Comprehensive Guide to Ryobi X430 Parts Diagram

In the realm of outdoor power tools, having a clear understanding of the inner workings is essential for effective maintenance and repair. This guide delves into the intricate details that enable users to navigate the various components of their machinery with confidence. By gaining insight into the structure and functionality, individuals can enhance their operational efficiency and prolong the life of their devices.

Every piece of equipment is composed of a myriad of elements, each playing a crucial role in overall performance. Knowing how these elements interact can demystify the complexities often associated with maintenance tasks. This knowledge empowers users to make informed decisions, whether they are troubleshooting issues or performing routine checks.

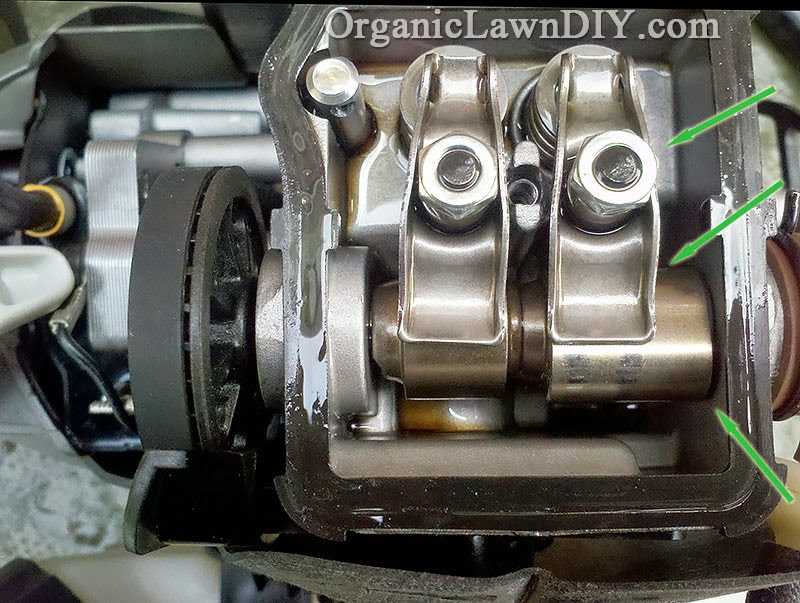

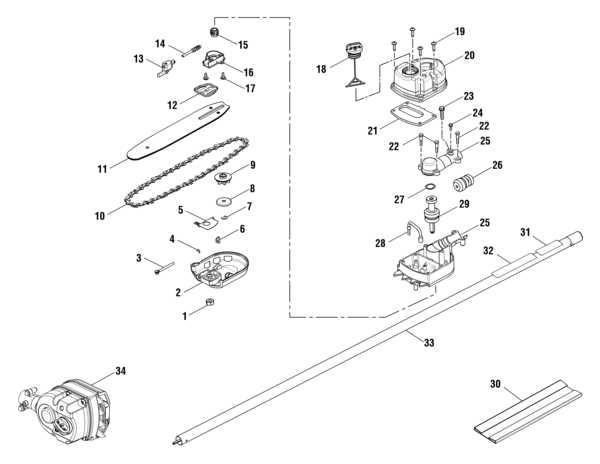

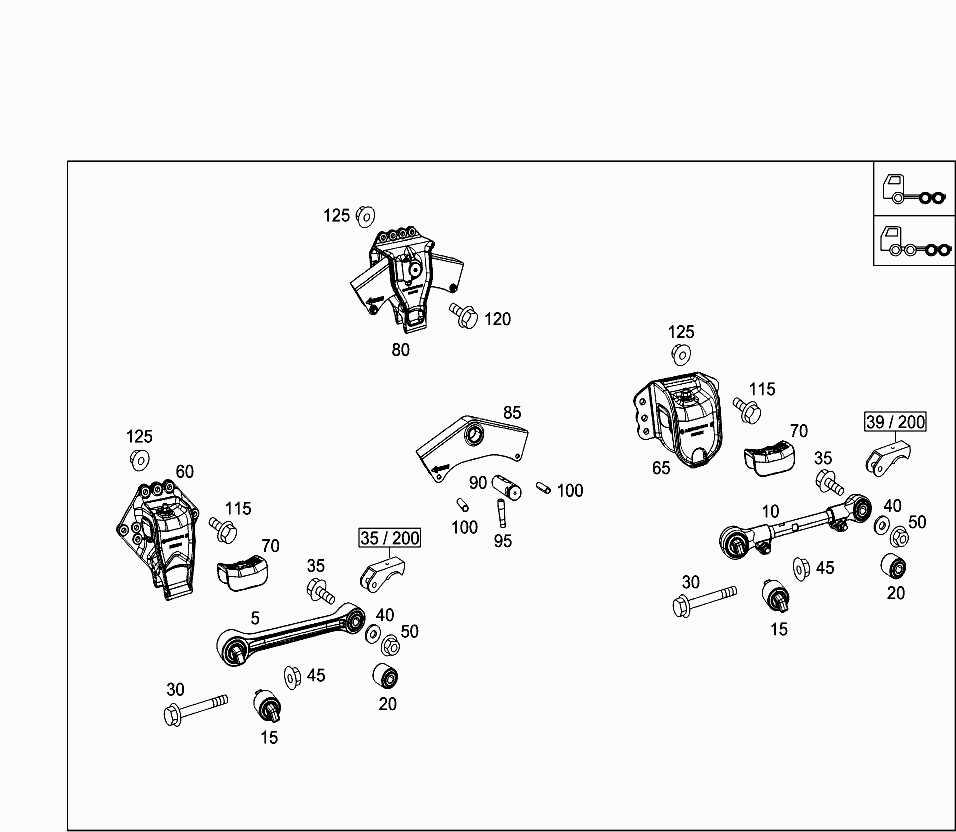

Moreover, visual aids that illustrate the configuration of these components can serve as invaluable resources. Such illustrations not only clarify the relationships between different parts but also provide a reference point during disassembly and reassembly. By utilizing these guides, users can approach their equipment with a newfound understanding and skill.

Understanding Ryobi X430 Parts

This section aims to provide a comprehensive overview of the various components associated with a specific outdoor tool, highlighting their functions and interconnections. Gaining insight into these elements is crucial for maintenance and efficient operation, ensuring that users can maximize performance and longevity.

Key Components Overview

Each element plays a vital role in the overall functionality. Familiarity with the essential components enhances the user’s ability to troubleshoot issues and perform necessary repairs. For instance, understanding the role of the engine, cutting mechanisms, and safety features is fundamental for effective usage.

Maintenance Tips

Regular upkeep of individual elements is essential for optimal performance. Inspection and cleaning of components not only prolong their lifespan but also ensure safety during operation. Users should consult the manufacturer’s recommendations for specific maintenance schedules and practices.

Overview of Ryobi X430 Model

This section provides an insight into a popular outdoor tool designed for versatility and efficiency. Renowned for its performance, this model caters to a wide range of gardening and landscaping needs, making it a favored choice among enthusiasts and professionals alike.

Key Features

The tool boasts a powerful engine, allowing for seamless operation even in demanding tasks. Its ergonomic design enhances user comfort, while the innovative technology incorporated ensures reliable functionality and durability over time.

Applications

This versatile equipment excels in various tasks, from trimming and cutting to maintenance of larger outdoor spaces. Its adaptability makes it suitable for both residential gardens and commercial landscapes, ensuring optimal results in diverse environments.

