Swimming Pool Pump Parts Overview

The proper maintenance and operation of a water circulation system rely heavily on understanding the different elements that work together to keep it running efficiently. Knowing the key components and how they interact can help ensure optimal performance and prevent potential issues. This section aims to provide a comprehensive overview of the main elements involved in such systems.

Each element plays a crucial role in ensuring that the water flows smoothly, is filtered correctly, and is maintained at the right level of cleanliness. By familiarizing yourself with these components, you can better identify any potential malfunctions and take the necessary steps to address them. This knowledge is essential for anyone looking to improve the longevity and functionality of the system.

In the following sections, we will delve into the various essential elements, explaining their functions and how they contribute to the overall efficiency of the system. This approach will provide a solid foundation for understanding how the entire system works as a cohesive unit.

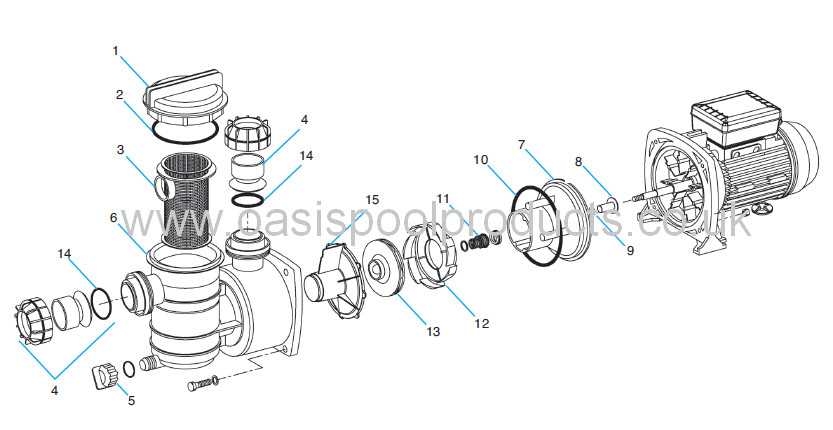

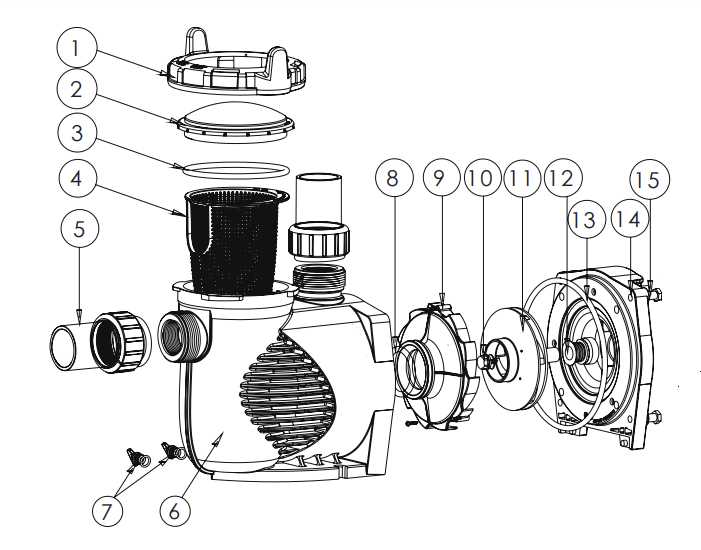

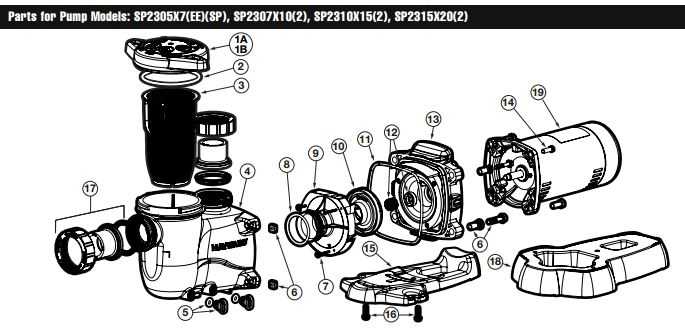

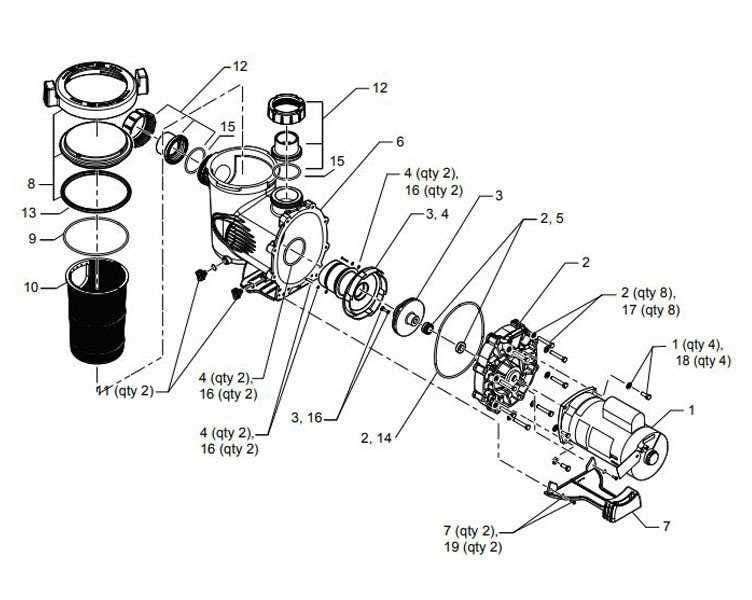

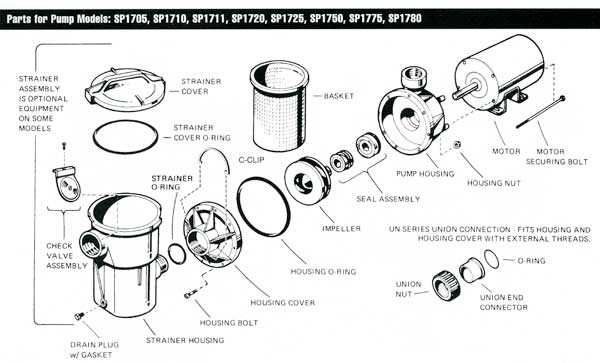

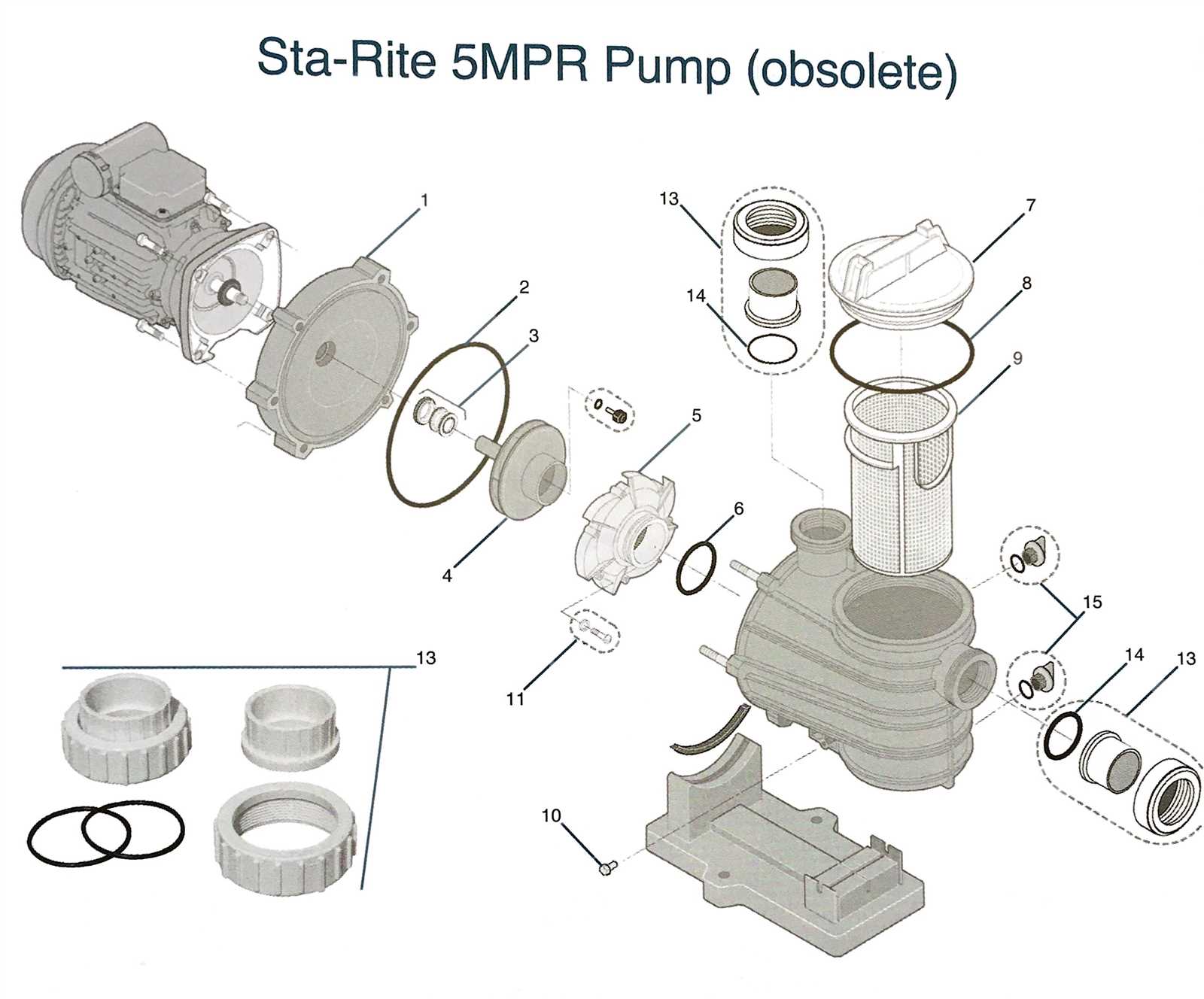

