Understanding the White Riding Mower Parts Diagram

The efficient functioning of outdoor equipment relies on a well-coordinated system of various mechanical elements. Each component plays a critical role in ensuring smooth operation and durability. To maintain peak performance, it’s important to become familiar with the arrangement and purpose of these elements.

In this section, we’ll explore the various elements that contribute to the overall function of the machine. By gaining a deeper understanding of these elements, you can better handle maintenance, repairs, and adjustments, ensuring long-term reliability.

Whether you’re performing routine maintenance or addressing a specific issue, knowing how each part connects and operates within the system will provide valuable insights into keeping everything running smoothly. This knowledge will also help when selecting replacements or upgrades for key components.

Understanding the Components of Your Lawn Mower

For efficient operation, it’s essential to recognize the primary elements of your garden equipment. Each mechanism works in harmony to deliver optimal performance, and knowing how they function will help maintain the equipment in top condition for years. Whether you’re dealing with the engine or the blades, each section plays a vital role in ensuring smooth and effective cutting of your lawn.

Key Mechanical Sections

The machinery is typically composed of several mechanical segments, each performing a specific task. The engine generates the power needed, while the blades are responsible for cutting. A sturdy frame supports the equipment, offering stability, while the control system allows precise

Engine Parts Overview and Functions

The internal components of the machine’s power system are crucial for ensuring smooth and efficient operation. Understanding the various elements within the engine and how they work together can help in maintaining performance and diagnosing potential issues.

Cylinder: The central part where fuel combustion occurs, the cylinder converts chemical energy into mechanical power. Proper upkeep is essential for longevity.

Piston: This moving component transfers the force from combustion to the crankshaft, enabling motion. Its precise movement ensures efficient energy conversion.

Crankshaft: Responsible for converting the reciprocating motion of

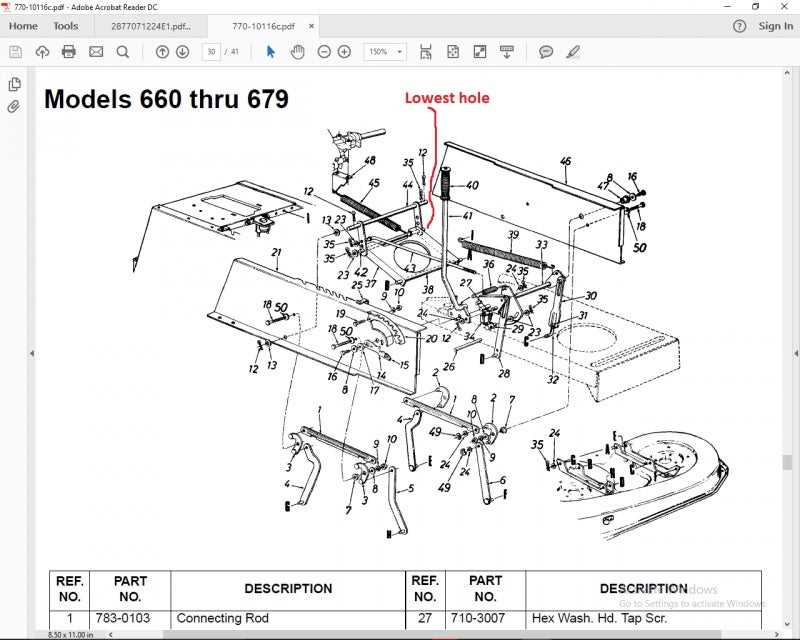

Blade Assembly: Key Elements Explained

The blade setup is an essential part of any machine designed for trimming or cutting vegetation. Its proper functioning ensures efficient performance and longevity of the equipment. Understanding the key elements of this system helps maintain optimal operation and enhances safety during use.

Below are the fundamental components involved in the blade assembly:

- Blade Mounting: The blade is securely attached to a rotating hub, allowing for smooth rotation. Proper fastening ensures stability and reduces vibration.

- Blade Design: Various shapes and sizes are available, each designed for specific tasks. The sharpness and angle of the blade significantly impact cutting efficiency.

