Understanding Husqvarna Riding Mower Deck Parts Diagram

Maintaining a well-groomed landscape requires an understanding of the various components that contribute to the efficiency of your equipment. Each element plays a crucial role in ensuring optimal performance, and familiarity with these can enhance both your experience and the results you achieve.

In this guide, we will explore the intricate workings of essential mechanisms within your outdoor machinery. By examining how each section interacts with the others, you can make informed decisions about maintenance and upgrades.

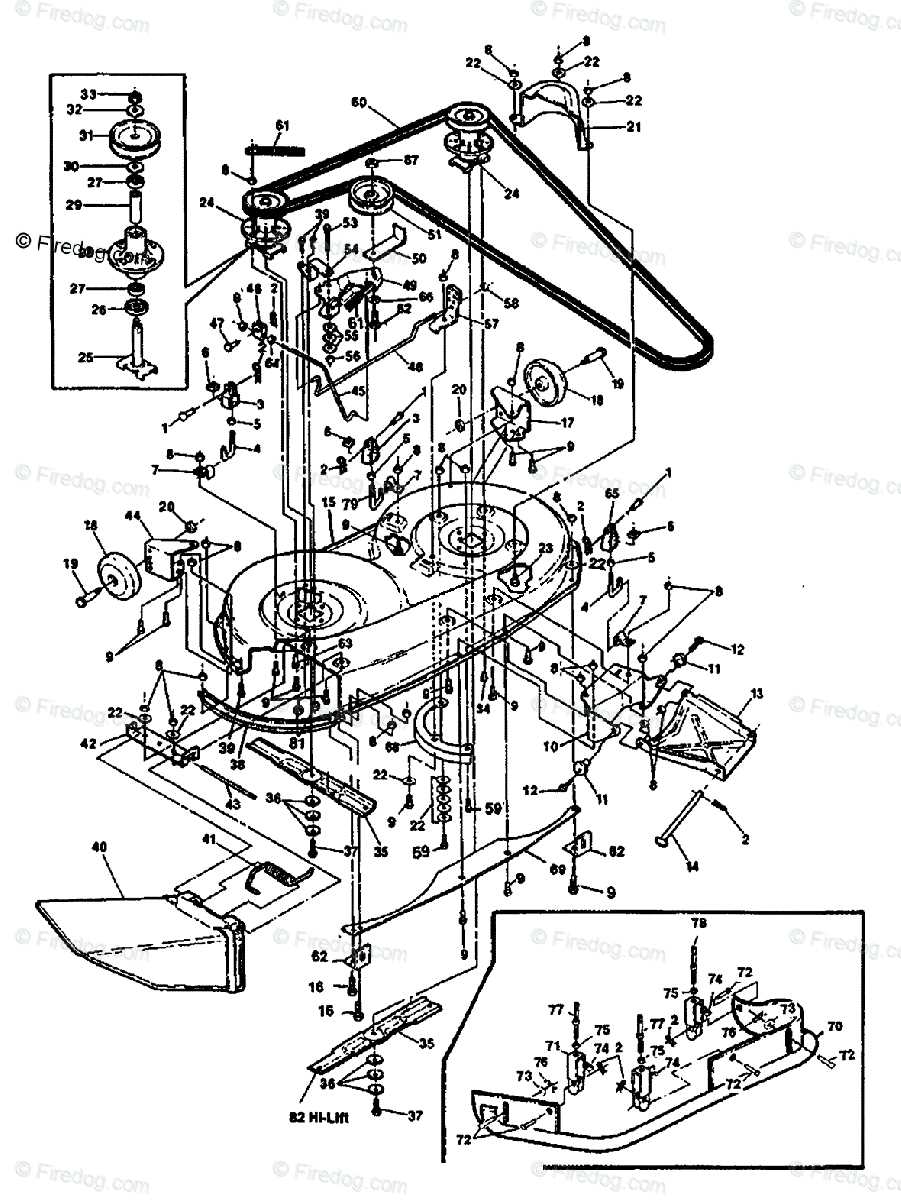

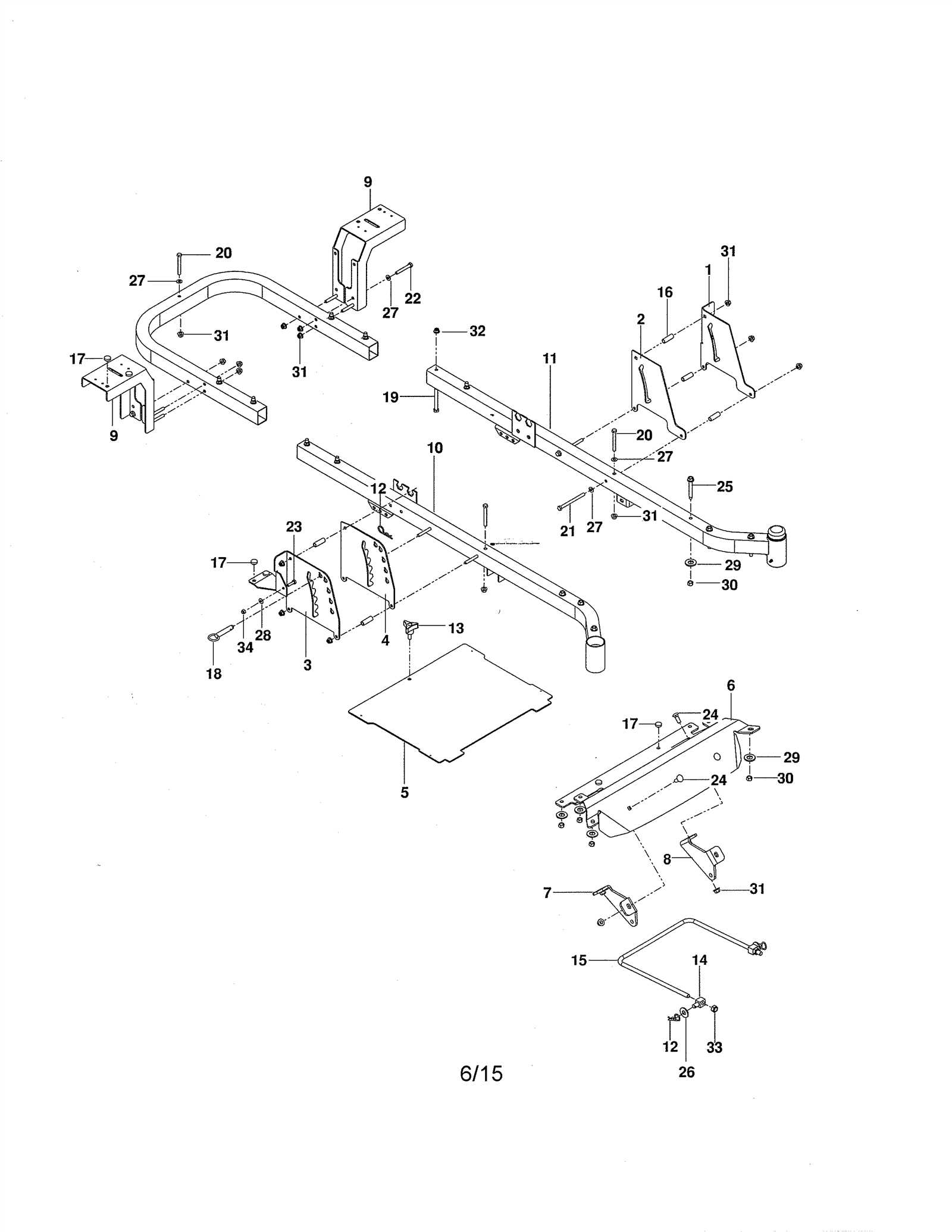

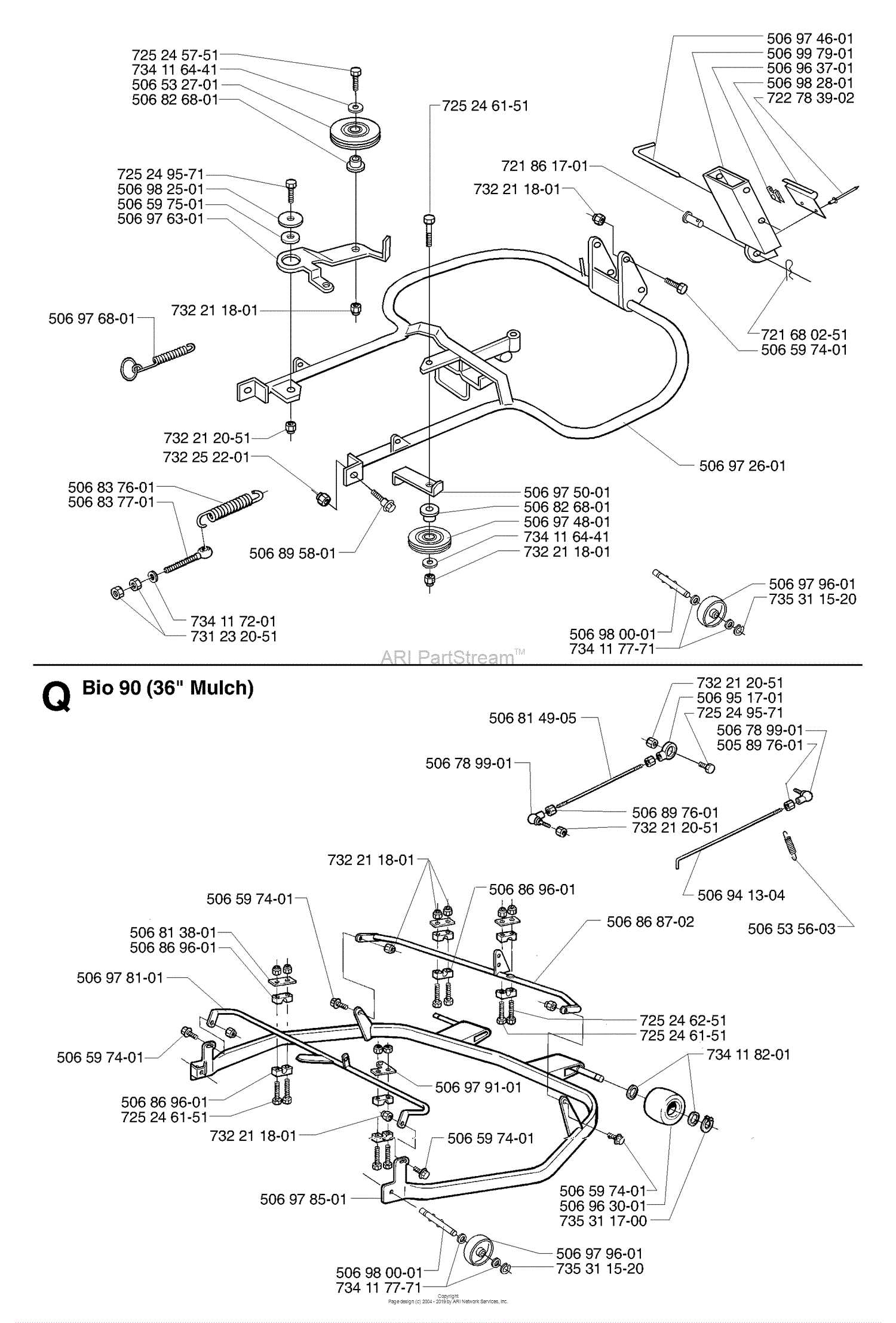

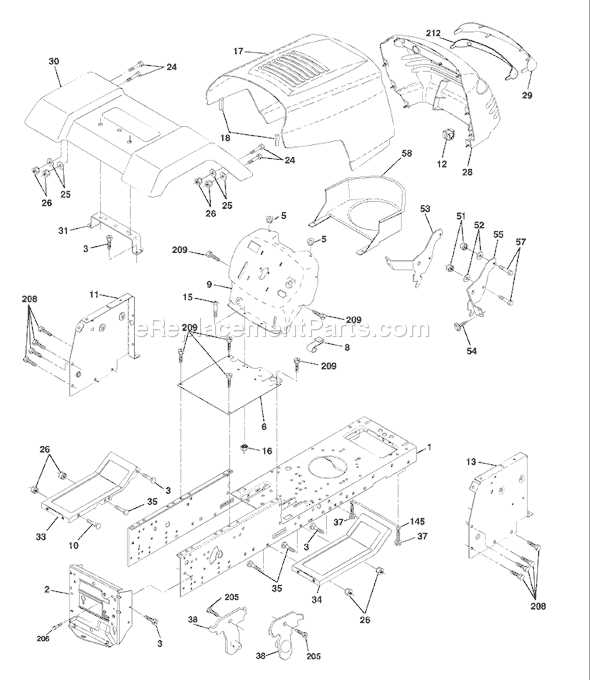

Utilizing a detailed illustration can be invaluable for both novices and seasoned users. It provides clarity on assembly, functionality, and troubleshooting, empowering you to take charge of your lawn care tasks with confidence.

Understanding Husqvarna Riding Mower Decks

Exploring the intricacies of cutting mechanisms reveals a wealth of information crucial for effective lawn care. These assemblies play a vital role in the overall performance and efficiency of your equipment. By delving into their construction and function, you can enhance maintenance practices and improve longevity.

