Understanding the Ryobi PCL500 Parts Diagram for Easy Repairs

When it comes to maintaining machinery, comprehending the individual elements that make up the device is crucial. A clear representation of these components not only aids in efficient repairs but also enhances overall functionality. By examining how each piece interacts, users can optimize their usage and troubleshoot issues effectively.

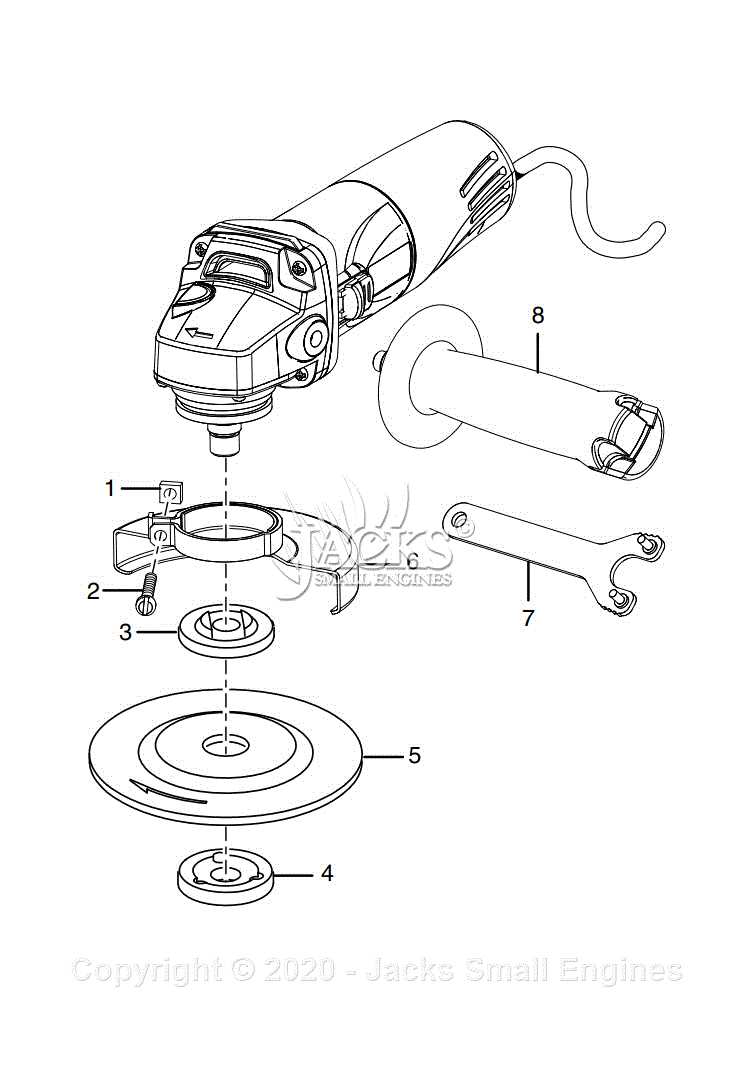

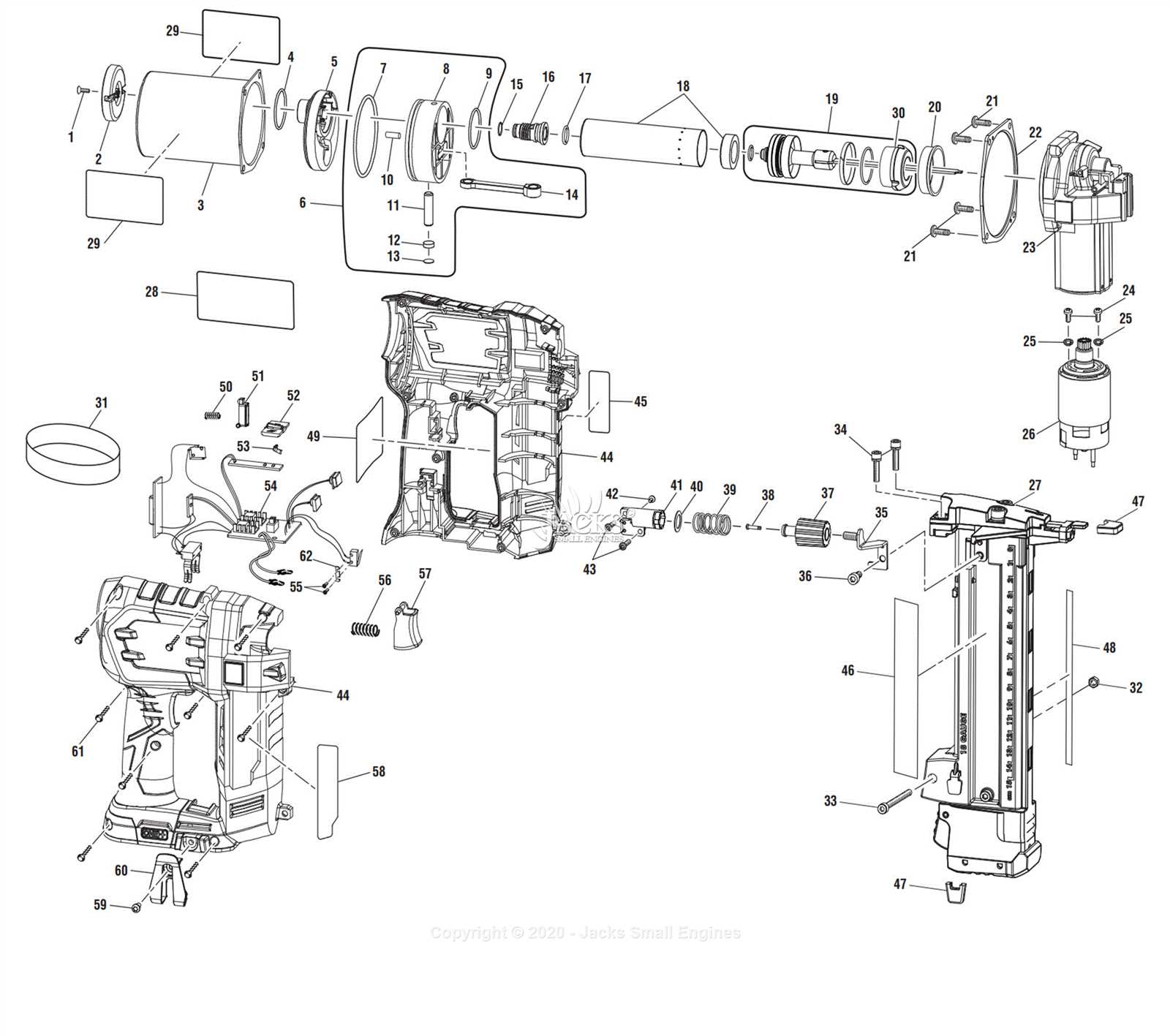

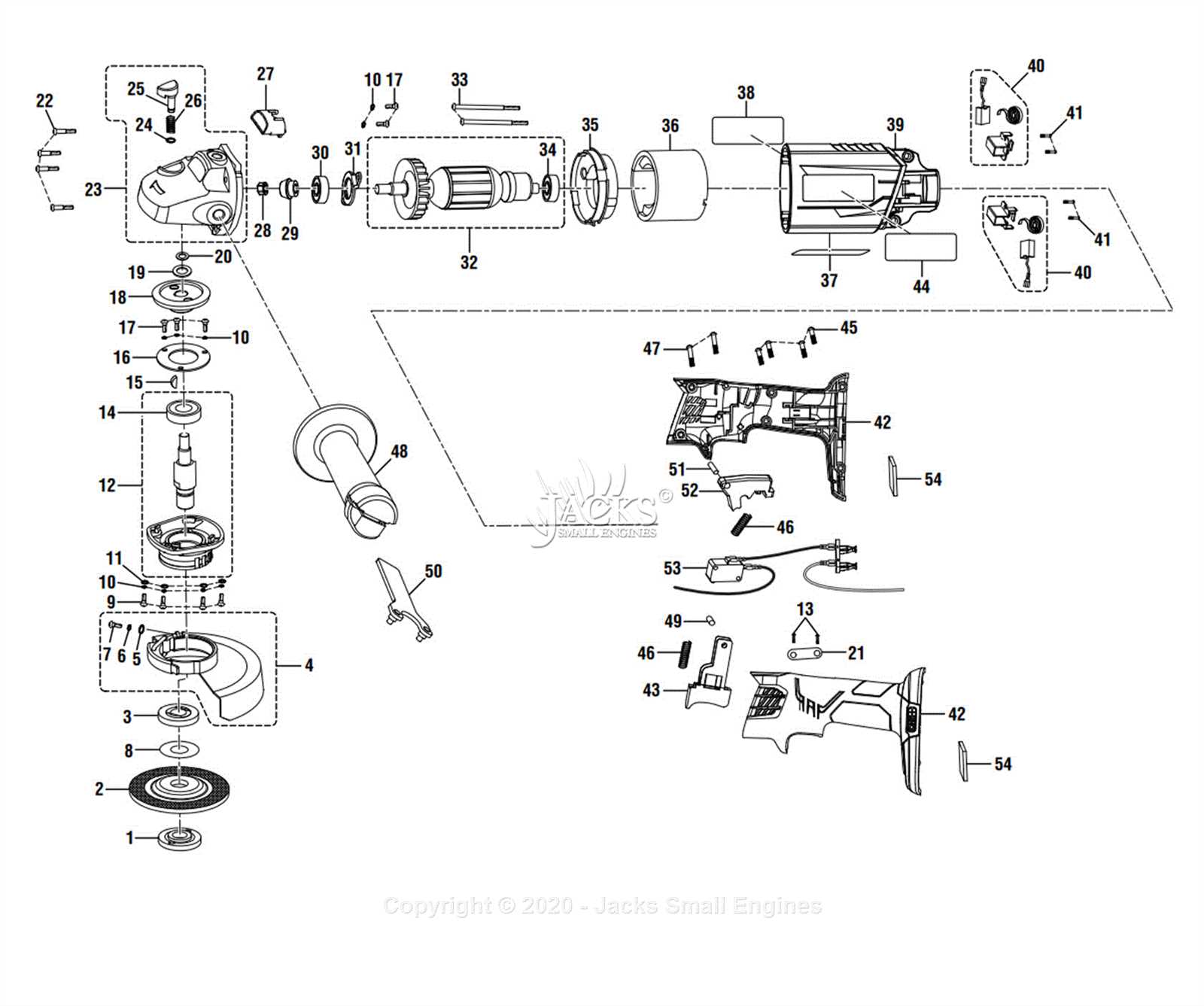

Visual guides play a significant role in this understanding. They provide an ultimate reference point, allowing individuals to easily identify necessary components during maintenance or replacement tasks. This knowledge empowers users, ensuring they can confidently manage their tools.

Delving into the intricacies of the equipment’s makeup reveals the importance of each part. Whether you’re an avid user or a novice, grasping this information ensures that your machinery remains in peak condition, ultimately prolonging its lifespan and performance.

Understanding Ryobi PCL500 Parts

In any machinery, familiarity with individual components is essential for maintenance and efficient operation. Each element plays a crucial role, contributing to the overall functionality of the device. Grasping how these elements interact and support each other can enhance your ability to troubleshoot and perform repairs effectively.

Key Components and Their Functions

Essential elements of the device include the motor, which provides the necessary power, and the housing that protects internal mechanisms. Additionally, various attachments serve specific purposes, enabling versatility in applications. Knowing the role of each component can simplify the repair process and extend the life of the equipment.

