Understanding the Ryobi Sawzall Parts Diagram for Easy Repairs

In the world of power tools, comprehending the intricate layout of components is essential for effective maintenance and repair. Each tool consists of numerous elements that work in harmony, and knowing how these pieces fit together can enhance functionality and extend lifespan.

Exploring the arrangement of these parts provides insight into the overall mechanics of the device. By familiarizing oneself with the specific functions of each component, users can tackle issues with confidence and optimize performance.

Furthermore, having a clear representation of the tool’s construction serves as an ultimate guide for both novice and experienced users alike. This knowledge empowers individuals to make informed decisions when servicing their equipment, ensuring reliability and safety during operation.

Understanding Ryobi Sawzall Components

Exploring the essential elements of a reciprocating cutting tool can significantly enhance your grasp of its functionality and maintenance. Each component plays a crucial role in ensuring efficient operation, making it vital for users to familiarize themselves with these intricate parts. Recognizing how these pieces work together can lead to better performance and longevity of the equipment.

Main Functional Elements

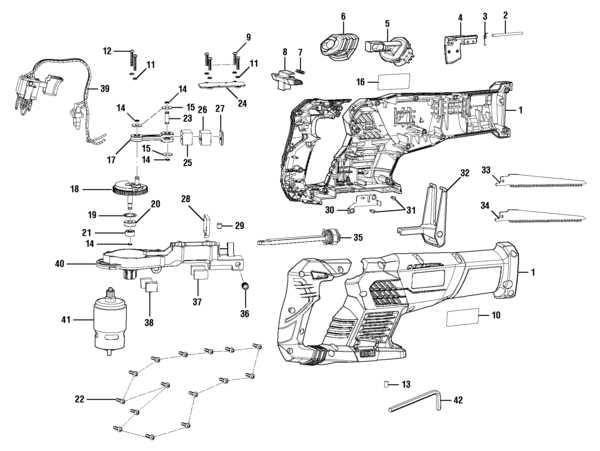

At the heart of any cutting device lies the motor, which provides the necessary power for operation. Coupled with the drive mechanism, this component facilitates rapid reciprocation, allowing for swift cuts through various materials. Additionally, the blade holder is designed to securely grip and support the cutting tool, ensuring stability during use.

Supporting elements such as the housing and handle are equally important. The casing protects internal mechanisms from debris and damage, while the ergonomic handle enhances user comfort and control. Understanding these supportive features is essential for effective handling and overall safety during operation. Proper maintenance of these components can prevent wear and tear, prolonging the tool’s lifespan.

Key Parts of Ryobi Sawzall

Understanding the essential components of a reciprocating tool is crucial for effective maintenance and operation. Each element plays a significant role in the overall functionality, contributing to the tool’s efficiency and performance during various tasks.

| Component | Description |

|---|---|

| Motor | Drives the blade with powerful oscillations for cutting through different materials. |

| Blade Clamp | Securely holds the blade in place, allowing for quick changes and optimal performance. |

| Trigger | Controls the speed and activation of the tool, providing user flexibility. |

| Foot Plate | Stabilizes the tool during operation, ensuring precise cuts and reducing vibration. |

| Housing | Encases internal mechanisms, protecting them from damage and providing structural integrity. |

Functionality of Each Component

Understanding the roles of individual elements in a power cutting tool is essential for effective operation and maintenance. Each part contributes uniquely to the overall performance, ensuring that the device operates smoothly and efficiently. By exploring these components, one can gain insights into how they work together to achieve precise cuts and enhance user experience.

Motor: The heart of the device, the motor converts electrical energy into mechanical motion. It drives the cutting action, allowing for various applications, from demolition to detailed work. The motor’s power rating directly influences the tool’s capability and speed.

Trigger Switch: This component provides the user with control over the tool’s activation. It regulates the power flow, enabling quick starts and stops, which is crucial for both safety and efficiency during use.

Gear Mechanism: Responsible for translating the motor’s rotational force into the linear motion of the blade. The gearing affects the speed and torque, impacting how effectively the tool can cut through different materials.

Blade Holder: This part securely fastens the cutting blade in place, ensuring stability during operation. A reliable blade holder is vital for maintaining precision and minimizing vibrations that can lead to inaccurate cuts.

Housing: The outer shell protects the internal components from damage and dust while providing a comfortable grip for the user. A well-designed housing enhances ergonomics, reducing fatigue during extended use.

Vibration Dampening System: This feature minimizes the impact of vibrations on the user, improving comfort and control. By absorbing shocks, it allows for better precision and reduces the risk of hand fatigue.