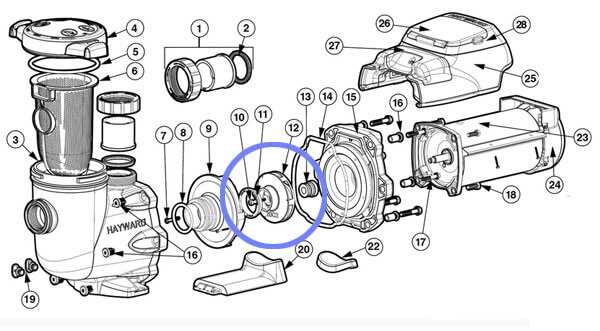

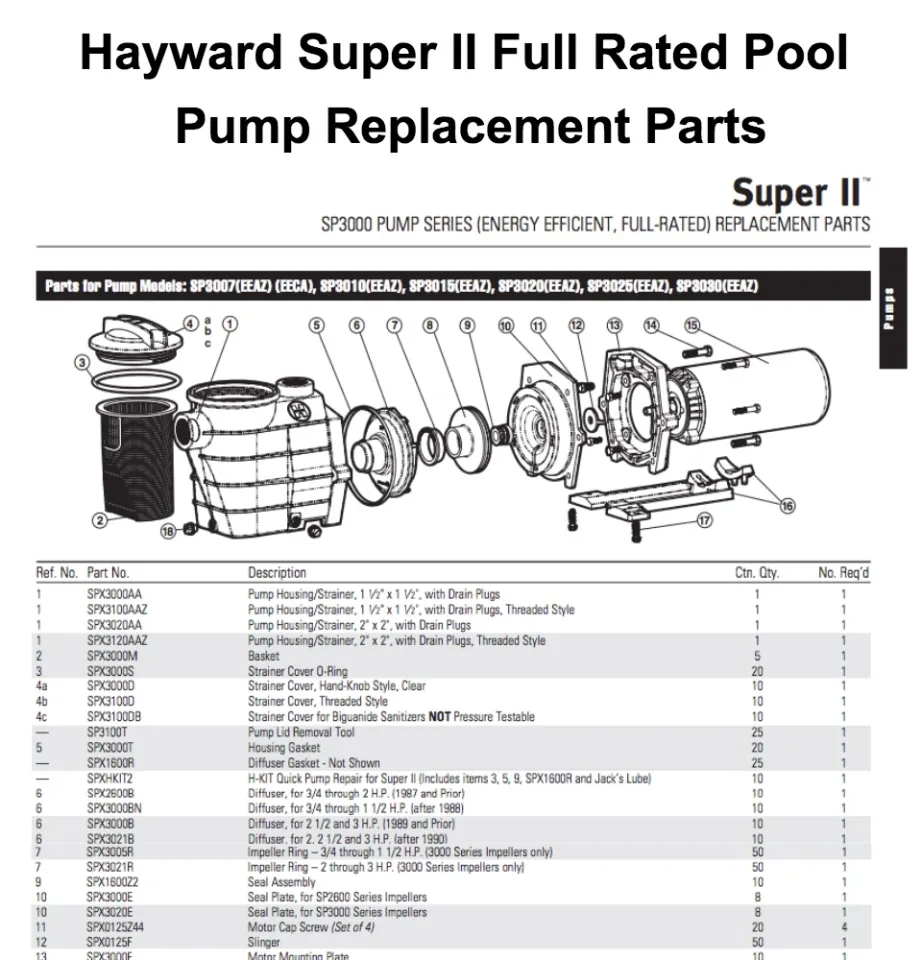

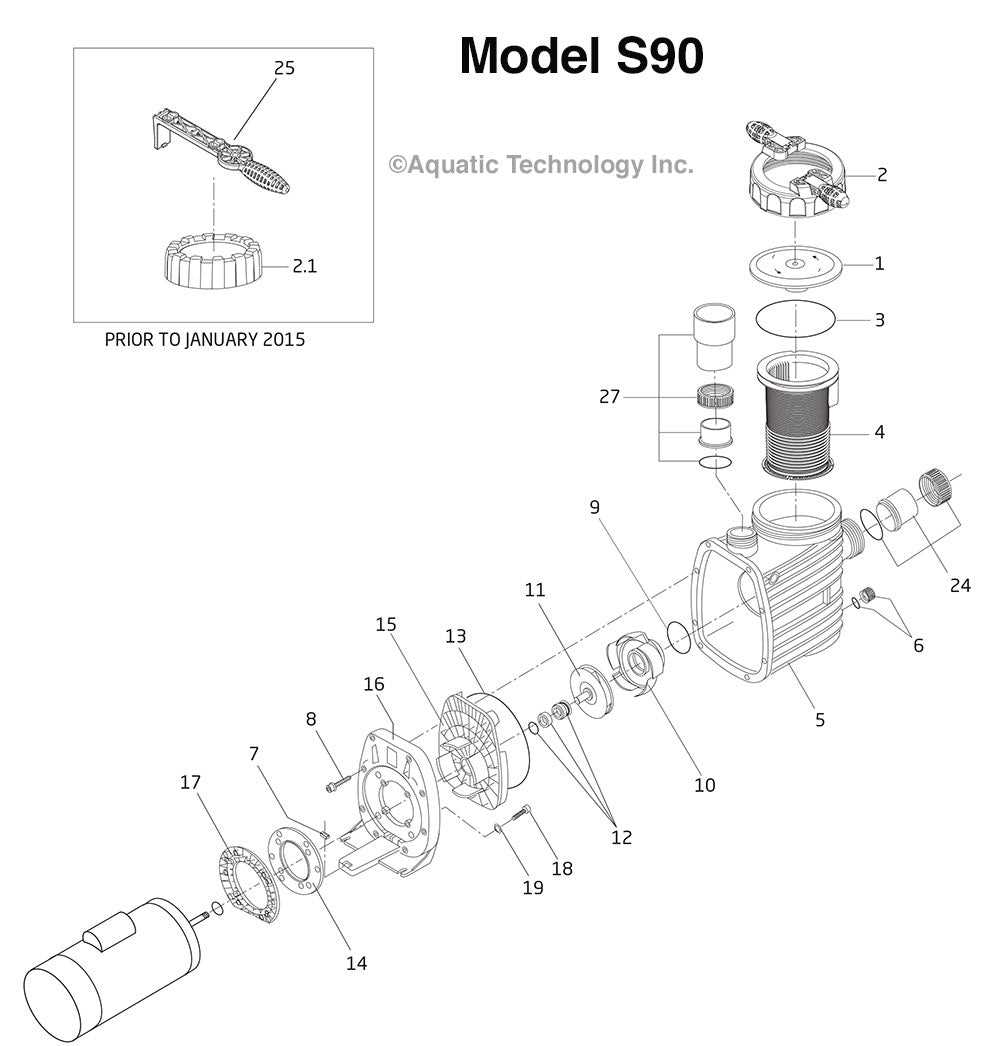

Swimming Pool Pump Parts Diagram

Understanding the components of a water circulation system is crucial for maintaining efficient operation and prolonging the lifespan of the equipment. A detailed overview of the key elements can help in identifying issues and conducting routine maintenance, ensuring everything functions smoothly.

Key Components of the Circulation System

The primary elements involved in moving water through the system include various mechanical and electrical parts that work together to keep the flow consistent. Some essential components regulate the water’s direction and pressure, while others contribute to filtration and temperature control. Knowing the role of each element can greatly aid in troubleshooting and replacing faulty components.

Maintenance and Troubleshooting Tips

Regular inspection of the system’s various elements can prevent breakdowns and improve efficiency. It is important to check for wear and tear, unusual sounds, and any irregularities in performance. Cleaning or replacing filters and monitoring connections will help avoid costly repairs and downtime. Being familiar with the system’s structure allows for more effective upkeep and timely interventions.

