Understanding the Traxxas Slash Rear Parts Diagram

When it comes to enhancing the performance and longevity of your high-speed machine, having a thorough understanding of its components is essential. Knowledge of each element’s function not only aids in maintenance but also empowers enthusiasts to make informed upgrades. This guide delves into the intricate details of the vehicle’s structure, offering a visual representation of its various sections.

By familiarizing yourself with the essential elements located at the back of the chassis, you can better appreciate the engineering that contributes to stability and maneuverability. This exploration will highlight critical components, ensuring that you can effectively troubleshoot any issues and optimize performance. A well-maintained setup leads to improved handling and an overall enhanced driving experience.

Moreover, gaining insight into these individual pieces allows for a more customized approach to modifications, enabling users to tailor their machines to specific preferences and needs. This resource aims to serve as a comprehensive reference, equipping you with the knowledge necessary to navigate your vehicle’s intricate assembly with confidence.

Understanding the Traxxas Slash Rear Assembly

The rear assembly of an off-road vehicle plays a crucial role in its overall performance and durability. This section delves into the intricacies of this specific assembly, highlighting key components and their functions. Grasping how each part interacts can greatly enhance maintenance and tuning efforts.

- Chassis Frame: The backbone of the vehicle, providing structural integrity and supporting various components.

- Suspension System: Comprises elements like shocks and springs, crucial for absorbing impacts and ensuring smooth handling on uneven terrains.

- Differential: Facilitates power distribution to the wheels, allowing for better traction and maneuverability during turns.

- Drive Shafts: Transfers power from the motor to the wheels, vital for propulsion and speed.

Each element must be maintained and understood to ensure optimal performance. Regular inspection and timely replacements are recommended to prevent breakdowns and enhance longevity.

- Identify any signs of wear on the suspension components.

- Check the differential for proper lubrication and functionality.

- Ensure that the drive shafts are aligned and secured correctly.

By familiarizing yourself with these aspects, you’ll be better equipped to troubleshoot issues and optimize the performance of your vehicle.

Essential Components of the Rear End

The back assembly of a vehicle plays a crucial role in its overall performance and stability. Understanding the fundamental elements involved can enhance your knowledge of maintenance and upgrades, leading to an improved driving experience.

Key Elements

Among the vital components are the suspension system, which absorbs shocks and provides stability, and the drive shaft, responsible for transferring power from the engine. The differential is another critical part, allowing for smooth turns by enabling the wheels to rotate at different speeds.

Importance of Quality

Investing in high-quality components ensures durability and performance. Upgrading these elements can lead to ultimate enhancements in handling and speed, making it essential to choose wisely.