Key Components and Their Functions

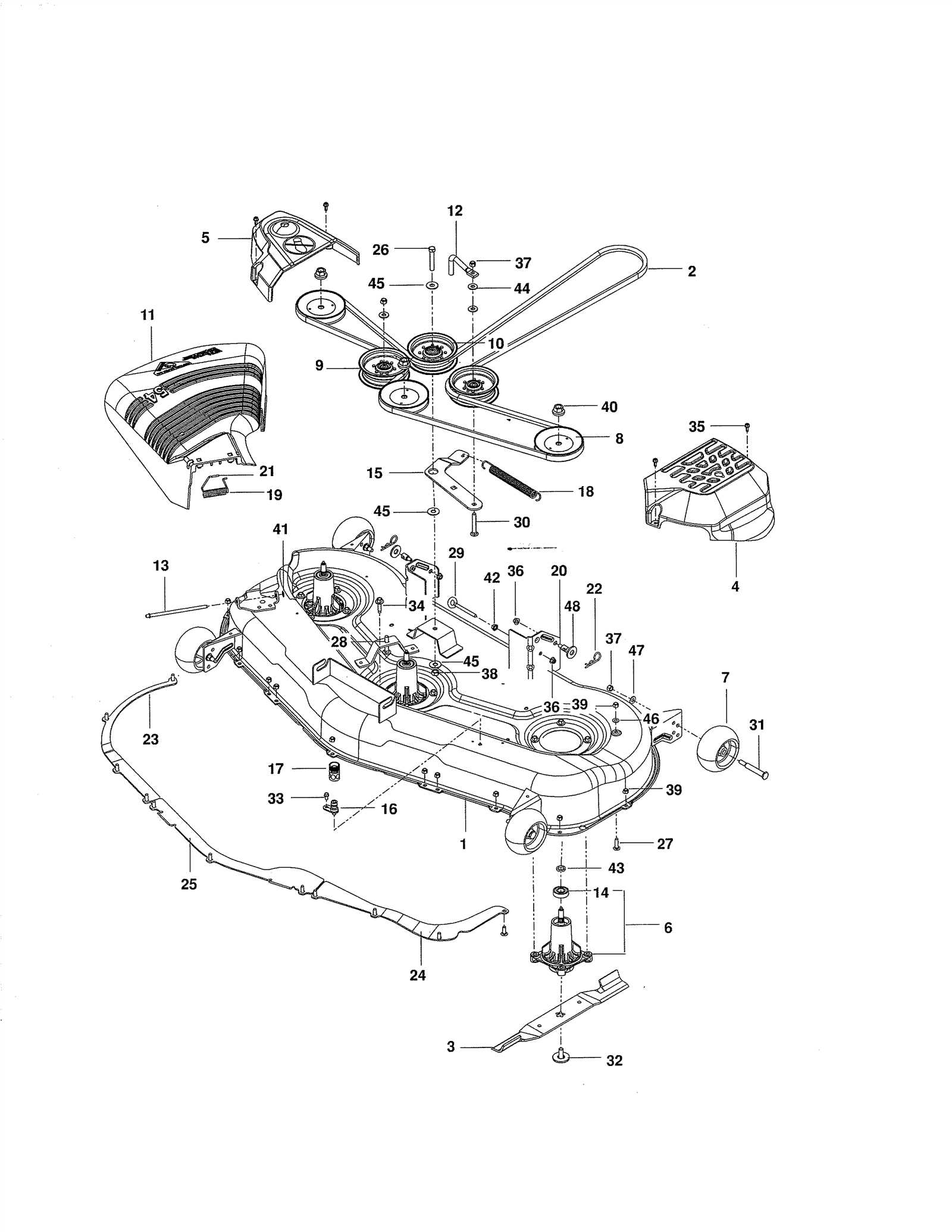

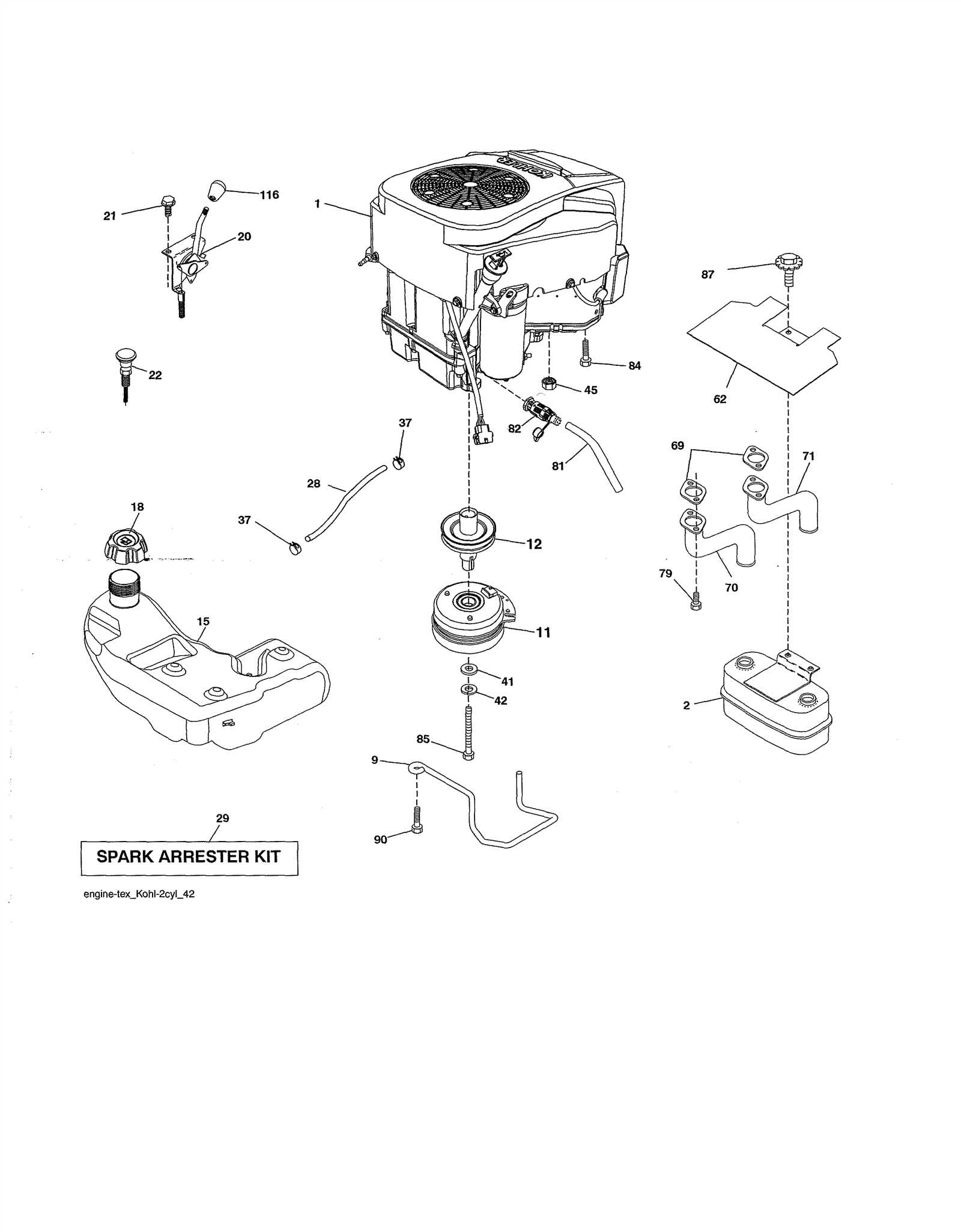

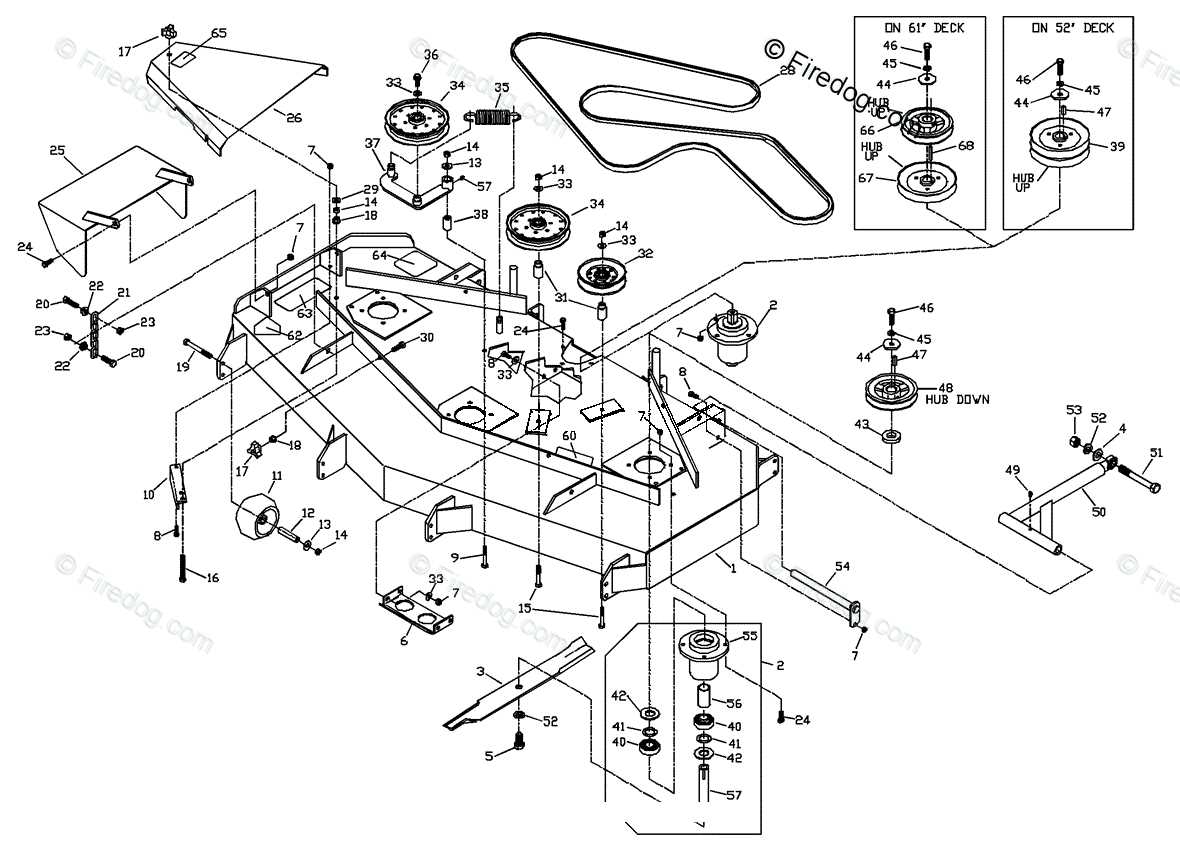

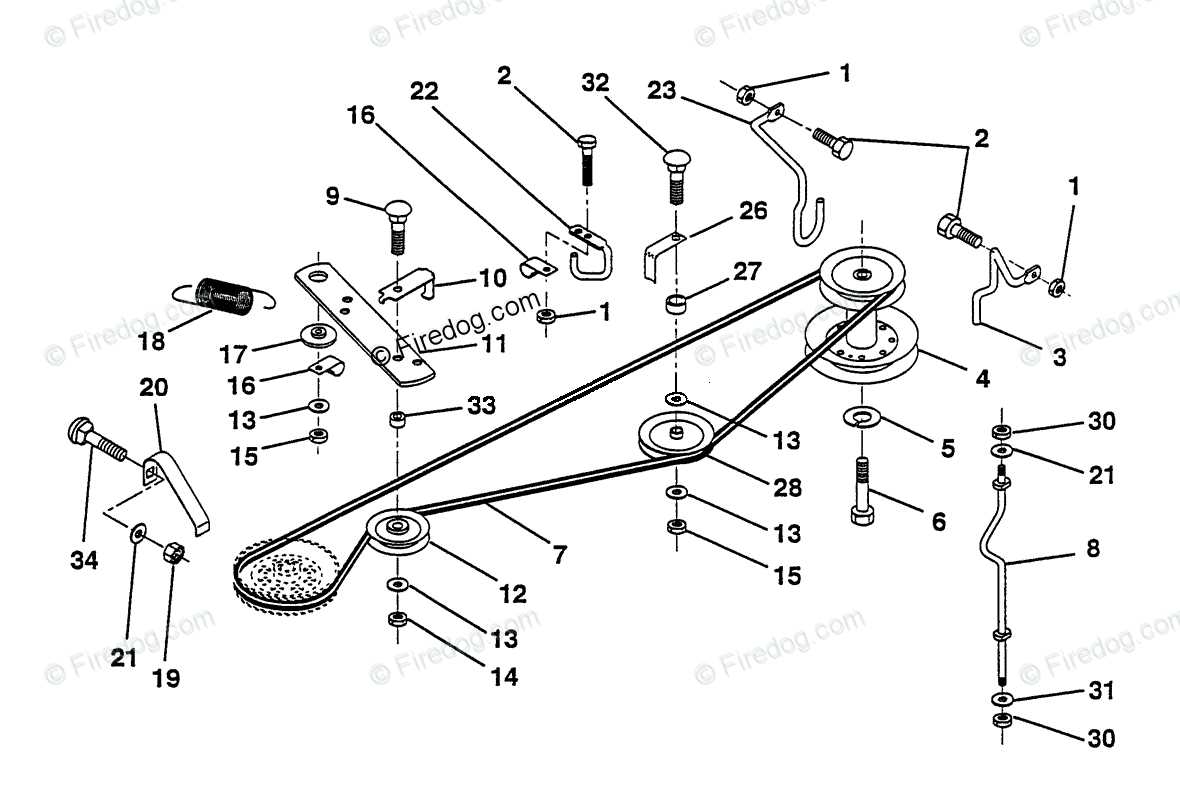

At the heart of any cutting system are various elements that work in unison. Blades, pulleys, and belts are just a few examples of essential components that dictate the performance of the machinery. Each part contributes to the effective distribution of power, ensuring a clean and even cut across diverse terrains. Understanding how these elements interact can lead to better troubleshooting and repairs.

Maintenance Tips for Longevity

Regular upkeep is imperative for sustaining optimal function. Inspection of the blades for sharpness, cleaning to remove grass buildup, and timely replacement of worn-out components are essential practices. Following a structured maintenance routine not only enhances performance but also extends the lifespan of your equipment.

