Understanding the Silca Pump Parts Diagram for Optimal Performance

When it comes to maintaining optimal tire pressure for cycling enthusiasts, knowing the intricate details of the equipment can make all the difference. This section aims to explore the essential elements that contribute to the functionality of inflation mechanisms, enabling users to achieve seamless performance during their rides.

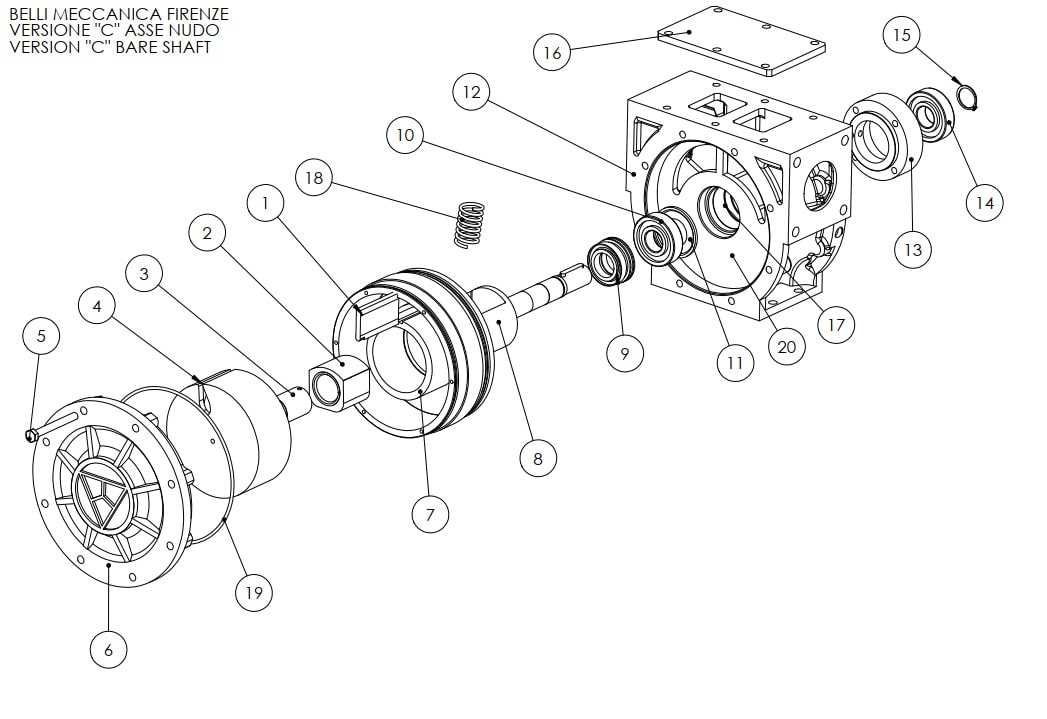

By examining a visual representation of these crucial components, one can gain insights into how each segment interacts within the system. Such knowledge empowers users to troubleshoot potential issues, enhancing both efficiency and longevity of their gear.

Furthermore, understanding the layout of these mechanisms not only aids in repair and maintenance but also cultivates a deeper appreciation for the technology behind cycling. This exploration will ultimately assist both novice and seasoned riders in optimizing their experience on the road.

Understanding Silca Pump Mechanics

This section explores the intricate workings of a specific type of inflating mechanism, focusing on the components and their interactions that ensure efficient operation. By grasping these fundamentals, one can appreciate the design and functionality that enhance performance.

Key Components

- Chamber: The core area where air is compressed.

- Valve: A critical element controlling airflow direction.

- Piston: The moving part that drives the compression process.

- Handle: The user interface for operation.

Operating Principles

- The handle initiates movement, engaging the piston.

- The piston compresses air in the chamber.

- The valve opens to release air as needed.

- Repeated cycles enhance pressure build-up for optimal performance.

