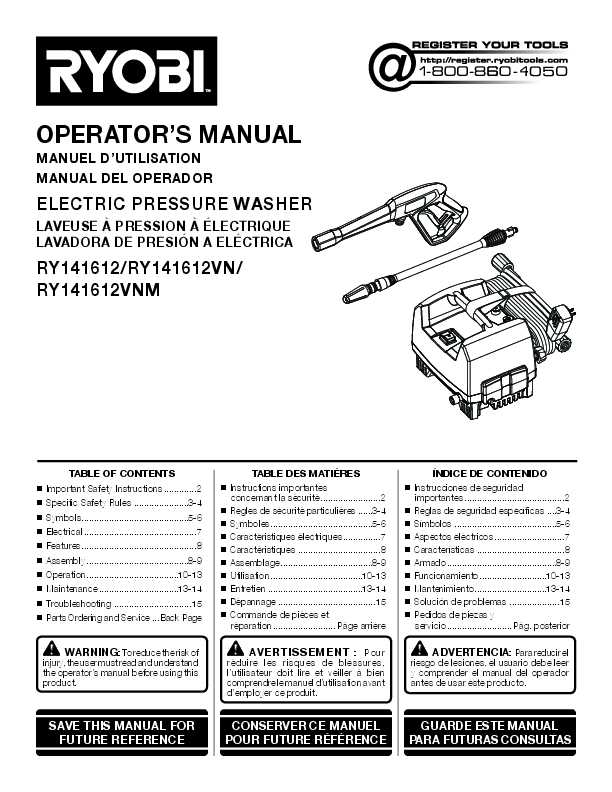

Understanding the Ryobi 1600-psi Pressure Washer Parts Diagram

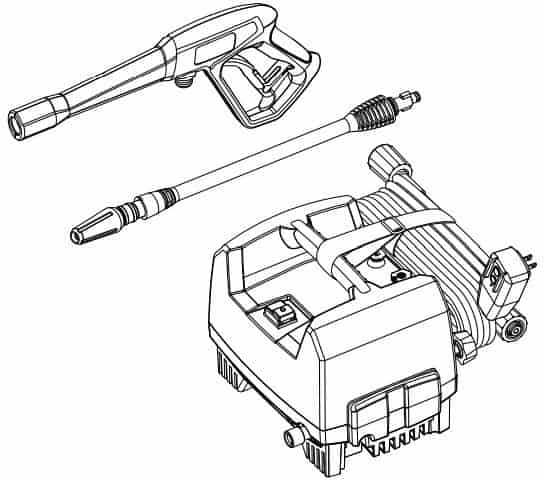

Maintaining the efficiency of your outdoor cleaning equipment is essential for achieving the best results. Knowing the various elements that comprise your device can enhance its longevity and performance. This section will explore the intricate arrangement of components that work together seamlessly.