Each of these elements plays a crucial role in the functionality of the tool, and understanding their individual contributions can greatly enhance both performance and safety during operation.

Common Issues with Ryobi Models

Understanding frequent challenges faced by users can significantly enhance the experience with various power tools. Many individuals encounter similar difficulties, which may stem from design flaws, wear and tear, or improper usage. Addressing these concerns can lead to better performance and longevity.

| Issue | Description |

|---|---|

| Overheating | This can occur due to prolonged use or inadequate cooling, leading to potential damage. |

| Blade Sticking | When the cutting blade binds, it can cause inefficiencies and increase the risk of accidents. |

| Vibration | Excessive vibration can result from worn components, affecting precision and user comfort. |

| Battery Issues | Users may face problems with battery life or charging, impacting tool functionality. |

Maintenance Tips for Longevity

Ensuring the durability of your power tools requires consistent care and attention. By following essential maintenance practices, you can enhance performance, minimize wear, and prolong the lifespan of your equipment. Simple routines can make a significant difference in functionality and reliability.

Regular Cleaning

Keep your tool free from dust and debris by regularly wiping it down after use. Pay special attention to vents and moving parts to prevent buildup that can hinder performance.

Lubrication and Inspection

Periodically check and lubricate moving components to reduce friction and wear. Inspect for any signs of damage or wear, replacing worn parts promptly to maintain optimal operation.

