Toro Riding Mower Parts Diagram for Easy Maintenance

In the realm of lawn maintenance equipment, a comprehensive understanding of its various components is essential for optimal performance and longevity. Each element plays a crucial role in ensuring the efficiency of the entire system, from the engine to the cutting mechanism. Grasping how these parts interact can significantly enhance the user experience and simplify troubleshooting.

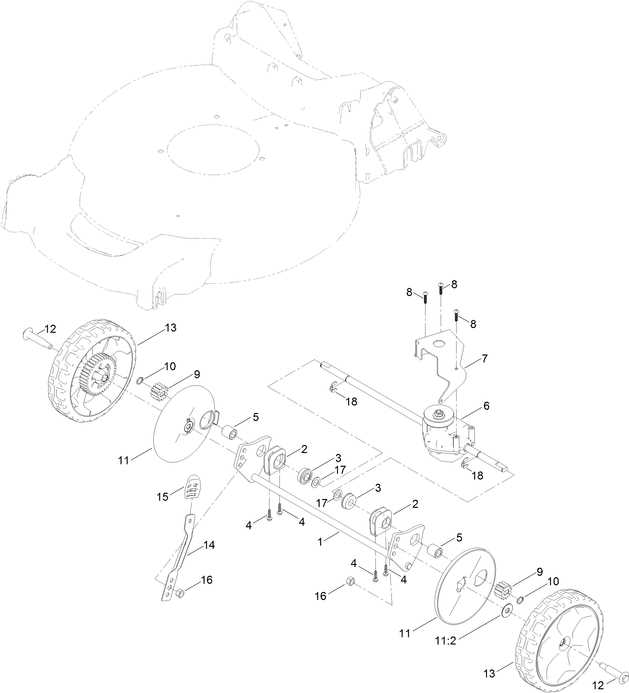

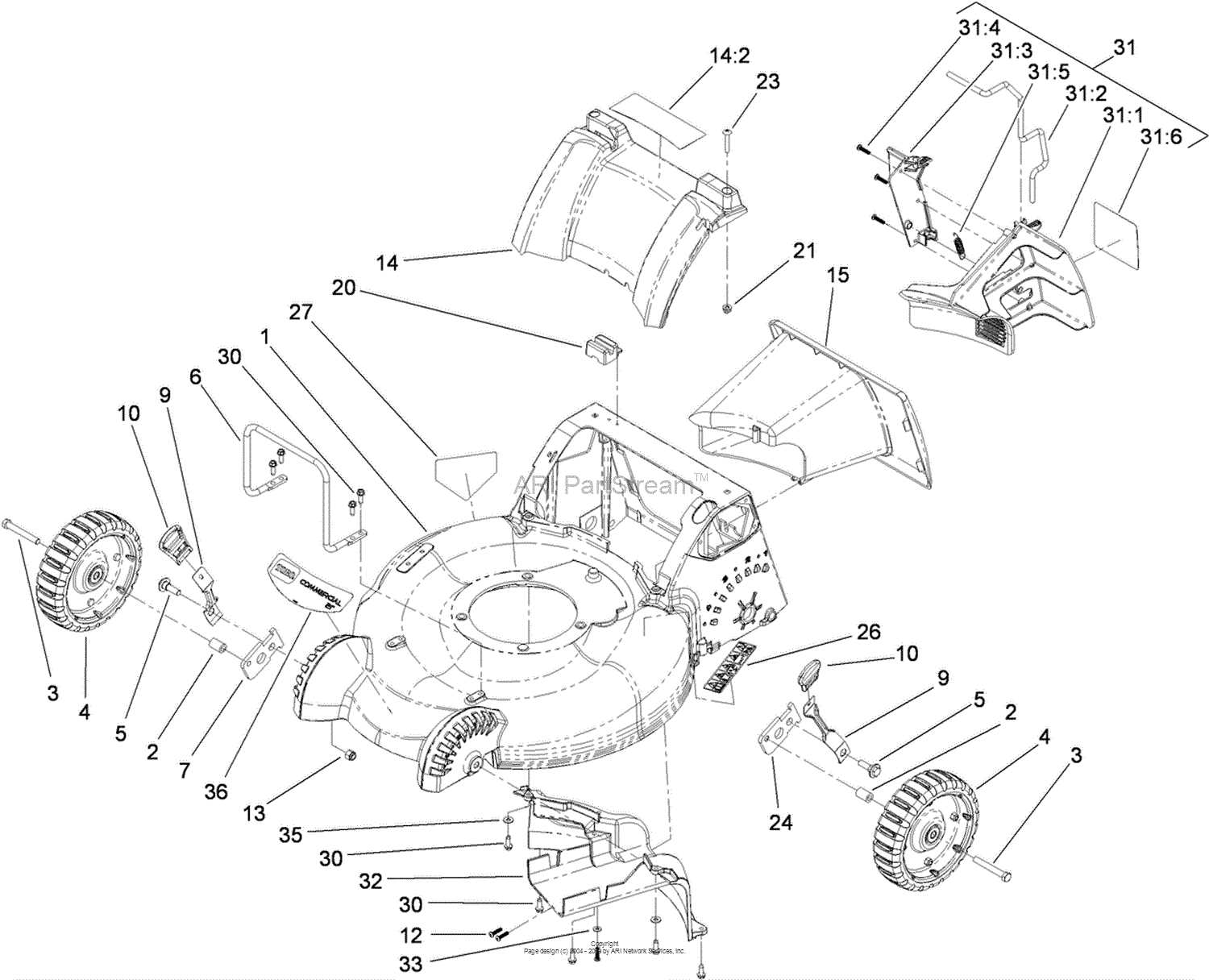

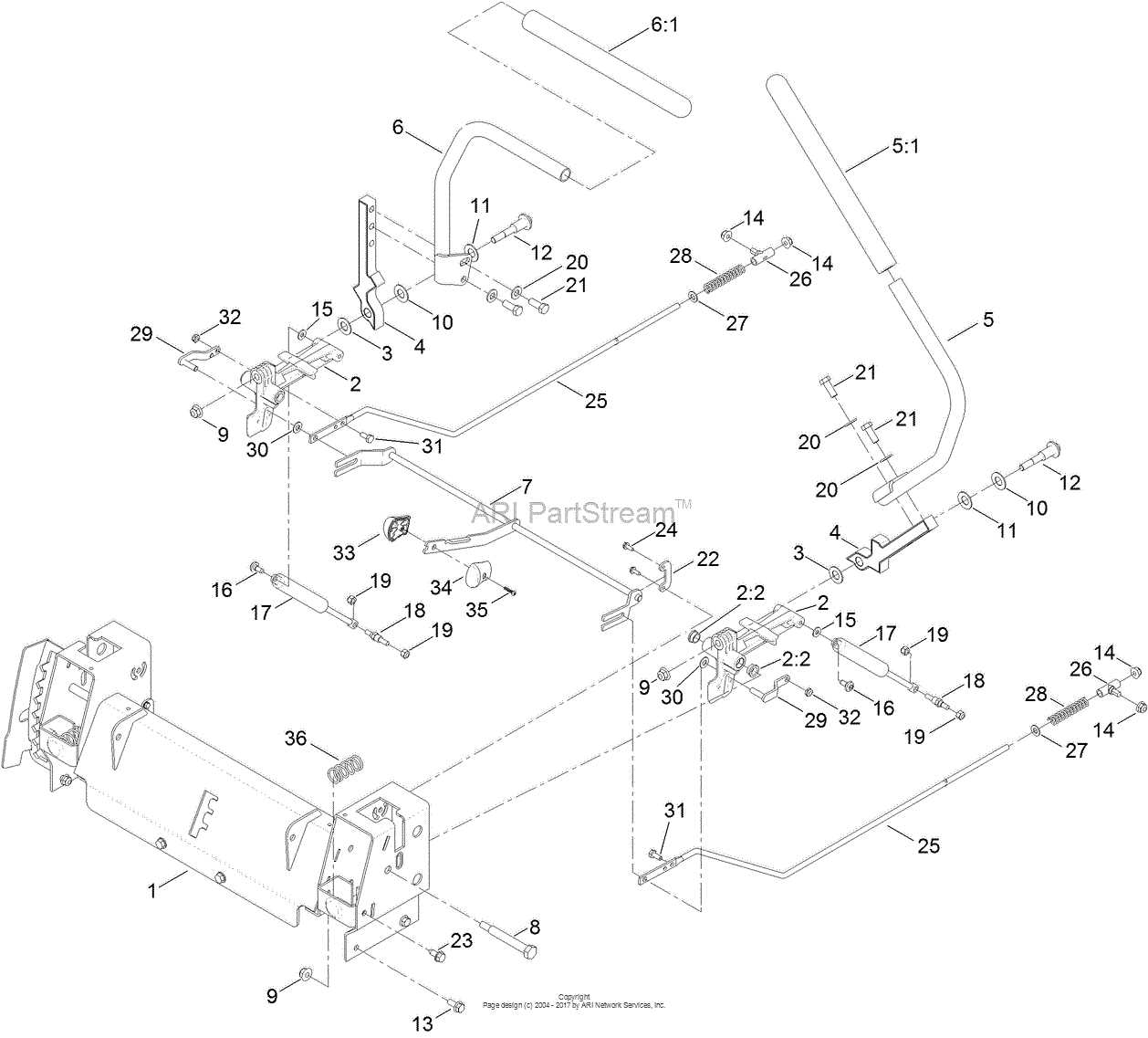