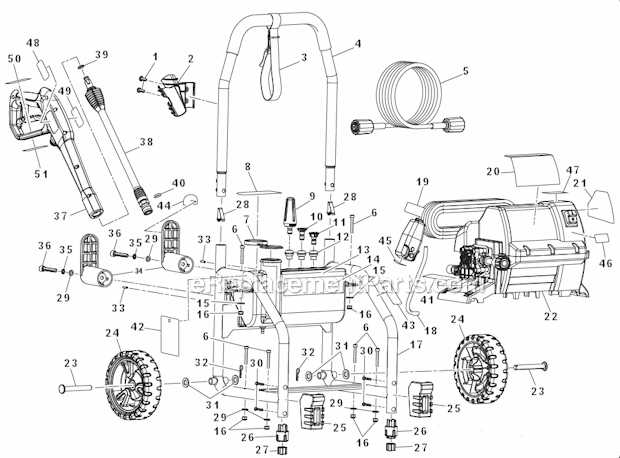

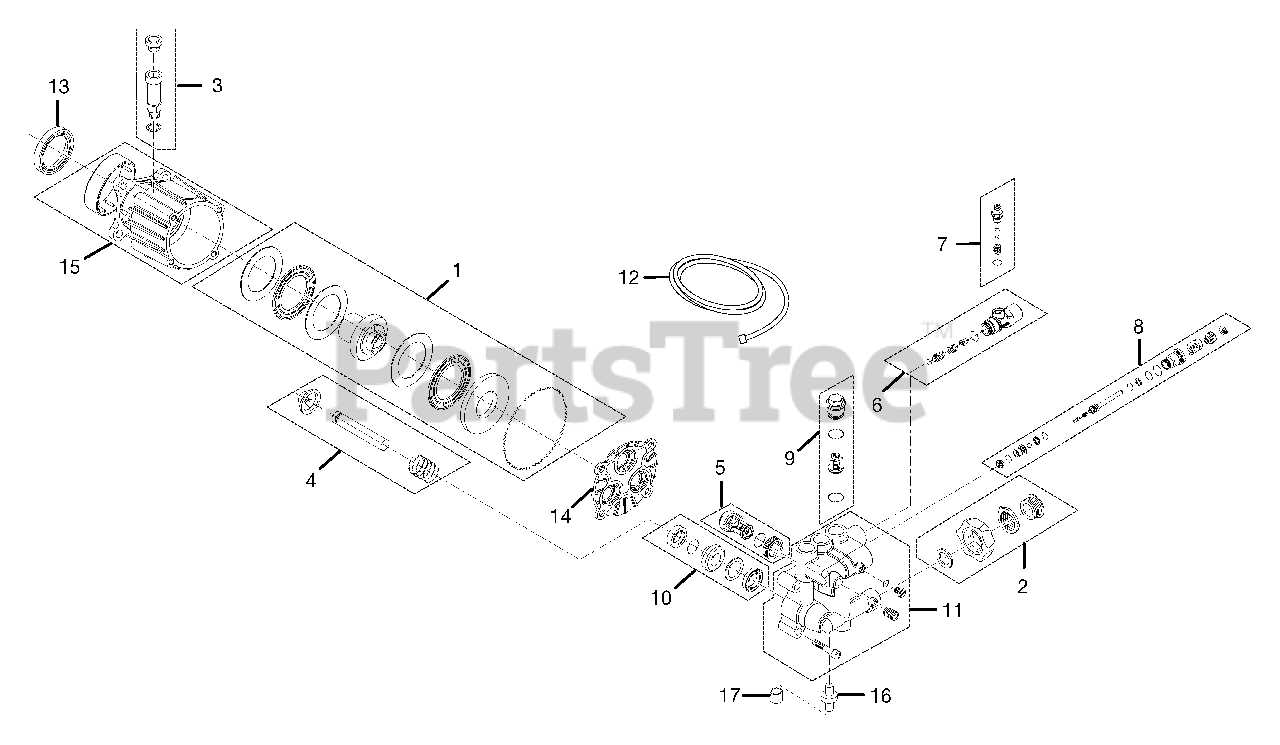

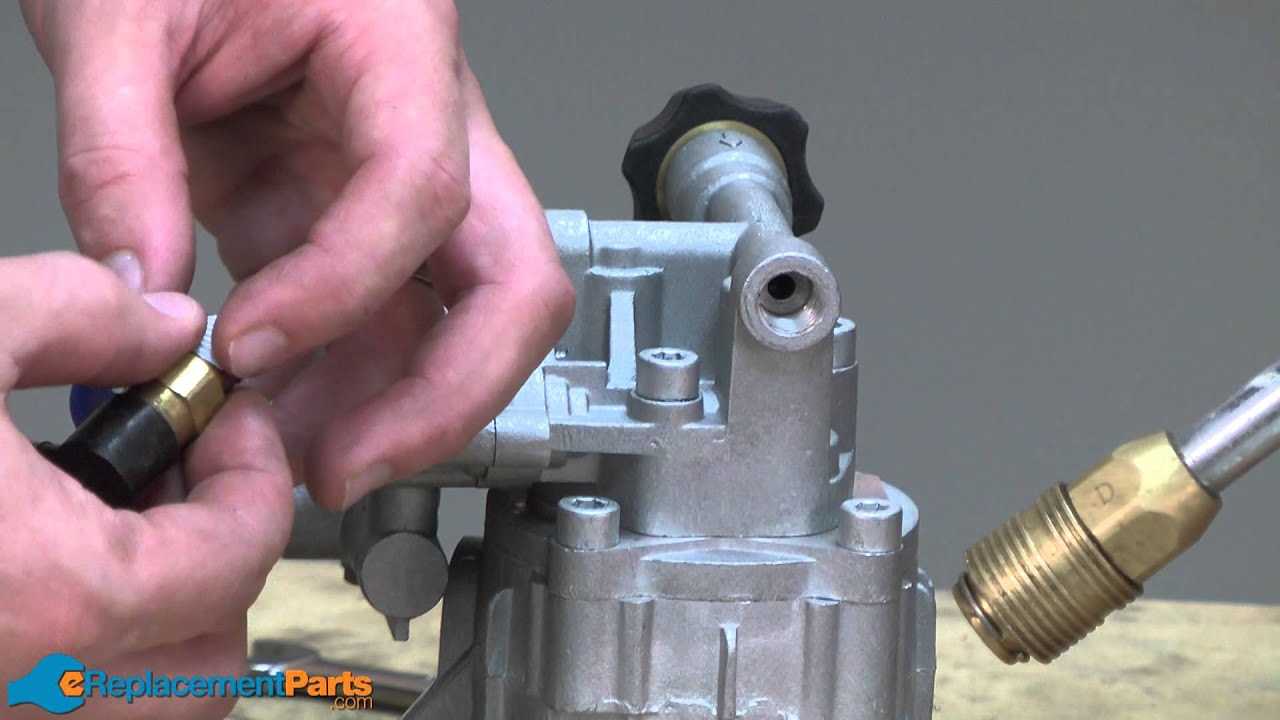

Visual aids play a crucial role in comprehending how these pieces fit together. By examining a well-structured representation, users can quickly identify each segment and its function within the overall system. This insight not only aids in troubleshooting but also assists in proper maintenance.

Whether you’re looking to repair or upgrade your cleaning tool, delving into the layout of its inner workings can provide you with the ultimate understanding needed to make informed decisions. Familiarity with each element empowers you to tackle issues with confidence and ensures that your machine operates at its best.