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential guides, allowing users to identify individual elements and their relationships within a system. These resources simplify troubleshooting, enabling users to pinpoint issues quickly and efficiently.

Moreover, these illustrations enhance communication between users and technicians. They provide a universal language, breaking down complex mechanical structures into manageable parts. This clarity fosters a better understanding of assembly processes and ensures that replacements are carried out accurately, reducing the risk of errors.

In addition, having access to these visual aids can prolong the lifespan of equipment. Users can perform regular maintenance with greater precision, addressing wear and tear before it escalates into major problems. Consequently, this proactive approach not only saves time but also cuts costs associated with repairs.

Ultimately, the availability of visual references is indispensable for anyone engaged in the upkeep of machinery. It empowers users with the knowledge they need to maintain optimal performance, ensuring reliability and longevity in their tools and equipment.

Common Parts of Ryobi X430

Understanding the essential components of a particular tool can significantly enhance maintenance and repair efficiency. This section outlines various key elements commonly found in this specific model, enabling users to familiarize themselves with its construction and functionality.

Main Components

- Motor Assembly

- Power Switch

- Fuel Tank

- Air Filter

- Cutting Head

Additional Accessories

- Replacement Blades

- Spools for String

- Protective Covers

- Handle Grips

- Adjustable Straps

Being aware of these components allows users to make informed decisions regarding repairs and upgrades, ensuring optimal performance over time.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of equipment. These visual aids offer a clear representation of components, helping users identify and locate specific items needed for service or replacement.

Identifying Components

Begin by familiarizing yourself with the key symbols and numbers used in the illustration. Each element typically corresponds to a specific part, often labeled for easy reference.

Understanding Layout and Order

The arrangement of the components usually reflects their assembly order. Recognizing this structure can guide you in disassembling or reassembling the machinery correctly.

| Symbol | Description |

|---|---|

| A | Component Name |

| B | Fastening Element |

| C | Connecting Part |

Replacement Parts Availability

Access to spare components is essential for maintaining the longevity and functionality of any tool. Ensuring that you can readily find the necessary elements for repair or enhancement not only saves time but also enhances the overall user experience. The market provides various options for sourcing these items, whether through official channels or third-party suppliers.

