Ariens 46 Riding Mower Parts Diagram Overview

When it comes to maintaining a well-groomed landscape, the effectiveness of a specific garden appliance can greatly impact the overall efficiency of your yard work. Each machine is composed of various elements that play critical roles in its functionality. By familiarizing yourself with these essential components, you can enhance your machine’s performance and ensure that it operates at its best.

Visual representations can serve as invaluable tools for both novice and experienced users. They provide clarity in understanding how different parts interact and assist in troubleshooting potential issues. A comprehensive illustration not only highlights the arrangement of the elements but also aids in identifying replacements when necessary.

Whether you are looking to upgrade, repair, or simply learn more about the intricacies of your garden equipment, having access to detailed visual guides can make the process significantly easier. This knowledge empowers you to take better care of your tools, ensuring that they remain reliable companions in your gardening endeavors.

Ariens 46 Riding Mower Overview

This section provides an insightful look into a particular model designed for efficient grass maintenance and landscape management. Known for its robust performance and user-friendly features, this machine is a reliable choice for homeowners and landscaping professionals alike. It incorporates advanced engineering to ensure optimal operation while providing comfort and control to the operator.

Key Features

The equipment is equipped with several notable attributes that enhance its functionality. These characteristics contribute to its overall performance and ease of use:

| Feature | Description |

|---|---|

| Engine | Powerful engine delivering high efficiency and durability. |

| Transmission | Smooth gear shifts for an enjoyable driving experience. |

| Cutting Width | Spacious cutting width for faster grass trimming. |

| Comfort | Ergonomic seating and controls for reduced operator fatigue. |

Maintenance Tips

- Regularly checking and changing the oil.

- Inspecting blades for wear and sharpness.

- Cleansing the chassis and engine components.

- Ensuring tire pressure is at optimal levels.