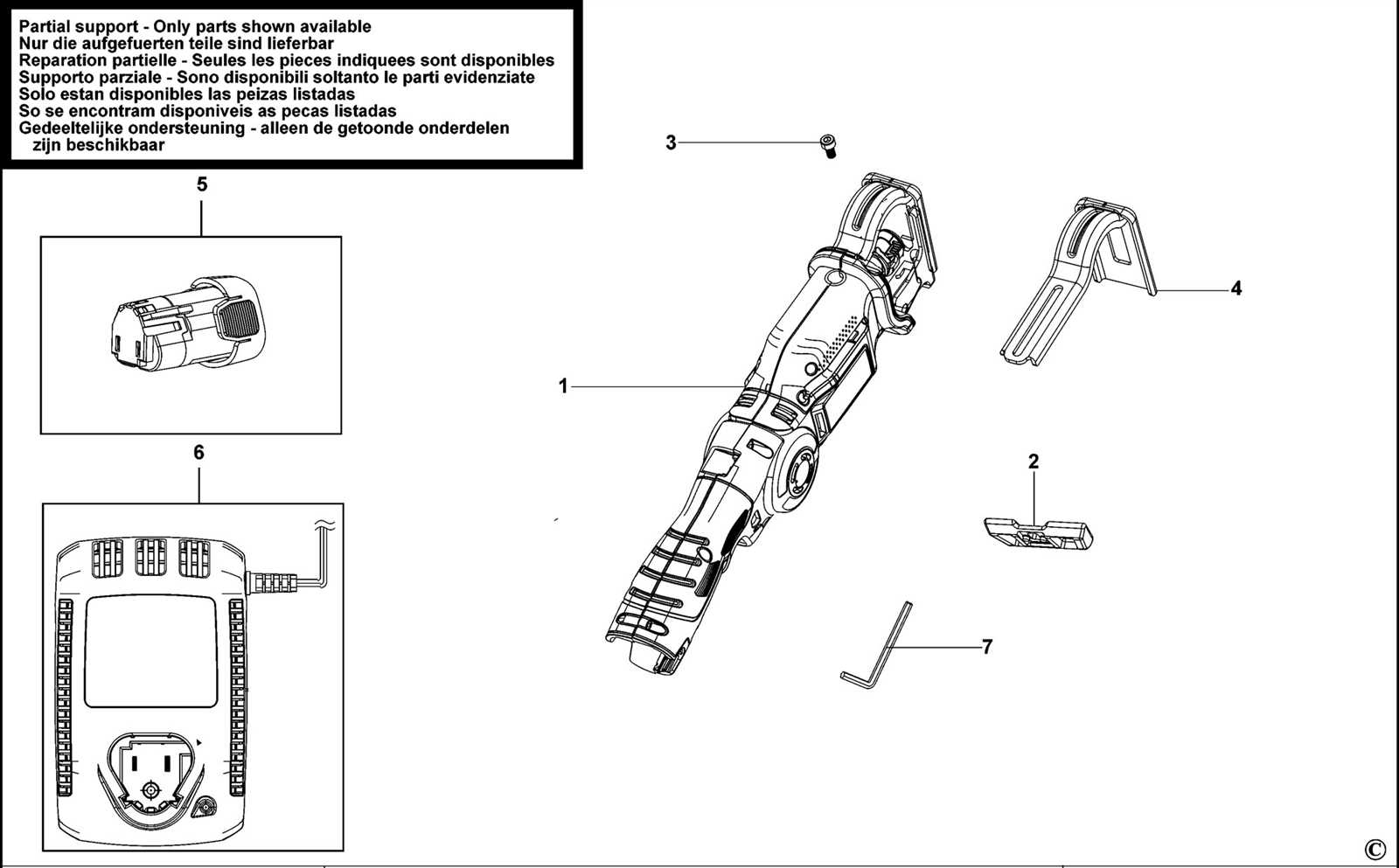

How to Identify Replacement Parts

When it comes to maintaining your tools, understanding how to locate and recognize the components that may need to be swapped out is essential. This process not only ensures optimal performance but also prolongs the lifespan of your equipment. Here are some effective strategies to help you pinpoint the necessary items for replacement.

Check the User Manual

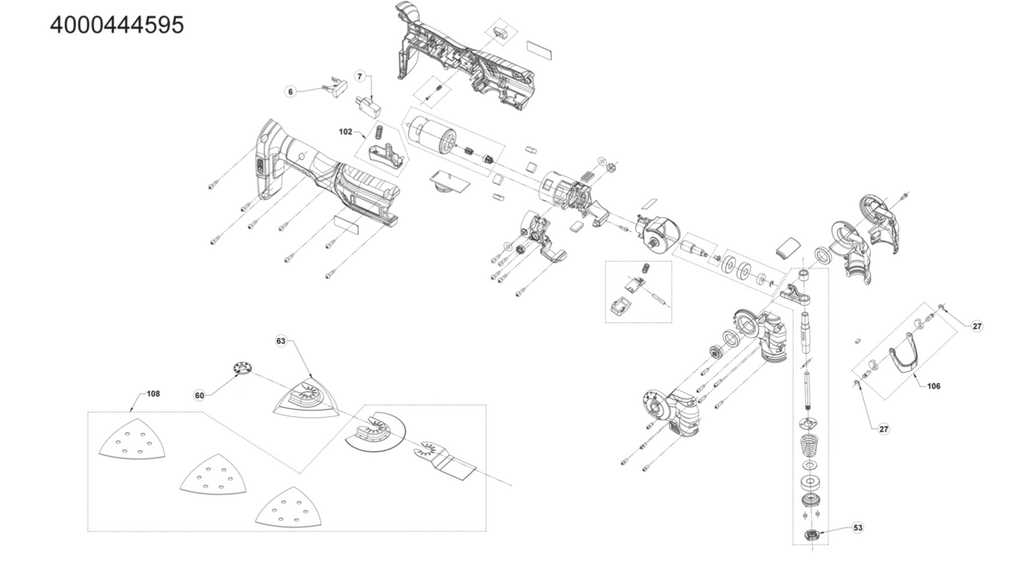

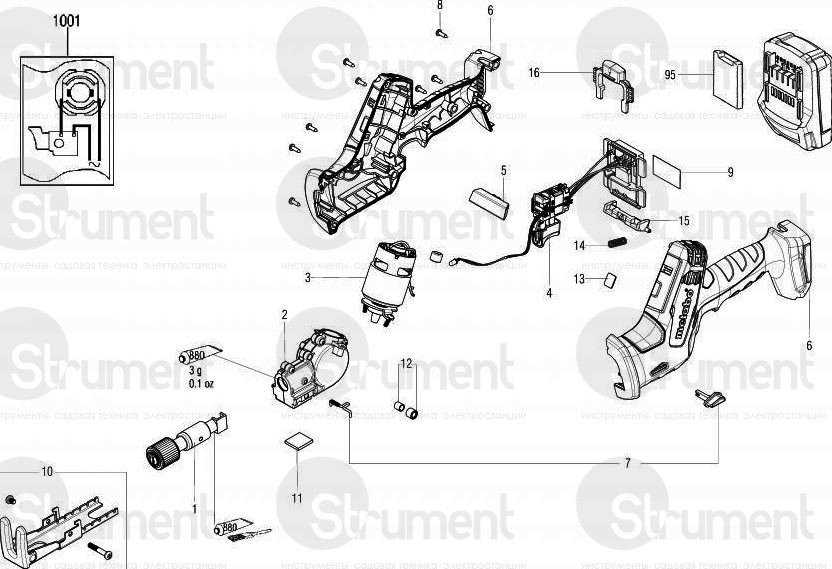

Your first step should be to consult the user manual that came with your device. This document often includes detailed information regarding various elements and their specific identifiers. Look for:

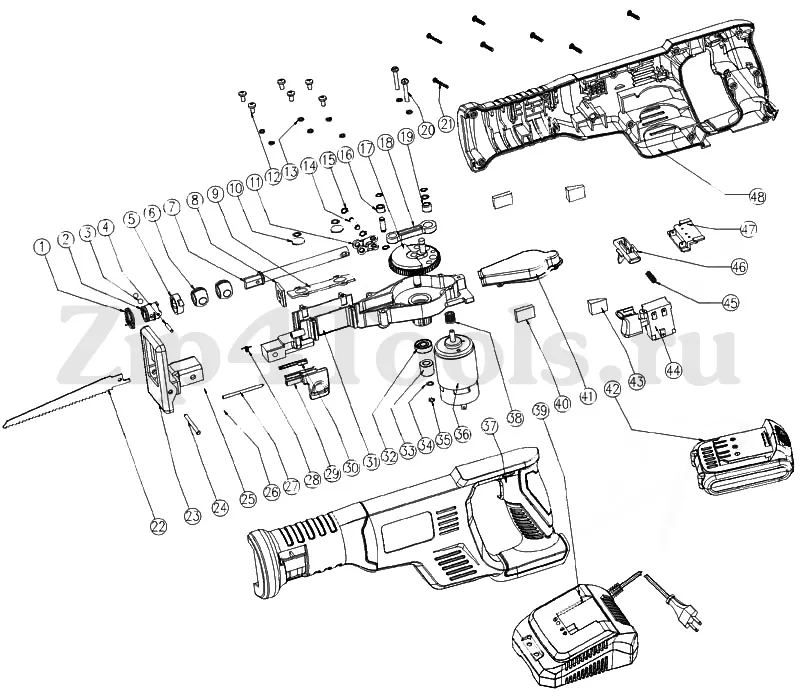

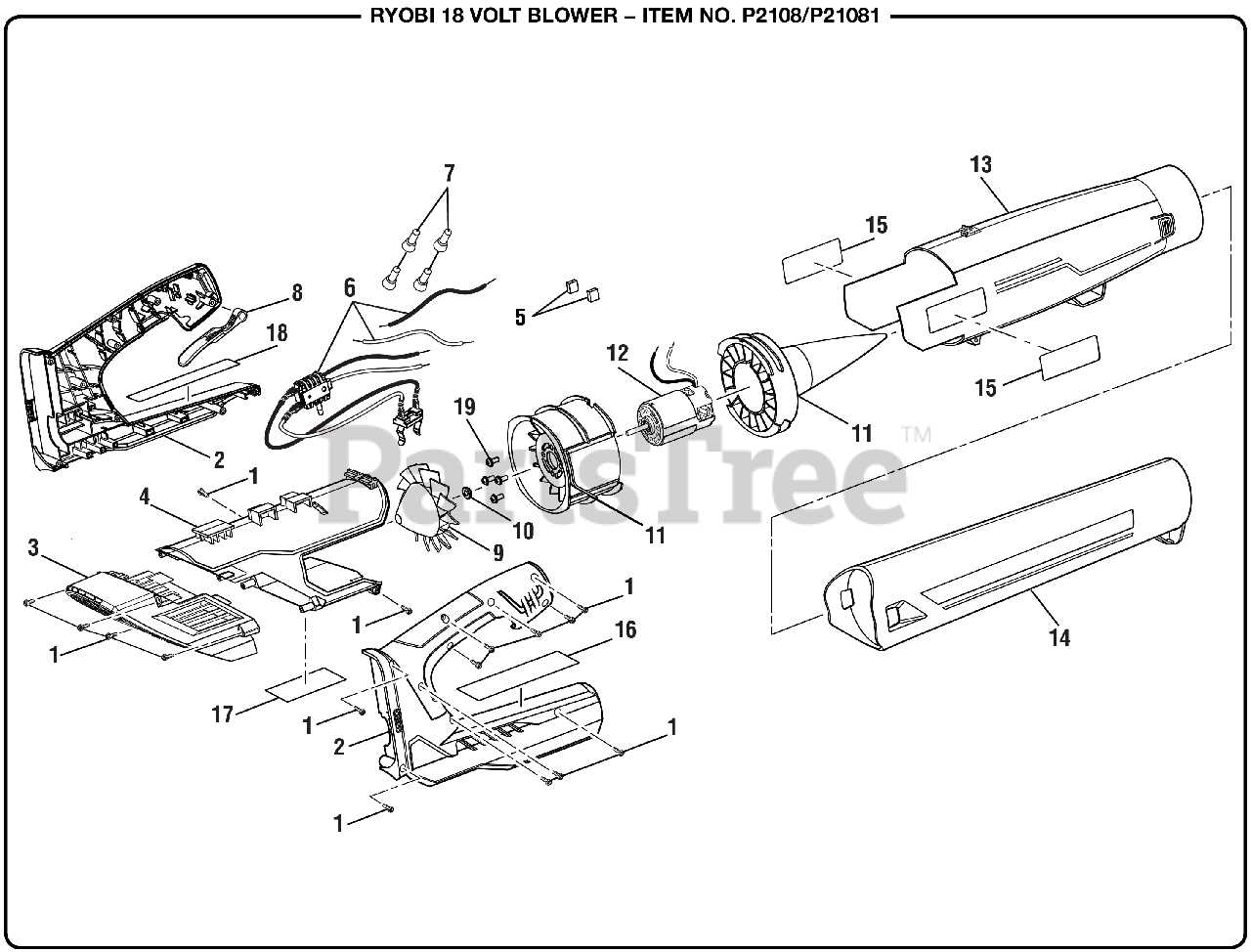

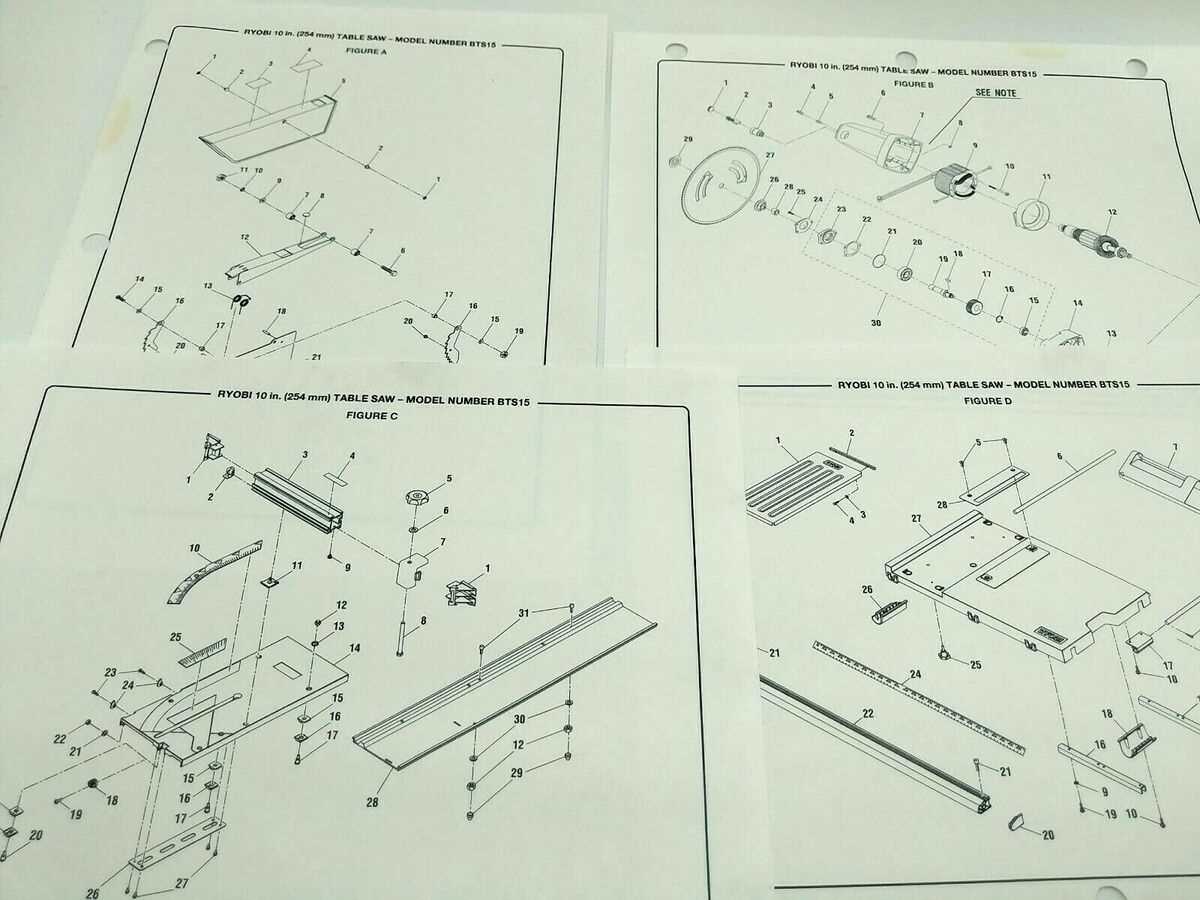

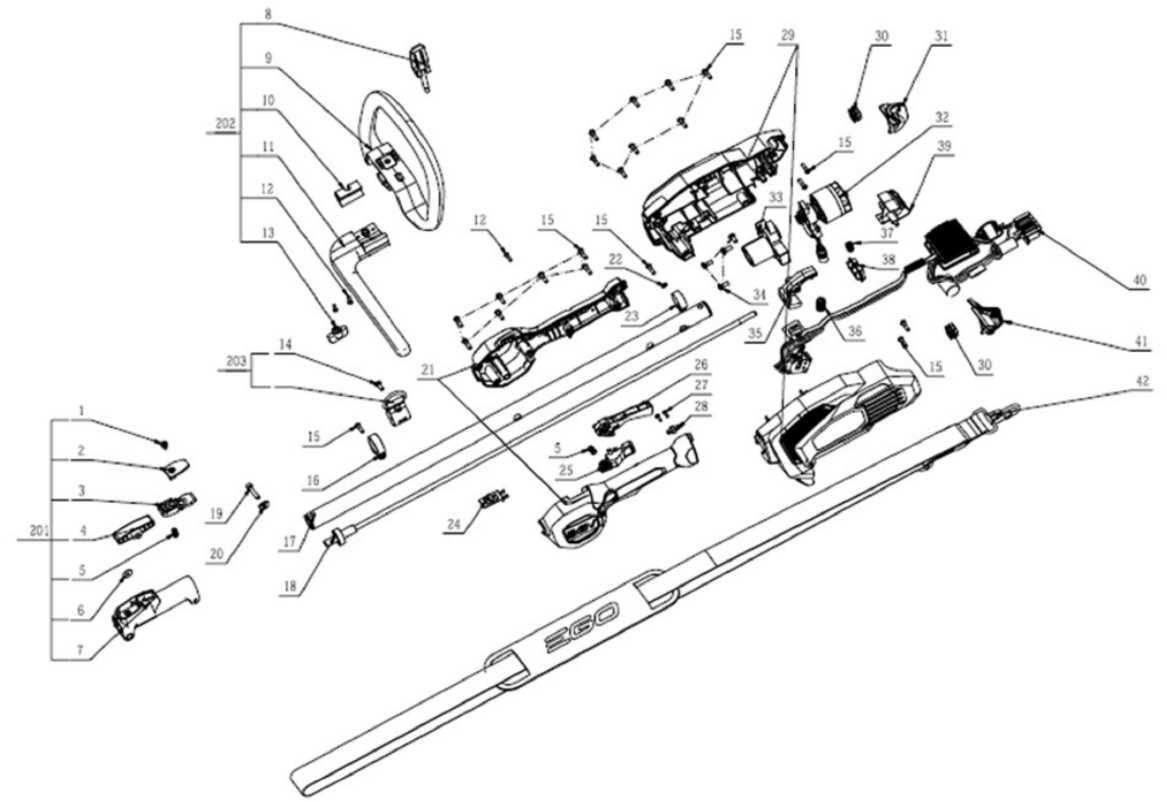

- Diagrams that outline the assembly

- Descriptions of each component

- Part numbers for easy reference

Online Resources and Communities

The internet is a valuable tool for finding additional information. Numerous websites and forums focus on tool maintenance and repairs. Consider the following approaches:

- Visit the manufacturer’s website for downloadable manuals or parts lists.

- Join online forums or social media groups where enthusiasts share advice and experiences.

- Utilize video tutorials that demonstrate common repairs and the parts involved.

By employing these methods, you can confidently identify and acquire the components you need, ensuring your tools remain efficient and reliable.