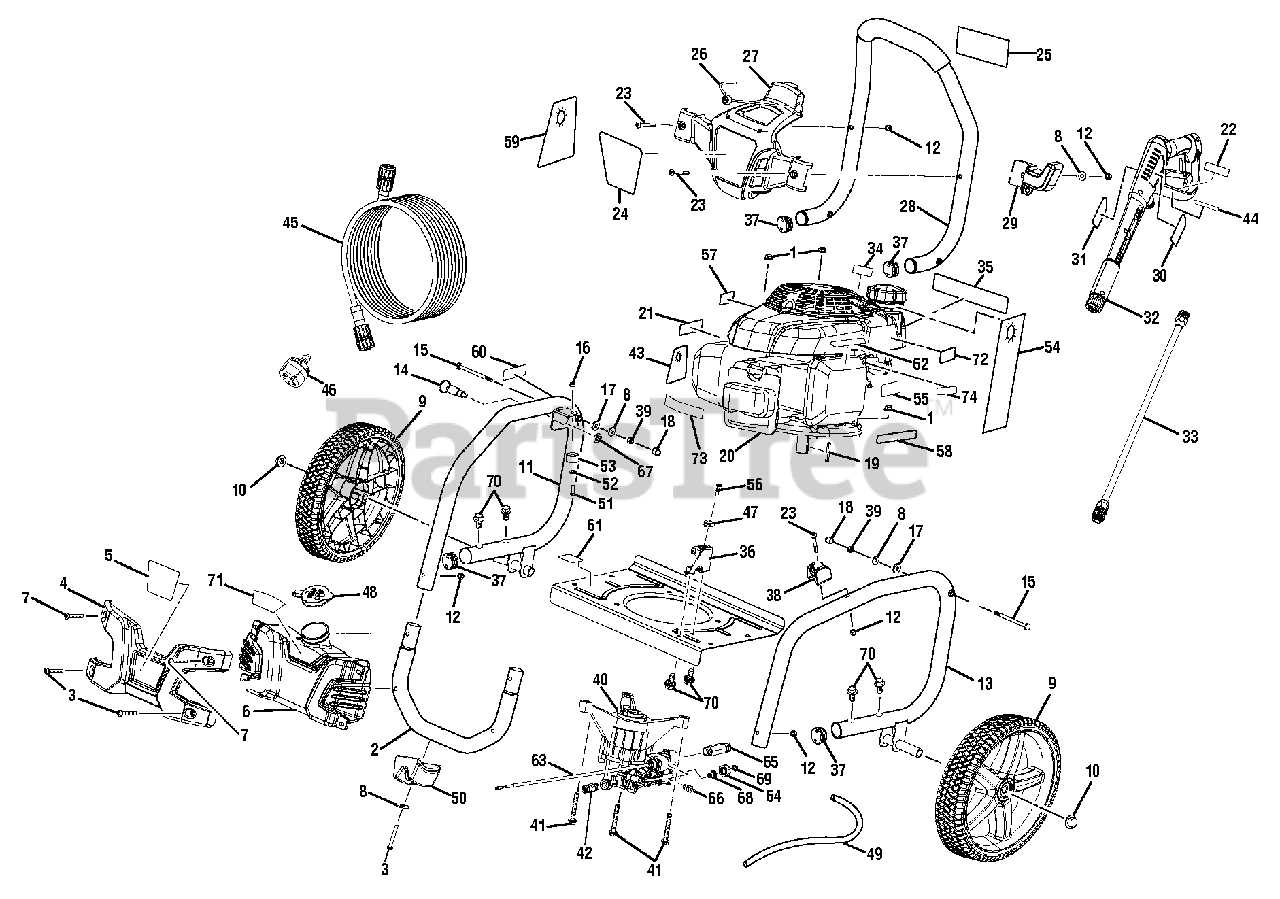

Understanding Ryobi Pressure Washer Components

Gaining insight into the essential elements of cleaning equipment enhances maintenance and efficiency. Familiarity with the various components enables users to troubleshoot issues and optimize performance.

Key components include:

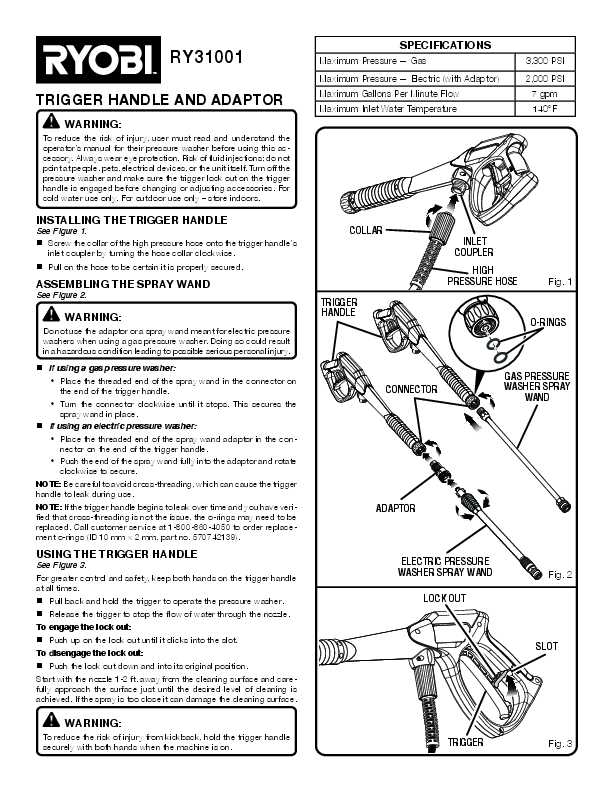

- Motor: Powers the system and drives the cleaning mechanism.

- Pump: Pressurizes water, delivering it forcefully through the nozzle.