Importance of Deck Maintenance

Proper upkeep of your cutting apparatus is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to inefficiencies and costly repairs, ultimately affecting the quality of your lawn care experience.

Benefits of Regular Maintenance

Routine checks and cleaning help prevent clogs and wear, promoting a healthier cutting environment. This practice not only enhances performance but also contributes to a smoother operation.

Key Maintenance Tasks

| Task | Frequency | Benefit |

|---|---|---|

| Cleaning | After each use | Prevents rust and buildup |

| Sharpening Blades | Every 20-25 hours | Ensures a clean cut |

| Lubrication | Every season | Reduces friction and wear |

Common Deck Problems and Solutions

Maintenance of cutting equipment can often reveal a range of issues that impact performance and efficiency. Identifying these challenges early is crucial for ensuring optimal operation and longevity. Below are some prevalent concerns and their corresponding solutions.

Uneven Cutting Height

One of the most frequent issues encountered is an inconsistent cutting height across the surface. This can result in an uneven appearance and may lead to additional wear on the blades.

Solution: To address this, first check the level of the cutting apparatus. Adjust the height settings according to the manufacturer’s guidelines. Additionally, inspect the tires for proper inflation and alignment, as imbalances can affect cutting performance.

Clogging and Debris Buildup

Another common problem is the accumulation of grass and debris, which can hinder the efficiency of the operation. Clogging may lead to reduced airflow and cutting effectiveness.