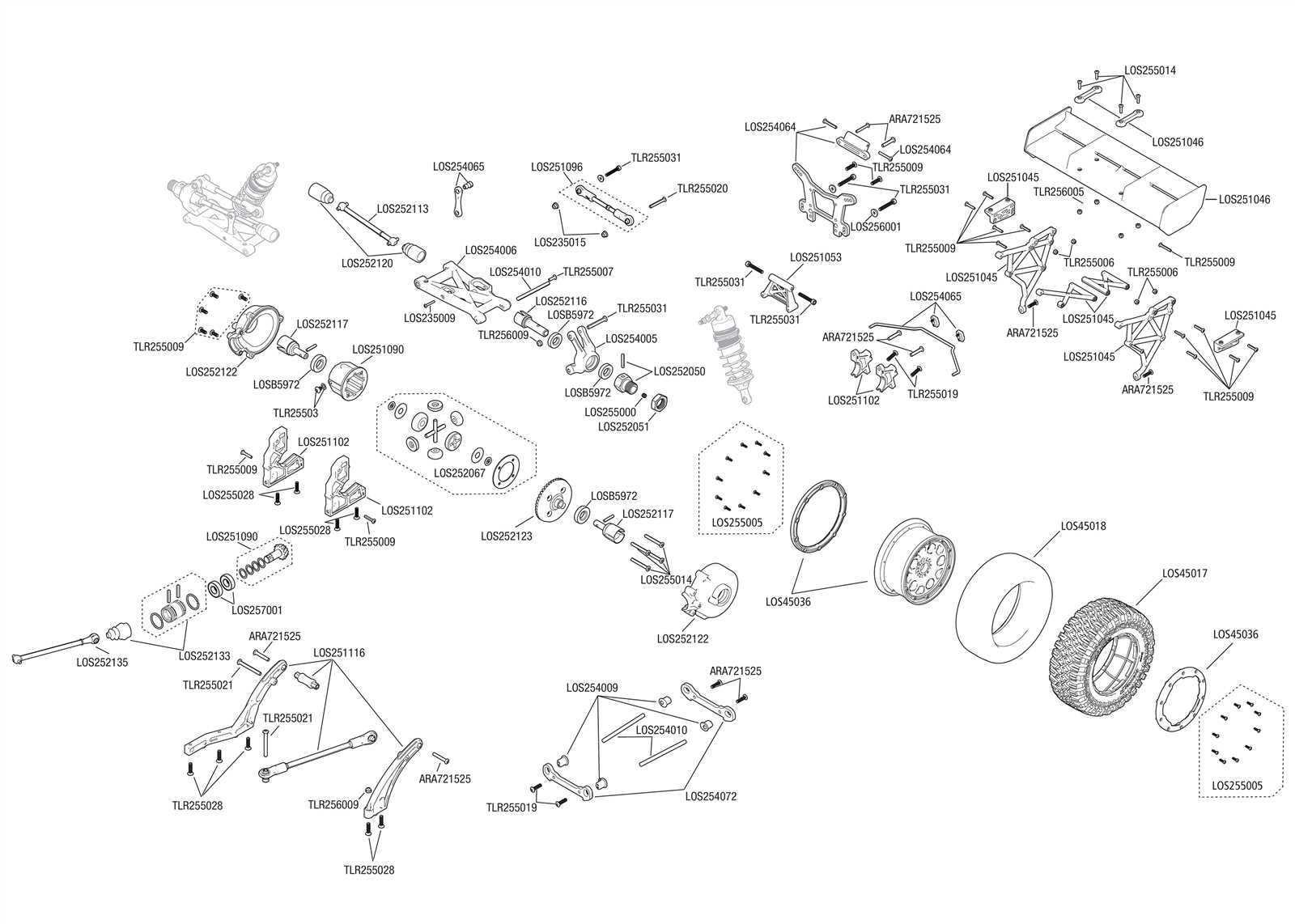

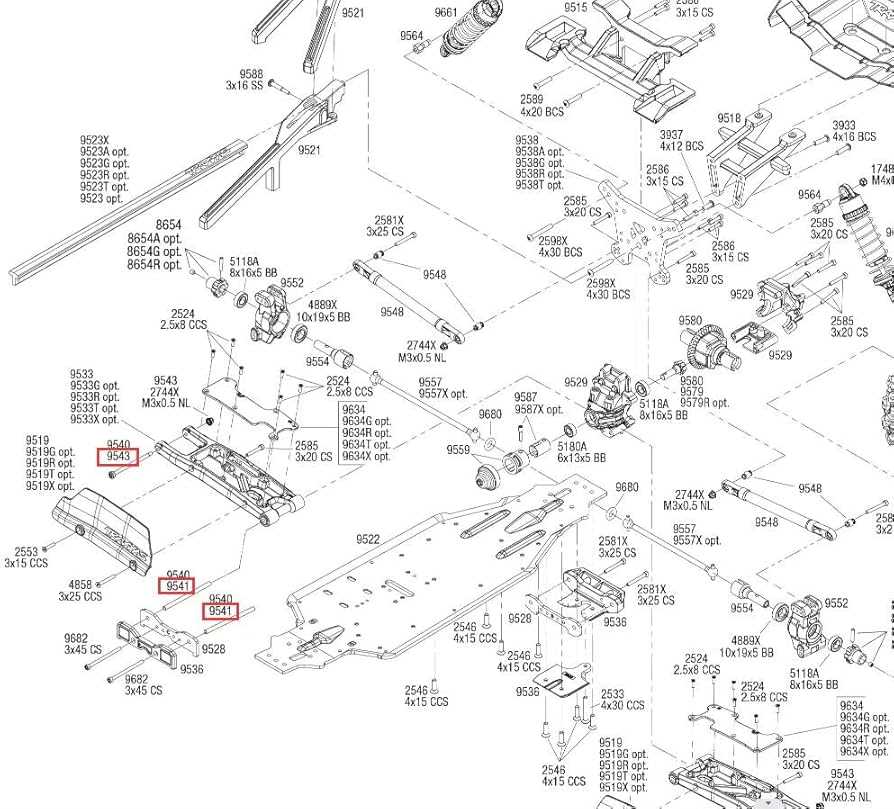

How to Interpret the Diagram

Understanding the visual representation of components is essential for effective assembly and maintenance of your vehicle. This guide will help you decode the elements and their relationships, enabling you to grasp the structure and function of each piece with confidence.

To begin, focus on the key components indicated in the illustration. Each part is typically labeled with a unique identifier, making it easier to locate the corresponding item in your inventory. Pay attention to the connections and orientations depicted, as these details are crucial for proper installation.

| Symbol | Description |

|---|---|

| A | Chassis Base |

| B | Suspension Arm |

| C | Shock Absorber |

| D | Wheel Hub |

| E | Drive Shaft |

When analyzing the layout, note how different elements interact with one another. The orientation and alignment of parts are key to ensuring optimal performance. Cross-reference the identifiers with your assembly manual to confirm compatibility and functionality. By carefully studying the representation, you’ll be better prepared for repairs or upgrades, enhancing your overall experience with the vehicle.

Common Issues with Rear Components

When operating remote-controlled vehicles, certain challenges may arise with the components at the back. These issues can lead to decreased performance, instability, or even damage if not addressed promptly. Understanding these common problems can help enthusiasts maintain optimal functionality and enjoy a smoother experience.

Wear and Tear

Excessive usage often results in wear on various elements, including suspension systems and wheel assemblies. Components may lose their effectiveness over time, necessitating regular inspection and potential replacement to ensure peak performance.

Alignment and Stability

Misalignment can cause significant handling issues. Check for any signs of skewing in the structure or attachment points, as this can lead to instability during operation. Keeping everything aligned is crucial for achieving the ultimate driving experience.

Replacement Parts Overview

This section provides an insight into essential components that may require substitution over time. Understanding these elements can enhance the performance and longevity of your model. Each item plays a crucial role in ensuring smooth operation and reliability.

| Component | Description |

|---|---|

| Chassis | The main frame that supports all other elements and affects stability. |