- Nozzle: Directs the flow and determines the spray pattern.

- Hose: Connects the pump to the nozzle, allowing fluid transfer.

- Trigger: Controls water flow, providing user command over operation.

Understanding these parts is crucial for effective use and maintenance, ultimately leading to a better cleaning experience.

Importance of Pressure Washer Diagrams

Understanding the layout and components of cleaning equipment is crucial for effective maintenance and repair. Diagrams serve as essential tools that provide users with a clear visual representation, enabling them to identify parts and their functions efficiently.

Enhanced Troubleshooting

When issues arise, having a visual guide simplifies the troubleshooting process. Users can quickly locate the source of a problem, minimizing downtime and maximizing efficiency.

Facilitating Repairs

Diagrams also aid in repairs, ensuring that every component is correctly reassembled. Without clear illustrations, individuals may struggle with reinstallation, leading to potential operational failures. Incorporating these resources can ultimately enhance the lifespan of the equipment.

Common Parts in Ryobi Models

This section explores essential components found in various models, highlighting their significance and functionality. Understanding these elements can enhance maintenance and overall performance.

- Motor: The heart of the device, responsible for powering all operations.

- Spray Gun: A crucial tool for directing the flow and intensity of the output.

- Nozzle: Different types adjust the spray pattern for various tasks.

- Hoses: Essential for delivering the fluid from the source to the application point.

- Filter: Keeps debris out of the system, ensuring optimal performance.

Familiarity with these components can assist in troubleshooting and repairs, ultimately prolonging the lifespan of the equipment.