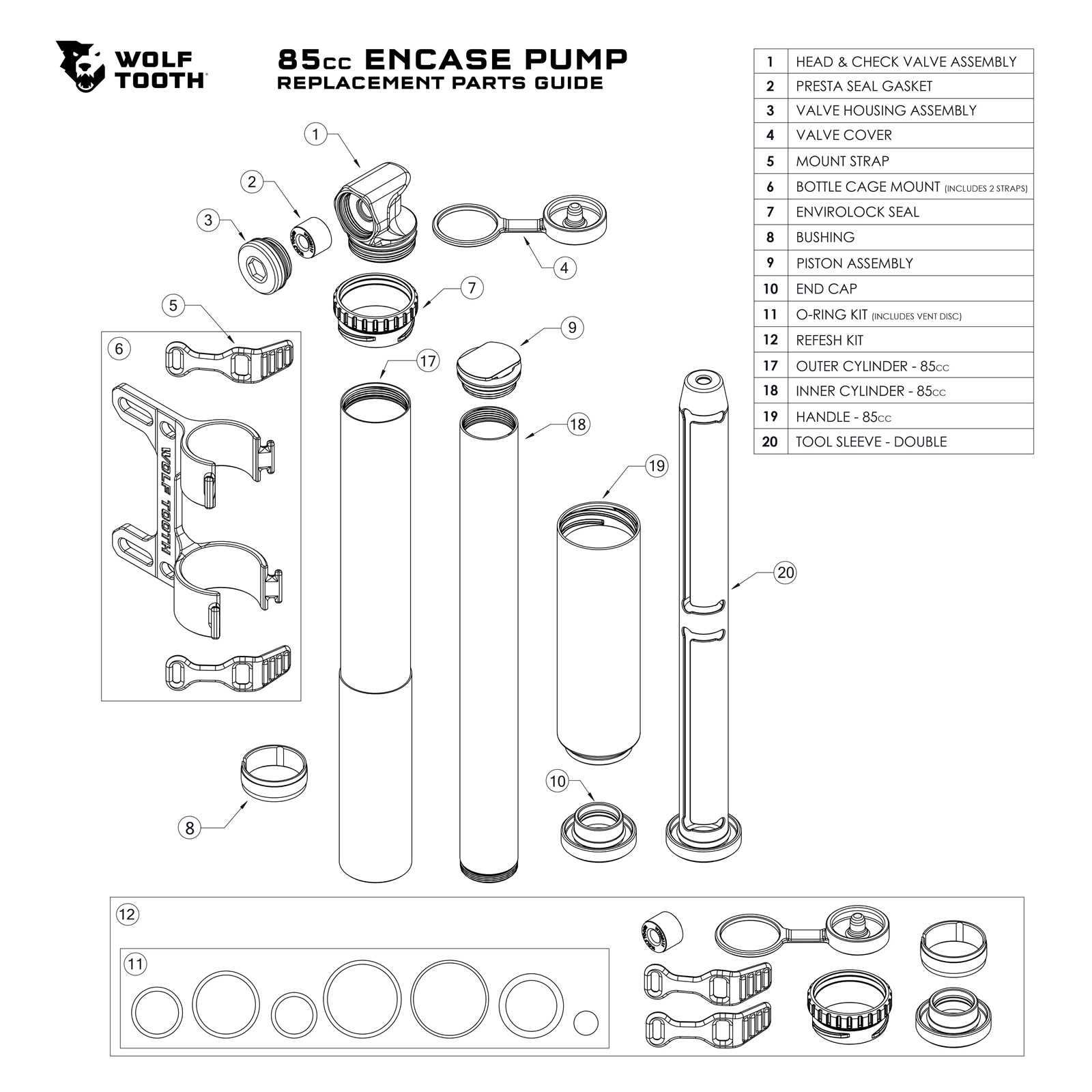

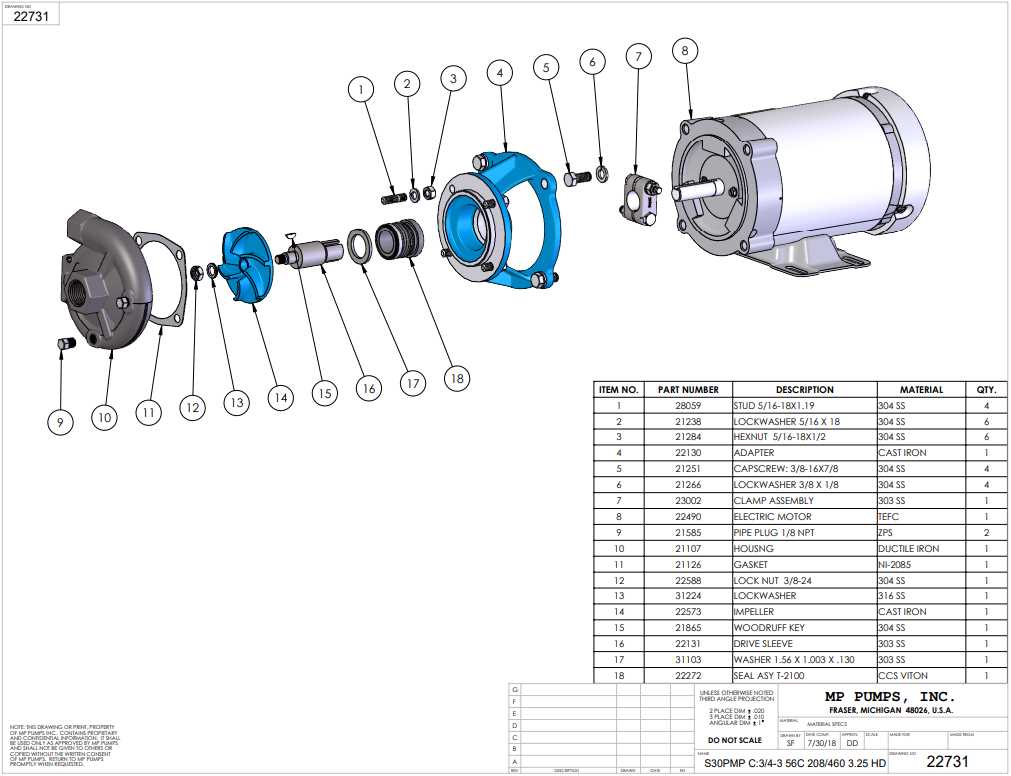

Key Components of Silca Pumps

Understanding the essential elements of these devices is crucial for ensuring optimal performance and longevity. Each component plays a significant role in the overall functionality, contributing to efficiency and reliability.

| Component | Description |

|---|---|

| Housing | The outer shell that protects internal mechanisms from damage and environmental factors. |

| Piston | A critical element that creates pressure by moving fluid through the system. |

| Seal | Ensures that no fluid leaks occur, maintaining pressure and efficiency. |

| Valve | Regulates the flow of fluid, allowing for precise control during operation. |

| Handle | Facilitates manual operation, providing leverage for effective usage. |

Importance of Pump Diagrams

Understanding the intricacies of mechanical systems is crucial for their effective maintenance and operation. Visual representations play a significant role in conveying complex information in a simplified manner, allowing users to grasp essential elements quickly. Such illustrations serve as a roadmap, guiding users through the various components and their interconnections.

Moreover, these visuals are invaluable during troubleshooting, as they help identify issues by clearly showing how different elements interact. A detailed representation can significantly reduce the time required to pinpoint problems, ultimately enhancing efficiency.

In addition, clear schematics aid in proper assembly and disassembly, ensuring that each component is positioned correctly. This not only prevents damage but also extends the lifespan of the system. Overall, the role of such illustrations in promoting understanding and facilitating effective operations cannot be overstated.