Maintenance Tips for Longevity

Regular upkeep is vital for optimal performance. Cleaning parts to prevent debris buildup, inspecting connections for wear and tear, and ensuring proper lubrication can all contribute to the durability of the equipment. Understanding each section’s needs will empower users to take proactive measures in maintaining their machinery.

Importance of Parts Diagrams

Understanding the layout and components of a machine is crucial for effective maintenance and repairs. Visual representations serve as valuable tools for technicians and enthusiasts alike, enabling them to identify and source the necessary elements with ease. These illustrations not only streamline the repair process but also enhance knowledge about the overall structure and functionality of the equipment.

| Benefits | Description |

|---|---|

| Clarity | Visual aids provide a clear view of where each component fits, reducing confusion. |

| Efficiency | Identifying specific components quickly saves time during repairs. |

| Knowledge | Familiarity with the layout fosters a deeper understanding of the machinery. |

| Accessibility | Having a visual reference makes sourcing replacement elements easier. |

Identifying Common Components

Understanding the essential elements of machinery is crucial for effective maintenance and repair. Familiarity with these components allows users to troubleshoot issues, enhance performance, and ensure longevity of the equipment. In this section, we will explore some of the key parts typically found in various models.

Key Elements Overview

Each piece of equipment contains several fundamental parts that play significant roles. Recognizing these components can simplify repairs and optimize functionality.

| Component | Description |

|---|---|

| Motor | The powerhouse that drives the machinery. |

| Gearbox | Transmits power and adjusts speed and torque. |

| Housing | Protects internal components from damage. |

| Trigger | Controls the operation of the device. |

Importance of Proper Identification

Accurate identification of these elements is essential for effective troubleshooting. Users can make informed decisions regarding repairs and replacements, ultimately leading to improved efficiency and reduced downtime.

How to Read the Diagram

Understanding a visual representation of components can greatly enhance your ability to maintain and repair your equipment. These illustrations provide crucial insights into the relationships and functions of each piece, allowing for effective troubleshooting and assembly. Familiarity with the symbols and layout will streamline your efforts and lead to more successful projects.

Identifying Key Symbols

Every visual guide employs a set of standardized symbols to represent different elements. Pay attention to these icons, as they often indicate the function or type of component. Familiarizing yourself with these representations is the first step towards comprehending the overall structure.

Interpreting Connections

Lines and arrows in these visuals usually depict connections between components. Understanding how these elements interact with one another is essential for diagnosing issues and reassembling parts correctly. Follow the pathways to ensure that you grasp the flow of operation, which can be vital for effective repair.

Where to Find Replacement Parts

When it comes to maintaining your tools, locating the right components is essential for optimal performance. Here are several avenues to explore for acquiring the necessary items.

- Manufacturer’s Website: Visit the official site for a comprehensive catalog of components.

- Local Retailers: Many hardware stores stock various essential items for popular tool brands.

- Online Marketplaces: Websites like eBay and Amazon often have a wide range of offerings, including new and used items.

- Specialized Suppliers: Look for retailers that specialize in tool accessories, as they may have hard-to-find components.

- Forums and Community Groups: Engaging with fellow enthusiasts can lead to valuable recommendations and resources.

By exploring these options, you can ensure you have access to the components needed to keep your equipment running smoothly.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your equipment requires regular attention and care. By following a few essential maintenance practices, you can significantly extend the lifespan of your tools and enhance their performance.

Regular Cleaning

- After each use, remove dust and debris to prevent build-up.

- Use a soft brush or cloth to clean sensitive areas.

- Inspect for any signs of wear or damage during cleaning.

Routine Inspections

- Check all moving parts for smooth operation.

- Look for any loose connections or fittings.

- Test electrical components for proper functionality.