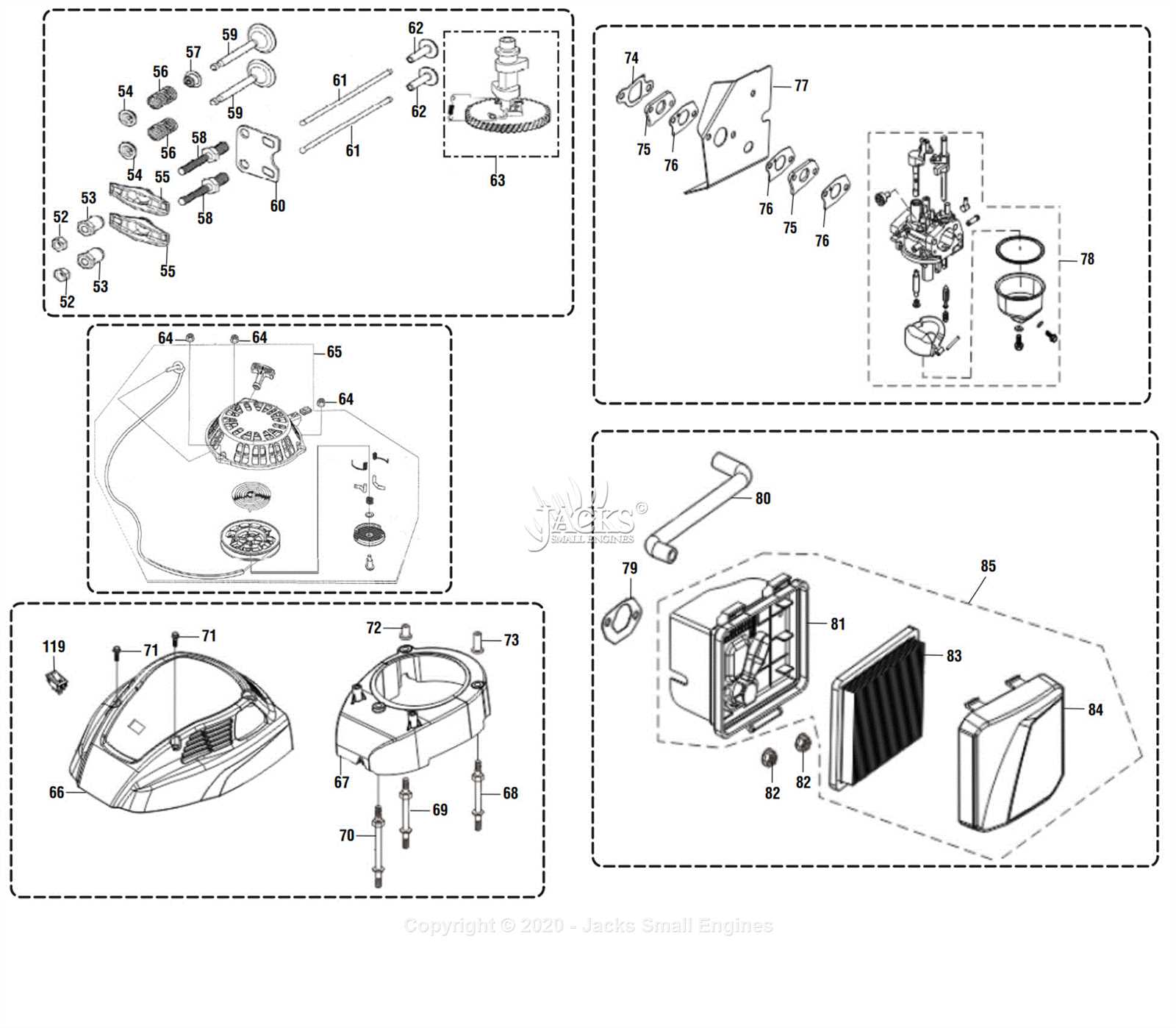

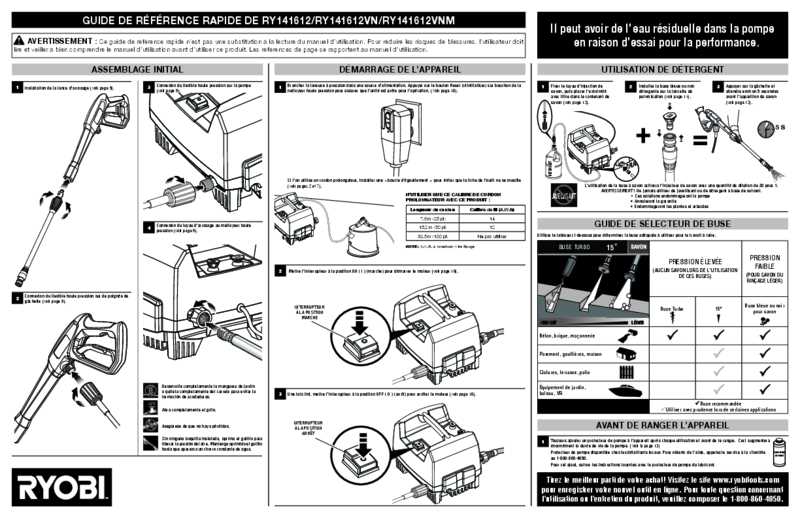

How to Interpret Parts Diagrams

Understanding assembly illustrations is essential for effective maintenance and repair. These visuals provide crucial insights into component organization and functionality, making it easier to identify and address issues.

Here are key steps to interpret these illustrations:

- Familiarize with Symbols: Learn common symbols and notations used in the illustration.

- Identify Components: Locate each item, noting its position and relation to others.

- Refer to Labels: Pay attention to labels that describe parts and their specifications.

- Use a Legend: Consult the legend for clarification on specific icons and numbers.

- Follow the Sequence: Understand the assembly sequence for proper reassembly.

By mastering these steps, you can efficiently navigate any assembly illustration and ensure a successful repair or maintenance process.

Identifying Faulty Components Quickly

Recognizing malfunctioning elements in your equipment is essential for maintaining optimal performance. By understanding common indicators of issues, you can efficiently troubleshoot and replace faulty components, ensuring longevity and reliability in operation.

Common Signs of Malfunction

Several symptoms can signal that a component is not functioning properly. Look for unusual noises, leaks, or a noticeable drop in efficiency. These signs often suggest wear and tear or improper function, allowing for timely interventions.

Steps for Quick Identification

Begin by conducting a visual inspection of all visible parts. Check for any signs of damage, such as cracks or corrosion. Next, perform functional tests to assess performance. This methodical approach enables you to pinpoint the faulty element swiftly, leading to quicker repairs.