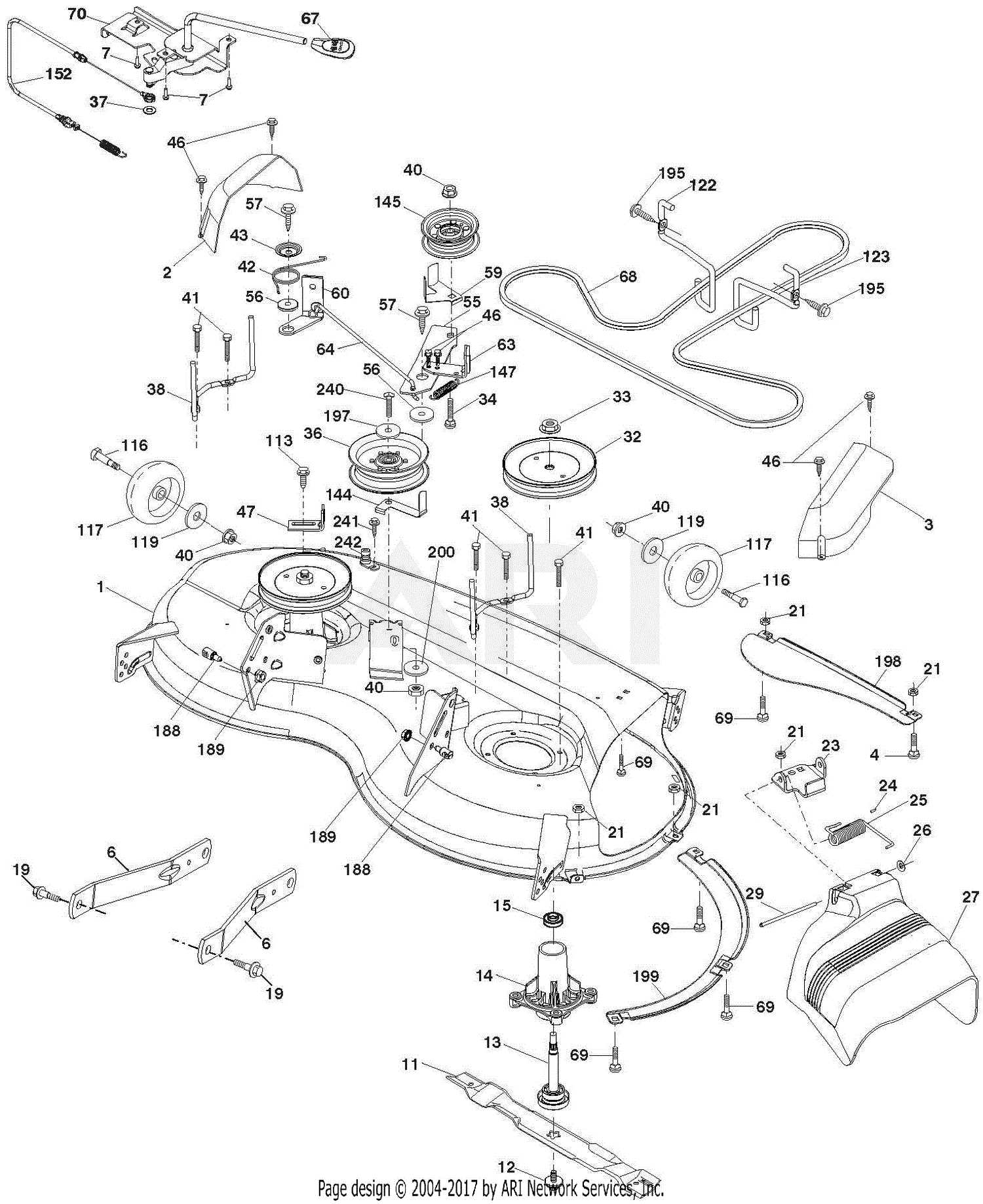

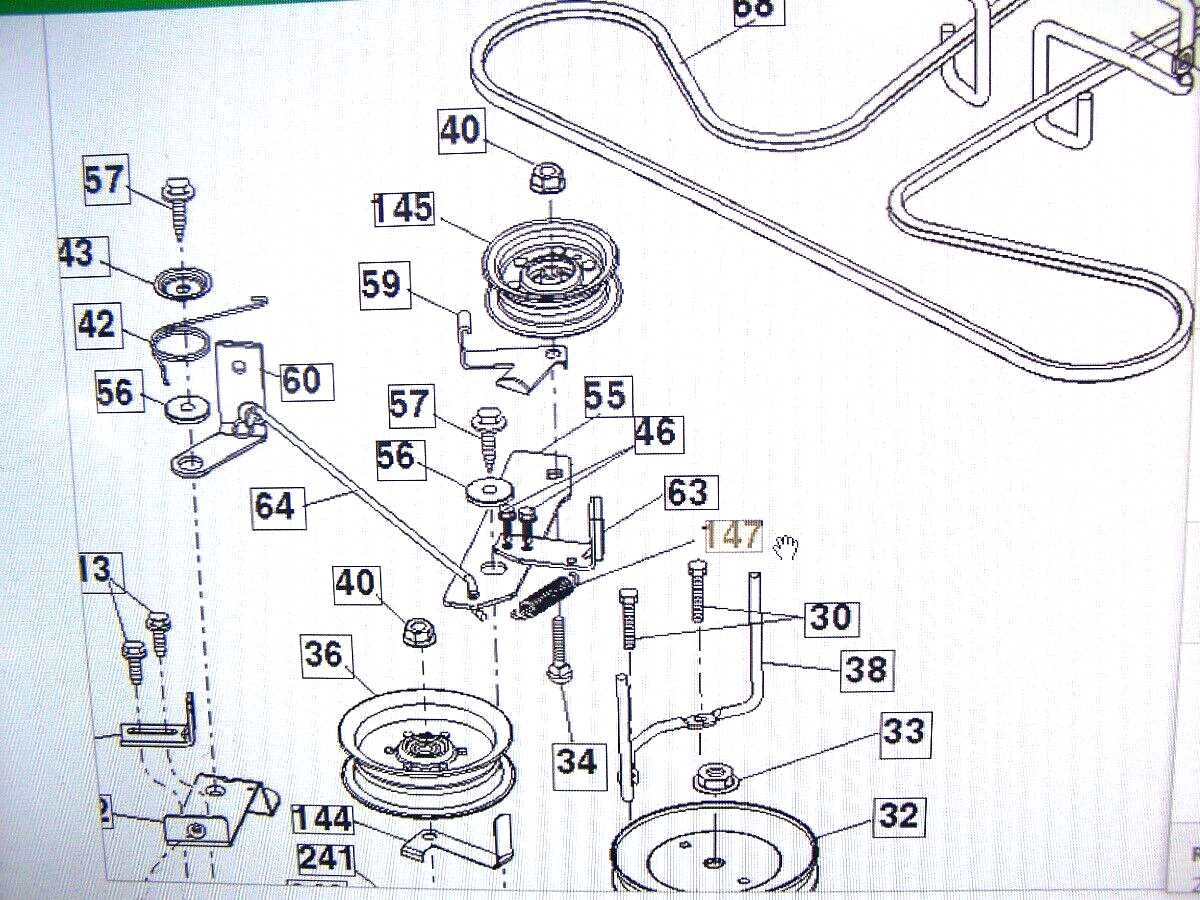

Key Components of the Mower

Understanding the essential elements of a lawn maintenance vehicle is crucial for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance, reliability, and ease of use. Familiarity with these integral parts will help users troubleshoot issues and facilitate smoother maintenance procedures.

Engine and Power System

The heart of any lawn care machine is its power unit. This engine is responsible for providing the necessary force to operate various functions and attachments. Its efficiency directly impacts the overall performance of the equipment.

Cutting Mechanism

The cutting assembly consists of blades and associated components designed to achieve a clean and even cut. Proper maintenance of this system is vital for achieving a professional-looking lawn.

| Component | Description |

|---|---|

| Engine | Drives the entire system, powering the blades and wheels. |

| Cutting Blades | Sharp edges that slice through grass for a clean finish. |

| Transmission | Transfers power from the engine to the wheels, enabling movement. |

