Understanding the Hayward TriStar Pump Parts Diagram

When it comes to maintaining an efficient water circulation system, comprehending the various elements involved is crucial. Each component plays a significant role in ensuring optimal performance and longevity. Recognizing how these parts interact can greatly enhance functionality.

In this section, we will explore the intricate layout and design of essential mechanisms that contribute to smooth operation. By examining these details, you can better troubleshoot issues and make informed decisions about replacements and upgrades.

Whether you’re a seasoned professional or a novice enthusiast, understanding the specifics of each section will empower you to delve deeper into maintenance practices. This knowledge ultimately leads to a more efficient and reliable system.

Understanding Hayward Tristar Pump Components

Familiarity with the essential elements of a water circulation system is crucial for optimal operation and maintenance. Each component plays a vital role in ensuring the overall efficiency and longevity of the equipment. Recognizing these individual parts will aid in troubleshooting and enhance performance management.

Key Elements of the System

Several fundamental components work together to facilitate the movement and filtration of water. Below is a brief overview of these integral pieces:

| Component | Description |

|---|---|

| Motor | Drives the entire mechanism, converting electrical energy into mechanical energy. |

| Impeller | A rotating element that propels water through the system, enhancing flow rate. |

| Strainer | Filters out debris and large particles before they enter the mechanism. |

| Diffuser | Distributes water evenly after it passes through the impeller, minimizing turbulence. |

| Housing | Encases the internal components, providing structural support and protection. |

Importance of Maintenance

Regular upkeep of these components is essential for preventing malfunctions and extending the lifespan of the system. Understanding the function of each part allows for targeted maintenance and timely repairs, ensuring that the entire system operates smoothly and efficiently.

Essential Parts of Hayward Tristar Pump

This section explores the critical components that contribute to the efficient operation of a filtration system. Understanding these elements can enhance performance and prolong the lifespan of the equipment.

Motor: The powerhouse of the mechanism, responsible for driving the entire unit and ensuring optimal flow rates.

Impeller: A crucial element that facilitates water movement, creating the necessary pressure for effective circulation.

Strainer Basket: This component traps debris, preventing clogs and ensuring smooth operation by keeping larger particles out of the system.

Volute: The casing that directs the flow of water and helps convert kinetic energy into pressure, enhancing efficiency.

Seal Assembly: Vital for preventing leaks, this component maintains integrity and protects against potential damage from water exposure.

Diffuser: Works in tandem with the impeller, distributing water evenly and optimizing flow through the system.

By delving into these fundamental elements, users can achieve a better understanding of their system and its maintenance needs, ultimately enhancing overall performance.

