Understanding the Ryobi TSS100L Parts Diagram for Easy Repairs

When working with power equipment, comprehending the layout of its various components is essential for effective maintenance and repair. This knowledge not only enhances functionality but also extends the lifespan of the machinery. Each tool is designed with specific parts that contribute to its overall performance, making it crucial for users to familiarize themselves with these elements.

By examining the arrangement of individual pieces, one can gain insights into how they interact and function together. This understanding empowers users to identify issues quickly and perform necessary interventions. Whether you are a seasoned professional or a hobbyist, grasping the intricacies of your tools is a valuable skill.

In this exploration, we will delve into the specifics of a particular model, shedding light on its essential elements and their configurations. Such knowledge will not only assist in troubleshooting but also enhance the overall experience of using the equipment effectively.

Understanding the Ryobi TSS100L Diagram

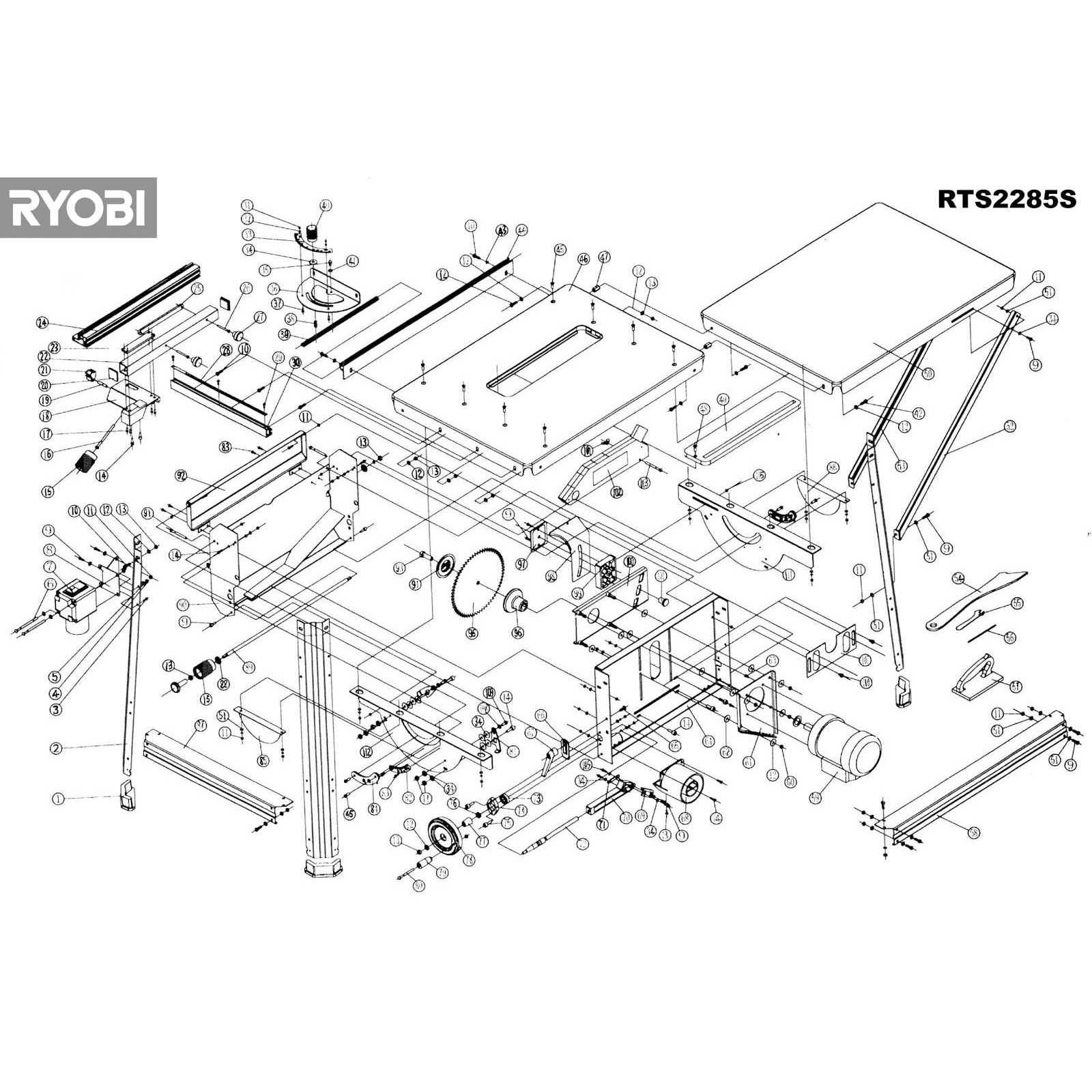

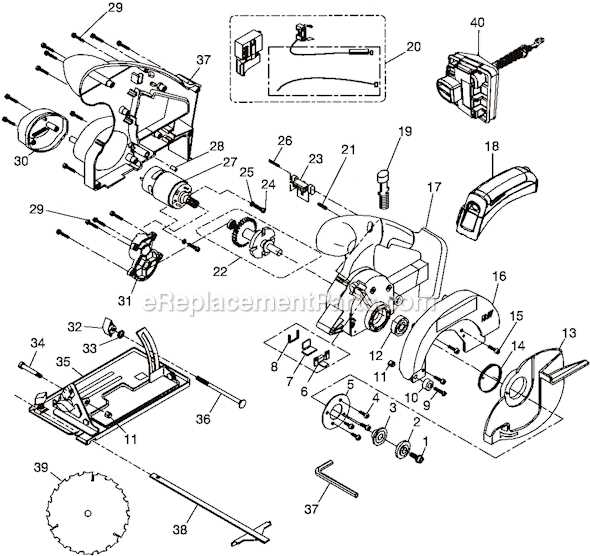

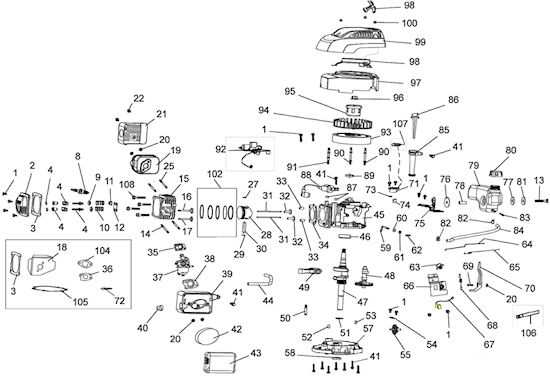

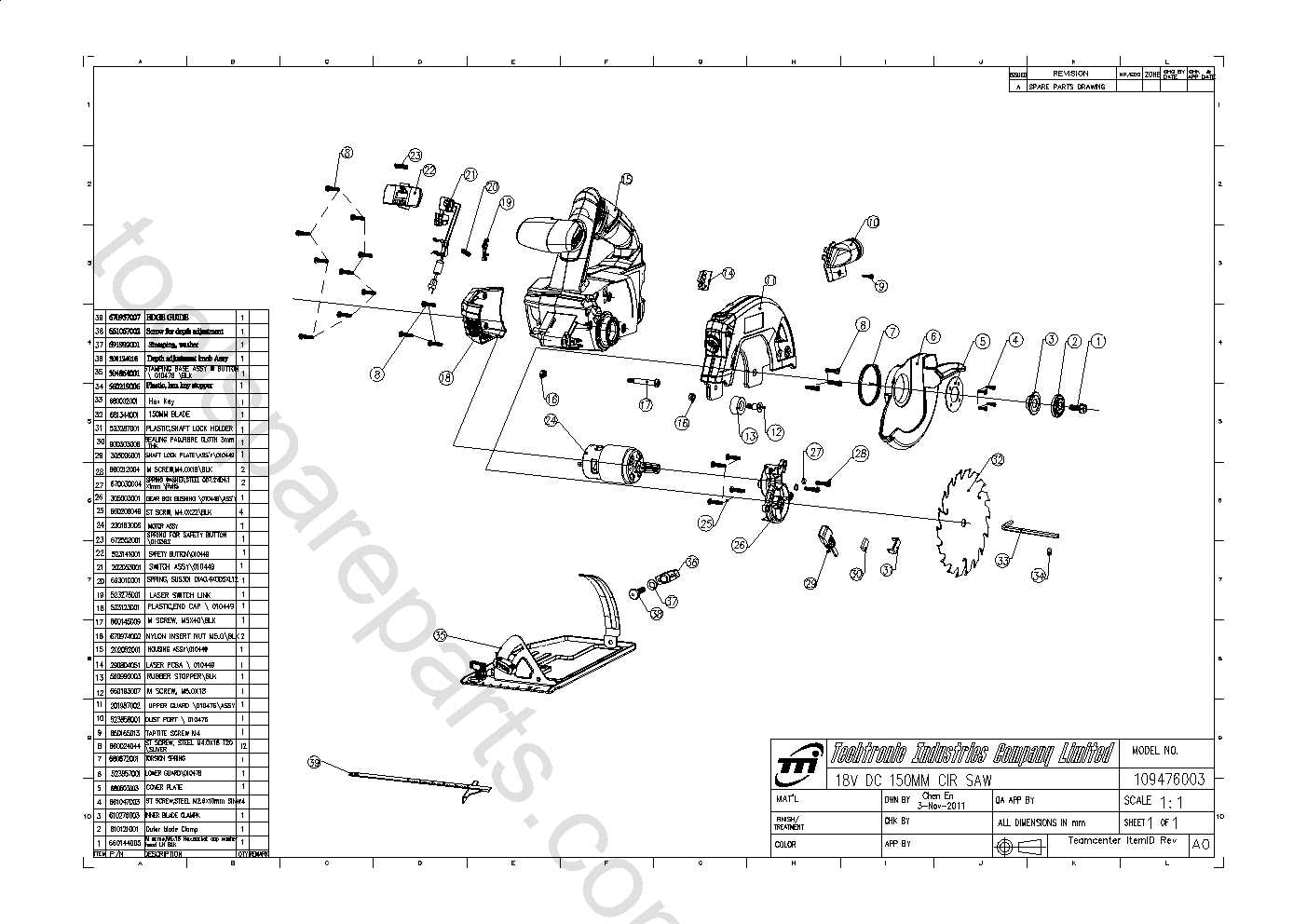

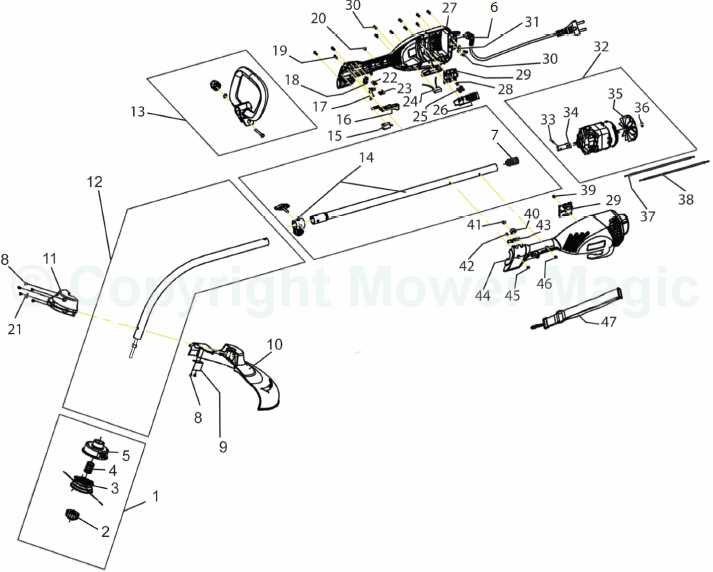

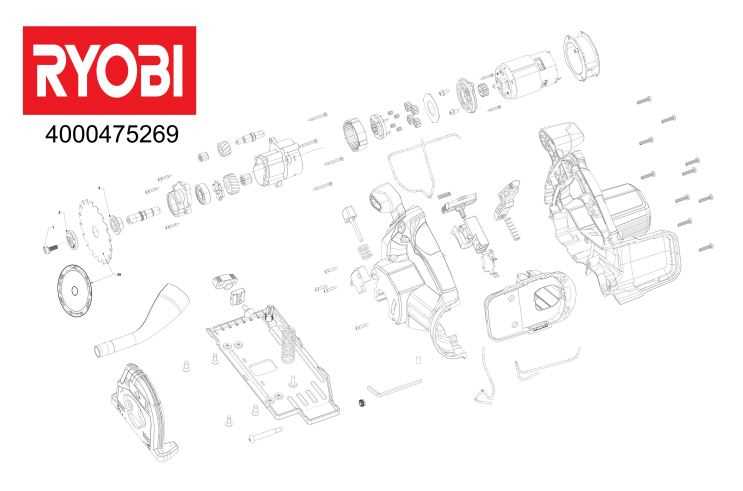

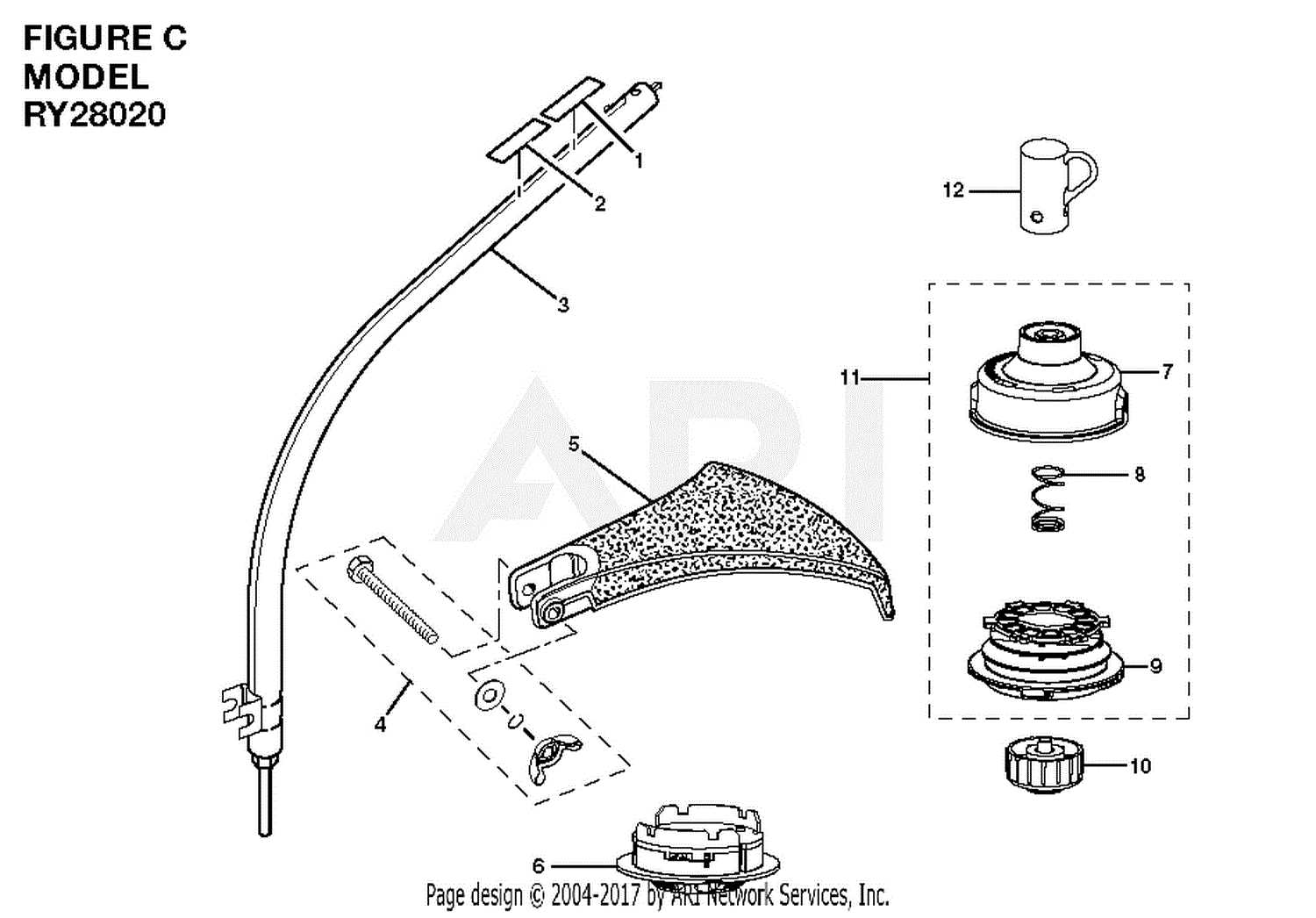

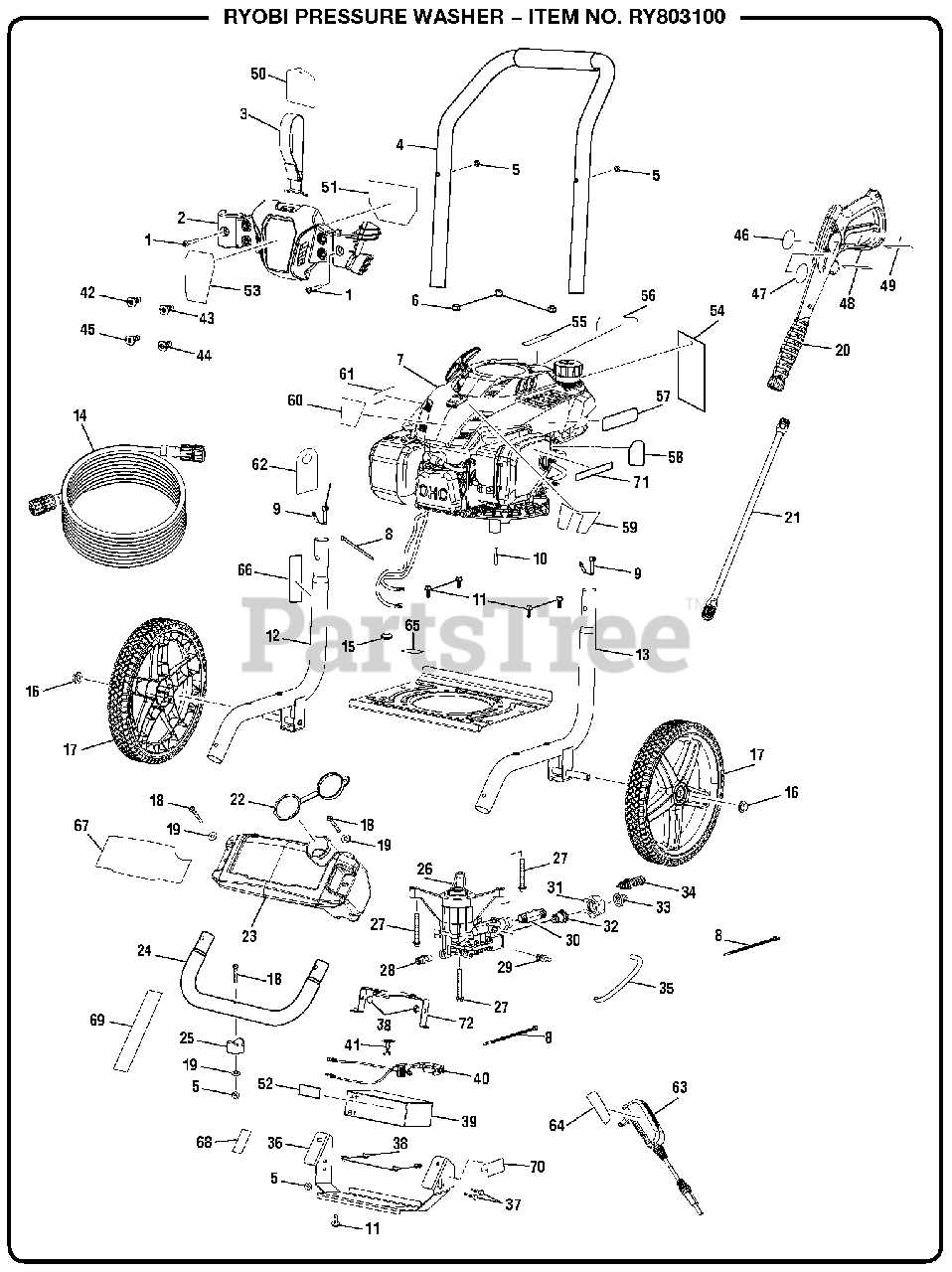

Comprehending the layout of a specific tool can greatly enhance your ability to maintain and troubleshoot it effectively. A well-structured visual representation serves as a crucial guide, offering insights into the various components and their interconnections. This understanding not only aids in repairs but also promotes better usage of the equipment.