Solution: Regularly clean the underside of the cutting unit to prevent buildup. Using a scraper can help remove stubborn clippings. Implementing a routine maintenance schedule, including thorough cleaning after each use, can significantly mitigate this issue.

Key Components of Riding Mower Deck

Understanding the essential elements of a lawn cutting system is crucial for maintaining its performance and longevity. These components work together to ensure efficient operation, providing a clean and precise cut. Below are the primary elements that contribute to the overall functionality.

Main Elements

- Blades: Sharp and durable, these are responsible for achieving the desired grass height and finish.

- Spindles: These rotating mechanisms hold the blades and facilitate their movement.

- Chassis: The structural framework supports the entire assembly, ensuring stability during use.

- Belts: These transfer power from the engine to the blades, enabling their rotation.

- Deck Shell: This outer casing protects internal components and directs grass clippings away.

Additional Features

- Height Adjustment System: Allows users to modify cutting height according to preference.

- Washout Port: Facilitates easy cleaning of the underside to prevent clippings buildup.

- Anti-Scalp Wheels: Help prevent damage to the lawn by maintaining an even cutting height.

- Mulching Kit: Enhances the ability to finely chop grass clippings for nutrient recycling.

How to Access the Deck Parts

Gaining access to the essential components of your machine is crucial for maintenance and repair. Understanding the process not only enhances performance but also prolongs the lifespan of the equipment. Follow these steps to easily reach the necessary elements for inspection or replacement.

- Safety First: Always ensure the engine is turned off and the spark plug wire is disconnected to avoid accidental starts.

- Prepare Your Tools: Gather the required tools, such as wrenches, screwdrivers, and safety gloves, to facilitate the process.

- Lift the Chassis: If applicable, raise the chassis using a hydraulic jack or ramps to provide better access to the underside.

- Remove Fasteners: Carefully unscrew or unclip any fasteners securing the cover or shield, taking note of their locations for reassembly.

- Detach the Assembly: Gently pull away the covering to expose the internal components, ensuring not to damage any wires or connections.

- Inspect and Replace: Once accessible, examine the components for wear or damage. Replace any parts as needed.

- Reassemble: After completing the necessary work, carefully reattach the covering and secure it with the fasteners.

Regularly checking these components can prevent larger issues down the line and ensure smooth operation.

Identifying Parts in Diagrams

Understanding the components represented in technical illustrations is crucial for effective maintenance and repairs. These visual guides provide a clear overview, allowing users to pinpoint specific elements essential for operation. By familiarizing oneself with the layout and terminology, one can streamline the troubleshooting process and enhance overall efficiency.

Firstly, it is important to recognize the common symbols and labels utilized in these representations. Each symbol corresponds to a particular component, making it easier to identify and reference during repair or assembly tasks. Pay attention to the accompanying legend or key, which often clarifies any abbreviations or unique icons.

Secondly, analyzing the arrangement of parts can offer insights into their functionality and interconnections. Components are typically organized in a manner that reflects their operational relationships, which can aid in diagnosing issues or planning modifications. Take note of any directional arrows or lines that indicate movement or flow, as these can be critical for understanding how each piece interacts with others.

Finally, documenting findings while consulting these illustrations can enhance comprehension. Sketching notes or marking important sections can serve as a handy reference for future tasks, ensuring that one remains informed about the necessary elements and their roles within the larger system.

Replacement Parts: Where to Buy

Finding suitable components for your lawn maintenance equipment can enhance its performance and longevity. Knowing where to purchase these essential items is crucial for effective upkeep. Below are some reliable sources where you can obtain high-quality replacements to ensure your machine operates smoothly.

| Source | Description | Advantages |

|---|---|---|

| Authorized Dealers | Official retailers specializing in specific brands. | Genuine parts, expert advice, warranty support. |

| Online Marketplaces | Websites offering a wide variety of components. | Convenience, competitive prices, user reviews. |

| Local Hardware Stores | Community shops often carry essential items. | Immediate availability, personal service, local support. |

| Specialty Repair Shops | Businesses focused on repairs may sell spare items. | Expert knowledge, potential installation services. |

Exploring these avenues can help you find the components needed to keep your equipment in top condition. Always verify compatibility and quality before making a purchase to ensure optimal functionality.

Tools Needed for Deck Repair

Repairing the cutting mechanism of your outdoor maintenance machine requires specific instruments to ensure a successful and efficient process. Having the right tools not only simplifies the task but also enhances the quality of the repairs, leading to better performance and longevity of the equipment.

Essential Tools:

Wrenches are critical for loosening and tightening bolts. A set of both standard and metric sizes will help accommodate various fasteners. Socket sets are also invaluable, as they allow for easier access to hard-to-reach areas, making the removal of components much simpler.

Additionally, pliers are useful for gripping and manipulating small parts, while screwdrivers in multiple sizes can help with different types of screws. For more complex repairs, torque wrenches ensure that bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

Finally, safety gear such as gloves and goggles should not be overlooked. These protect against injuries while working with sharp blades and heavy materials. Proper preparation with the right tools and safety equipment sets the foundation for a successful maintenance job.