| Chassis | The framework that supports all components and provides stability. |

| Deck | Houses the blades and protects the operator from debris. |

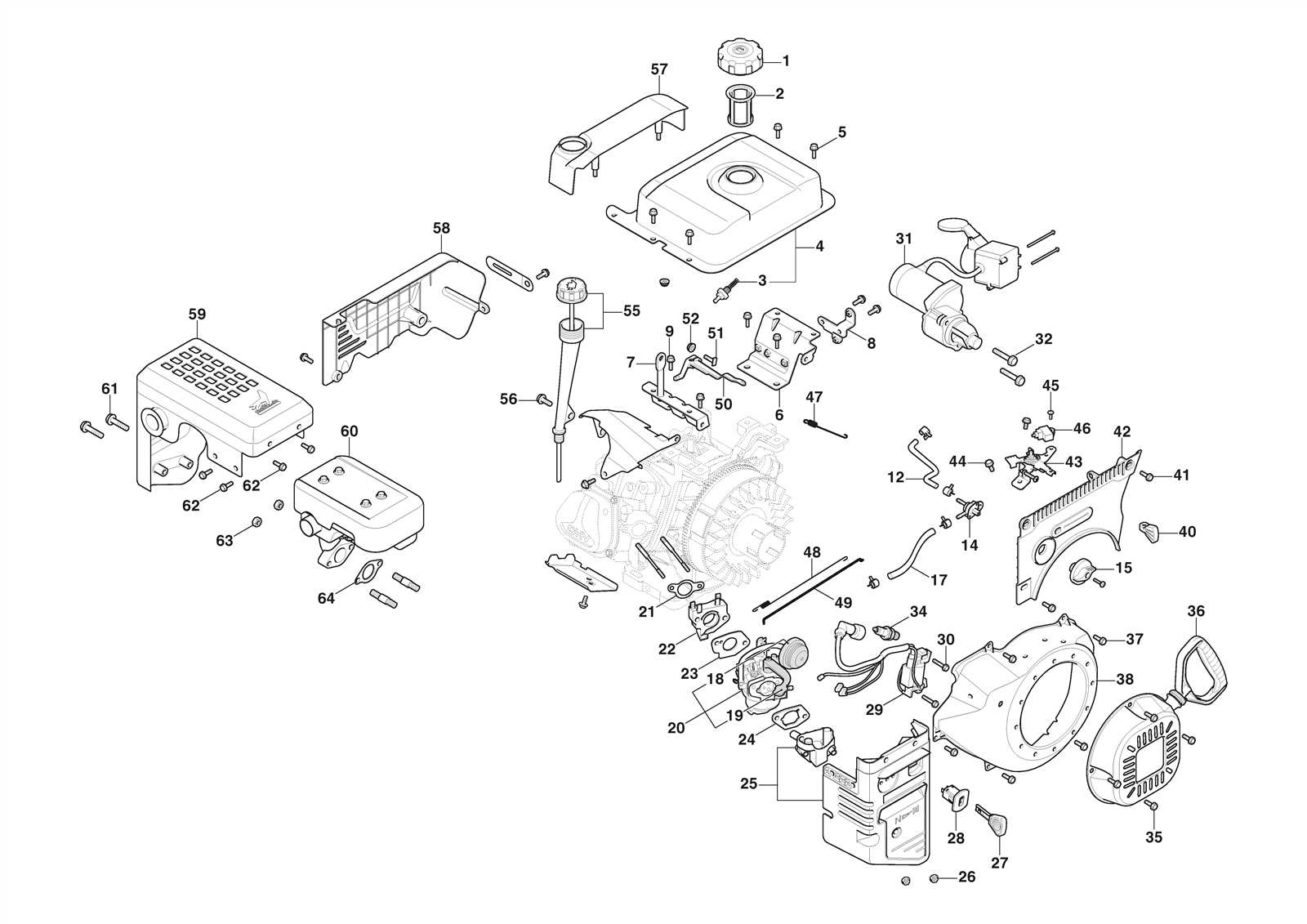

Understanding the Mower’s Engine

The engine serves as the heart of any grass-cutting equipment, providing the necessary power to operate efficiently. Grasping the fundamental aspects of this crucial component can enhance maintenance and performance, ensuring longevity and reliability.

Key Components

- Crankshaft: Converts the linear motion of the pistons into rotational energy.

- Piston: Moves up and down within the cylinder, creating the necessary compression.

- Fuel System: Delivers the mixture of fuel and air required for combustion.

- Ignition System: Initiates the combustion process, enabling the engine to start.

- Cooling System: Prevents overheating by dissipating heat generated during operation.

Maintenance Tips

- Regularly check and change the oil to ensure optimal performance.

- Inspect air filters and replace them if they become clogged.

- Keep the fuel system clean to avoid blockages and ensure smooth operation.

- Monitor spark plugs for wear and replace them as needed.

- Examine belts and hoses for signs of wear and tear, replacing them promptly.

By understanding these elements and adhering to maintenance practices, operators can significantly improve the functionality and lifespan of their equipment.

Blade Assembly and Maintenance Tips

Proper upkeep of the cutting mechanism is crucial for optimal performance and longevity. Understanding the assembly components and routine care will ensure effective operation and enhance the durability of the equipment. Regular maintenance not only improves cutting efficiency but also reduces the risk of damage.

Assembly Procedure

When assembling the cutting mechanism, begin by aligning the blades correctly. Ensure that all components are securely fastened to prevent any movement during operation. It is advisable to refer to the manufacturer’s guidelines for specific torque settings to maintain the integrity of the assembly. Periodically check the attachment points for wear and replace any damaged parts as necessary.

Maintenance Practices

Routine maintenance should include sharpening the blades to achieve a clean cut. Dull blades can stress the engine and lead to uneven cutting. Additionally, inspect the blades for signs of corrosion or damage after each use. Cleaning the assembly of grass clippings and debris will also help maintain its efficiency. Always use protective gear when handling blades, and follow safety protocols during maintenance tasks.