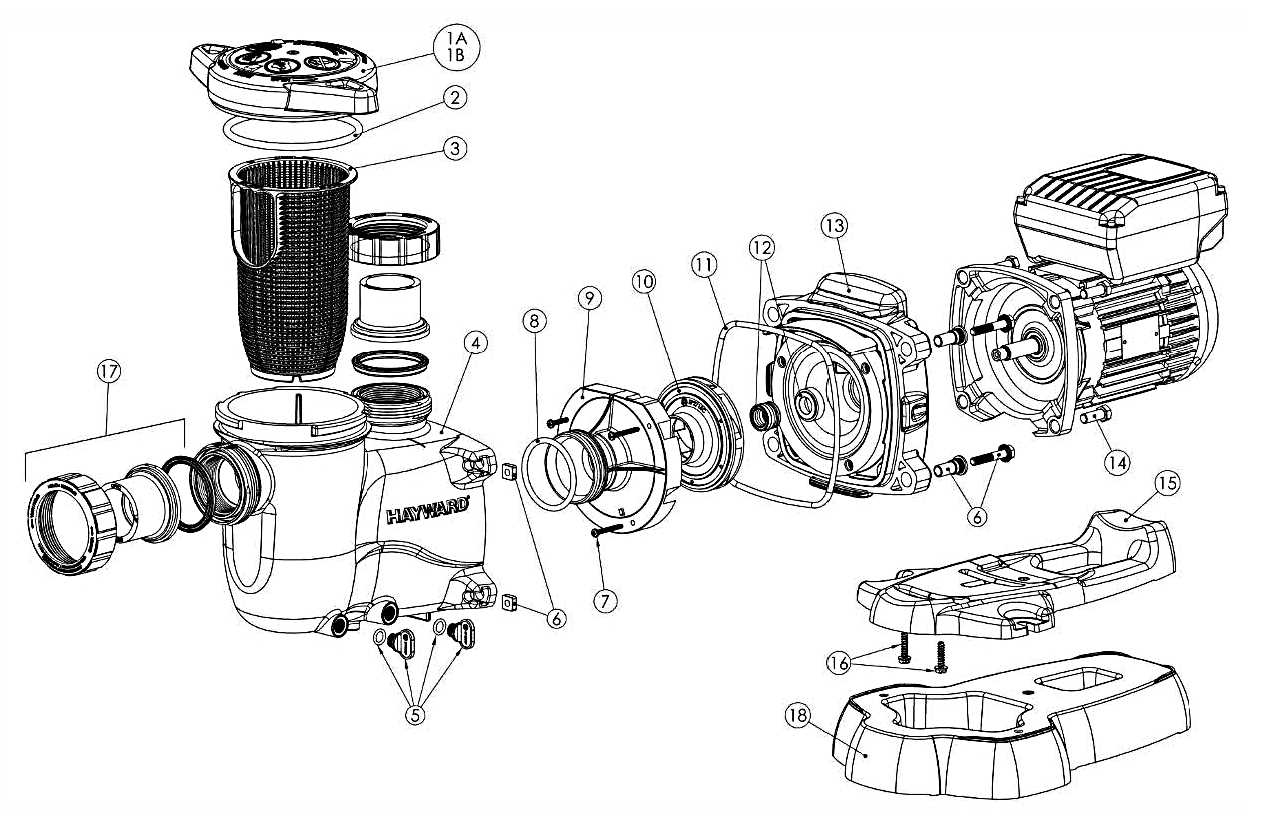

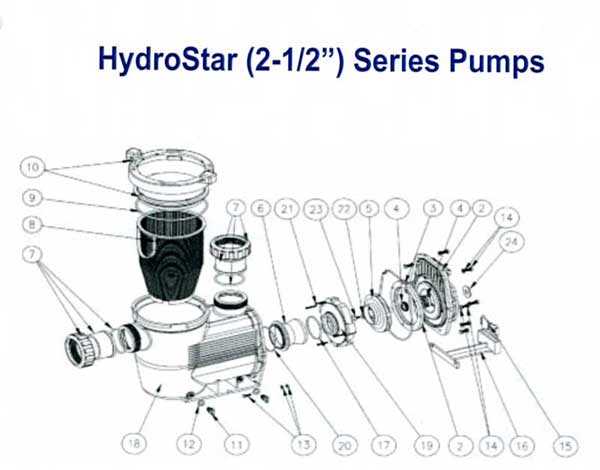

How to Read the Parts Diagram

Understanding a schematic representation of components can significantly enhance your maintenance and repair skills. It serves as a visual guide, illustrating the relationship and positioning of various elements within a mechanical assembly. Familiarity with this type of illustration is essential for identifying individual pieces and comprehending their functions.

To begin, locate the legend or key, which typically provides crucial information about symbols and notations used in the representation. This will assist you in accurately interpreting each component’s role. Pay close attention to the labeled sections, as they often indicate specific parts and their connections, ensuring you grasp the overall layout.

As you analyze the schematic, take note of any reference numbers associated with individual items. These references usually correspond to a list of components, which can help you identify what you need for repairs or replacements. Understanding the flow of operation, often indicated by arrows, will further enhance your comprehension of how each part interacts within the system.