Step-by-Step Repair Guide

Maintaining your equipment is crucial for its longevity and performance. This guide provides a structured approach to troubleshooting and fixing common issues. By following these steps, you can ensure your machine operates smoothly and efficiently.

1. Identify the Issue

Start by observing the symptoms of the malfunction. Look for unusual noises, uneven cutting, or performance drops. Document these observations as they will help you diagnose the problem more effectively. Conduct a thorough visual inspection to identify any visible damage or wear.

2. Gather Necessary Tools

Before beginning any repair, assemble the tools you will need. Common tools may include wrenches, screwdrivers, and pliers. Having everything at hand will streamline the process and prevent interruptions. Ensure that your workspace is organized and well-lit for safety and efficiency.

3. Disassemble Components

Once the issue is identified and tools are ready, carefully disassemble the necessary components. Take pictures during this process to serve as a reference for reassembly. Keep track of screws and small parts to avoid losing them.

4. Replace or Repair Damaged Parts

After disassembly, examine the individual components. If you find any that are damaged, replace them with compatible alternatives. If repair is feasible, ensure that you follow the correct techniques to restore functionality without compromising safety.

5. Reassemble and Test

Once repairs or replacements are completed, reassemble the components in reverse order of disassembly. Double-check connections and fastenings to ensure everything is secure. After reassembly, perform a test run to verify that the issue has been resolved and that the machine operates as intended.

Following this structured approach will help you effectively address and resolve issues, prolonging the life of your equipment.

Upgrading Your Mower Deck

Enhancing the performance and efficiency of your cutting equipment can significantly improve your landscaping tasks. By selecting advanced components and innovative features, you can optimize the overall functionality, leading to a more enjoyable experience and better results.

Benefits of Upgrading

- Improved cutting precision

- Increased durability

- Enhanced efficiency

- Better grass collection

Key Components to Consider

- Blades: Choose high-quality materials for sharper cuts.

- Spindles: Upgrade to ensure smoother operation and less vibration.

- Belts: Opt for reinforced options to reduce wear and tear.

- Wheels: Consider larger or more robust wheels for improved maneuverability.

Seasonal Maintenance Tips

Regular upkeep is essential for ensuring the longevity and efficiency of your outdoor equipment. Adopting a seasonal maintenance routine not only enhances performance but also helps prevent costly repairs. By focusing on key areas of care throughout the year, you can keep your machinery running smoothly and effectively.

Spring Preparations

As the weather warms, it’s crucial to prepare your tools for the upcoming growing season. Begin by inspecting the blades for sharpness; dull blades can damage grass and lead to uneven growth. Additionally, check for any debris or rust that may have accumulated over the winter months. Replacing oil and filters is vital to ensure optimal engine performance. Lastly, inspect the tires for proper inflation and wear, ensuring a stable operation during use.

Fall Maintenance

As the season shifts, focus on protecting your equipment from harsh winter conditions. Clean the machinery thoroughly to remove any grass clippings or dirt that may cause corrosion. Consider adding a fuel stabilizer to prevent the gasoline from degrading. It’s also advisable to store your equipment in a dry, sheltered area, covered to keep dust and moisture at bay. A final inspection of all components can help identify any issues before the equipment is put away for the season.

Understanding Mower Deck Adjustments

Proper adjustment of the cutting mechanism is crucial for achieving an even and efficient cut. These settings can influence the quality of the lawn, affecting the health and appearance of the grass. By fine-tuning the height and angle, operators can ensure optimal performance and longevity of the equipment.

Importance of Correct Height Setting

Setting the right height is essential for different types of grass. Each species thrives at specific lengths, and improper cutting can stress the plant. Maintaining the correct height not only promotes growth but also minimizes weed proliferation.

Adjustment Techniques

To achieve the desired configuration, several techniques can be employed. Regularly checking the alignment and ensuring that all components are functioning correctly will enhance overall performance.

| Adjustment Type | Recommended Range |

|---|---|

| Cutting Height | 2 to 4 inches |

| Leveling | Even across all sides |

| Angle | Perpendicular to ground |

Safety Precautions During Repairs

Engaging in maintenance and repair activities requires a clear understanding of safety measures to prevent accidents and injuries. By following essential guidelines, individuals can ensure a secure working environment while addressing mechanical issues.

General Safety Guidelines

- Always wear appropriate personal protective equipment, such as gloves and safety glasses.

- Ensure the machine is powered off and disconnected from any power source before beginning work.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Keep the workspace tidy to prevent slips and falls.

Specific Precautions

- Check for leaks and damages before starting repairs, as they can pose hazards.

- Use the correct tools for the job to avoid accidents caused by improper equipment.

- Follow the manufacturer’s instructions and guidelines for safe handling.

- Be cautious of sharp edges and moving parts during the repair process.