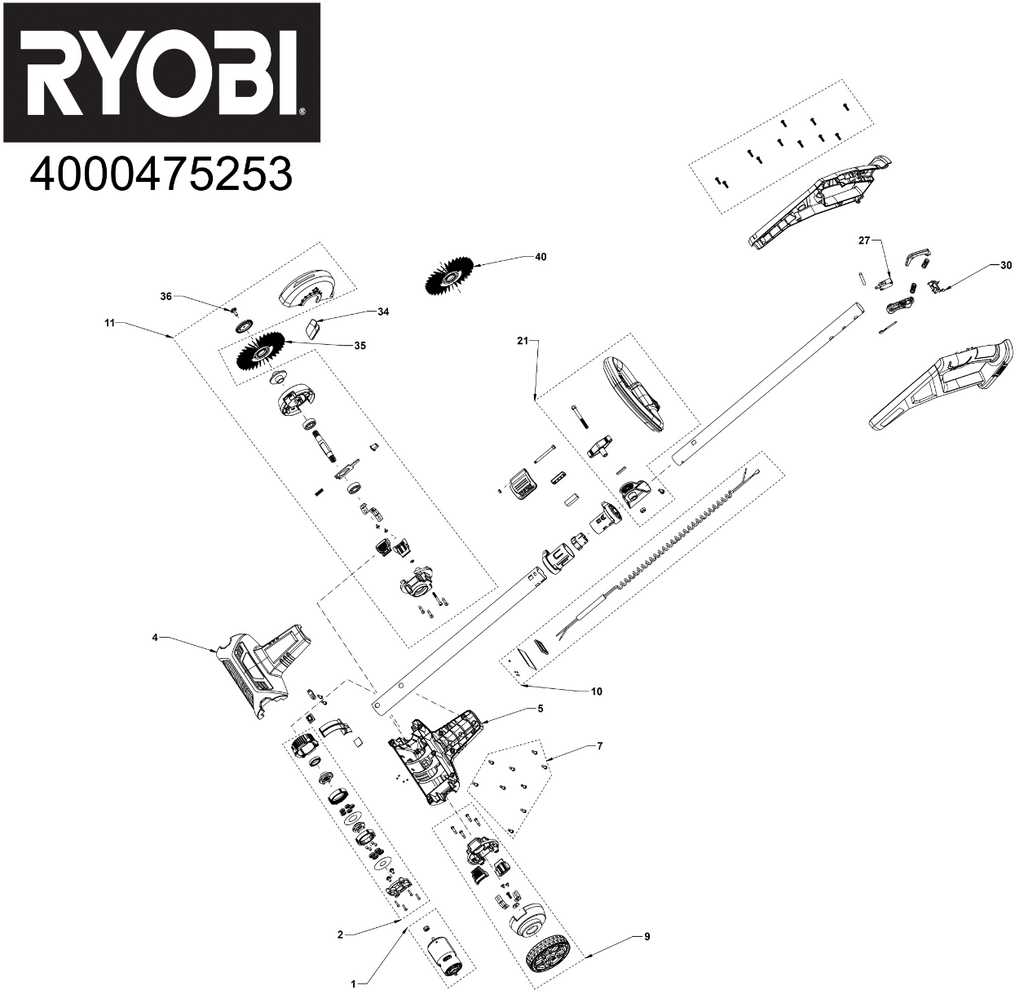

Diagrams for Easy Reference

Visual representations serve as invaluable tools for simplifying complex machinery. By providing a clear overview of components and their arrangement, these illustrations enhance understanding and facilitate efficient maintenance.

Benefits of Visual Guides

- Improved clarity in identifying parts

- Faster assembly and disassembly processes

- Enhanced troubleshooting capabilities

How to Utilize These Illustrations

- Refer to diagrams before starting any repair.

- Compare actual components with visual references.

- Keep a printed copy handy for quick access.

Where to Find Original Parts

Locating authentic components for your power tool can significantly enhance its performance and longevity. It’s essential to explore reliable sources to ensure quality and compatibility with your equipment.

Online Retailers

- Official brand websites

- Trusted e-commerce platforms

- Specialty tool retailers

Local Stores

- Authorized dealers

- Home improvement centers

- Tool supply shops

By exploring these options, you can delve into a variety of selections and find the ultimate components needed for your tool’s optimal functionality.

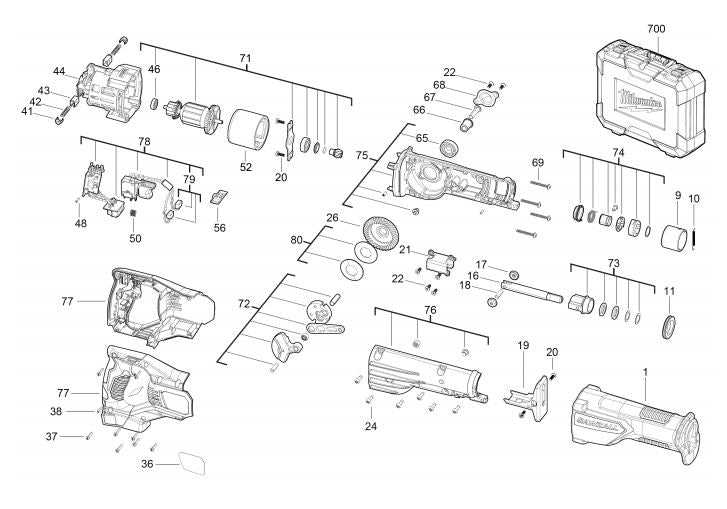

Aftermarket Options for Savings

Exploring alternative components can lead to significant savings without compromising performance. Many users find that aftermarket products offer comparable quality at a fraction of the cost, making them an appealing choice for budget-conscious consumers.