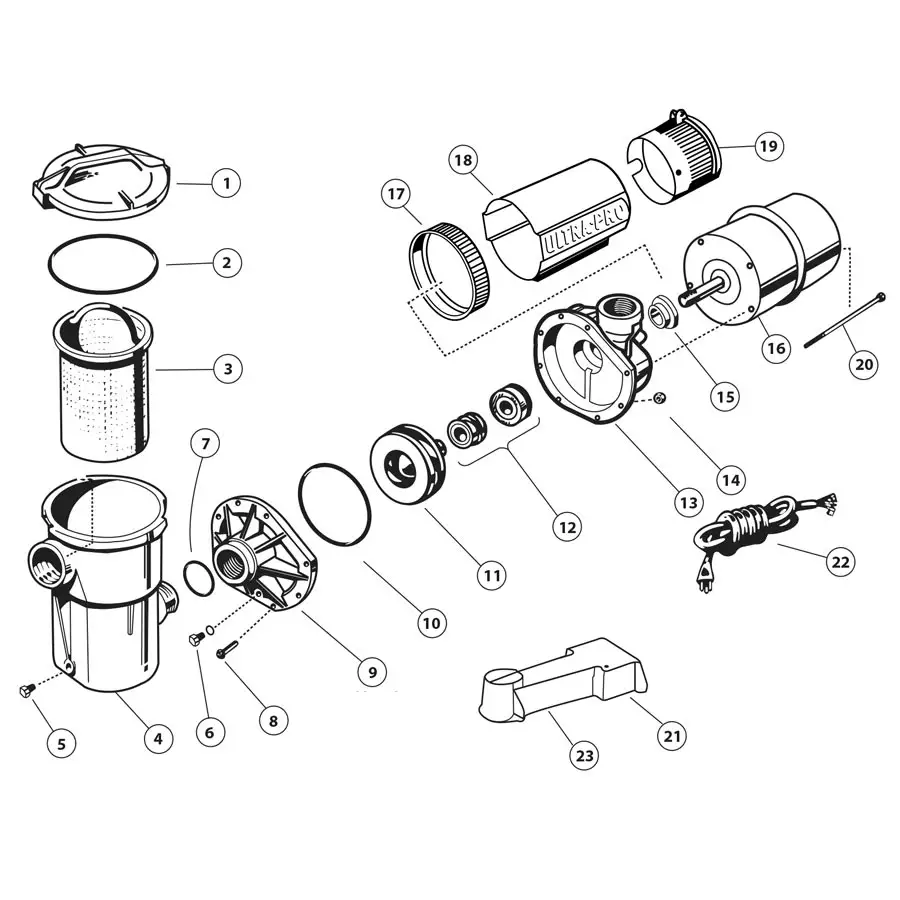

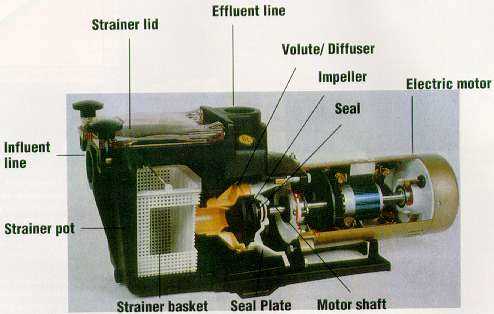

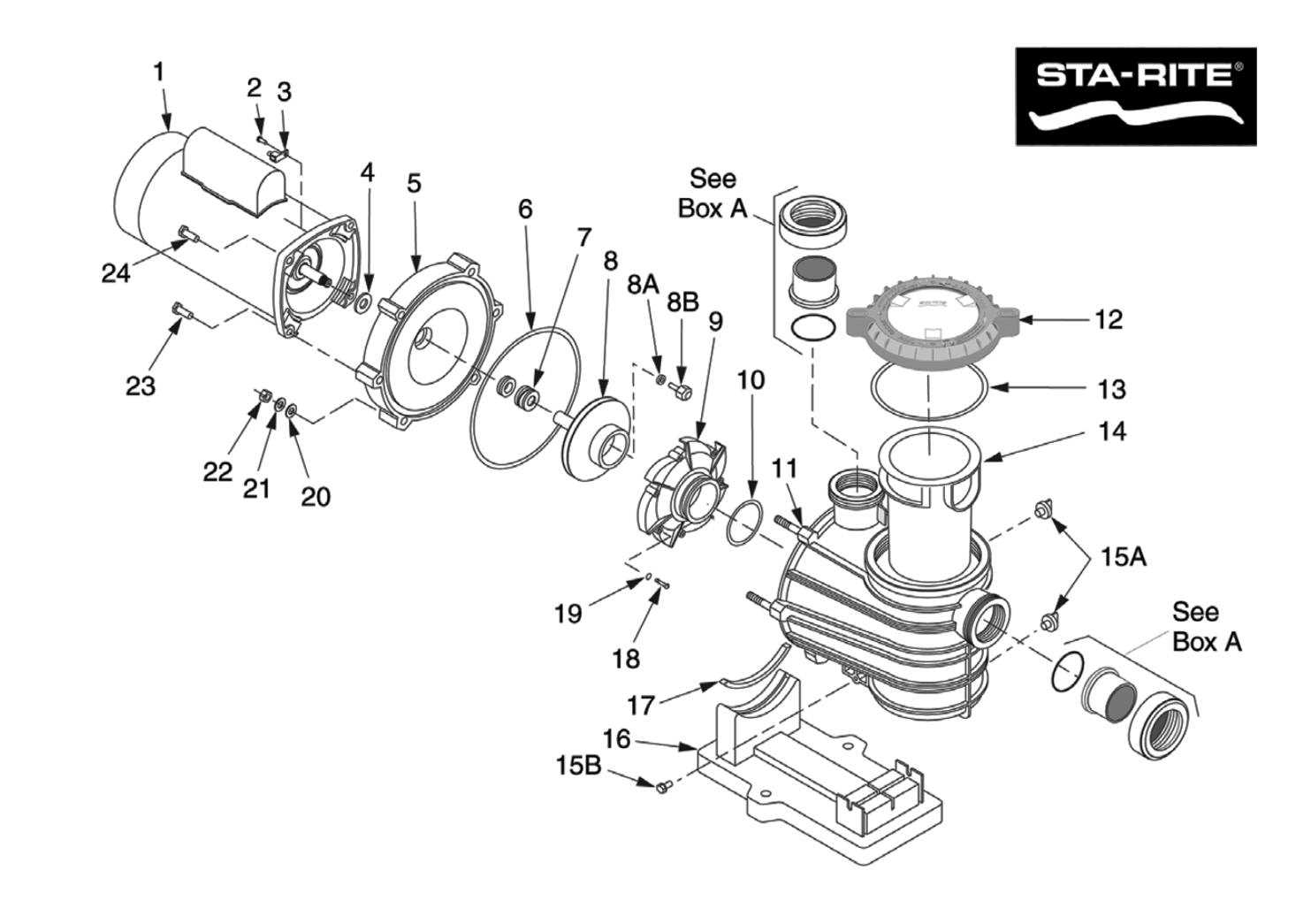

Understanding the Pump Structure

The core mechanism of this device involves various interconnected components working together to ensure efficient fluid movement. By examining each section, it’s possible to gain a deeper insight into the overall functionality, which is crucial for proper maintenance and troubleshooting.

The housing serves as the outer shell, protecting the internal elements from external damage and providing a sturdy frame for mounting. Its design helps to direct the flow through the system efficiently.

The impeller is a key rotating element that generates the necessary force to push the liquid forward. As it spins, it creates a centrifugal effect, causing the liquid to move rapidly through the device.

Seals and gaskets play an essential role in preventing leaks. They ensure that all junctions remain tightly closed, even under high pressure, which helps to maintain optimal performance and safety.

The motor is the power source that drives the rotating components. Its performance directly affects the overall efficiency and reliability, making regular inspection important for long-term operation.