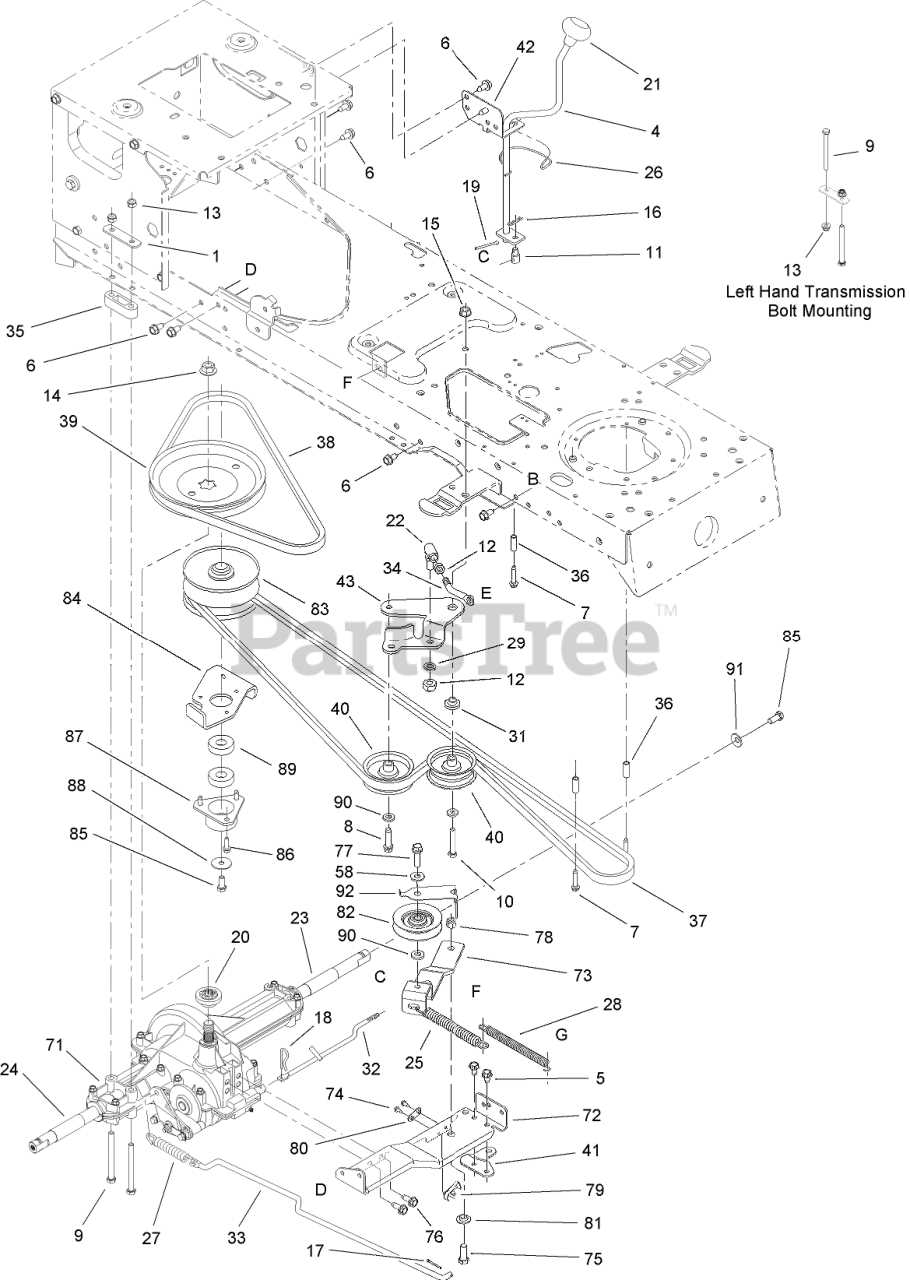

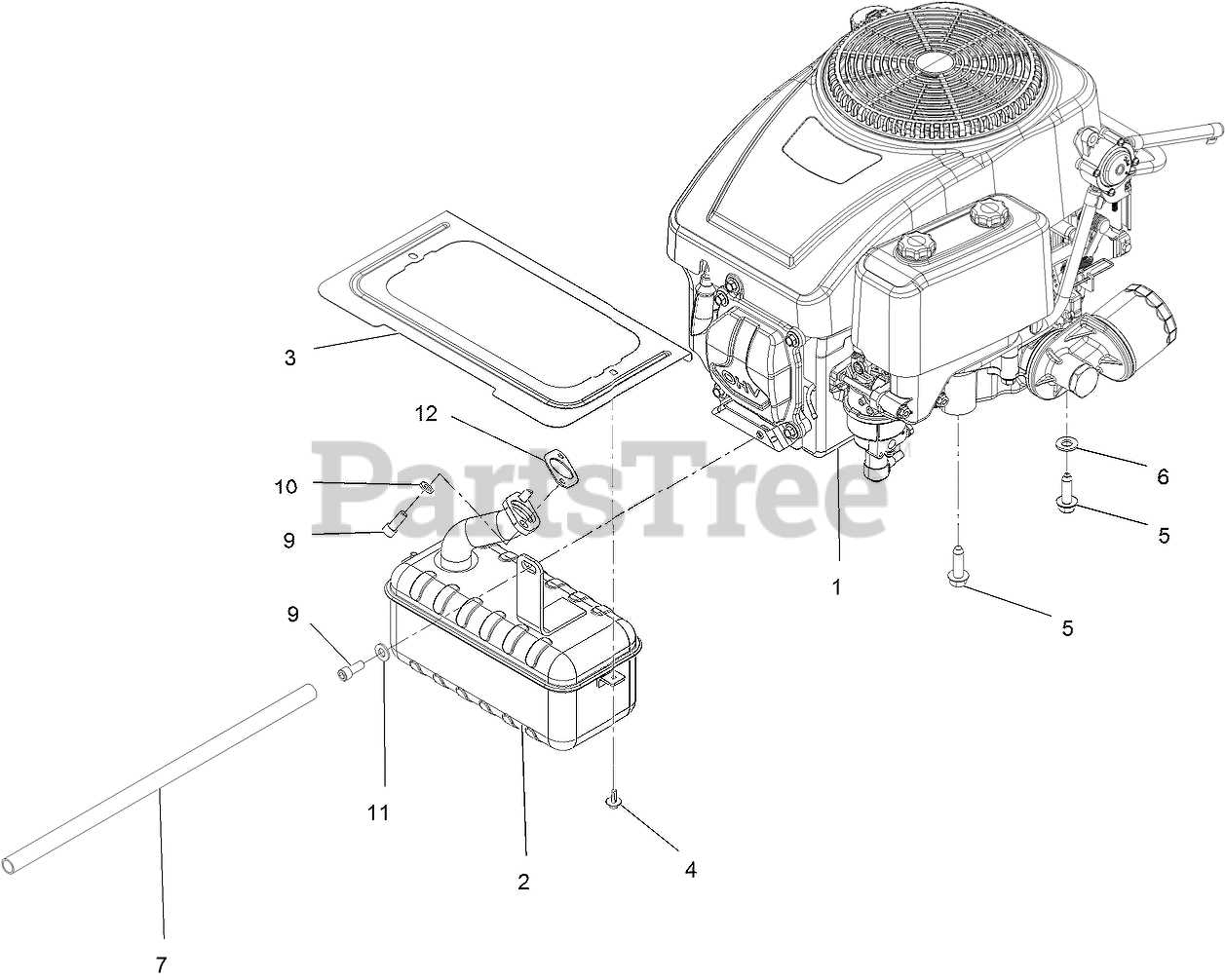

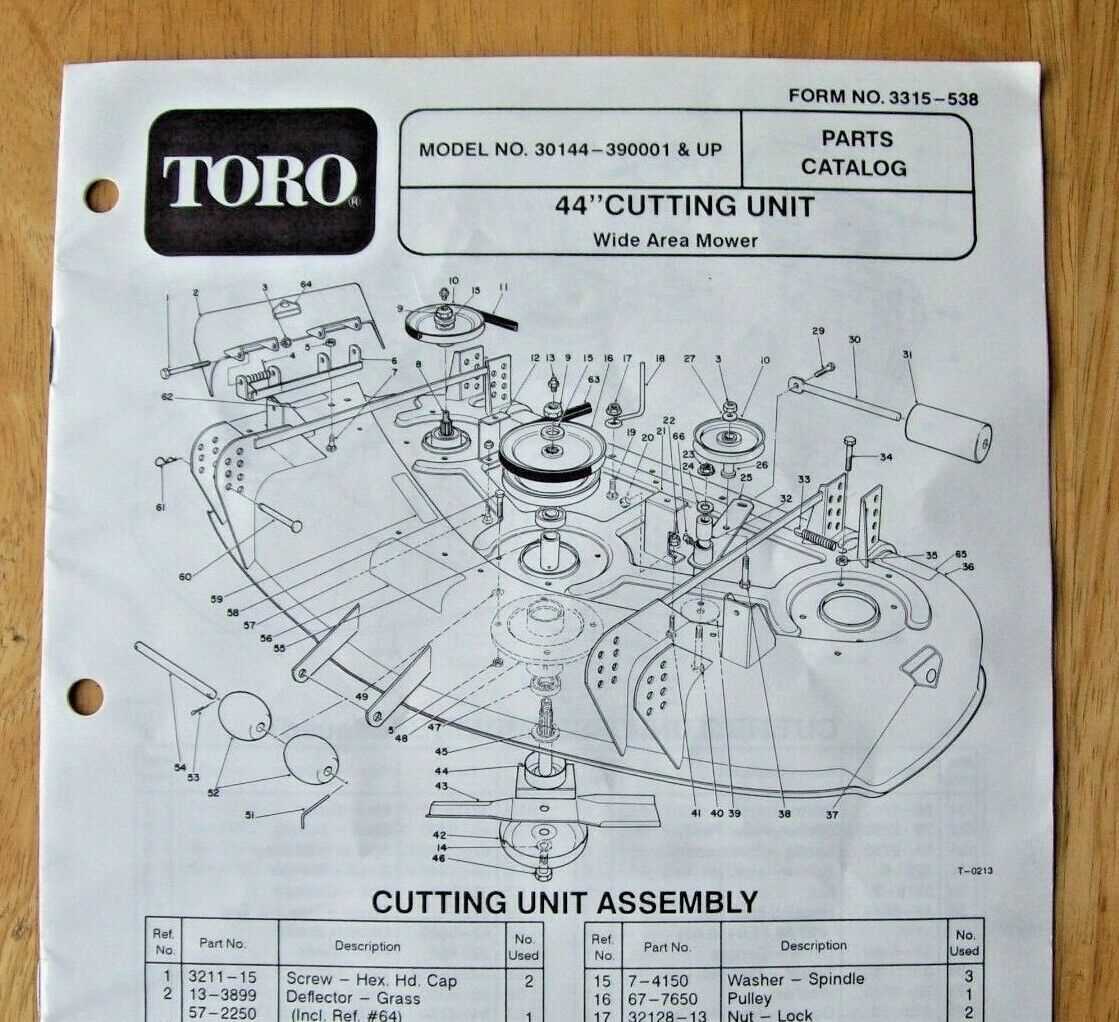

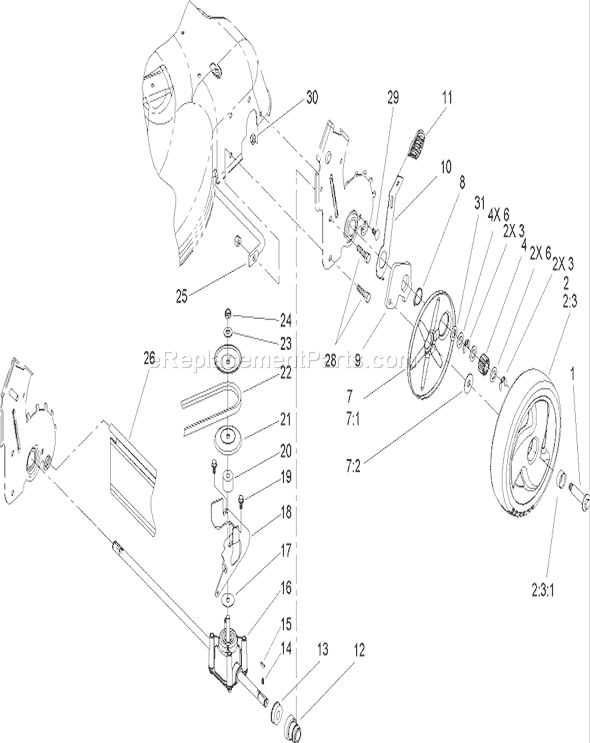

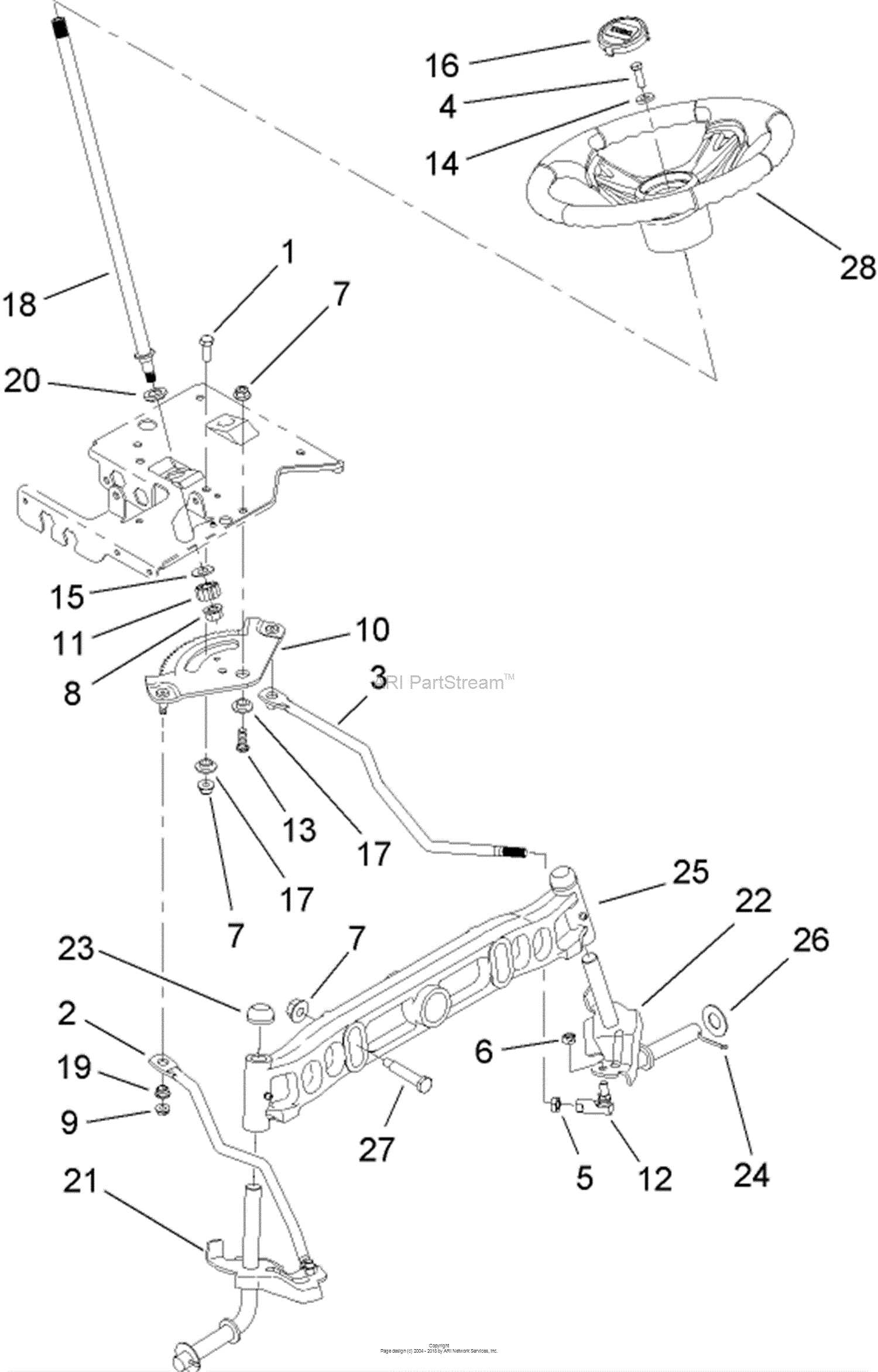

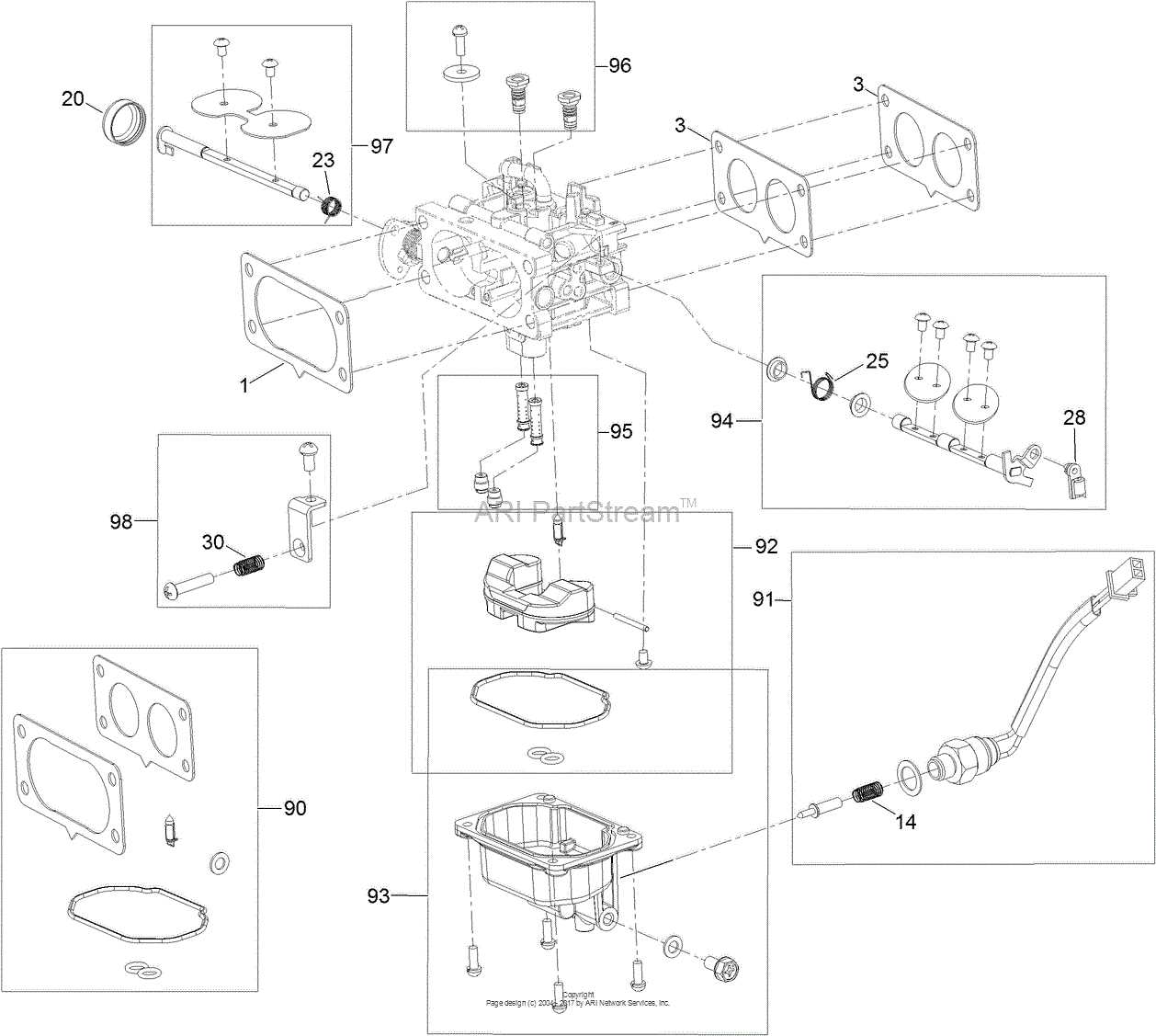

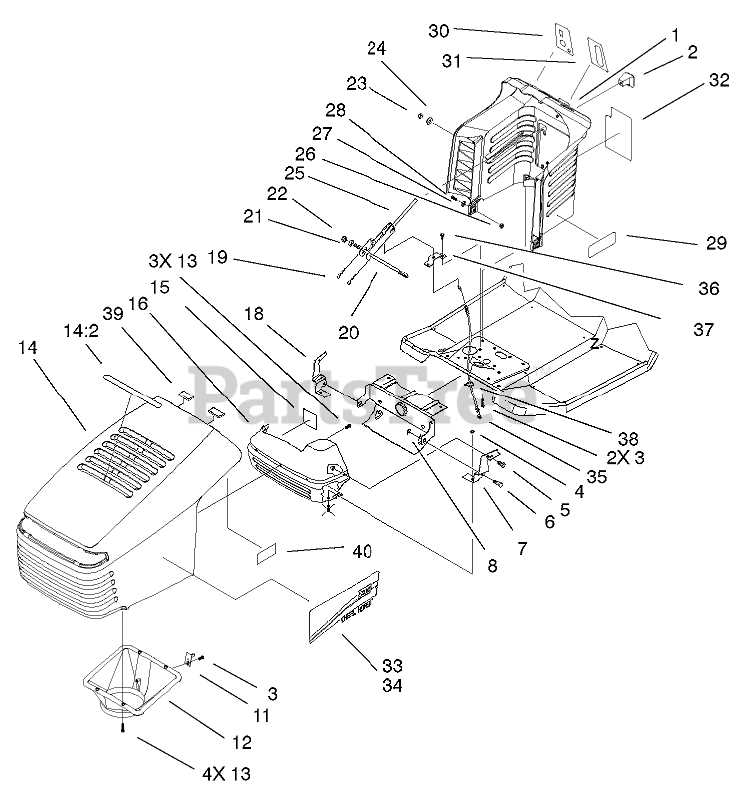

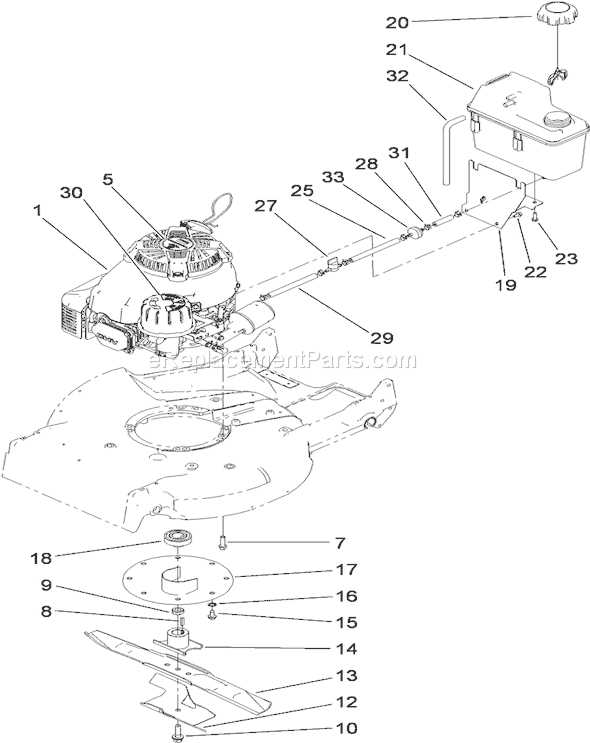

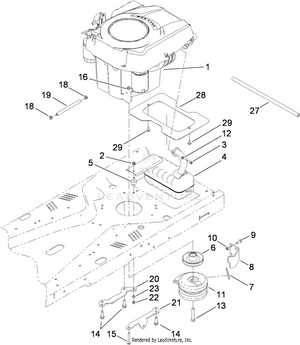

Visual aids that outline the specific arrangement and function of these elements provide invaluable assistance to both novice users and seasoned operators. By familiarizing