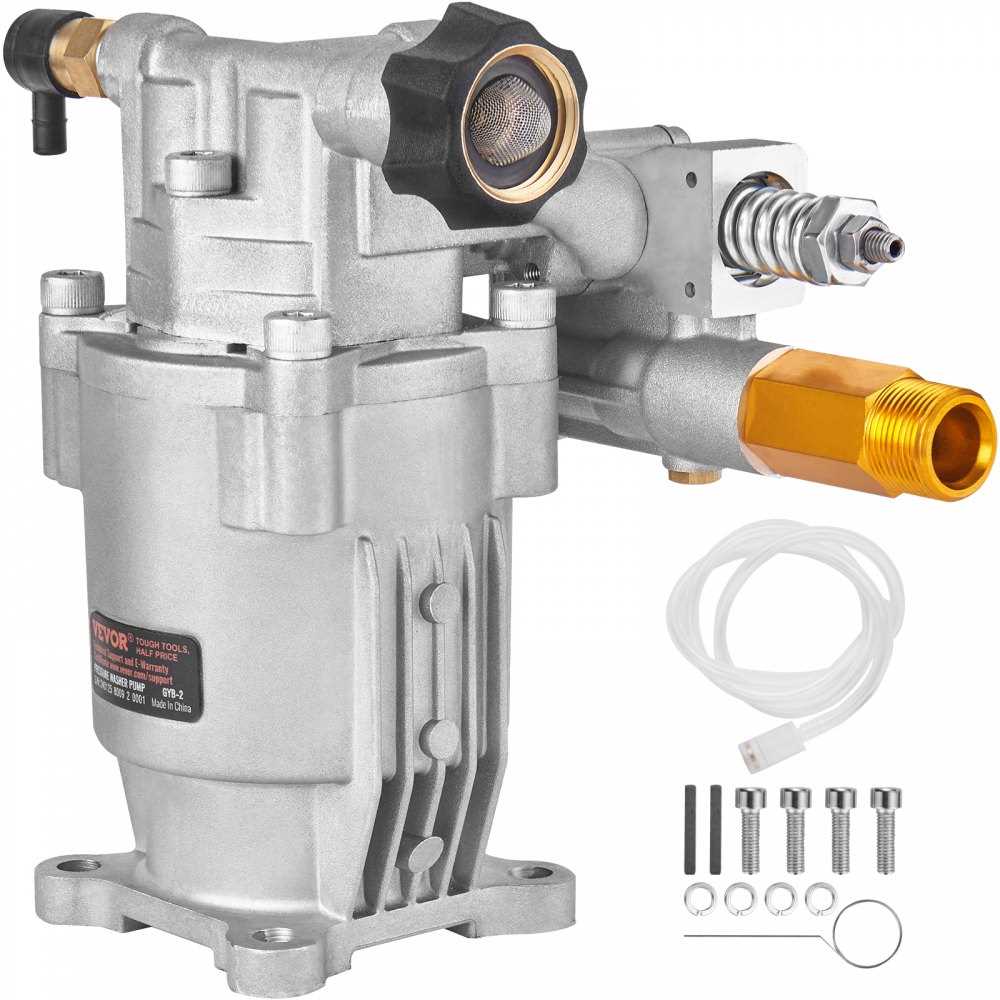

Replacement Options for Damaged Parts

When components of your cleaning device sustain damage, exploring effective alternatives is crucial to maintain functionality. This section provides an overview of various avenues to consider when seeking replacements, ensuring optimal performance and longevity.

OEM Components: Original equipment manufacturer items are specifically designed to match the original specifications. They guarantee compatibility and reliability, making them a top choice for those who prioritize quality.

Aftermarket Alternatives: Numerous third-party manufacturers offer replacements that often come at a lower cost. While they may provide good performance, it’s essential to evaluate their durability and fit to avoid future complications.

Repair Kits: For certain issues, a repair kit can be a practical solution. These kits typically include all necessary components, allowing you to fix specific problems without replacing entire units.