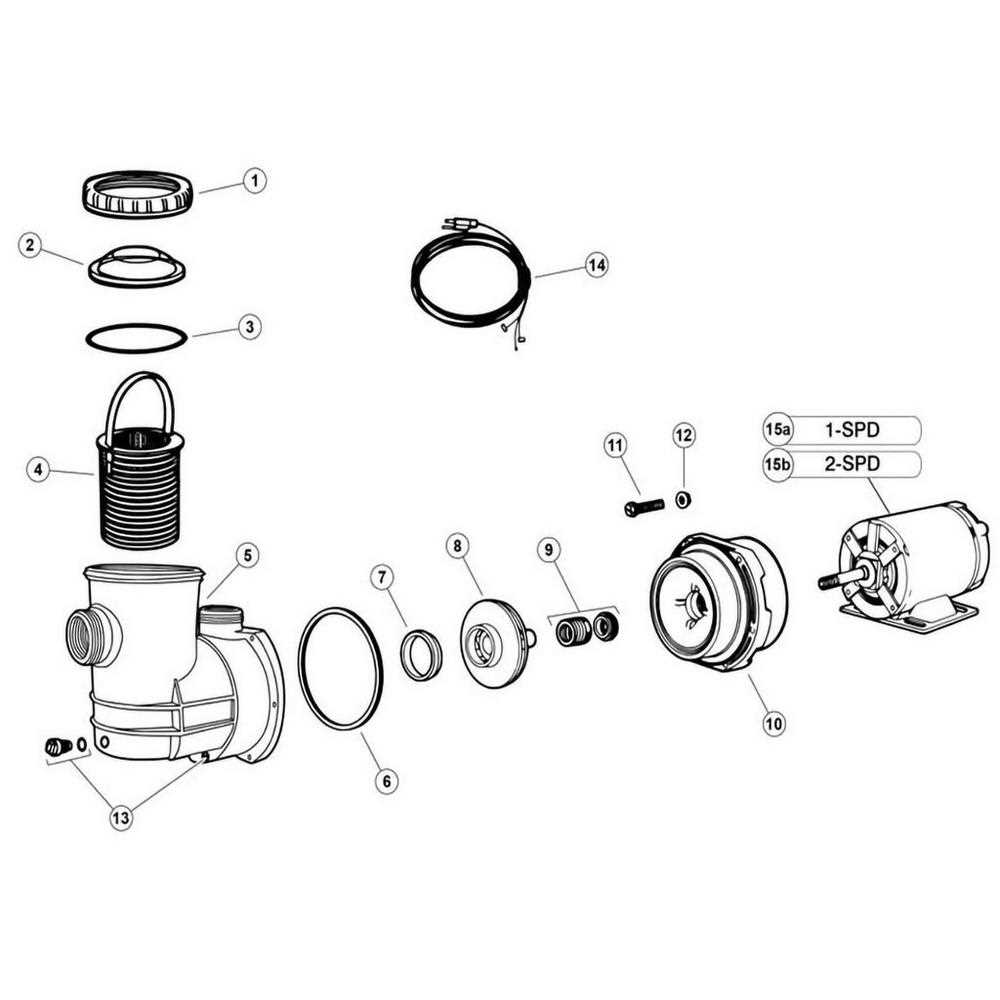

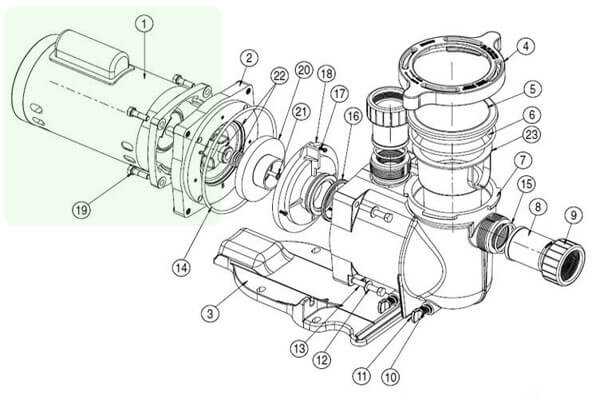

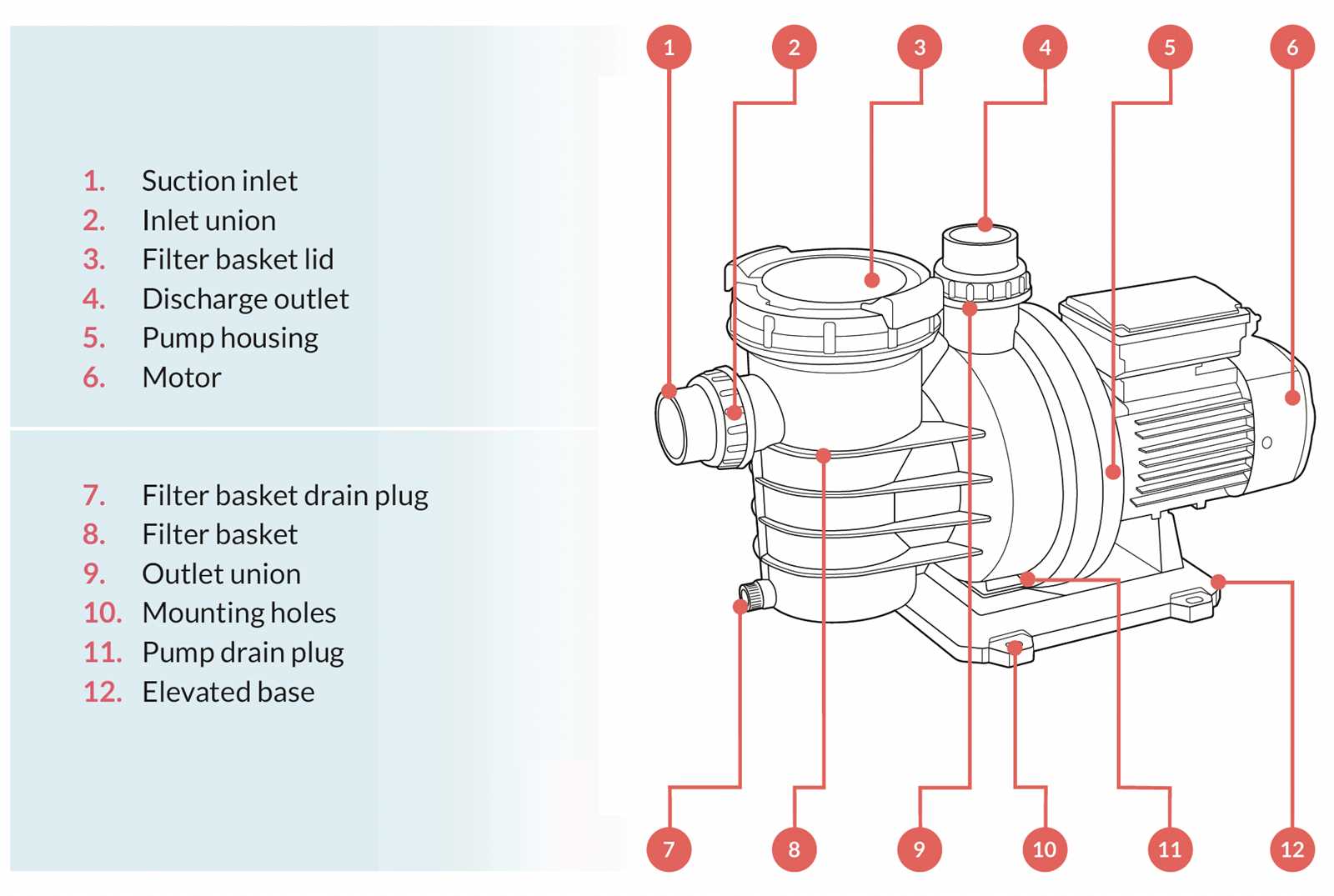

Common Pump Components Explained

The mechanics behind fluid circulation involve various elements working together to ensure efficient operation. Each component has a distinct role, contributing to the system’s overall functionality and longevity. Understanding these elements can help in identifying potential issues and maintaining the system properly.

| Component | Description | |||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Impeller | A rotating blade that transfers energy from the motor to the fluid, pushing it through the system. | |||||||||||||||||||||||||||||||||||||||||||

| Housing | An outer casing that encloses the internal parts, directing the fluid’s flow and protecting the internal mechanisms. | |||||||||||||||||||||||||||||||||||||||||||