In conclusion, becoming adept at reading these illustrations empowers you to tackle maintenance tasks more effectively, making you a more confident technician.

Common Issues with Tristar Pumps

Operating a circulation device can present various challenges that users may encounter over time. Understanding these frequent problems is crucial for effective maintenance and ensuring optimal performance. Addressing these issues promptly can prevent further complications and extend the lifespan of the equipment.

Reduced Flow Rate

A significant drop in the flow of water can indicate underlying problems. Common causes include blockages in the filtration system, worn-out components, or issues with the motor. Regular inspection and cleaning can help mitigate this issue, ensuring smooth operation.

Unusual Noises

Strange sounds during operation often signal mechanical issues. These may arise from loose parts, debris in the system, or bearing wear. Identifying the source of the noise is essential; ignoring it can lead to more severe damage and costly repairs. Regular maintenance checks can help catch these problems early.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your equipment requires regular upkeep and attention. By adhering to specific maintenance practices, you can prevent potential issues and maintain peak functionality. This section outlines essential strategies to keep your system running smoothly.

Regular Inspections

Conducting routine examinations is crucial for identifying wear and tear before it leads to significant problems. Check for any visible signs of damage, leaks, or corrosion.

Cleaning Protocols

Maintaining cleanliness is vital for optimal operation. Accumulated debris can hinder performance and cause overheating. Implement a regular cleaning schedule for all accessible components.

| Task | Frequency | Notes |

|---|---|---|

| Inspect seals and gaskets | Monthly | Replace if worn or damaged |

| Clean intake and discharge areas | Bi-weekly | Use a soft brush |

| Check fluid levels | Weekly | Ensure proper levels for optimal operation |

| Test electrical connections | Quarterly | Look for signs of corrosion |

By incorporating these maintenance practices into your routine, you can enhance the reliability and performance of your system, ultimately extending its lifespan and ensuring efficient operation.

Replacement Parts Availability and Sources

Access to quality components is crucial for maintaining the functionality of your equipment. Various options exist for sourcing these essential items, ensuring that users can keep their systems running smoothly and efficiently. Understanding where to find reliable replacements can save both time and money.

Online Retailers offer a wide selection of components, often at competitive prices. Websites dedicated to home improvement and specialized suppliers can provide quick access to the necessary items.

Local Distributors can be invaluable, especially for those who prefer to see items before purchasing. Establishing a relationship with nearby suppliers may lead to personalized service and expert advice on compatible components.

Manufacturer Support is another reliable source. Many manufacturers maintain comprehensive catalogs and customer service teams to assist with sourcing genuine replacements, ensuring compatibility and quality.

Community Forums and user groups often share tips on where to find components, providing recommendations based on personal experiences. Engaging with these communities can lead to discovering lesser-known sources.

Steps to Disassemble Your Pump

Disassembling your device can seem daunting, but with the right approach, it can be a straightforward process. Understanding the components and following a systematic method will help ensure that you can safely access the internal mechanisms for cleaning or repair.

Preparation and Safety

Before you begin, make sure to turn off and disconnect the unit from any power source. Gather the necessary tools such as screwdrivers, wrenches, and a container for small components. Wearing safety goggles and gloves is also advisable to protect yourself during the process.

Step-by-Step Disassembly

Start by removing the outer casing, typically secured by screws or clips. Carefully set these aside for later reassembly. Once the exterior is off, locate the main assembly and identify any additional fasteners that may need to be removed. Proceed with caution, taking note of the order and orientation of each component as you disassemble. Labeling parts can be extremely helpful for reinstallation.

After detaching the main elements, inspect the seals and gaskets, as these may need to be replaced during reassembly. Once everything is disassembled, you can perform the necessary maintenance or repairs. Always refer to the manufacturer’s guidelines for any specific instructions related to your model.

Identifying Compatible Replacement Parts

When maintaining a water circulation system, finding suitable components is essential for optimal performance. The right replacements not only ensure efficiency but also enhance the longevity of the entire setup. Understanding the specifications and compatibility of various elements is crucial in this process.