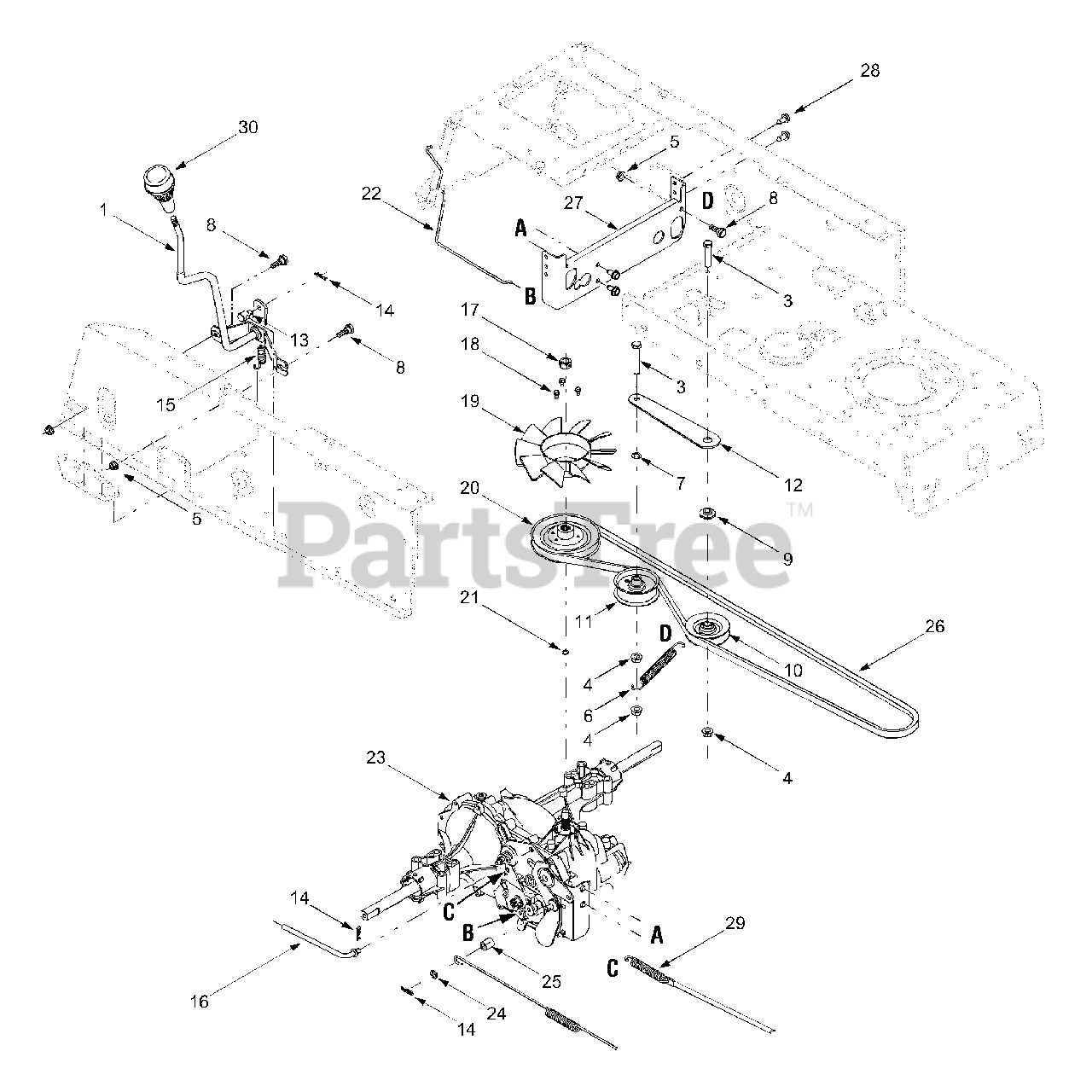

- Drive System and Transmission Layout

The drive system is an essential component that ensures smooth and efficient movement. It connects various mechanical parts, allowing them to work in unison to propel the vehicle forward or backward. The transmission layout plays a crucial role in controlling speed and torque, adjusting the power output to match the demands of different terrains or tasks.

Power Delivery through the system is carefully managed, ensuring that energy is efficiently transferred to the wheels. This process relies on a combination of gears, pulleys, and belts, all working together to provide the necessary force and control. The design ensures the system can handle changes in terrain while maintaining stability and control.