Transmission System Explained

The transmission system plays a vital role in the efficient operation of a vehicle, enabling smooth transitions between different speed ranges and enhancing overall performance. This mechanism is responsible for transferring power from the engine to the wheels, allowing for various driving conditions and terrains. Understanding its components and functionality is crucial for proper maintenance and troubleshooting.

Key Components of the Transmission

The transmission system comprises several essential elements that work in harmony to ensure effective power delivery. Each component has a specific function that contributes to the overall efficiency of the system. Below is a summary of the key parts:

| Component | Function |

|---|---|

| Gearbox | Facilitates the selection of different gear ratios to match the vehicle’s speed and torque requirements. |

| Clutch | Engages and disengages the engine’s power from the transmission, allowing for smooth gear shifts. |

| Driveshaft | Transfers rotational force from the transmission to the wheels, enabling movement. |

| Torque Converter | Amplifies engine torque during acceleration, enhancing power delivery without manual shifting. |

Importance of Maintenance

Regular upkeep of the transmission system is crucial for optimal functionality and longevity. Routine inspections and fluid changes help prevent wear and tear, ensuring that all components operate smoothly. Neglecting maintenance can lead to costly repairs and diminished performance, highlighting the importance of proactive care.

Electrical System and Wiring Insights

The electrical framework of a lawn care machine plays a pivotal role in its overall functionality. Understanding the intricacies of this system is essential for effective maintenance and troubleshooting. From the ignition to the lighting, each component is interlinked to ensure seamless operation.

Key Components: The main elements of the electrical assembly include the battery, starter motor, ignition coil, and various switches. These parts work in unison to power the engine and control the machine’s features. Regular inspection of these components can help prevent unexpected failures and extend the lifespan of the equipment.

Wiring Schematics: Proper wiring is crucial for safe and efficient operation. Familiarizing oneself with the wiring layout can aid in diagnosing issues and performing repairs. It is advisable to consult the appropriate documentation or seek professional assistance if complications arise during the examination or repair process.

In summary, a thorough understanding of the electrical system and its wiring is vital for ensuring the reliable performance of lawn care machinery. Regular checks and maintenance of these components will contribute to optimal functioning and minimize the risk of operational disruptions.

Deck and Frame Specifications

The structural elements of a cutting apparatus play a crucial role in its overall performance and durability. These components are designed to provide stability and support while ensuring efficient operation during use. Understanding the specifications of these elements can help users maintain and optimize their equipment effectively.

Frame Construction

The frame serves as the backbone of the machine, designed to withstand various stresses and strains. Typically made from robust materials, its design includes reinforcements at critical junctions to enhance durability. The overall geometry is tailored to ensure proper weight distribution, allowing for better maneuverability and control on diverse terrains.

Cutting Deck Design

The cutting deck is engineered to deliver optimal grass cutting performance. Its shape and size influence the efficiency of the mowing process. The deck often incorporates features such as adjustable heights, which allow users to customize the cutting length based on specific requirements. Additionally, the construction includes protective elements to reduce wear and prevent damage from obstacles encountered during operation.

Wheels and Tire Information

Understanding the significance of wheel and tire components is essential for maintaining optimal performance in garden machinery. These elements play a crucial role in ensuring stability, traction, and maneuverability across various terrains.

When considering the wheels and tires, several key factors come into play:

- Size: The dimensions of the wheels and tires directly affect the handling and efficiency of the equipment. Proper sizing ensures that the machinery operates effectively on different surfaces.

- Tread Pattern: The design of the tread impacts traction and grip. Depending on the terrain–be it muddy, grassy, or paved–selecting the appropriate tread is vital for optimal performance.

- Pressure: Maintaining the correct tire pressure is essential for safety and performance. Under-inflated or over-inflated tires can lead to uneven wear and compromised handling.

- Material: The composition of tires can vary, with options available for enhanced durability and puncture resistance. Choosing the right material can prolong the lifespan of the tires and improve overall functionality.

