Comprehensive Guide to Rear End Parts Diagram

In the world of automotive mechanics, a clear visualization of the various elements located at the rear of a vehicle is essential for effective maintenance and repair. Recognizing the intricate relationship between these components can significantly enhance your knowledge and skills.

Mastering the layout of these crucial structures allows enthusiasts and professionals alike to identify potential issues before they escalate. Each element plays a unique role in the overall functionality, ensuring safety and performance.

To truly delve into the intricacies of these components, one must appreciate their arrangement and interaction. Gaining a comprehensive understanding of this area ultimately empowers you to tackle any challenges that may arise, ensuring your vehicle remains in optimal condition.

Understanding Rear End Parts

This section aims to provide clarity on the essential components that contribute to the performance and functionality of the vehicle’s rear assembly. By exploring these elements, readers can gain insight into their roles and importance in overall vehicle dynamics.

Key Components

- Differential

- Axles

- Hub Assembly

- Suspension Links

- Brake Components

Functionality and Importance

Each component serves a specific function that is vital for the smooth operation of the vehicle. Understanding these roles helps in maintaining performance and ensuring safety.

- Distributes power to the wheels.

- Absorbs shocks from the road.

- Ensures stability during turns.

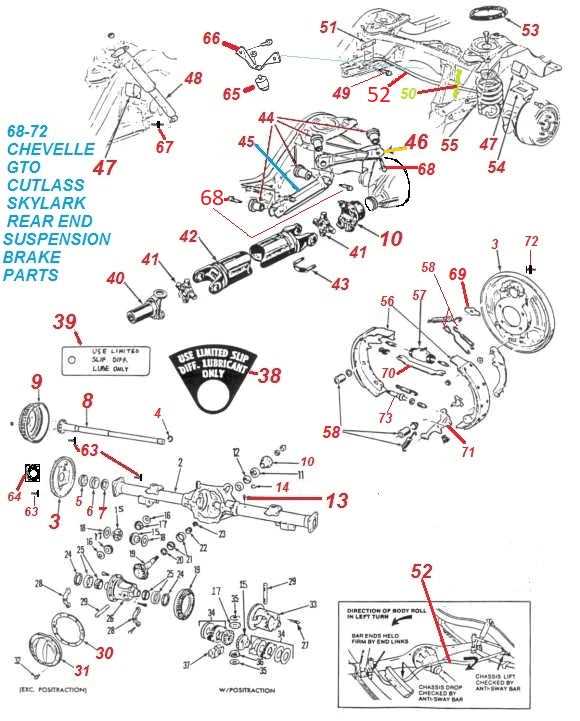

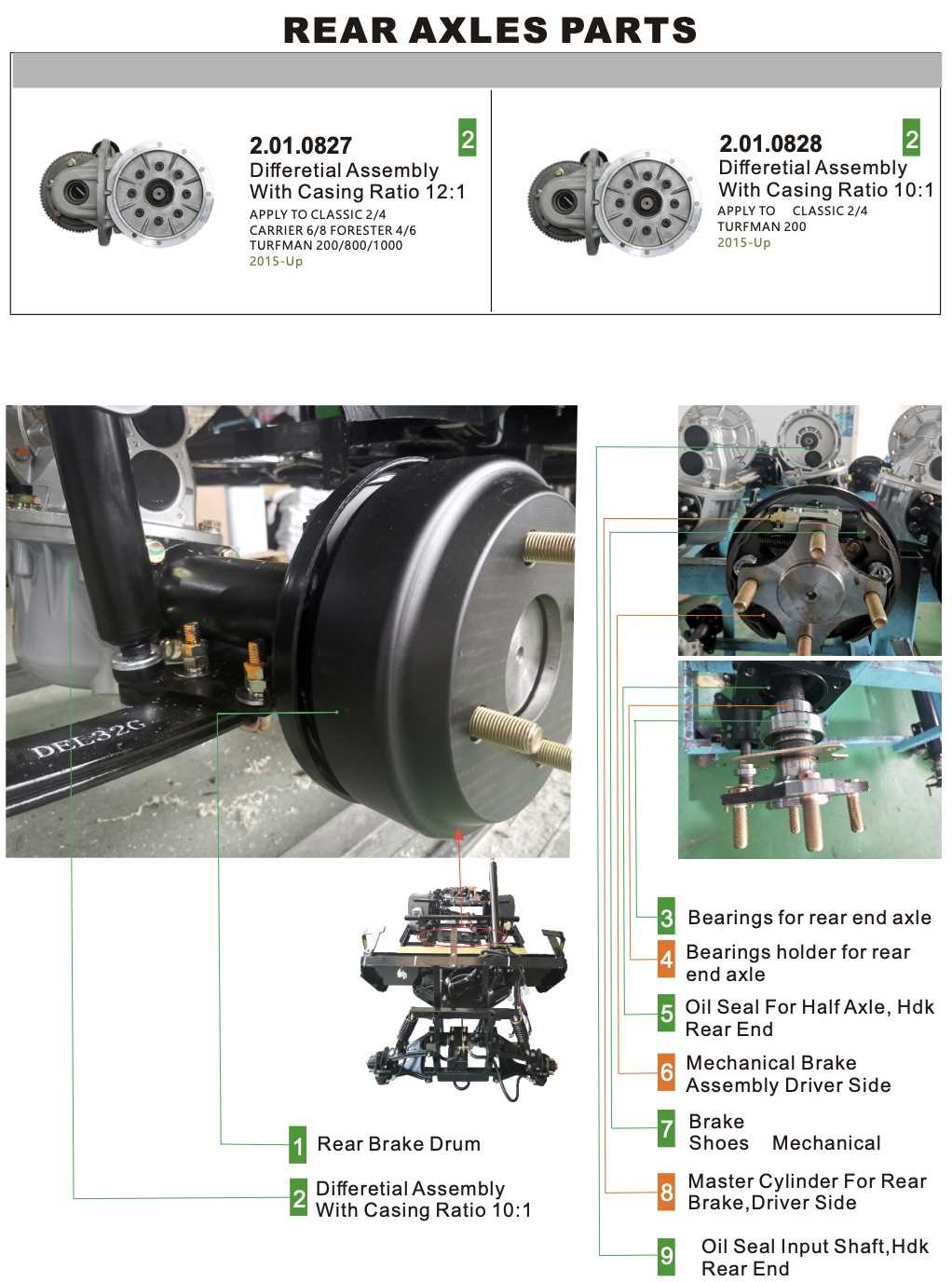

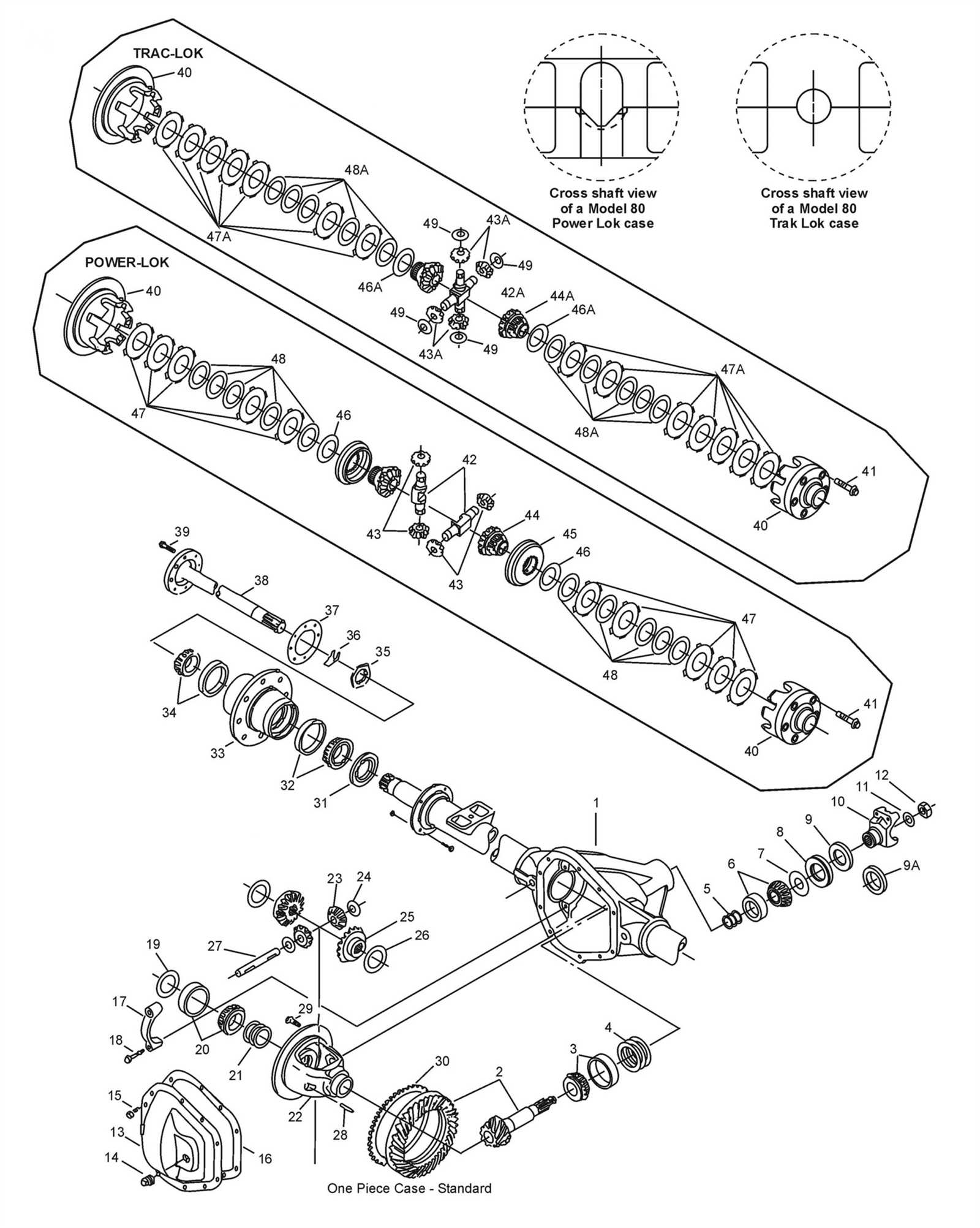

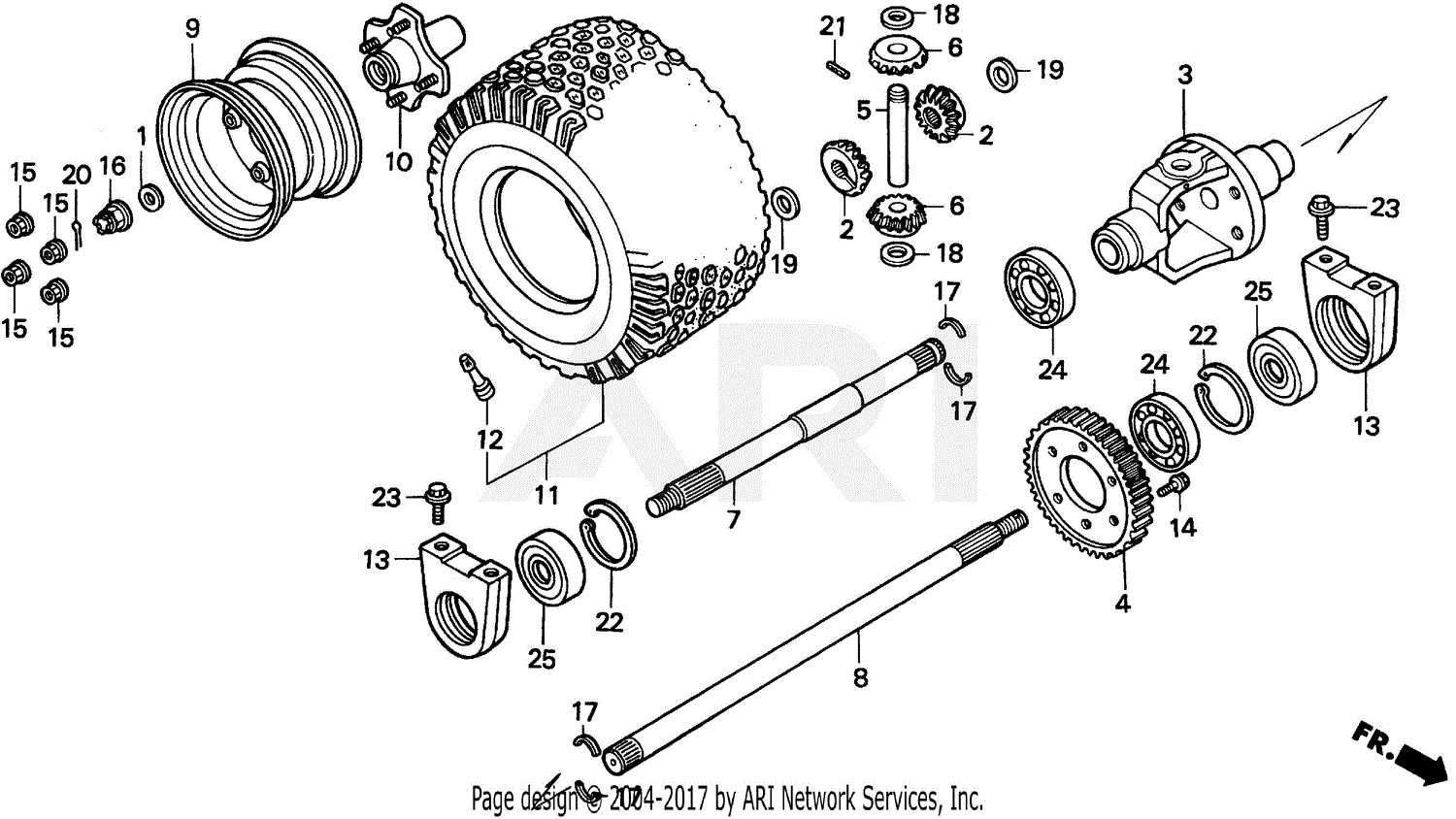

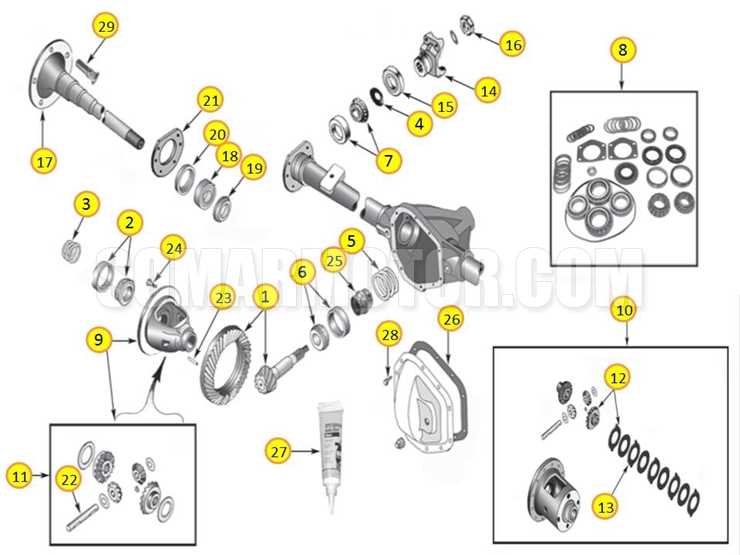

Key Components of Rear End Systems

Understanding the crucial elements of a vehicle’s propulsion system is essential for maintaining performance and safety. These components work in harmony to ensure efficient