oneself with the intricate layout of a machine’s internals, one can easily identify issues and perform necessary repairs or replacements. This knowledge not only promotes effective maintenance but also contributes to a smoother operational experience.

Furthermore, having access to detailed illustrations empowers users to make informed decisions regarding upgrades or replacements. Understanding the nuances of each component allows for better planning and preparation, ultimately leading to improved performance and satisfaction. As we delve deeper into the subject, we will explore the various features and configurations of these essential machines.

Understanding Toro Riding Mower Components

When it comes to maintaining your lawn care equipment, a solid grasp of its various elements is essential. Each component plays a crucial role in ensuring optimal performance and efficiency. By familiarizing yourself with these essential parts, you can enhance your knowledge and effectively troubleshoot any issues that may arise.

Key Elements of Lawn Care Equipment

- Engine: The powerhouse that drives the entire machine, providing the necessary energy for operation.

- Transmission: Responsible for controlling the speed and movement, allowing for smooth maneuverability across your lawn.

- Deck: The cutting area that houses the blades, designed to provide an even and clean cut.

- Wheels: Essential for mobility, these components facilitate movement across different terrains.

- Steering Mechanism: Enables precise control and direction, enhancing the overall handling experience.

Maintenance Tips for Longevity

- Regularly inspect the engine for any signs of wear or leaks.

- Keep the transmission fluid at optimal levels to ensure smooth operation.

- Clean the cutting deck frequently to prevent grass buildup.

- Check tire pressure regularly to maintain proper traction.

- Lubricate moving parts to reduce friction and wear.

Understanding these vital components not only aids in efficient upkeep but also empowers users to make informed decisions regarding repairs and upgrades. Proper knowledge is key to extending the lifespan of your equipment and achieving the best results in your lawn care efforts.