In these visual guides, each element is meticulously labeled, allowing users to identify parts quickly. Whether you are replacing a worn component or upgrading an existing one, recognizing the function of each piece can streamline the process. This familiarity fosters confidence and efficiency, transforming potentially daunting tasks into manageable ones.

Moreover, being acquainted with the configuration can prevent unnecessary damage during assembly or disassembly. Knowledge of how each part interacts with the others contributes to a holistic understanding, ensuring that users can perform maintenance safely and effectively. This level of insight is invaluable for both novice and seasoned users, empowering them to maximize the lifespan and performance of their equipment.

Key Components of the TSS100L

Understanding the essential elements of this cutting tool can significantly enhance its functionality and maintenance. Each part plays a crucial role in ensuring optimal performance, allowing users to achieve precise and efficient cuts for various projects.

Base Unit: The foundation of the equipment, providing stability and support during operation. A solid base is vital for accurate cuts and overall safety.

Blade Assembly: Central to the tool’s performance, the cutting mechanism requires regular inspection and replacement. Different blade types can be used to suit specific materials and applications.

Motor: The powerhouse of the device, delivering the necessary torque and speed for efficient cutting. Understanding its specifications helps users gauge the tool’s capabilities.

Safety Features: These components are designed to protect users from potential hazards. Ensuring that safety mechanisms are in place and functional is essential for a secure working environment.