power transfer, stability, and control. Each element plays a significant role in the overall functionality of the automotive system.

Essential Elements

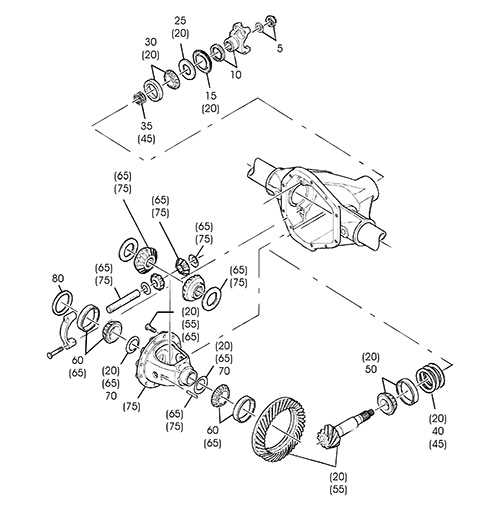

- Differential: This mechanism allows for the variation in wheel speed between the left and right sides, enabling smooth turning and better traction.

- Axles: These shafts transmit power from the differential to the wheels, supporting the weight of the vehicle and ensuring stability.

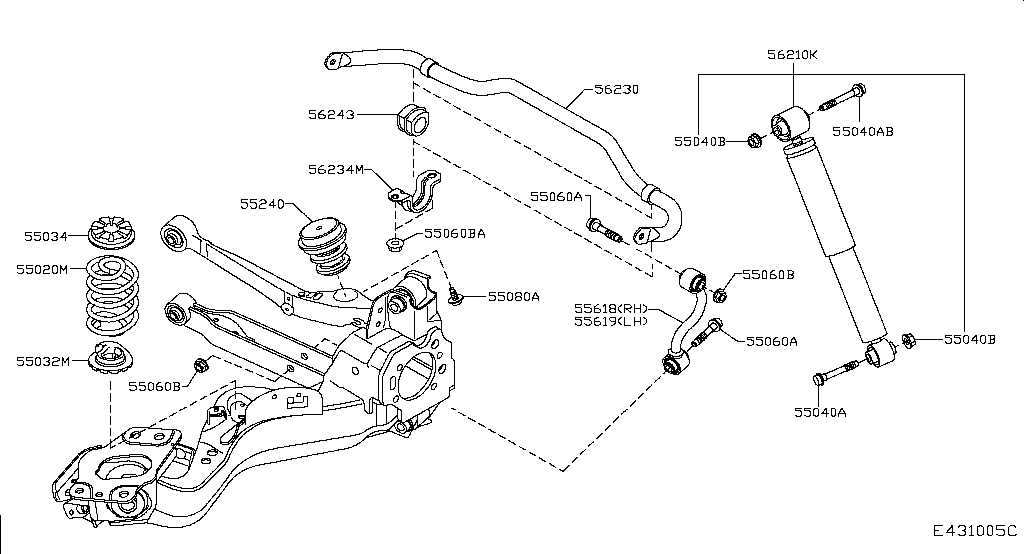

- Suspension: This system absorbs shocks from the road, enhancing comfort and handling by maintaining tire contact with the surface.