- Replacement: Regular inspection and timely replacement of worn or damaged tires ensure safety and efficiency. Knowing when to replace tires is critical for effective operation.

By paying close attention to these factors, operators can ensure their equipment remains in peak condition, ready to tackle any gardening task with ease.

Hydraulic System Functionality

The hydraulic system is a vital component in many types of machinery, providing the necessary power and control for various operations. This system utilizes fluid to transmit force, allowing for the efficient movement of parts and enabling complex functions within the equipment. By harnessing the principles of hydraulics, operators can achieve precise control over various mechanisms, enhancing overall performance and productivity.

How the Hydraulic System Works

At the core of the hydraulic mechanism lies a pump that generates pressure, pushing fluid through a network of hoses and valves. This pressurized fluid is directed to actuators or cylinders, converting hydraulic energy into mechanical movement. The system’s design allows for rapid response times and the ability to handle significant loads, making it ideal for tasks that require strength and precision.

Benefits of Hydraulic Systems

One of the primary advantages of hydraulic systems is their ability to provide a smooth and controlled motion, which is crucial in applications requiring fine adjustments. Additionally, these systems are capable of lifting and moving heavy objects with minimal effort, significantly reducing operator fatigue. The use of hydraulics also contributes to improved durability and longevity of the machinery, as they can operate under varying conditions while maintaining efficiency.

Safety Features and Recommendations

Ensuring safe operation of garden machinery is paramount for preventing accidents and injuries. Proper understanding of safety mechanisms, combined with adherence to best practices, significantly enhances user protection. This section highlights essential safety elements and offers valuable advice for optimal usage.

- Operator Presence Control: This feature stops the machine when the operator leaves the seat, preventing unintended movement.

- Safety Interlocks: Designed to prevent engine start unless specific conditions are met, such as engaging the brake.

- Emergency Stop Mechanism: Allows for immediate cessation of operation in case of an emergency, providing quick response options.

- Protective Shields: These barriers guard against debris and other hazards, safeguarding the user during operation.

To further enhance safety, consider the following recommendations:

- Always read the user manual to familiarize yourself with all safety features.

- Wear appropriate personal protective equipment, such as gloves and closed-toe shoes.

- Conduct a pre-operation inspection to ensure all safety mechanisms are functioning correctly.

- Keep the working area clear of obstacles and debris to prevent accidents.

- Never operate machinery in wet or slippery conditions to maintain traction and control.

By prioritizing safety features and adhering to recommended practices, users can significantly reduce the risk of injury while effectively operating their equipment.

Common Troubleshooting Steps

When encountering issues with outdoor lawn care equipment, it’s essential to follow systematic methods to identify and resolve common problems. By understanding key components and their functionalities, users can effectively address performance challenges and ensure optimal operation.

Identifying Engine Issues

If the engine fails to start or runs inconsistently, check the fuel supply, ensuring that it’s clean and at the appropriate level. Inspect the air filter for blockages that could hinder airflow and examine the spark plug for wear or damage. These components are vital for proper engine function, and addressing them can often resolve starting problems.

Examining Cutting Mechanism

In cases where the cutting system is underperforming, inspect the blades for dullness or damage. Ensure they are securely attached and free from debris. Additionally, verify that the height adjustment settings are correctly configured for the desired cutting level. Regular maintenance of the cutting apparatus is crucial for achieving an even and clean cut.

Where to Find Replacement Parts

When it comes to maintaining your equipment, locating suitable components is crucial for ensuring optimal performance and longevity. Various sources provide access to high-quality replacements that cater to your specific needs.

Online Retailers

The internet offers a plethora of options for sourcing components. Here are some reliable platforms:

- Specialty websites dedicated to outdoor machinery

- General e-commerce sites with a wide selection

- Manufacturer’s official online store

Local Suppliers

Visiting physical stores can also yield great results. Consider checking:

- Home improvement centers with gardening sections

- Authorized dealerships that stock original replacements

- Independent repair shops that may offer aftermarket alternatives