Adjustable Angles: Many models include the ability to adjust cutting angles, providing versatility for various tasks. This feature allows users to execute bevel cuts and miter angles with precision.

By familiarizing oneself with these critical components, users can maximize the performance and longevity of the cutting tool, ensuring it meets their needs effectively.

How to Read the Parts Diagram

Understanding a technical illustration can significantly enhance your ability to maintain and repair your equipment. These visual representations are designed to help users identify and locate individual components efficiently. By familiarizing yourself with the layout and symbols used in these schematics, you can streamline your troubleshooting and replacement processes.

Typically, these illustrations include a variety of elements such as labels, reference numbers, and outlines that correlate with a list of items. It’s essential to pay close attention to the following aspects to interpret the information accurately:

| Element | Description |

|---|---|

| Labels | Each component is usually accompanied by a label that provides its name or function. |

| Reference Numbers | These numbers correspond to a list that details specifications, including part numbers and quantities. |

| Connection Lines | Lines indicate how parts are connected or interact with each other, which is crucial for assembly and disassembly. |

| View Angles | Different perspectives may be provided to give a comprehensive understanding of the configuration. |

By taking the time to study these components, you will be better equipped to handle repairs and ensure the longevity of your equipment. A thorough comprehension of these visuals is key to effective maintenance practices.