- Brake Components: Efficient braking systems are crucial for safety, consisting of discs, calipers, and pads that work together to slow or stop the vehicle.

Supporting Features

- Driveshaft: Transfers torque from the engine to the differential, playing a vital role in the vehicle’s movement.

- Wheel Hubs: Connect the wheels to the axles, facilitating rotation and supporting the weight of the vehicle.

- Alignment Adjustments: Ensuring proper alignment is key to maintaining tire wear and vehicle handling.

Each component is interdependent, contributing to the overall functionality and efficiency of the vehicle. Regular maintenance and understanding of these systems can lead to enhanced performance and longevity.

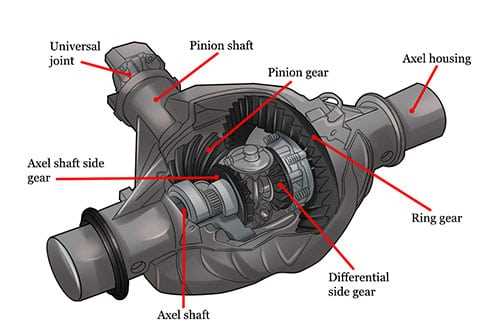

Functionality of Rear Differential

The component in question plays a crucial role in the smooth operation of vehicles, particularly during cornering and varying speed conditions. Its primary function is to distribute torque effectively between the drive wheels, allowing for optimal traction and stability.

Torque Distribution

By enabling one wheel to rotate faster than the other, this mechanism facilitates better handling during turns. This functionality is vital for maintaining control and ensuring a safe driving experience.

Types of Differentials

| Type | Functionality |

|---|---|

| Open Differential | Allows for speed variation between wheels, ideal for standard conditions. |

| Limited Slip Differential | Provides enhanced grip by transferring torque to the wheel with more traction. |

| Locking Differential | Locks both wheels together for maximum traction in off-road situations. |

Understanding the mechanics of this component is essential for appreciating its significance in vehicle performance and safety.

Common Types of Rear Ends

In the world of automotive engineering, the configuration of the drive mechanism plays a crucial role in vehicle performance and handling. Different variations cater to various driving needs, whether for everyday commuting, off-road adventures, or high-performance racing. Understanding these configurations helps enthusiasts and owners make informed choices about upgrades and maintenance.

Types of Configurations

Various designs are employed in vehicles, each offering unique benefits. Below is a summary of some widely used configurations:

| Configuration | Description | Benefits |

|---|---|---|

| Open | Allows for different wheel speeds, ideal for standard driving conditions. | Simple design, cost-effective, good for fuel efficiency. |

| Limited Slip | Distributes power to both wheels, enhancing traction. | Improved grip in slippery conditions, better performance in turns. |

| Locking | Locks both wheels together for maximum traction. | Excellent for off-road situations, provides stability on uneven surfaces. |

Performance Considerations

Choosing the right configuration depends on several factors, including driving style and terrain. For those who frequently navigate challenging landscapes, options like locking configurations may be preferable. Conversely, everyday drivers might prioritize efficiency and simplicity. Ultimately, understanding these variations allows drivers to enhance their vehicle’s capabilities effectively.

Importance of Gear Ratios

Understanding the role of gear ratios is essential for optimizing performance in various mechanical systems. These ratios influence how power is transmitted, impacting speed, torque, and efficiency.

Effects on Performance

- Higher ratios enhance torque, aiding acceleration.

- Lower ratios improve speed, ideal for cruising.

- Balancing these aspects maximizes overall effectiveness.

Applications in Different Fields

- Automotive industry: Tailored for specific driving conditions.

- Industrial machinery: Ensures optimal operation under load.

- Cycling: Affects gear selection for varied terrain.

Identifying Wear and Tear

Recognizing deterioration in components is essential for maintaining optimal performance and safety. Regular inspections can help in spotting early signs of damage, ensuring timely interventions and preventing further issues.

| Signs of Wear | Possible Causes | Recommended Actions |

|---|---|---|

| Cracks | Excessive stress or impact | Replace or repair immediately |

| Unusual Noise | Lack of lubrication or misalignment | Inspect and lubricate |

| Discoloration | Heat exposure or chemical damage | Assess and replace if necessary |

| Deformation | Overloading or fatigue | Evaluate structural integrity |

Rear End Lubrication Methods

Effective lubrication is crucial for maintaining the longevity and performance of vehicle components. Various techniques exist to ensure that critical areas receive the necessary fluid, enhancing efficiency and reducing wear. Understanding these methods allows for optimal maintenance and improved functionality.