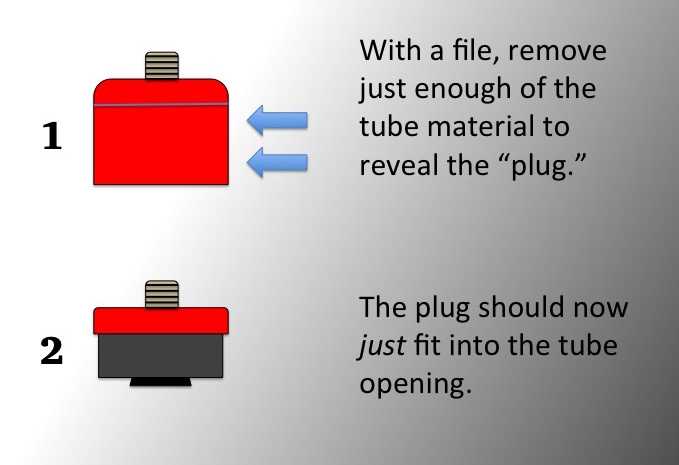

How to Read a Pump Diagram

Understanding a schematic representation of a device can greatly enhance your ability to maintain and troubleshoot it effectively. By familiarizing yourself with various symbols and annotations, you can easily identify components and their relationships. This knowledge allows for more efficient repairs and improvements, ultimately leading to better performance.

Begin by examining the legend, which typically provides definitions for the symbols used. Each icon corresponds to a specific element, such as valves, seals, or hoses. Pay attention to the lines connecting these symbols, as they illustrate how different components interact within the system. Dotted lines may represent secondary connections or optional elements, while solid lines indicate primary pathways.

Next, note any directional arrows present, as they indicate the flow of fluid or energy. Understanding this flow is crucial for diagnosing issues or optimizing function. Additionally, look for numbers or labels next to components, which may provide vital information like specifications or part numbers, aiding in replacement or upgrades.

Finally, take a holistic view of the entire representation. By considering the layout and interconnectivity, you can grasp how each element contributes to the overall mechanism. This comprehensive understanding will empower you to make informed decisions regarding maintenance and enhancements.

Common Issues in Silca Pumps

Understanding typical challenges associated with these essential tools can greatly enhance their longevity and performance. Users often encounter various malfunctions or inefficiencies that may arise from improper maintenance or design flaws. Addressing these issues promptly can prevent further complications and ensure smooth operation.

Frequent Problems

- Leakage: A common issue often caused by worn seals or loose fittings.

- Reduced Efficiency: Can result from blockages or air bubbles within the system.

- Noisy Operation: This may indicate loose components or the need for lubrication.

- Inconsistent Output: Fluctuations can occur due to varying pressure or malfunctioning valves.

Prevention and Solutions

- Regularly check and replace seals to prevent leaks.

- Keep the system clean and free of debris to maintain efficiency.

- Ensure all components are tightly secured to minimize noise.

- Perform routine inspections to detect any inconsistencies early.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular attention and care. Proper upkeep not only enhances performance but also extends the lifespan of your tools. By following a few simple practices, you can maintain optimal functionality and prevent premature wear.

Regular Cleaning: Keep your tools free from dirt and debris. A gentle wash with mild soap and water can help prevent build-up that may cause inefficiencies. After cleaning, ensure everything is thoroughly dried to avoid rust or corrosion.

Lubrication: Apply suitable lubricants to moving components to reduce friction. This simple step can significantly enhance performance and minimize wear. Always choose a lubricant recommended for your specific equipment.

Inspection: Conduct periodic checks to identify any signs of damage or wear. Early detection of issues allows for timely repairs, preventing more extensive damage down the line.

Storage: When not in use, store your tools in a dry and protected area. This helps safeguard them from environmental factors that could lead to deterioration. Consider using protective cases or bags for added security.

Follow Manufacturer Guidelines: Adhere to any maintenance recommendations provided by the manufacturer. These guidelines are tailored to your equipment and can help ensure it operates effectively for years to come.

Upgrading Silca Pump Parts

Enhancing the functionality of your inflating device can significantly improve performance and user experience. By selecting high-quality components, you can ensure greater efficiency, durability, and ease of use. This section explores various options for upgrading essential elements, providing valuable insights for enthusiasts and professionals alike.

Benefits of Enhanced Components

Upgrading individual elements not only boosts the overall efficiency but also extends the lifespan of the device. Improved materials can lead to better sealing, reduced air loss, and increased pressure output. Investing in quality ensures that your equipment will withstand the rigors of regular use, making it a worthwhile endeavor for serious cyclists.

Choosing the Right Upgrades

When considering enhancements, focus on key aspects such as valves, hoses, and seals. Each component plays a crucial role in performance. Research and select components that align with your specific requirements, whether for racing, commuting, or leisure rides. A tailored approach will yield the best results, enhancing both functionality and satisfaction.