Refurbished Items: Purchasing refurbished components can be a budget-friendly option. Ensure they have been tested and certified to function properly, providing a balance between cost and performance.

Ultimately, considering these alternatives will help you make informed decisions and restore your equipment to its former efficiency.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your cleaning equipment requires regular attention and care. By adopting simple maintenance practices, you can enhance performance and extend its lifespan.

- Clean the exterior regularly to prevent dirt buildup.

- Check and replace worn or damaged components promptly.

- Store the unit in a dry, sheltered area to avoid weather-related damage.

Additionally, consider these specific tips:

- Inspect hoses for leaks and ensure proper connections.

- Flush the system with clean water after each use to prevent clogging.

- Regularly lubricate moving parts to maintain smooth operation.

By incorporating these practices into your routine, you will ultimately ensure optimal functionality and longevity of your equipment.

Where to Find Genuine Parts

Locating authentic components for your equipment can significantly enhance its performance and longevity. Reliable sources not only guarantee quality but also ensure compatibility, helping you avoid the pitfalls of substandard alternatives.

Manufacturer’s Website: The most trustworthy place to seek original components is the official website of the manufacturer. Here, you can find a comprehensive selection of items tailored for your specific model, along with detailed descriptions and usage instructions.

Authorized Dealers: Another excellent option is to visit authorized retailers. These outlets are recognized by the manufacturer and often carry a wide array of genuine items. Plus, staff at these locations can provide valuable insights and assistance.

Online Marketplaces: Reputable online platforms also offer a vast selection of components. However, it’s crucial to verify the seller’s credibility and ensure they provide original merchandise. Look for ratings, reviews, and return policies to safeguard your purchase.

Local Repair Shops: Don’t overlook local repair shops that specialize in your type of equipment. Many of these establishments have access to genuine components and can also provide expert installation and maintenance services.

By exploring these avenues, you can confidently procure authentic components that will keep your machinery operating smoothly and efficiently.

DIY Repairs vs. Professional Help

When it comes to fixing equipment, individuals often face the choice between handling repairs themselves or seeking expert assistance. Both options have their advantages and drawbacks, making it essential to evaluate personal skills and the complexity of the issue at hand.

Choosing a DIY approach can be rewarding, offering the chance to save money and learn valuable skills. Many find satisfaction in tackling tasks independently, especially with the right resources and guidance available online. However, this method can also be time-consuming and may lead to further complications if not executed properly.

On the other hand, enlisting professional help guarantees expertise and efficiency. Professionals possess the necessary tools and experience to resolve issues quickly, ensuring high-quality results. Yet, this convenience often comes at a higher cost, which may deter some individuals from opting for this route.

Ultimately, the decision rests on the specific situation and personal preferences. Delving into the pros and cons of each approach can help determine the best course of action for effective repairs.

Customer Reviews on Ryobi Parts

Feedback from users provides invaluable insights into the performance and reliability of components. Many consumers appreciate how well these elements function, often highlighting their durability and ease of installation.

Positive experiences frequently mention the effectiveness and efficiency of these components, making maintenance tasks easier and more straightforward. Users often express satisfaction with the long-lasting quality, which enhances overall performance.

On the other hand, some reviews address occasional issues with compatibility or availability. Customers emphasize the importance of verifying specifications to ensure the right fit for their needs.

Overall, user testimonials reflect a mix of commendations and constructive feedback, contributing to a well-rounded understanding of these essential items.

Upgrading Your Pressure Washer Experience

Enhancing your cleaning routine can significantly improve efficiency and results. By exploring various enhancements and accessories, you can elevate your equipment’s performance and adapt it to a wider range of tasks. This approach not only saves time but also ensures a more enjoyable experience during use.

Choosing the Right Accessories

Selecting compatible tools and attachments can drastically change how you tackle different surfaces. From specialized nozzles that adjust the spray pattern to extension wands for hard-to-reach areas, the right accessories can make a substantial difference. Consider the types of projects you’ll undertake to choose the most beneficial upgrades.

Regular Maintenance Tips