Types of Lubrication Techniques

Several approaches can be employed to provide adequate lubrication. Manual lubrication involves directly applying lubricant to specific areas, ensuring coverage where needed. In contrast, automated systems distribute fluid through a network of channels, offering consistent application without manual intervention. Each method has its benefits depending on the application and environmental conditions.

Importance of Regular Maintenance

Regular checks and timely replacement of lubricants are essential to prevent issues related to insufficient lubrication. Routine inspections can identify potential problems before they escalate, allowing for proactive measures. By prioritizing lubrication practices, vehicle owners can ultimately enhance performance and extend the lifespan of their machinery.

Tools for Rear End Maintenance

Proper upkeep of vehicle components at the back is essential for ensuring optimal performance and longevity. A variety of specialized instruments are required to effectively carry out these maintenance tasks. Selecting the right tools can significantly enhance efficiency and accuracy during service.

Essential Tools

- Socket Set: Crucial for loosening and tightening bolts.

- Wrenches: Various sizes for different applications.

- Torque Wrench: Ensures precise torque settings.

- Jack Stands: For safely lifting the vehicle.

- Fluid Pump: Useful for changing lubricants.

Additional Equipment

- Brake Cleaner: Essential for cleaning components.

- Measuring Tools: Calipers and gauges for accurate measurements.

- Inspection Mirror: Allows for better visibility in tight spaces.

- Grease Gun: Necessary for lubrication of moving parts.

- Diagnostic Scanner: Helps in identifying electronic issues.