Common Issues and Solutions

In the realm of power tools, users may encounter various challenges that can hinder performance and efficiency. Identifying these common problems and understanding their remedies can greatly enhance the overall experience and extend the lifespan of the equipment.

Frequent Problems

One of the most typical issues faced by operators is the tool’s inability to start. This can stem from several factors, including electrical faults or worn components. Additionally, inconsistent cutting performance can arise due to dull blades or improper settings.

Effective Solutions

Addressing these concerns involves a systematic approach. For starting issues, checking the power source and inspecting for any loose connections can often resolve the problem. Regular maintenance, including replacing blades and ensuring correct calibration, is crucial for optimal performance.

| Issue | Possible Cause | Solution |

|---|---|---|

| Tool won’t start | Power supply issue | Check connections and ensure power source is functional |

| Inconsistent cutting | Dull blade | Replace or sharpen blade |

| Excessive vibration | Loose components | Tighten screws and check for wear |

Ordering Replacement Parts Effectively

When it comes to maintaining and repairing equipment, acquiring the right components is essential for ensuring optimal performance. A systematic approach to procuring these items can save time, money, and hassle. This guide will help streamline the process of obtaining necessary replacements with efficiency and accuracy.

First and foremost, identifying the specific components required is crucial. Referencing an appropriate schematic can aid in pinpointing the exact parts needed for your equipment. Additionally, understanding the model and specifications will prevent any mismatches.

| Step | Description |

|---|---|

| 1 | Gather all relevant information, including model number and specifications. |

| 2 | Consult a detailed schematic or manual to identify necessary components. |

| 3 | Research reputable suppliers who offer quality replacements. |

| 4 | Verify the availability and pricing of each item before making a purchase. |

| 5 | Place an order through a trusted channel, ensuring secure payment methods. |

In summary, effectively acquiring replacement components involves thorough research, accurate identification, and careful selection of suppliers. By following these steps, you can ensure a smooth purchasing experience and maintain the functionality of your equipment.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life and optimal performance of your equipment. Regular maintenance not only enhances functionality but also helps prevent unexpected failures. By adhering to a few straightforward practices, you can significantly prolong the lifespan of your tools and maintain their efficiency.

Routine Cleaning

Cleaning your equipment after each use is crucial. Remove any debris, dust, or residue that may accumulate during operation. Use a soft brush or a damp cloth to wipe down surfaces, ensuring that moving parts remain unobstructed. Regular cleaning helps to prevent rust and other forms of deterioration.

Regular Inspections

Conducting periodic inspections can catch potential issues before they escalate. Check for signs of wear and tear, such as loose components or frayed wires. Lubricate moving parts according to the manufacturer’s guidelines to reduce friction and wear. Keeping a close eye on your tools will ensure they remain in peak condition for years to come.

Comparison with Other Ryobi Models

This section delves into the similarities and differences among various tools within the same brand, highlighting their unique features and capabilities. Understanding these distinctions can help users choose the right equipment for their specific needs, whether for professional tasks or home projects.

| Model | Power Source | Cutting Capacity | Weight | Features |

|---|---|---|---|---|

| Model A | Electric | 12 inches | 35 lbs | Laser guide, adjustable speed |

| Model B | Battery | 10 inches | 30 lbs | Compact design, built-in light |

| Model C | Gas | 14 inches | 40 lbs | High power, rugged build |

Each variant offers distinct advantages, catering to different user preferences and operational contexts. Whether prioritizing portability, power, or precision, there is an option that aligns with the specific demands of any project.

Where to Find Authentic Parts

Ensuring the longevity and optimal performance of your tools requires sourcing genuine components. Authentic replacements not only guarantee compatibility but also enhance safety and efficiency. Here are some reliable avenues to explore when searching for high-quality replacements.

Official Retailers

- Visit manufacturer websites for direct purchases.

- Check authorized dealer locations for local availability.

- Explore official online stores for exclusive offers and stock.

Online Marketplaces

- Utilize trusted e-commerce platforms known for their extensive inventory.

- Look for vendors with high ratings and positive customer feedback.