To aid in identifying the appropriate components, it is important to consider several key factors, such as model numbers, dimensions, and material specifications. Each of these aspects plays a significant role in ensuring that the replacements function seamlessly with existing equipment.

| Factor | Description |

|---|---|

| Model Number | Check the model number on the existing equipment to find exact matches. |

| Dimensions | Measure the size of the current parts to ensure the new ones fit properly. |

| Material | Choose components made from compatible materials to avoid chemical reactions. |

| Manufacturer Guidelines | Refer to the manufacturer’s recommendations for approved replacements. |

By following these guidelines, users can confidently select components that will function effectively within their systems, minimizing downtime and maximizing efficiency.

Upgrading vs. Repairing: What to Consider

When facing equipment issues, the decision between enhancement and restoration can significantly impact both performance and costs. Understanding the nuances of each option is crucial for making an informed choice.

Factors to Consider

- Cost-effectiveness: Analyze the total expenses involved in both approaches.

- Efficiency gains: Consider the performance improvements an upgrade might offer.

- Longevity: Evaluate how long the existing model will last versus a new installation.

- Compatibility: Ensure new components work seamlessly with existing systems.

When to Upgrade

- Frequent breakdowns suggest it may be time for a change.

- Newer models offer advanced features that can enhance overall efficiency.

- Older systems may struggle to meet current demands.

Visual Guide to Pump Assembly

This section provides a comprehensive overview of the assembly process for a specific type of circulation device. Understanding the various components and their arrangement is crucial for ensuring optimal functionality and longevity. With clear visual aids and detailed explanations, this guide will facilitate a smoother assembly experience, whether you are a novice or an experienced technician.

Key Components and Their Functions

Each element plays a vital role in the overall system. From the motor to the volute, each component must be correctly positioned and secured. Understanding the function of each part will enhance your ability to troubleshoot and maintain the equipment effectively. For instance, the motor serves as the powerhouse, driving the flow, while the impeller is responsible for moving the liquid.

Step-by-Step Assembly Process

Following a structured approach during assembly is essential. Begin by organizing all elements and ensuring that you have the necessary tools at hand. Step 1 involves attaching the motor securely to its base. Next, Step 2 includes positioning the volute correctly to align with the intake and discharge openings. Finally, ensure all seals are in place to prevent leaks. By adhering to these steps, you will achieve a successful assembly and enhance the performance of your device.

Preventive Measures for Longevity

Maintaining optimal performance and extending the lifespan of your equipment requires a proactive approach. Regular inspections, timely replacements, and consistent upkeep can significantly reduce the risk of unexpected failures. By implementing specific strategies, you can ensure that your system operates smoothly for years to come.

Here are some essential preventive measures to consider:

| Action | Description | Frequency |

|---|---|---|

| Visual Inspections | Check for signs of wear, leaks, or damage to components. | Monthly |

| Cleaning | Remove debris and buildup from the system to maintain efficiency. | Bi-weekly |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction. | Quarterly |

| Parts Replacement | Replace worn or damaged components to prevent further issues. | Annually |

| System Testing | Conduct performance tests to ensure all components are functioning correctly. | Seasonally |

By adhering to these preventive practices, you can safeguard your investment and enhance overall reliability, ultimately leading to a more efficient and durable operation.

Expert Recommendations for Troubleshooting

Addressing common issues with your equipment requires a systematic approach. By understanding the fundamental components and their functions, you can effectively diagnose and resolve problems that may arise during operation.

Identifying Symptoms

Begin by observing the device’s performance. Unusual noises, fluctuations in pressure, or reduced efficiency are key indicators of underlying issues. Document these symptoms to assist in the troubleshooting process.

Systematic Approach

To delve deeper, inspect each element thoroughly. Check connections, seals, and electrical components for wear and tear. Regular maintenance and timely replacements of worn parts can significantly enhance longevity and performance.