Below is a comparison of different sources where you can acquire the required components, along with their advantages and disadvantages:

| Source | Advantages | Disadvantages |

|---|---|---|

| Official Manufacturer | High quality, guaranteed compatibility | Often higher prices, limited availability |

| Online Retailers | Convenient shopping, often competitive pricing | Variable quality, potential shipping delays |

| Local Hardware Stores | Immediate availability, no shipping costs | Limited selection, may not carry all components |

| Aftermarket Suppliers | Cost-effective options, diverse choices | Quality may vary, less assurance of fit |

Identifying the best source for your needs will help ensure you have the right components on hand for any repairs or upgrades. Regular maintenance and timely replacement can significantly extend the life of your tools and ensure optimal performance.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your tools requires consistent care and attention. By adopting a few essential practices, you can significantly extend their lifespan and maintain optimal performance.

Regular Cleaning: After each use, clean your equipment thoroughly to remove dust, debris, and residue. This prevents buildup that can lead to malfunctions.

Lubrication: Periodically apply lubricant to moving parts to reduce friction and wear. This simple step can enhance efficiency and prevent overheating.

Storage Solutions: Store your tools in a dry, organized space. Avoid exposure to moisture, which can cause rust and corrosion, ultimately compromising functionality.

Routine Inspections: Conduct regular check-ups to identify any signs of wear or damage early. Addressing issues promptly can prevent more significant problems down the line.

Use According to Guidelines: Follow the manufacturer’s recommendations for operation. Using tools outside of their intended purpose can lead to premature wear and tear.

Identifying Compatible Parts

Ensuring that you select suitable components for your equipment can enhance both performance and longevity. When determining which replacements will work, it’s crucial to examine specifications, material quality, and fit. Identifying compatible items helps avoid mismatches and ensures that each piece will integrate seamlessly with the system.

| Component | Compatibility Factors | Materials |

|---|---|---|

| Blade Assembly | Size, connection type | Steel, composite |

| Handle Grip | Diameter, grip texture | Rubber, plastic |

| Engine Mount | Mounting points, alignment | Metal alloy, steel |

Common Repairs and Solutions

Maintenance and occasional repairs are essential to keep equipment running smoothly. Over time, some components may wear out or require adjustment to maintain optimal performance. Recognizing common issues and understanding how to address them can extend the life of your tool and prevent more significant problems.

One frequent issue is reduced power, which can often be traced back to clogged filters or worn-out connectors. Cleaning or replacing these parts can quickly restore functionality. Another common challenge is unusual vibrations during use, which might indicate loose bolts or fasteners. Tightening or replacing these as necessary ensures safe operation.

Sometimes, the equipment may fail to start altogether, often due to a depleted power source or faulty switches. Checking and replacing these components can usually resolve the issue. By regularly inspecting and addressing minor problems, users can ensure their tools remain reliable and efficient.

Tools Required for Disassembly

Before starting the breakdown of a machine, having the correct tools on hand is essential to ensure a smooth process. The tools required will depend on the specific structure and components involved, but several common tools are typically needed for disassembly.

Essential Hand Tools

- Screwdrivers: Both flathead and Phillips screwdrivers are usually required for loosening various screws and bolts.

- Wrenches: A set of adjustable wrenches can help with different sized nuts and bolts.

- Pliers: Needle-nose pliers are ideal for handling small parts and pulling out pins or clips.

Additional Equipment

- Socket Set: Useful for removing larger bolts, a socket set provides the leverage needed for secure fastening.

- Rubber Mallet: This tool can be helpful for gently tapping components loose without causing damage.

- Work Gloves: To protect hands from sharp edges or hot parts, sturdy gloves are recommended.

Safety Precautions During Repairs

Ensuring safety when performing repairs is crucial to prevent accidents and injuries. Before beginning any maintenance work, it is essential to follow basic guidelines that minimize risk and promote a secure environment for effective repair work. Below are some key precautions to keep in mind.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use appropriate safety equipment, such as gloves, goggles, and sturdy footwear, to protect against potential hazards. |

| Disconnect Power Sources | Make sure all power sources are unplugged and de-energized to avoid electrical shocks and other injuries. |

| Work in a Well-Lit Area | Good visibility is essential to perform accurate repairs. Ensure your workspace is well-lit to easily spot any issues. |

| Use the Correct Tools | Utilize tools specifically designed for the task at hand. Using improper tools can lead to mistakes or injuries. |

| Follow Manufacturer Guidelines | Adhering to provided instructions or manuals can significantly reduce the risk of damage and ensure safe operations. |

Where to Find Professional Help

When tackling technical issues or repairs, finding skilled assistance can make the process easier and ensure quality results. Many people turn to professional services to avoid common pitfalls and to achieve reliable outcomes, especially with more complex or intricate projects.

Consulting Repair Experts

Experienced technicians can offer guidance and hands-on support. Local repair shops often have trained staff who are familiar with a wide range of tools and equipment, making them valuable resources for troubleshooting and repairs.

- Check Online Directories: Websites dedicated to professional services often have listings for specialists, making it easy to find someone who fits your needs.

- Ask for Recommendations: Friends, family, and colleagues may know trusted experts who have provided quality service in the past.

Using Manufacturer Services

Official service centers typically have certified technicians who are trained to handle specific repairs. These centers can provide high-quality repairs and may offer warranties on their work.

- Visit the manufacturer’s website for authorized service center locations.

- Contact customer support for advice on finding the nearest certified technician.