- Verify authenticity through seller certifications or guarantees.

By exploring these avenues, you can ensure you acquire reliable components that will keep your equipment functioning at its best.

Tools Required for Assembly

Assembling equipment can be a straightforward process if you have the right instruments at your disposal. Utilizing appropriate tools not only streamlines the task but also ensures safety and precision. Below is a list of essential items you will need to effectively put together your machinery.

Basic Hand Tools

Start with screwdrivers, which are crucial for fastening components securely. A variety of sizes may be necessary to accommodate different screws. Additionally, a set of wrenches will aid in tightening nuts and bolts. Don’t forget pliers, which can assist in gripping or bending parts during assembly.

Specialized Equipment

In some cases, having power tools can significantly enhance efficiency. A cordless drill, for instance, can simplify the process of inserting screws into various materials. Furthermore, a level is important for ensuring that your setup is perfectly aligned, which is crucial for optimal performance.

Safety Precautions During Repairs

When undertaking any maintenance or repair tasks, prioritizing safety is essential. Proper precautions can significantly reduce the risk of accidents, ensuring a secure environment for both the technician and the equipment. Understanding potential hazards and implementing safety measures will enhance the overall repair process.

Use Protective Gear

Always wear appropriate personal protective equipment (PPE). This includes gloves to shield hands from sharp edges and hazardous substances, as well as safety goggles to protect eyes from debris. Ear protection may also be necessary if the equipment operates at high noise levels. Ensuring that you are properly equipped will help mitigate injury risks during the repair process.

Maintain a Clean Work Environment

A tidy workspace is crucial for safe repairs. Clutter can lead to trips, slips, or falls, and can make it challenging to locate tools when needed. Keep all tools organized and materials stored securely. Moreover, be mindful of electrical cords and other potential hazards that may obstruct movement. A clean environment not only promotes safety but also enhances efficiency.

User Experiences and Reviews

This section delves into the insights and opinions of users who have interacted with this particular tool. By gathering firsthand accounts, we can better understand the strengths and weaknesses, performance, and overall satisfaction associated with its use. These reviews offer valuable perspectives for potential buyers and seasoned users alike, highlighting real-world applications and experiences.

Positive Feedback

Many users praise the tool for its precision and ease of use. They often note how effortlessly it handles various tasks, making it a favorite among both amateurs and professionals. The reliability and robust construction are frequently highlighted, ensuring it withstands the rigors of daily use. Customers appreciate the detailed user manual, which simplifies the setup process and enhances the overall experience.

Constructive Criticism

While there are numerous positive reviews, some users have pointed out areas for improvement. A common concern is the weight of the tool, which can be cumbersome for extended use. Additionally, a few individuals have mentioned that certain components could be better designed for durability. Overall, feedback reflects a balanced view, with suggestions aimed at enhancing user satisfaction in future models.

Frequently Asked Questions

This section addresses common inquiries related to the components and maintenance of a specific cutting tool. Understanding these elements can enhance your experience and ensure optimal performance.

General Queries

Many users seek clarification on the functionality and compatibility of various components. Below are some frequently asked questions regarding these aspects.

| Question | Answer |

|---|---|

| What should I do if a part is missing? | Check the packaging and ensure all items are accounted for. If still missing, contact the retailer or manufacturer for assistance. |

| How can I identify the correct component for my model? | Refer to the user manual or manufacturer’s website for detailed specifications and compatibility lists. |

| Are there any maintenance tips for extending the lifespan of components? | Regular cleaning, proper storage, and timely replacement of worn parts can significantly enhance durability. |

Technical Assistance

Technical difficulties may arise during usage. Here are some common issues and their solutions.

| Issue | Solution |

|---|---|

| The tool won’t power on. | Ensure it is properly plugged in or charged. Check for any blown fuses. |

| Parts are not aligning correctly. | Verify that all components are correctly assembled according to the instructions. |

| There’s unusual noise during operation. | Inspect for loose parts or debris. If the issue persists, consult a technician. |