |

|---|---|

| Housing | Encases the internal elements, providing protection and structural integrity. |

| Valve Assembly | Regulates fluid flow, ensuring proper direction and pressure management. |

| Piston | Creates the necessary pressure by moving within the cylinder, facilitating fluid movement. |

| Seals | Prevents leakage and maintains pressure, crucial for operational efficiency. |

| Drive Mechanism | Converts energy into mechanical motion, driving the fluid movement process. |

Importance of Accurate Diagrams

Precise illustrations play a crucial role in understanding complex systems. They serve as essential tools for communication, ensuring that everyone involved has a clear grasp of the components and their interactions. Without such clarity, misunderstandings can lead to inefficiencies and errors.

In technical fields, the significance of accuracy cannot be overstated. Detailed visuals help in identifying the essential elements and their functions, making troubleshooting and maintenance more straightforward. This ultimately enhances overall efficiency and safety.

| Benefits of Accurate Illustrations | Consequences of Inaccuracy |

|---|---|

| Clear understanding of systems | Potential for errors and misunderstandings |

| Efficient troubleshooting | Increased downtime and costs |

| Improved safety measures | Risk of accidents and failures |

In summary, accurate representations are indispensable for effective operation and maintenance, underscoring the need for attention to detail in technical documentation.

Common Parts of Comet Pumps

This section explores essential components found in various fluid transfer systems, highlighting their functions and significance in ensuring optimal operation.

- Housing: The outer shell that encases internal elements, providing structural integrity.

- Impeller: A rotating device that imparts energy to the fluid, facilitating movement.

- Seal: A critical element that prevents leakage and maintains pressure within the assembly.

- Drive Shaft: The rod that transmits mechanical power from the motor to the impeller.

- Check Valve: A mechanism that ensures unidirectional flow, preventing backflow.

Understanding these components allows for effective troubleshooting and maintenance, ultimately enhancing performance.

How to Read Pump Diagrams

Understanding schematics is crucial for effective maintenance and troubleshooting. By familiarizing yourself with the symbols and layout, you can gain insights into the system’s functionality and identify components more easily.

Familiarize Yourself with Symbols

Every representation utilizes specific symbols to denote various elements. Take time to learn these symbols, as they provide essential information about connections and functions within the system.

Follow the Flow Direction

Most representations indicate the direction of fluid movement. Recognizing this flow is vital for diagnosing issues and ensuring that everything operates smoothly.

Maintenance Tips for Pump Parts

Regular upkeep of machinery components is essential for optimal performance and longevity. By implementing a consistent maintenance routine, you can prevent unexpected failures and extend the life of your equipment. Here are some effective strategies to ensure your mechanical elements remain in top condition.

Regular Inspections

Conducting frequent evaluations is crucial. Look for signs of wear and tear, such as cracks, corrosion, or loose fittings. Early detection can save time and money by addressing issues before they escalate. Documenting your findings can help track the condition over time and identify patterns that may require intervention.

Cleaning and Lubrication

Keeping components clean is vital. Accumulated dirt and debris can impede functionality and cause damage. Use appropriate cleaning solutions and tools to remove contaminants without harming the surfaces. Additionally, proper lubrication reduces friction, ensuring smooth operation. Follow manufacturer guidelines for the type and frequency of lubrication needed.

Identifying Wear and Tear

Recognizing signs of deterioration is crucial for maintaining efficiency and extending the lifespan of machinery. Regular inspection can reveal subtle changes that indicate components may be underperforming or nearing the end of their service life. By understanding the common indicators of wear, users can take proactive steps to address issues before they escalate into more significant problems.

Common Indicators of Deterioration

Visual inspection is often the first step in identifying issues. Look for discoloration, cracks, or surface irregularities on the exterior. These signs can suggest exposure to harsh conditions or stress. Additionally, listen for unusual noises during operation, as they may indicate internal friction or misalignment.

Maintenance Practices

Implementing routine maintenance can significantly reduce wear. Regular cleaning prevents the buildup of debris that can cause friction and damage. Furthermore, lubricating moving parts according to the manufacturer’s recommendations helps maintain smooth operation and minimizes wear over time. Keeping a log of maintenance activities can also assist in tracking performance trends and identifying recurring issues.

Replacement Parts Overview

Understanding the various components essential for maintenance and repair is crucial for ensuring optimal functionality of your equipment. This section provides an overview of essential replacements necessary for efficient operation and longevity. Proper knowledge of these elements helps in identifying wear and tear, ensuring that your unit continues to perform at its best.