| Shock Absorbers | Key for managing impacts and ensuring a smooth ride. |

| Wheels | Essential for traction and maneuverability on various surfaces. |

| Motor | Drives the vehicle and influences speed and acceleration. |

| Battery | Powers the model, impacting runtime and performance. |

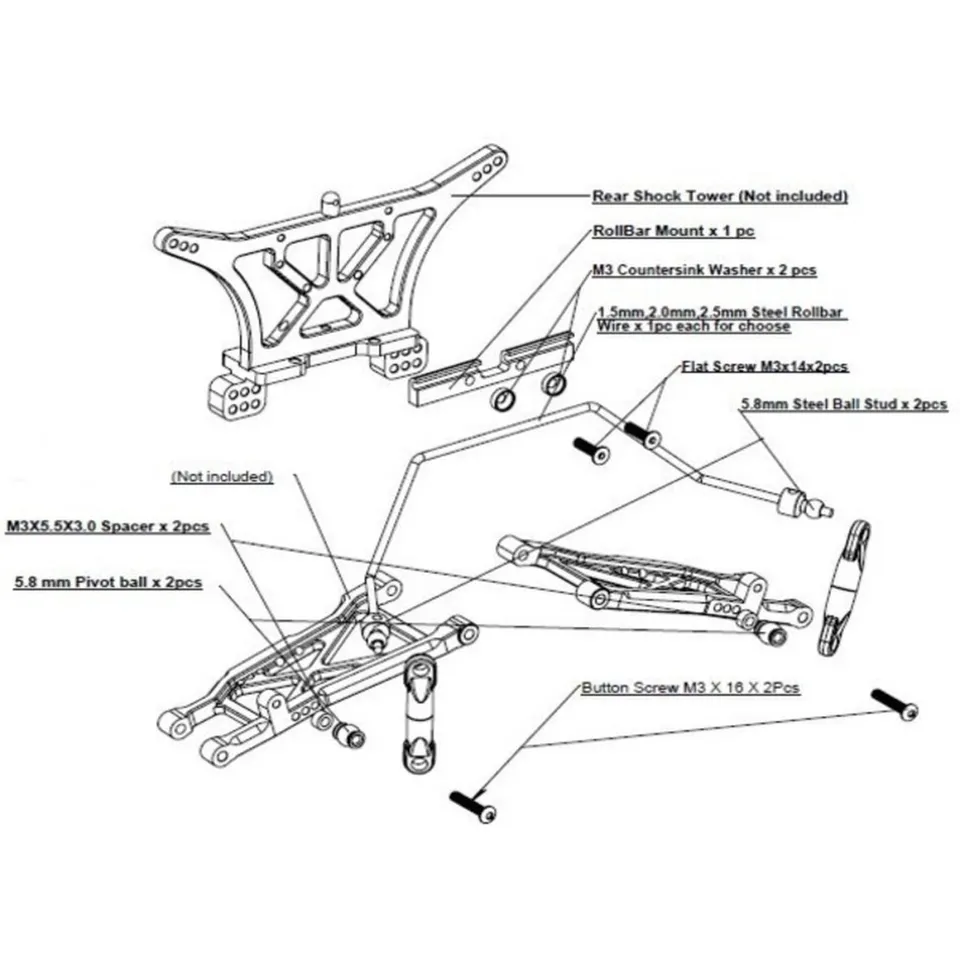

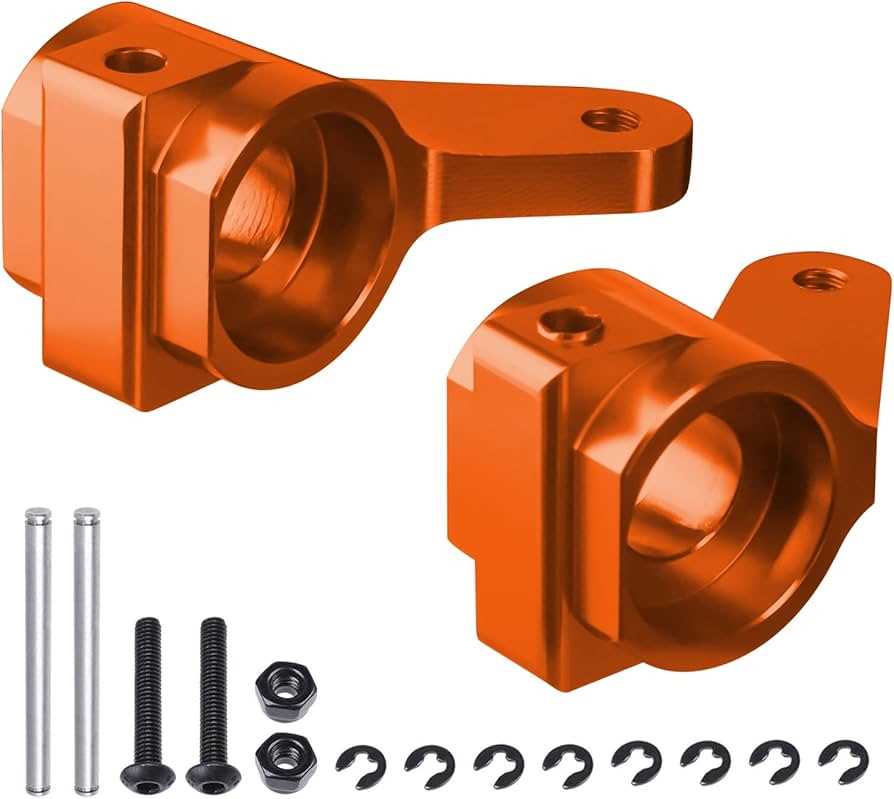

Upgrading Rear Components for Performance

Enhancing the performance of your vehicle involves a thorough understanding of its dynamics and the role of various components. By focusing on the back end, you can significantly improve stability, traction, and overall handling. This section explores effective upgrades that will elevate your ride’s capabilities on diverse terrains.

Choosing the Right Suspension System

A quality suspension system is crucial for maximizing performance. Upgrading to adjustable shocks can provide better control and adaptability to varying conditions. Consider options that allow for tuning preload and damping, ensuring your setup aligns with your driving style and environment.

Improving Stability with Upgraded A-arms

Switching to reinforced A-arms can enhance durability and stability during high-speed maneuvers. Opt for lightweight materials that maintain strength while reducing overall weight. This not only aids in responsiveness but also contributes to longer-lasting performance in challenging situations.