Quality vs. Cost

While original equipment can be pricey, third-party manufacturers often produce durable substitutes that meet or exceed industry standards. It’s essential to research and choose reputable brands to ensure reliability and longevity.

Benefits of Alternatives

In addition to cost savings, aftermarket solutions can provide a broader selection of options tailored to specific needs. This flexibility allows users to delve into customized configurations, ultimately enhancing their tool’s functionality and efficiency.

Tools Needed for Repairs

To effectively carry out maintenance and fix issues with your cutting tool, having the right equipment is essential. Proper tools not only streamline the repair process but also ensure safety and efficiency.

- Screwdrivers: A set of both flathead and Phillips screwdrivers will be necessary for removing and securing screws.

- Wrenches: Adjustable and socket wrenches are crucial for loosening or tightening various bolts and nuts.

- Plier Set: Needle-nose and standard pliers are helpful for gripping and manipulating small components.

- Hex Keys: These are often required for assembling or disassembling parts that utilize hex screws.

- Multimeter: For diagnosing electrical issues, a multimeter is invaluable in testing voltage and continuity.

- Cleaning Supplies: Brushes and cloths will help maintain cleanliness and performance of the tool during repairs.

- Safety Gear: Always wear protective goggles and gloves to ensure personal safety while working.

By equipping yourself with these essential tools, you’ll be well-prepared to address any repair needs that may arise.

Step-by-Step Repair Process

Undertaking a repair task can seem daunting, but breaking it down into manageable steps simplifies the process. This guide aims to provide a clear approach to troubleshooting and restoring your tool, ensuring you can tackle any issue with confidence.

Begin by gathering all necessary tools and materials. Familiarize yourself with the assembly to identify areas that may require attention. Next, disconnect the power source to ensure safety while working on the equipment.

Once you have a secure workspace, inspect each component for wear or damage. If specific parts appear faulty, refer to a reference guide to locate replacements easily. Carefully remove the damaged elements using appropriate tools, taking note of the assembly for reinstallation.

After removing the defective pieces, install the new components in the correct order. Double-check that everything fits snugly and is secured properly. Once assembled, reconnect the power source and conduct a test to ensure the equipment functions as intended.

Finally, maintain a regular inspection routine to prevent future issues and enhance the longevity of your tool. With careful attention and systematic steps, you can successfully restore performance and efficiency.

Safety Precautions When Working

When engaging in any cutting or demolition tasks, prioritizing safety is essential to prevent accidents and injuries. Understanding proper protocols and using the right protective equipment can significantly reduce risks associated with power tools and hazardous materials.

Before starting any project, ensure your workspace is organized and free of obstacles. A cluttered area can lead to trips or falls, so keeping it tidy is crucial. Additionally, familiarize yourself with the equipment you are using, including its controls and emergency shut-off features.

| Safety Measure | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear such as safety glasses, gloves, and hearing protection to shield against potential hazards. |

| Stable Positioning | Maintain a firm footing and balance while operating equipment to enhance control and reduce the risk of slips. |

| Tool Inspection | Regularly check tools for any damage or wear to ensure they function properly and safely. |

| Emergency Preparedness | Have a first aid kit accessible and know how to use it in case of an injury. Be aware of emergency contact numbers. |

By adhering to these precautions, you can create a safer working environment and ensure that your projects proceed smoothly and efficiently.

Customer Reviews on Ryobi Products

Consumer feedback plays a crucial role in understanding the quality and performance of tools available in the market. Reviews offer valuable insights into user experiences, helping potential buyers make informed decisions. Below, we explore common themes and sentiments expressed by users regarding their experiences with various tools.

Many customers appreciate the following aspects:

- Affordability: Users often highlight the competitive pricing, making high-quality equipment accessible to a broader audience.

- Ease of Use: Many reviews emphasize how intuitive and user-friendly the products are, even for beginners.

- Reliability: Several consumers note the durability and consistent performance of their tools over time.

- Versatility: Many users appreciate the wide range of applications, allowing them to tackle various projects with a single tool.

However, some feedback includes concerns such as:

- Battery Life: A number of users mention the need for longer battery duration during extensive tasks.

- Weight: Some reviewers find certain models heavier than expected, which can be a drawback for prolonged use.

- Customer Support: A few users express dissatisfaction with the responsiveness of the customer service team.

Overall, user reviews indicate a generally positive perception, with many expressing satisfaction and recommending the tools for both casual and professional use. The combination of value, functionality, and performance continues to resonate with a wide range of consumers.