By implementing these straightforward maintenance strategies, you can ensure your tools remain efficient and reliable for years to come.

DIY Repairs Using the Diagram

Understanding the layout of your equipment can significantly simplify maintenance and troubleshooting. By having a visual reference, you can identify components and their functions, allowing for efficient repairs without the need for professional assistance.

| Component | Common Issues | DIY Fixes |

|---|---|---|

| Motor | Overheating | Clean vents and check wiring |

| Battery | Short lifespan | Ensure proper charging cycles |

| Switch | Non-responsiveness | Clean contacts and replace if needed |

By delving into each part’s specifics, you can tackle issues directly and gain a deeper understanding of your tool’s functionality, leading to the ultimate satisfaction in DIY maintenance.

Frequently Asked Questions

This section addresses common inquiries related to the components and maintenance of power tools. Whether you are looking for troubleshooting tips or need guidance on replacement parts, we aim to provide clear and concise answers to enhance your understanding.

What should I do if a component is missing?

If you notice that a specific piece is absent, first check the packaging and your workspace. If it is still unaccounted for, consider contacting the retailer or manufacturer for assistance in obtaining a replacement.

How can I identify the correct part for my tool?

Identifying the right component can be done by referencing the user manual or visiting the manufacturer’s website, where you can find detailed descriptions and images of each part.

What are the signs of wear that I should look out for?

Common indicators of wear include unusual noises, decreased performance, and visible damage to the exterior. Regular inspections can help prevent further issues.

Is it necessary to use original components?

While using original components is recommended for optimal performance and longevity, high-quality aftermarket alternatives may also be viable. Ensure they are compatible with your specific model.

Where can I find maintenance tips?

Maintenance tips can be found in the user manual, online forums, and dedicated websites. Following a regular maintenance schedule is essential for extending the lifespan of your equipment.

Comparing with Other Ryobi Models

When evaluating different power tools from a renowned manufacturer, it’s essential to understand the nuances that set each model apart. This comparison highlights key features and functionalities, enabling users to make informed decisions based on their specific needs and preferences.

Feature Overview

| Model | Power | Weight | Battery Life |

|---|---|---|---|

| Model A | 1200W | 5.5 lbs | 30 mins |

| Model B | 1500W | 6.0 lbs | 40 mins |

| Model C | 1000W | 4.8 lbs | 25 mins |

Performance Insights

In terms of functionality, various options offer different power levels and weights, influencing usability for specific tasks. Users seeking higher performance may favor models with greater wattage, while those prioritizing portability might opt for lighter alternatives.

Tools Needed for Repairs

When it comes to undertaking maintenance or fixing equipment, having the right instruments is crucial for achieving successful results. Proper tools not only streamline the repair process but also enhance safety and efficiency. From basic hand tools to specialized equipment, understanding what is necessary can save time and frustration.

Essential Hand Tools

Basic hand tools are the backbone of any repair task. A reliable set typically includes screwdrivers, wrenches, and pliers. These instruments allow for the adjustment and removal of components with ease. Additionally, having a good pair of gloves and safety goggles ensures protection during the repair process.

Specialized Equipment

In some cases, repairs may require more advanced tools. Items such as torque wrenches, multimeters, or even diagnostic devices can be indispensable for specific tasks. Investing in quality specialized equipment can make complex repairs manageable and improve the overall outcome.

Customer Support and Resources

Accessing assistance and information is vital for ensuring optimal performance and longevity of your equipment. Reliable support systems can help users troubleshoot issues, find replacement components, and enhance their overall experience with the product.

Support Channels

Users can reach out through various support channels, including phone consultations, online chat, and email assistance. Comprehensive guides and FAQs are also available on the official website, providing detailed insights into common problems and solutions.

Additional Resources

For those looking to deepen their understanding, numerous tutorials and instructional videos can be found online. Community forums are also excellent platforms for sharing experiences, tips, and recommendations from fellow users.