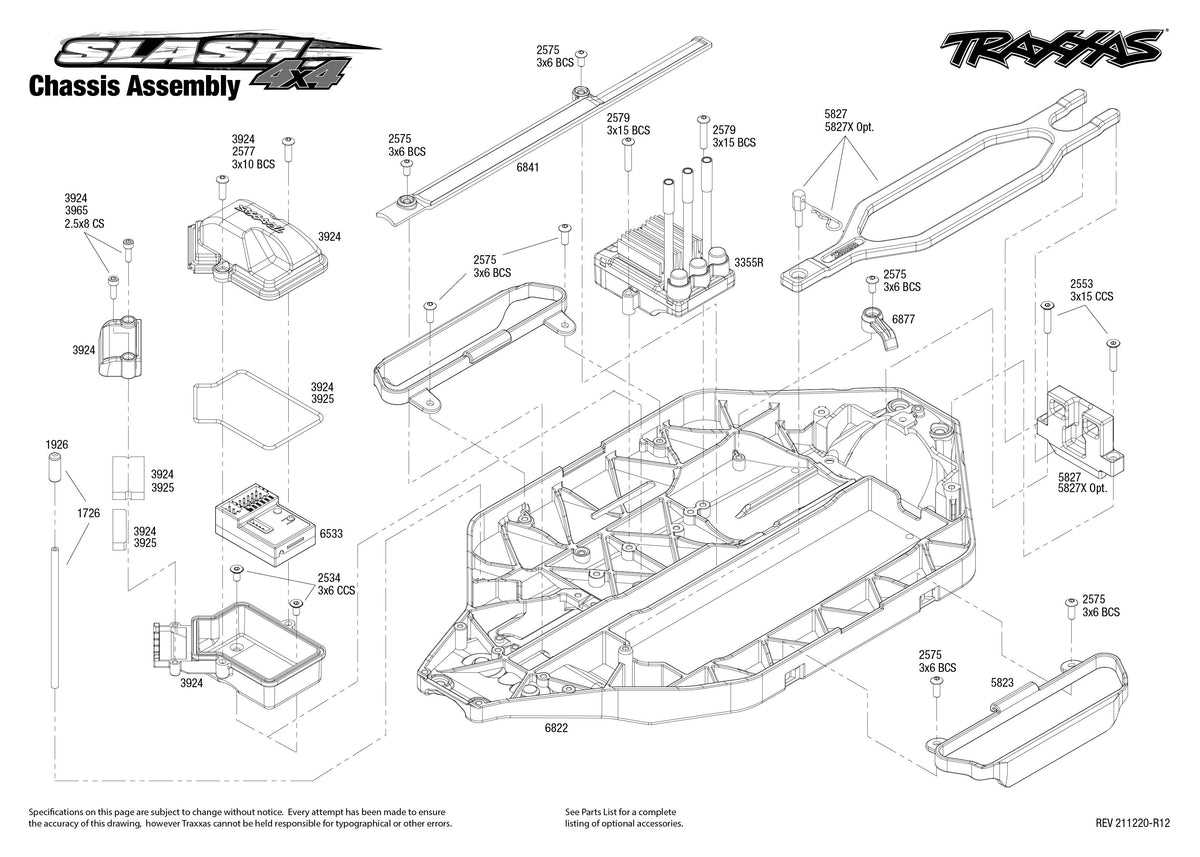

Step-by-Step Rear Assembly Guide

This section provides a comprehensive approach to assembling the back section of your model. By following these detailed instructions, you’ll ensure that every component fits perfectly, leading to enhanced performance and durability. The assembly process is broken down into manageable steps, making it easy for both beginners and experienced hobbyists to follow along.

Gathering Necessary Components

Before you start, it’s crucial to collect all the essential elements required for the assembly. This includes the chassis, suspension pieces, drive components, and any additional accessories you plan to incorporate. Having everything organized will streamline the process and minimize interruptions.

Assembly Steps

1. Begin with the Chassis: Secure the main frame on a stable surface. Ensure that the mounting points are clean and free from debris.

2. Attach Suspension Components: Align the shock absorbers with the designated points on the chassis. Use the appropriate screws and tighten them securely to avoid any movement during operation.

3. Connect Drive Elements: Position the drive shaft and ensure it fits snugly into the designated housing. Test for smooth rotation to confirm proper installation.

4. Final Checks: Once all components are assembled, conduct a thorough inspection. Ensure that all screws are tightened and that there are no loose parts. This step is vital for the longevity of your model.

Following these guidelines will lead to a successful assembly process, setting a solid foundation for enjoyable and efficient operation.

Tools Needed for Rear Repairs

When undertaking maintenance on your vehicle’s posterior assembly, having the right tools is essential for efficiency and effectiveness. A well-equipped toolkit ensures that every task can be completed smoothly, allowing for a seamless restoration or upgrade process.

Essential tools include a reliable set of screwdrivers, both flathead and Phillips, for tackling various fasteners. Pliers are crucial for gripping and manipulating components, while a wrench set will help with any nut and bolt adjustments. Additionally, a hex driver is often necessary for specific screws. For precision tasks, consider a caliper to measure parts accurately, and don’t forget a good quality lubricant to keep everything running smoothly.

Lastly, safety gear, such as goggles and gloves, should always be on hand to protect against potential hazards during repairs. With this toolkit, you’ll be well-prepared to address any challenges that arise.

Maintaining Your Rear Suspension

Proper upkeep of your vehicle’s suspension system is crucial for optimal performance and longevity. Regular maintenance ensures that components function smoothly, providing stability and comfort during operation. By following a few essential practices, you can enhance the durability and responsiveness of your setup.

Regular Inspection

Performing frequent checks can help identify wear and tear before it becomes a major issue. Focus on the following areas:

- Shock absorbers: Look for leaks or signs of damage.

- Springs: Check for any signs of sagging or corrosion.

- Mounting points: Ensure all connections are secure and free from rust.

Cleaning and Lubrication

Keeping components clean is essential for smooth operation. Here’s how to maintain cleanliness and lubrication:

- Use a soft brush or cloth to remove dirt and debris.