Adjustable transmission

Fuel System Diagram and Maintenance

The fuel delivery system plays a crucial role in ensuring efficient operation by providing the necessary energy to power the equipment. Proper understanding of this system allows for smooth functionality, helping to avoid disruptions and performance issues. Regular care and timely inspection of the components are essential to maintain optimal conditions.

Key Components of the Fuel System

The fuel system consists of several critical elements, including the tank, filter, and lines that transport the liquid to the engine. These parts must work in unison to ensure a steady flow of fuel. It’s important to regularly check for clogs, leaks, or any signs of wear in these areas to prevent future malfunctions.

Understanding the Electrical Components

When dealing with any machine that relies on electrical systems, it is essential to understand how the components interact to ensure proper functionality. This section explores the key elements that make up the electrical network of a mechanical device, focusing on the critical parts responsible for power distribution and operation control.

The electrical assembly includes various components that manage the distribution of power, control the activation of mechanisms, and ensure safety during operation. Understanding how each piece contributes to the overall system helps in troubleshooting and maintenance, ensuring the device runs efficiently.

Component Function Battery Stores energy to power the system’s electrical needs. Ignition Switch Activates the system by supplying power to key components when turned on. Starter Motor Engages the engine by converting electrical energy into mechanical force. Fuse Protects the electrical system by cutting off power in case of overload. Alternator Generates electrical power to recharge the battery and support the electrical system during operation. Wiring Harness Connects various components, enabling the flow of electricity throughout the system. Wheels and Axles: Parts Breakdown

Understanding the key components that support movement is crucial for smooth operation. The essential elements in this system work together to ensure stability and efficiency when navigating various terrains. This section outlines the critical pieces involved in the rotational and directional system, offering insights into their functionality and structure.

Component Description Wheel The circular component that ensures traction and mobility across different surfaces. Axle The shaft that connects and allows rotation of the wheels, providing the core structure for movement. Hub The central part of the wheel that connects to the axle, enabling the wheel to rotate smoothly. Spindle A rod that supports the wheel and axle assembly, often used in steering and rotation mechanisms. Bearings Small components that reduce friction and wear, ensuring smooth rotation of the wheels. Steering Mechanism and Linkages

The steering system is crucial for maneuvering and controlling the vehicle. It consists of various components that work together to translate the driver’s inputs into precise movements. These elements, often found in vehicles of similar nature, enable smooth turning and directional control.

Typically, the steering system is composed of the following key components:

- Steering Wheel – The main control interface for the operator, providing feedback and initiating directional changes.

- Steering Shaft – A rotating element that transmits motion from the steering wheel to the rest of the system.

- Linkages – Mechanical rods or bars that connect various parts, facilitating the transmission of motion and adjusting the vehicle’s angle.

- Pivot Points – Areas where the components rotate, enabling flexibility and responsiveness in the steering mechanism.

- Wheel Bearings – Help to reduce friction and allow smooth turning of the wheels.

The linkages play a vital role by ensuring that the steering wheel’s movement is efficiently transferred to the wheels. These components must be well-maintained to guarantee precise control over the vehicle’s movements and prevent excessive wear or failure.

Common issues in steering systems often arise from misalignment or wear in the linkages, which can lead to poor responsiveness or uneven turning. Regular checks and proper lubrication of these parts ensure that the system remains in optimal working condition.

Deck Components and Adjustments

The cutting assembly is a crucial aspect of lawn maintenance equipment, responsible for ensuring a precise and uniform cut. Proper functioning relies on multiple elements working together harmoniously. Regular inspection and adjustment of these parts are essential for optimal performance and durability.

Blades are one of the most critical components in the cutting mechanism. They need to be kept sharp to ensure a clean and effective cut. If dull or damaged, they should be replaced to avoid straining the motor and creating an uneven finish.

Height Adjustment controls the cutting level, allowing users to set the grass length to their desired specification. Incorrect adjustment can lead to uneven cutting, scalping, or inefficient grass trimming. It is recommended to check the height settings regularly to adapt to varying grass conditions.

Spindle Assembly holds the blades in place and ensures their stable rotation. Over time, it can wear out or become misaligned, affecting the quality of the cut. Lubricating and checking for signs of wear is vital to maintaining smooth operation.