Identifying Wear and Tear

Recognizing signs of deterioration is essential for maintaining optimal performance. Over time, components can show various levels of fatigue, impacting functionality. By understanding these indicators, one can ensure longevity and efficiency in usage.

Common Indicators

Look for unusual sounds during operation, which may suggest misalignment or damage. Additionally, visual inspections can reveal cracks, discoloration, or excessive wear on surfaces.

Maintenance Tips

Regularly clean and inspect all elements to prevent buildup of debris. Implementing a routine check can help catch issues early, extending the lifespan of critical components.

Benefits of Regular Inspections

Conducting routine assessments of equipment can significantly enhance longevity and performance. Regular evaluations help identify potential issues before they escalate, ensuring that systems operate smoothly and efficiently.

Enhanced Performance

By routinely checking components, users can maintain optimal functionality. Early detection of wear or damage can lead to timely repairs, reducing downtime and maintaining productivity.

Cost Savings

Frequent inspections can lead to considerable financial savings. Addressing minor problems early prevents costly repairs and replacements in the future.

| Inspection Frequency | Benefits |

|---|---|

| Monthly | Immediate issue detection and minimal downtime. |

| Quarterly | Comprehensive performance review and preventive measures. |

| Annually | Thorough assessment ensuring long-term reliability. |

Choosing Quality Replacement Parts

Selecting superior components is crucial for ensuring optimal performance and longevity of your equipment. High-quality substitutes not only enhance functionality but also contribute to the overall reliability and efficiency of the system. It is essential to consider materials, craftsmanship, and compatibility when evaluating options.

When assessing alternatives, prioritize reputable manufacturers known for their commitment to excellence. Researching user reviews and expert recommendations can provide valuable insights into the durability and performance of various components. Additionally, verify that the replacements align with the specifications of your original equipment to guarantee a proper fit and operation.

Investing in quality replacements ultimately saves time and resources in the long run, reducing the likelihood of future issues. By focusing on craftsmanship and reliability, you can ensure that your equipment functions at its best, allowing you to enjoy seamless operation for years to come.

Exploring Pump Efficiency Factors

Understanding the elements that contribute to operational effectiveness is crucial for maximizing performance in fluid movement systems. Various components and their interplay significantly impact the overall functionality and output, ultimately determining how effectively a system performs its intended task.

Key Elements Influencing Performance

- Design: The architecture and configuration play a vital role in efficiency.

- Material Quality: High-quality materials reduce wear and enhance longevity.

- Flow Dynamics: The way fluid moves within the system affects output.

- Maintenance Practices: Regular upkeep ensures optimal operation.

Performance Optimization Strategies

- Conduct regular performance assessments to identify inefficiencies.

- Invest in quality components to minimize losses.

- Implement advanced technologies for real-time monitoring.

- Educate personnel on best practices for operation and maintenance.

Comparing Silca Models and Features

This section explores various designs and characteristics found in different models of a well-known brand. Each version offers unique functionalities tailored to specific user needs, making it essential to understand their distinctions.

- Model A: Known for its lightweight construction and portability.

- Model B: Features enhanced durability and a robust design for long-term use.

- Model C: Offers advanced technology for optimal performance in diverse conditions.

When choosing among these variants, consider the following factors:

- Weight and portability

- Durability and material quality

- Technology and ease of use

Ultimately, understanding these elements can guide you toward selecting the right tool for your specific requirements.

Resources for Silca Pump Owners

For enthusiasts and caretakers of high-quality inflation devices, having access to comprehensive materials can enhance both maintenance and performance. This section offers valuable insights and tools that help ensure longevity and reliability in your equipment.

Maintenance Guides

Regular upkeep is essential. Detailed manuals and instructional videos can be found online, guiding users through various maintenance procedures. Utilize these resources to keep your equipment functioning optimally.

Community Forums

Connecting with fellow enthusiasts can provide support and innovative solutions. Online communities often share tips, troubleshooting advice, and modifications, making them an ultimate resource for any user.