Key Components to Consider

Several critical elements warrant attention when planning for replacements. These include seals, valves, and connectors, which play a vital role in the overall operation. Regular inspections of these items can prevent significant issues and enhance the reliability of the machinery.

Ordering and Compatibility

When selecting replacements, it is important to ensure compatibility with your specific model. Quality is paramount; therefore, sourcing components from reputable suppliers guarantees reliability and performance. Additionally, keeping a record of part numbers can streamline the ordering process and reduce downtime.

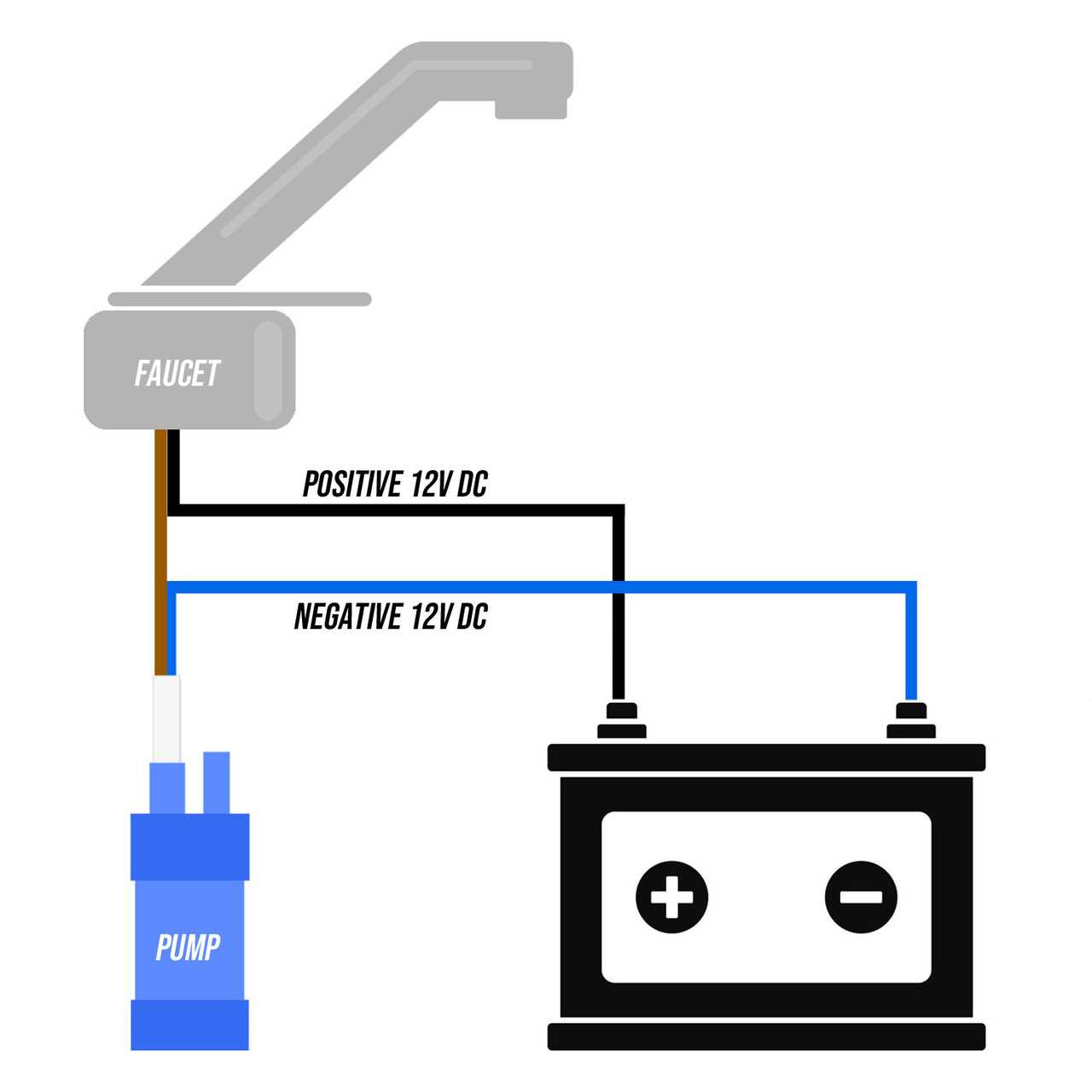

DIY Repairs for Pump Issues

Understanding how to address common mechanical challenges can greatly enhance the longevity and efficiency of your equipment. When issues arise, often a hands-on approach can save time and resources. With a bit of knowledge and the right tools, many problems can be diagnosed and resolved without the need for professional assistance.