Deck Belt connects the motor to the spindle assembly, enabling the transfer of power necessary for blade rotation. If this belt becomes loose, frayed, or damaged, it can hinder performance or cause the blades to stop rotating. Periodically inspecting and replacing the belt is necessary to avoid unexpected breakdowns.

Battery and Charging System Details

The power source and charging components are essential for maintaining the proper function of the equipment. These elements ensure that the device operates efficiently and remains ready for use, whether for long or short durations. The battery provides the necessary energy to start the system and run its components, while the charging system keeps it replenished during use.

The system typically includes a sealed lead-acid or lithium-ion battery, which is responsible for storing energy. A voltage regulator ensures that the battery is charged correctly, preventing overcharging or undercharging that could damage the battery’s lifespan. A charging circuit, usually connected to the engine’s alternator, generates power to recharge the battery while in operation.

Proper maintenance of these components, such as checking for corrosion on terminals and ensuring clean connections, helps maintain optimal performance. Regular inspection of the charging system also helps avoid potential issues that could result in power loss or system failure.

Brake System Parts and Functionality

The braking mechanism is essential for controlling the motion and ensuring the safety of a vehicle or equipment. This system relies on various components working together to provide effective deceleration. Understanding each element’s role helps in maintaining proper function and preventing accidents or mechanical failures.

Key Components of the Braking Mechanism

The braking system consists of several critical components, each with a unique role in stopping or slowing down the vehicle. These include the brake pedal, brake pads, calipers, and rotors. The brake pedal serves as the operator’s input, which triggers the process. The brake pads apply pressure to the rotors, converting kinetic energy into heat, which slows down the motion.

How the Braking Mechanism Operates

When the brake pedal is pressed, it activates a series of actions that ultimately halt the movement. The calipers squeeze the brake pads against the rotors, creating friction. This friction slows down the system, converting the energy of motion into heat. Over time, regular maintenance ensures the system remains responsive and efficient, preventing wear and tear on its components.

Seat and Operator Control Layout

The seating and control system of a machine plays a vital role in the user’s comfort and ease of operation. Proper positioning and accessibility of various components ensure smooth functioning and minimize fatigue during extended use. This layout includes key elements such as the seat, levers, pedals, and control switches, each designed to enhance the overall experience while maintaining safety and control during operation.

Seat Positioning

The seat is positioned for optimal comfort and control, allowing the operator to easily reach all necessary controls. Adjustable settings allow the user to modify the position for a personalized fit, ensuring better posture and improved handling of the vehicle. Key features include:

- Adjustable seating for height and depth

- Comfortable padding to reduce strain

- Backrest angle adjustment for better support

Operator Controls

The layout of the controls is designed to be intuitive, providing easy access to essential functions. Operators can quickly adjust the speed, direction, and engage various operational modes with minimal effort. Common control elements include:

- Steering wheel or handlebar for maneuvering

- Pedals for throttle and brake control

- Levers for adjusting speed and cutting height

- Switches for activating lights and other features

Maintenance Guide for Moving Parts

Proper care of the components that facilitate motion in mechanical equipment is essential for optimal performance and longevity. Regular inspection and maintenance ensure smooth operation and prevent costly repairs or replacements. Following a consistent routine for these elements can extend the lifespan of your machinery and maintain its efficiency.

Below are some key maintenance practices to keep in mind:

- Lubrication: Ensure that all moving components are well-lubricated to reduce friction and wear. Regularly check the manufacturer’s recommendations for the appropriate type of lubricant.

- Cleaning: Dust, dirt, and debris can accumulate over time, affecting the functionality of moving parts. Clean these areas regularly to avoid any hindrance to movement.

- Inspection: Regularly inspect key moving components for signs of wear, such as cracks, corrosion, or loosening. Early detection of any issues can prevent more severe damage.

- Adjustment: Ensure that the mechanical links, belts, or other moving elements are properly tensioned. Loose or overly tight components can lead to malfunction or reduced performance.

- Replacement: If any moving parts show signs of significant wear or damage, replace them promptly to avoid compromising the overall function of the machine.

Following these practices can help maintain the reliability of the equipment and ensure its continued efficient operation.