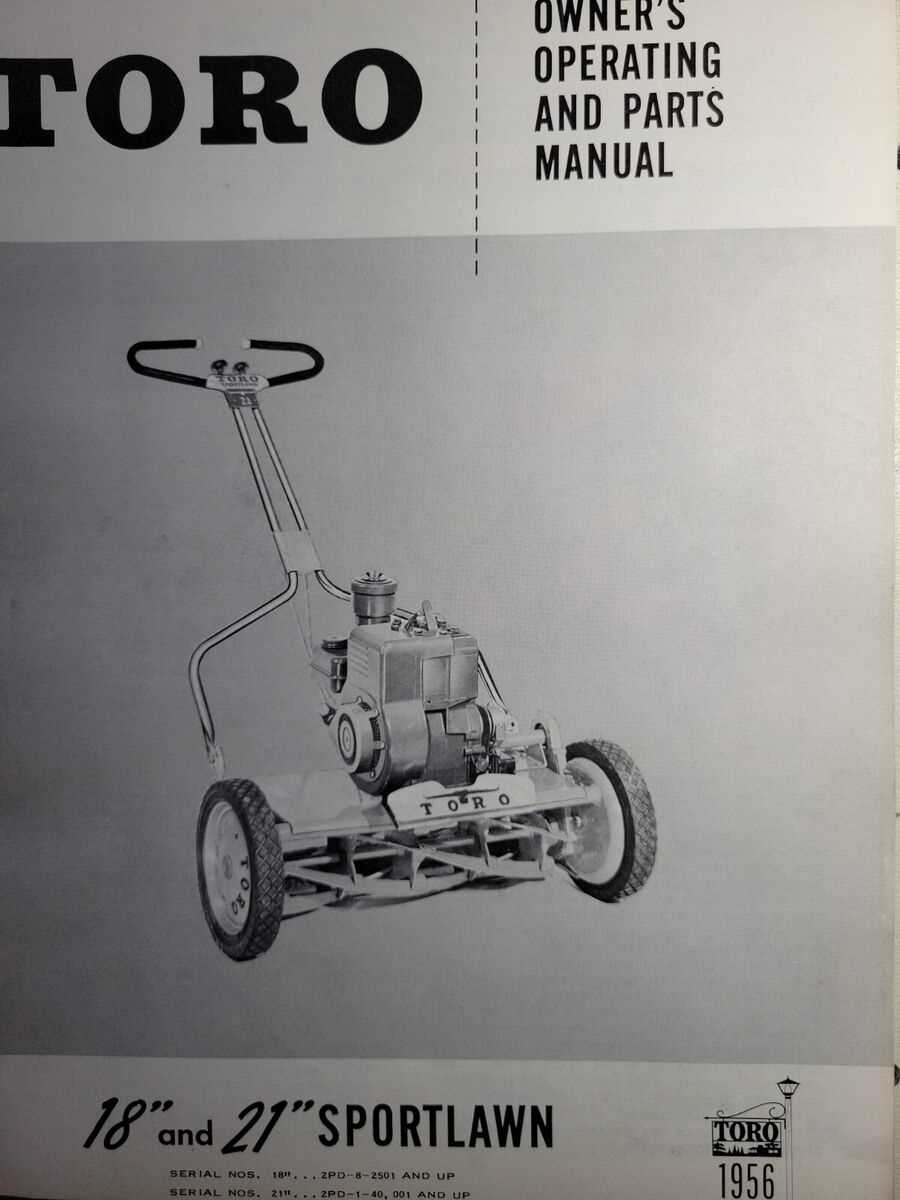

Key Features of Toro Riding Mowers

This section highlights the essential characteristics of these popular outdoor machines, showcasing their advanced technology and user-friendly designs. Understanding these features can greatly enhance the experience of maintaining your lawn effectively.

Performance and Efficiency

One of the standout aspects is the powerful engine performance that ensures smooth operation on various terrains. Coupled with efficient cutting systems, these machines provide a clean and precise finish, making lawn care effortless.

| Feature | Description |

|---|---|

| Engine Power | High-performance engines designed for durability and optimal speed. |

| Cutting Width | Various cutting deck sizes available to suit different lawn sizes. |

| Fuel Efficiency | Designed to consume less fuel while delivering maximum power. |

User Comfort and Control

The ergonomic design ensures that operators can maneuver easily, reducing fatigue during extended use. Features such as adjustable seats and intuitive controls make it suitable for users of all experience levels.

| Comfort Feature | Benefit |

|---|---|

| Adjustable Seat | Provides personalized comfort for different users. |

| Easy Controls | Simplifies operation and enhances user experience. |

| Visibility | Designed to provide clear sightlines for safe navigation. |

Importance of a Parts Diagram

Understanding the layout and components of machinery is crucial for effective maintenance and repair. A visual representation of these elements serves as a valuable tool for both novice and experienced users, facilitating a clearer understanding of how everything fits together.

Here are several reasons why having access to such a visual guide is essential:

- Enhanced Clarity: A detailed illustration eliminates confusion by showing the exact location and relationship of various components.

- Streamlined Repairs: Knowing where each element is situated can significantly speed up the repair process, reducing downtime.

- Improved Maintenance: Regular upkeep becomes easier when one can identify which parts require attention or replacement.

- Accurate Ordering: When parts need replacement, a visual guide helps ensure that the correct components are ordered, minimizing the risk of errors.

- Educational Tool: For those new to machinery, these illustrations serve as an excellent learning resource to understand how different elements interact.

In summary, a visual representation of components is not just a reference; it is an essential resource that enhances efficiency, accuracy, and knowledge in maintenance and repair tasks.

Common Toro Mower Part Names

Understanding the essential components of a lawn care machine can greatly enhance maintenance and repair efficiency. Each element plays a vital role in the overall functionality, ensuring smooth operation and optimal performance. Below are some commonly encountered terms associated with these machines.

Engine: The power source responsible for driving the entire system, often measured in horsepower.

Deck: The housing that encloses the cutting mechanism, typically designed for durability and effective grass collection.

Blade: A crucial element that performs the cutting action, available in various shapes and sizes to suit different grass types.

Transmission: The component that transfers power from the engine to the wheels, allowing for speed and directional control.

Wheels: These support the unit’s weight and provide mobility, available in different sizes for diverse terrains.

Fuel Tank: The reservoir that holds gasoline or alternative fuel, designed for easy access and efficient fuel delivery.

Battery: Essential for starting the engine and powering electrical components, typically rechargeable.

Chassis: The framework that provides structural integrity, supporting various parts and components.

Grass Catcher: An accessory designed to collect clippings, enhancing convenience and reducing cleanup time.

Familiarity with these terms can significantly aid in troubleshooting and servicing, leading to improved longevity and performance of the equipment.

How to Read the Diagram

Understanding the layout of components in machinery is essential for effective maintenance and repairs. A well-organized visual representation can simplify the identification of various elements, helping you navigate the intricate systems involved. Familiarizing yourself with the format and symbols used will enhance your ability to diagnose issues and perform necessary tasks efficiently.

Key Elements to Look For

Start by examining the main sections of the visual guide. Each area typically corresponds to a specific function or group of related components. Labels will often indicate the names or numbers of parts, while lines and arrows may illustrate connections or pathways. Pay attention to any color coding, as this can provide further insights into the nature of each element, such as electrical versus mechanical components.

Interpreting Symbols and Notations

Different types of symbols are frequently used to represent various components. Rectangles might denote physical items, while circles could indicate connections or junctions. Look for a legend or key that explains the symbols specific to the representation you are studying. This will aid in clarifying any confusing elements and ensuring accurate interpretation as you work through repairs or maintenance tasks.

Maintenance Tips for Riding Mowers

Regular upkeep is essential to ensure the longevity and efficiency of your outdoor equipment. By implementing a consistent maintenance routine, you can prevent costly repairs and enhance performance. This guide provides valuable insights into how to keep your machine in optimal condition throughout the seasons.