- Apply appropriate lubricants to moving parts, avoiding over-application.

- Wipe off excess lubricant to prevent attracting more dirt.

By following these maintenance tips, you can significantly improve the performance and lifespan of your vehicle’s suspension system. Regular attention will lead to a more enjoyable driving experience and better handling on various terrains.

Comparing Traxxas Slash Versions

When exploring the diverse options available in the world of remote-controlled vehicles, enthusiasts often find themselves intrigued by the various iterations of a popular model. Each version brings unique features, performance enhancements, and aesthetic choices, making it essential for users to understand the distinctions to select the right one for their needs.

Performance Characteristics

The evolution of this vehicle series showcases improvements in speed, handling, and durability. The latest models typically incorporate advanced suspension systems and powerful motors that enhance driving experience on different terrains. Additionally, upgrades in battery technology contribute to longer run times and improved acceleration, making newer editions a compelling choice for competitive racing.

Design and Customization

Visual appeal and the ability to personalize a model play significant roles in owner satisfaction. Variants differ not only in color schemes but also in body styles and frame construction. Aftermarket options allow hobbyists to modify their vehicles extensively, from enhancing aesthetics to optimizing performance. Understanding these design variations can help enthusiasts make informed decisions about their preferred choice.

Customization Options for Rear Setup

Enhancing your vehicle’s performance often starts with optimizing the back assembly. A variety of modifications can improve handling, stability, and overall driving experience. By exploring different components and configurations, enthusiasts can tailor their machines to better suit their specific driving styles and terrain conditions.

Suspension Upgrades

One of the most impactful areas to customize is the suspension system. Upgrading shock absorbers and springs can significantly alter how the vehicle responds to obstacles and maneuvers. Considerations include spring rates, shock length, and damping characteristics.

| Component | Benefits |

|---|---|

| Oil-filled Shocks | Improved damping and smoother ride quality |

| Progressive Springs | Better handling over rough terrain |

| Adjustable Shock Towers | Customization of shock positioning for optimal performance |

Wheel and Tire Choices

The selection of wheels and tires plays a crucial role in traction and stability. Opting for wider tires can enhance grip, while lightweight wheels can improve acceleration and maneuverability. Additionally, experimenting with tire tread patterns can help adapt the vehicle to different surfaces.

| Wheel Type | Tire Type | Application |

|---|---|---|

| Aluminum | All-terrain | Versatile use across various terrains |

| Plastic | Racing | Optimized for speed and performance |

| Heavy-duty | Mud | Excellent traction in soft, loose surfaces |

Tips for Troubleshooting Rear Problems

When encountering issues with the back section of your vehicle, it’s crucial to approach the situation systematically. By understanding common symptoms and their potential causes, you can effectively diagnose and resolve the challenges you face. This guide will provide essential insights to help you navigate these problems efficiently.

1. Check for Alignment Issues

Misalignment can lead to uneven wear and handling difficulties. Inspect the components closely to ensure everything is in the correct position. Adjusting any misaligned elements may restore balance and improve performance.

2. Inspect for Wear and Tear

Over time, certain components may show signs of fatigue. Look for cracks, breaks, or excessive wear on key parts. Replacing worn elements promptly can prevent further damage and maintain optimal functionality.

3. Examine Suspension Settings

Incorrect suspension adjustments can drastically affect performance. Review the settings and make necessary tweaks to improve handling and stability. Fine-tuning these elements can enhance overall ride quality.

4. Look for Loose Fasteners

Vibrations during use can lead to loosened screws and bolts. Conduct a thorough check of all fasteners to ensure they are securely tightened. This simple step can often resolve a myriad of issues.

5. Test Wheel Bearings

Damaged or worn wheel bearings can cause noise and hinder movement. Spin the wheels to detect any irregularities, and replace any compromised bearings to restore smooth operation.

By following these tips and maintaining a proactive approach, you can address various concerns effectively and enjoy a more reliable experience with your vehicle.