Initial Assessment is crucial in determining the root cause of any malfunction. Begin by examining the device for visible signs of wear or damage. Check for leaks, unusual noises, or irregular performance. Gathering this information will help pinpoint the specific area that requires attention.

Once you have identified the problem area, disassemble the unit carefully to access internal components. Keep track of each piece and its orientation to facilitate reassembly. During this process, clean any debris or buildup that may be affecting functionality. Lubricating moving parts can also prevent future issues and improve efficiency.

If a specific component appears damaged, consider replacing it with a compatible alternative. Ensure that any replacement pieces meet the original specifications for optimal performance. Before reassembling, double-check all connections and seals to prevent any leaks or further complications.

Lastly, test the system after reassembly. Monitor its performance for a short period to ensure everything operates smoothly. Regular maintenance checks can help identify potential problems early, prolonging the lifespan of your equipment and ensuring reliable operation.

Tools Needed for Repairs

When it comes to maintaining and fixing equipment, having the right tools at your disposal is crucial. The proper instruments not only facilitate the repair process but also ensure that the work is done efficiently and safely. Below is a list of essential tools that can aid in the repair of various mechanical devices.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is necessary for removing and securing screws.

- Wrenches: Adjustable and socket wrenches are essential for loosening and tightening nuts and bolts.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping and manipulating small parts.

- Socket Set: A comprehensive socket set allows for efficient handling of different bolt sizes.

- Utility Knife: A sharp utility knife is handy for cutting through various materials, including seals and gaskets.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Multimeter: Useful for diagnosing electrical issues by measuring voltage, current, and resistance.

- Cleaning Supplies: Brushes and solvents help in maintaining the cleanliness of components, which is vital for optimal performance.

Equipped with these tools, you can approach repairs with confidence, ensuring that each task is completed correctly and effectively.

Safety Precautions When Servicing

Ensuring safety during maintenance activities is paramount to preventing accidents and ensuring a secure working environment. Following specific guidelines helps mitigate risks associated with handling equipment and components, thereby protecting both personnel and machinery.

Prior to initiating any service procedures, it is crucial to conduct a thorough assessment of the workspace and equipment involved. Adhering to safety protocols not only safeguards the technician but also prolongs the lifespan of the equipment.

| Precaution | Description |

|---|---|

| Wear Personal Protective Equipment (PPE) | Always don appropriate safety gear, including gloves, goggles, and protective clothing, to shield against potential hazards. |

| Disconnect Power Source | Before starting any maintenance, ensure that the power supply is completely disconnected to avoid electrical shocks. |

| Follow Manufacturer Guidelines | Consult the operation manual for specific instructions and safety warnings related to the equipment being serviced. |

| Maintain a Clean Work Area | Keep the workspace tidy and free of clutter to minimize the risk of accidents and improve efficiency during maintenance tasks. |

| Use Proper Tools | Utilize the correct tools for the job to prevent damage to components and ensure effective servicing. |

By adhering to these safety measures, individuals can significantly reduce the likelihood of mishaps while working on equipment, fostering a safer and more efficient service environment.

Resources for Further Learning

Exploring the intricate mechanisms and components of fluid-moving devices can be an enriching experience. To deepen your understanding and enhance your skills, a variety of educational materials and platforms are available.

Books and Manuals: Numerous publications provide detailed insights into the functioning and maintenance of various machinery. Look for technical manuals or guides that cover assembly, operation, and troubleshooting techniques.

Online Courses: Websites dedicated to technical education often feature courses focusing on mechanical systems. These platforms offer structured learning pathways, complete with video tutorials and quizzes to test your knowledge.

Forums and Community Groups: Engaging with online communities can be beneficial. Discussion forums allow enthusiasts and professionals to share experiences, ask questions, and provide solutions to common challenges encountered in the field.

Video Tutorials: Many educational channels on video-sharing platforms offer comprehensive walkthroughs and demonstrations. These visual resources can significantly aid in grasping complex concepts and procedures.

Manufacturer Websites: Official sites often have extensive resources, including technical documents, troubleshooting guides, and customer support sections. These can be invaluable for understanding specific configurations and recommendations.