Routine Checks

Performing routine inspections is crucial. Examine the blades for sharpness and any signs of wear. Regularly check the oil level and replace it according to the manufacturer’s recommendations. Clean or replace air filters to guarantee proper airflow, which is vital for engine performance.

Seasonal Maintenance

As seasons change, so do maintenance needs. Before winter, ensure your equipment is winterized to prevent damage from freezing temperatures. In spring, conduct a thorough inspection to prepare for the busy growing season. Lubricate moving parts and inspect tires for proper inflation and tread wear.

Emphasizing preventive care will not only extend the lifespan of your equipment but also enhance its efficiency, making your tasks easier and more enjoyable. Regular attention to detail can save time and money in the long run.

Identifying Worn Out Parts

Recognizing components that have lost their effectiveness is crucial for maintaining optimal performance. Understanding the signs of wear can prevent further damage and ensure the longevity of the equipment. This section outlines common indicators of deterioration, allowing for timely replacements and repairs.

Common Signs of Deterioration

Components may exhibit various symptoms when they begin to degrade. Here are a few typical indicators to watch for:

| Indicator | Description |

|---|---|

| Unusual Noises | Grinding or squeaking sounds may signal that parts are not functioning smoothly. |

| Excessive Vibration | Increased vibration can indicate misalignment or worn elements. |

| Difficulty in Operation | If the equipment struggles to perform tasks it once handled easily, it may be time to inspect various components. |

| Visible Wear | Cracks, fraying, or corrosion are physical signs that parts need attention. |

Steps for Evaluation

To effectively assess the condition of components, follow these steps:

- Conduct regular inspections to identify early signs of wear.

- Listen for any unusual sounds during operation.

- Monitor performance changes over time.

- Consult manuals for specific maintenance guidelines.

Replacement Parts for Toro Models

Maintaining your outdoor equipment is essential for optimal performance and longevity. When components wear out or break, it’s crucial to know where to find suitable replacements. This section covers the various options available for sourcing essential elements for specific models, ensuring your machinery continues to operate smoothly.

- Aftermarket Suppliers: Numerous manufacturers offer alternatives that meet or exceed original specifications.

- OEM Options: Genuine components are available through authorized dealers, ensuring compatibility and reliability.

- Local Retailers: Many home improvement stores carry a selection of essential components for common models.

Identifying the exact model and year of your equipment is vital for sourcing the right elements. Here are some tips to help you find what you need:

- Check the model number: It is usually located on the frame or beneath the seat.

- Consult the user manual: This often includes a list of recommended replacements.

- Online Resources: Websites dedicated to outdoor machinery frequently provide detailed information and compatibility charts.

With the right information and resources, maintaining your equipment becomes a straightforward task, allowing you to keep it in peak condition for years to come.

Tools Needed for Repairs

When it comes to maintaining and fixing outdoor machinery, having the right tools at your disposal is crucial for effective and efficient work. Proper equipment not only ensures that repairs are completed successfully but also enhances safety during the process. Below is a list of essential tools you may need for various repair tasks.

Basic Tools

- Wrenches (adjustable and socket)

- Screwdrivers (flathead and Phillips)

- Pliers (needle nose and regular)

- Ratchet set

- Torque wrench

Specialized Tools

- Blade sharpener

- Grease gun

- Fuel siphon

- Diagnostic scanner

- Multimeter

Equipping yourself with these tools will streamline your repair efforts, making it easier to address issues and keep your equipment in optimal condition.

Safety Precautions During Maintenance

When performing upkeep on machinery, ensuring personal safety should be the foremost priority. Proper precautions help prevent accidents and injuries while enhancing the efficiency of maintenance tasks. By adhering to safety guidelines, individuals can protect themselves and prolong the life of their equipment.

Always wear appropriate protective gear, such as gloves, safety goggles, and sturdy footwear. This attire safeguards against potential hazards, including sharp components and hazardous materials. Additionally, it is essential to keep the work area clean and organized to minimize the risk of slips and falls.

Before starting any maintenance work, disconnect the power source to prevent accidental activation. This step is critical to ensure that the equipment remains inoperable during repairs. Furthermore, familiarize yourself with the machinery’s manual to understand specific safety protocols and recommended procedures.

Regularly inspect tools and equipment for any signs of wear or damage. Using faulty tools can lead to serious accidents. If you notice anything unusual, address it immediately before proceeding with maintenance tasks. Lastly, always work in a well-ventilated area when dealing with chemicals or lubricants to avoid inhalation of harmful substances.

Where to Find Genuine Parts

When it comes to maintaining your outdoor equipment, sourcing authentic components is crucial for optimal performance and longevity. Ensuring that you use original elements not only enhances the reliability of your machinery but also preserves any warranties you may have. Below are some reliable sources to consider when searching for these essential items.

| Source | Description |

|---|---|

| Authorized Dealers | These retailers specialize in specific brands and often carry a comprehensive range of original components. |

| Manufacturer’s Website | Official sites usually have sections dedicated to replacement items, ensuring you receive genuine products directly. |

| Online Marketplaces | Reputable platforms may offer original items, but it’s important to verify the seller’s authenticity and ratings. |

| Local Repair Shops | Many repair specialists stock original components or can order them on your behalf, providing personal service. |

By exploring these avenues, you can find the right components to keep your equipment running smoothly, ensuring you have the right tools for the job.

Benefits of Regular Inspections

Conducting routine evaluations of your equipment is essential for maintaining optimal performance and longevity. Regular check-ups help identify potential issues before they escalate, ensuring smooth operation and reducing the likelihood of costly repairs.

- Prolonged Lifespan: Consistent inspections help extend the overall lifespan of machinery, allowing for prolonged use and better investment return.

- Enhanced Performance: Regular maintenance ensures that all components function efficiently, contributing to better overall performance.

- Safety Assurance: Evaluating equipment can prevent accidents caused by malfunctioning parts, promoting a safer working environment.

- Cost Savings: Early detection of issues can save money on major repairs and replacements in the long run.

- Improved Reliability: Frequent assessments lead to more dependable operation, minimizing downtime and enhancing productivity.

Incorporating regular inspections into your maintenance routine is a proactive approach that yields numerous benefits, ultimately leading to a more effective and efficient experience.