| Seal | Prevents leakage by providing a tight barrier between the moving parts and the stationary parts. | |||||||||||||||||||||||||||||||||||||||||||

| Motor | Converts electrical energy into mechanical energy to drive the rotating components inside the system. | |||||||||||||||||||||||||||||||||||||||||||

| Strainer | Tr

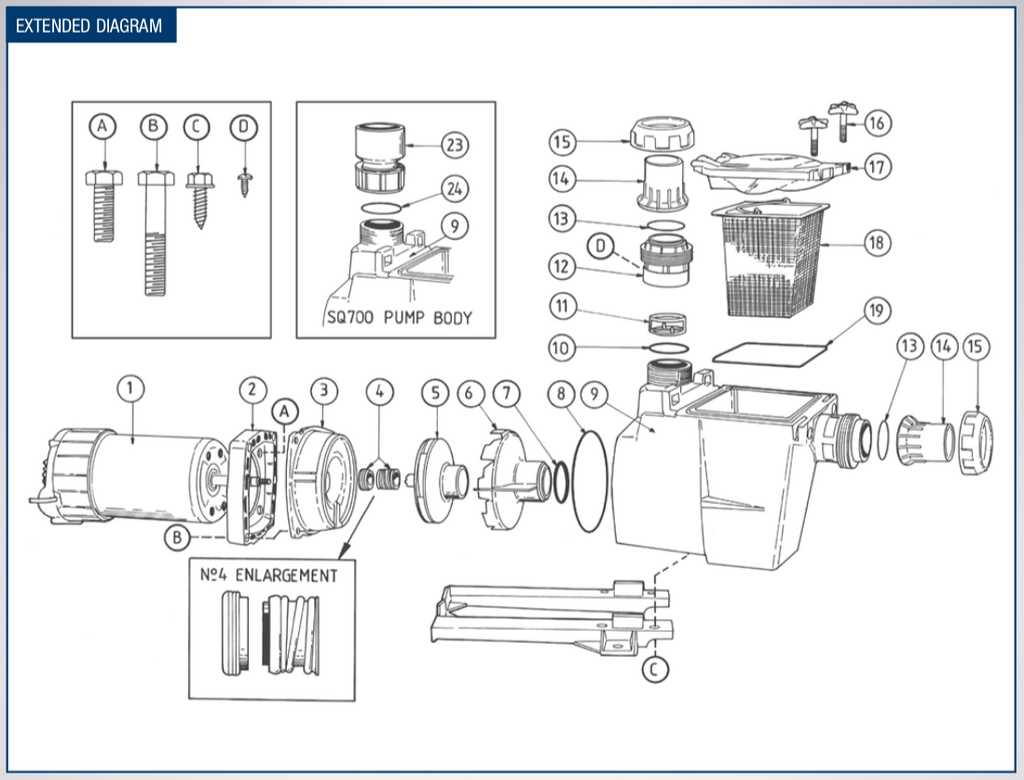

Identifying Key Internal PartsUnderstanding the essential components within a mechanical system helps in maintaining its functionality and optimizing its performance. Knowing these elements allows for effective troubleshooting and regular upkeep, ensuring the system operates smoothly over time. Main Mechanical ComponentsSeveral core elements work together to facilitate the system’s operation. These components interact to drive the entire mechanism, providing the necessary flow and efficiency.

Supporting ElementsAlong with the main mechanical components, additional supporting elements play vital roles in stabilizing the system and enhancing its performance.

|