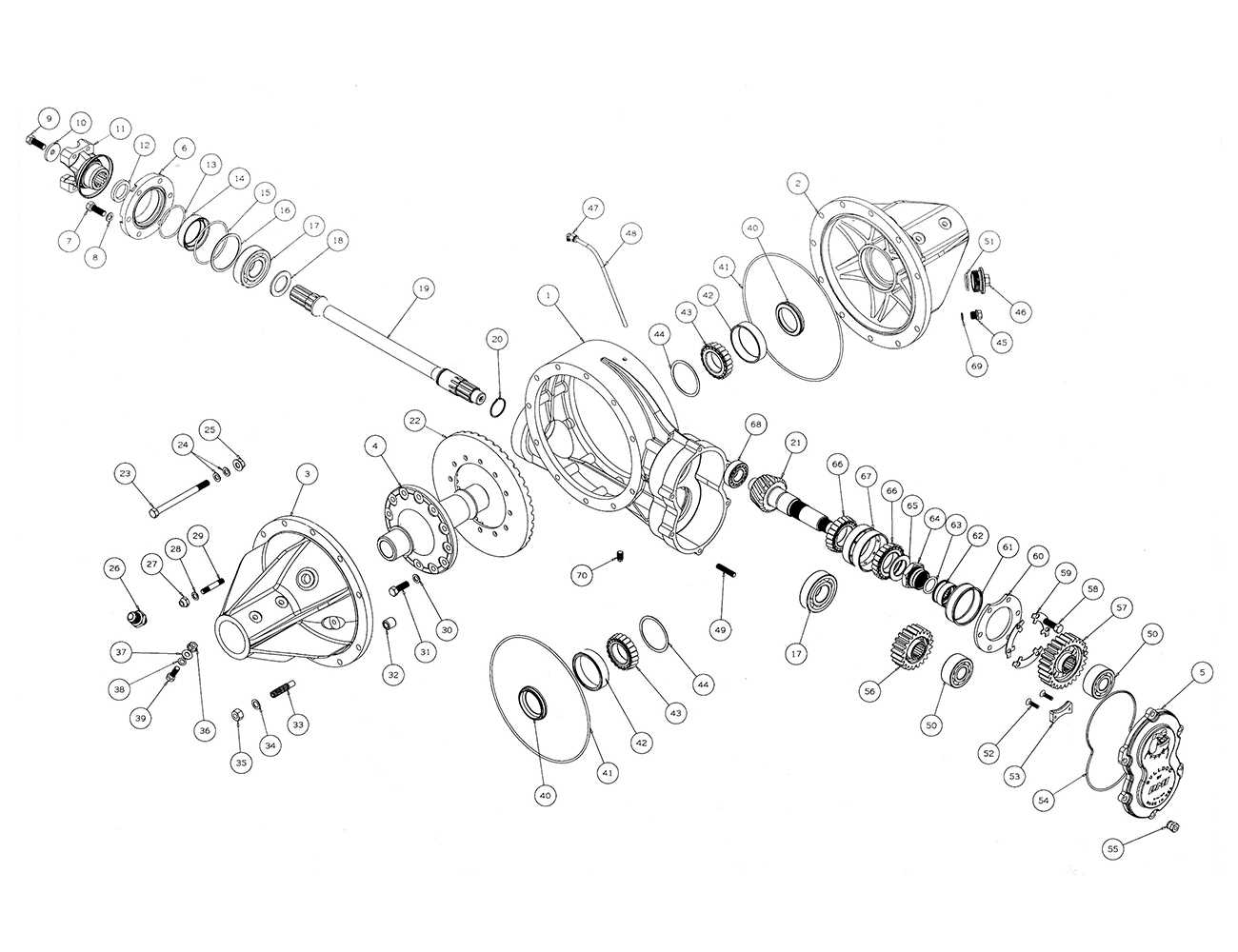

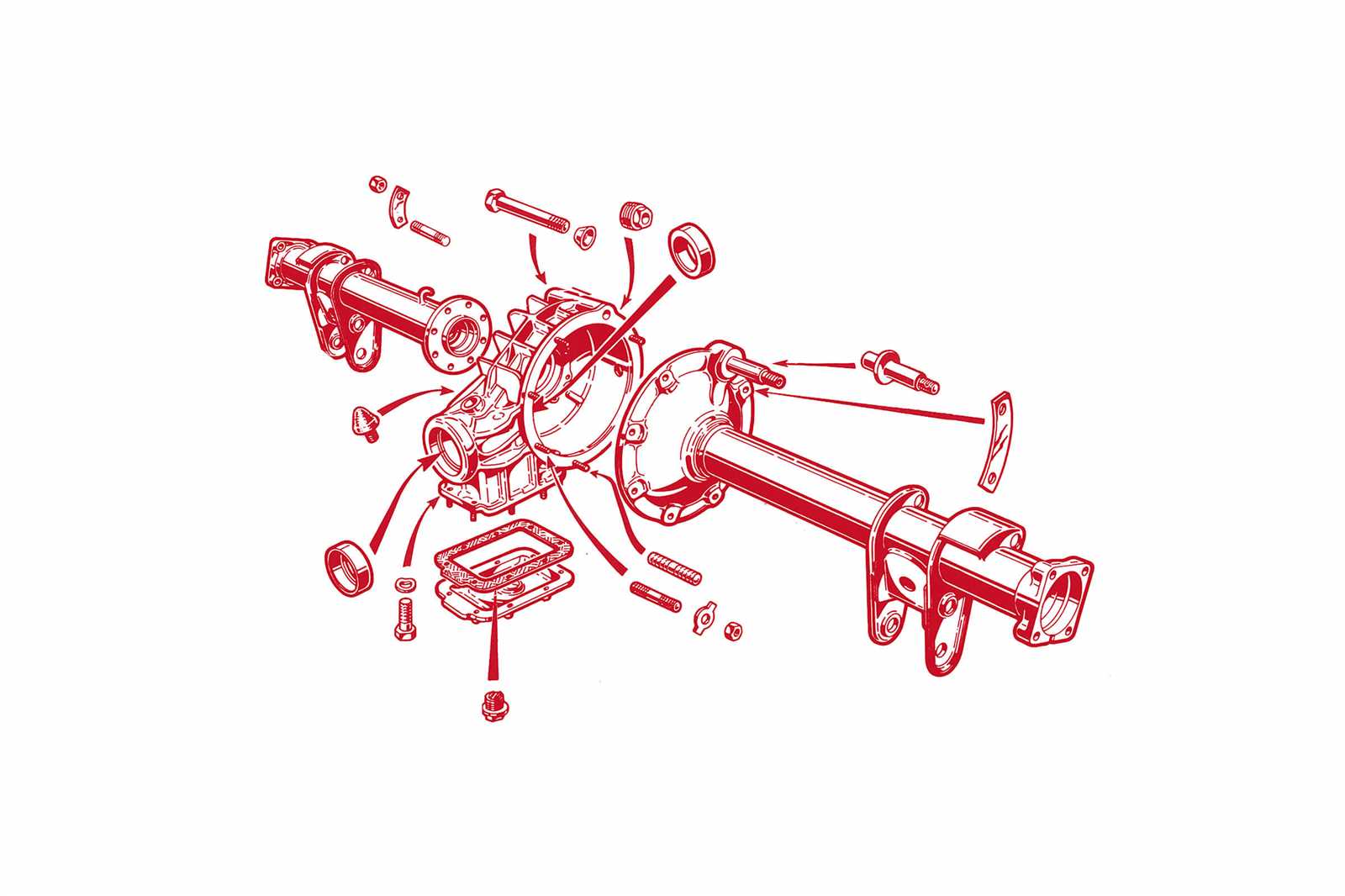

Step-by-Step Assembly Guide

This section provides a comprehensive approach to assembling components efficiently and effectively. By following each step in detail, you will ensure that all elements fit together seamlessly, resulting in a reliable and functional assembly. This guide emphasizes clarity and precision, making the process straightforward for both beginners and experienced individuals.

Preparation Phase

Before diving into the assembly, gather all necessary tools and materials. Ensure you have a clean workspace to facilitate the process and minimize the risk of losing any small items.

| Tool/Material | Purpose |

|---|---|

| Screwdriver | To fasten components together |

| Wrench | For tightening nuts and bolts |

| Measuring tape | To ensure correct dimensions |

| Assembly Manual | Provides detailed instructions and diagrams |

Assembly Steps

Follow these steps for a successful assembly:

- Start with the base component and ensure it is placed securely on a level surface.

- Align the secondary elements according to the instructions provided in the manual.

- Secure each connection with the appropriate fasteners, checking for stability as you progress.

- Complete the assembly by double-checking all connections and ensuring that everything is aligned properly.

By adhering to these guidelines, you will achieve a robust and durable assembly that meets your expectations and requirements.

Troubleshooting Common Issues

Understanding and addressing frequent problems can significantly enhance the performance and longevity of your vehicle. By identifying symptoms early, you can avoid more extensive damage and costly repairs. This section provides insights into common challenges and practical solutions to keep your automobile running smoothly.

Identifying Symptoms

Many issues manifest through noticeable signs. Strange noises, vibrations, or warning lights are key indicators that something may be amiss. Regularly observing these signs can help pinpoint the root cause, allowing you to take timely action.

Practical Solutions

Once symptoms are identified, troubleshooting can begin. Checking fluid levels, inspecting for leaks, and ensuring all connections are secure can often resolve basic issues. If problems persist, consulting a professional is the ultimate step to ensure thorough diagnosis and repair.

Upgrading Rear End Performance

Enhancing the overall dynamics of your vehicle can lead to a more exhilarating driving experience. By focusing on specific components and their interaction, one can significantly improve handling, stability, and traction. This upgrade process involves meticulous planning and the selection of high-quality replacements.

Key Components to Consider

First, consider the differential and its gearing. Upgrading to a more performance-oriented differential can enhance acceleration and cornering capabilities. Additionally, swapping out bushings and mounts for stiffer alternatives can provide improved feedback and responsiveness.

Suspension Enhancements

Revising the suspension system is crucial for optimizing performance. Upgraded shock absorbers and springs can greatly affect ride quality and handling precision. Furthermore, incorporating sway bars can reduce body roll, allowing for sharper turns and greater control.

In conclusion, a thoughtful approach to enhancing your vehicle’s lower mechanics can lead to the ultimate driving experience. Embrace the journey of improvement for an unparalleled thrill on the road.

Safety Considerations for Rear Ends

When it comes to vehicle safety, certain components play a crucial role in ensuring stability and control. Understanding the intricacies of these assemblies can significantly enhance overall performance and reduce the risk of accidents. Proper maintenance and awareness of potential hazards are essential for any vehicle owner.

Importance of Regular Inspections

Regular checks can help identify wear and tear that might compromise safety. Ensuring all components function correctly is vital for optimal performance.

Common Risks and Precautions

Several risks are associated with improper maintenance. Drivers should be aware of signs indicating that attention is needed.

| Risk | Precaution |

|---|---|

| Worn components | Conduct routine inspections |

| Fluid leaks | Check for leaks regularly |

| Improper alignment | Ensure professional alignment checks |

Future Trends in Rear End Design

The evolution of automotive structures is poised to transform the industry, enhancing safety, performance, and aesthetics. As technology advances, manufacturers are exploring innovative materials and designs that not only improve functionality but also align with sustainability goals.

Innovative Materials

One of the most significant shifts is the use of lightweight composites and advanced alloys. These materials reduce overall weight, improving fuel efficiency and handling while maintaining durability. Manufacturers are also focusing on recyclable materials to minimize environmental impact.

Enhanced Aerodynamics

Streamlined shapes are becoming the norm, as designers aim to reduce drag and increase efficiency. Active aerodynamic features will play a crucial role, adjusting in real-time to driving conditions to optimize performance. This trend promises not only better fuel economy but also a more dynamic driving experience.