Briggs and Stratton 1450 Snow Series Parts Diagram

Maintaining peak performance in cold conditions requires a clear understanding of how the various mechanical elements function together. In the context of specialized winter machinery, proper knowledge of its internal structure is essential for efficient operation. Each component plays a crucial role in ensuring smooth functionality, particularly during challenging weather conditions.

This guide delves into the critical sections of the machinery, highlighting their roles within the overall mechanism. By exploring the core elements, users can gain insight into how the system is designed to withstand low temperatures and deliver consistent results.

Whether for repair or regular upkeep, having a clear map of the unit’s design will make it easier to address any issues that arise. Recognizing the arrangement of key parts is fundamental for ensuring durability and optimal performance during harsh winter months.

Briggs and Stratton 1450 Snow Series Overview

The device under discussion is a powerful machine designed for efficient operation in challenging outdoor conditions. Built to handle various environmental factors, this equipment ensures optimal performance and reliability in cold weather tasks. Its durable construction and specialized components are engineered to maintain functionality in harsh conditions, making it a trusted choice for many users.

Engine Performance and Durability

At the heart of the system lies a robust motor, designed to deliver steady power output. The engine’s durability is enhanced by features that support long-term usage, even in extreme environments. It offers consistent performance, maintaining efficiency despite heavy workloads.

Innovative Cold-Weather Technology

This model incorporates advanced technology to enhance its operation in freezing temperatures. Key innovations ensure that the equipment starts reliably in cold conditions and continues to function smoothly, preventing issues related to freezing or difficult starting. This makes it a dependable choice for users requiring reliable outdoor performance.

Key Components in the Snow Series

When analyzing the essential elements of this mechanical system, it’s important to recognize the core parts that ensure its functionality in cold conditions. Each unit is designed to work efficiently, contributing to the overall reliability of the machine during heavy-duty tasks.

- Engine block – The central piece that powers the system, offering the necessary force to drive other components.

- Carburetor – Responsible for regulating the mixture of air and fuel to optimize combustion and efficiency.

- Muffler – Designed to reduce noise levels while also directing exhaust gases safely away from the machine.

- Throttle control – Allows the user to adjust the speed and output of the machine based on the task at hand.

- Fuel tank – Holds the fuel required to power the engine, ensuring sustained operation over long periods.

These primary components, when functioning together, form a cohesive and powerful system, optimized for consistent performance in harsh conditions.

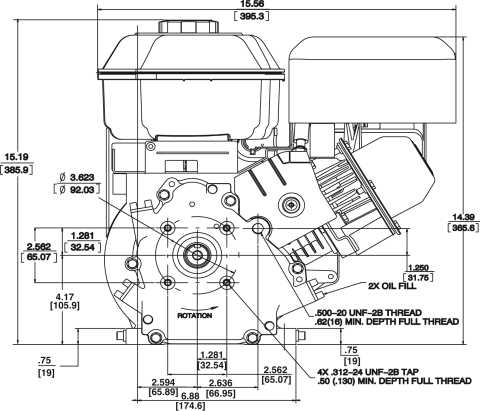

Understanding Engine Layout and Function

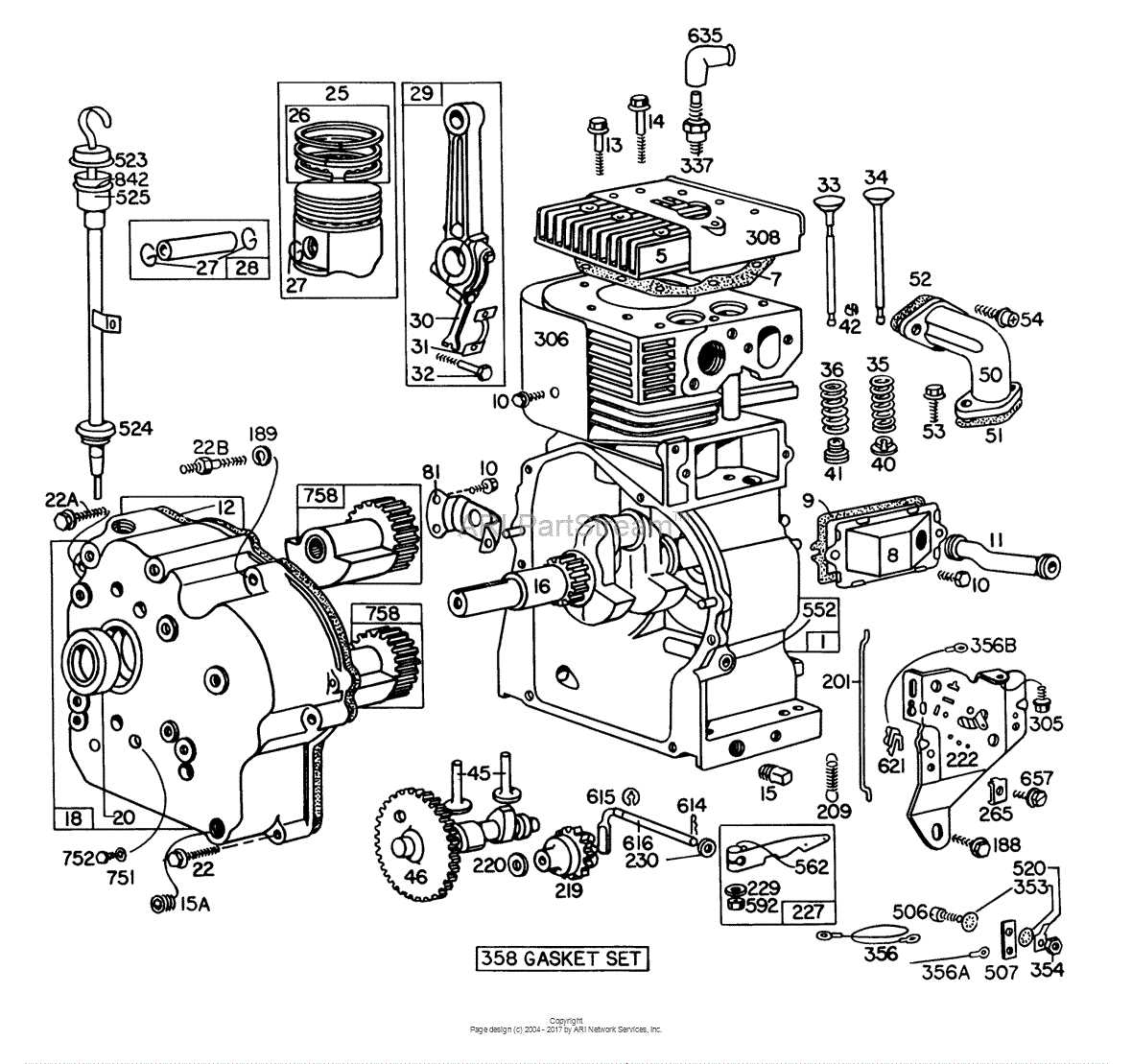

The arrangement and operation of internal mechanisms in a typical power unit are essential for ensuring efficient performance. Each component within the system has a designated role, contributing to the overall function. By exploring the layout, we can better understand how these elements interact and influence the operation of the entire machine.

Core Components Overview

The structure of a typical power unit consists of several key parts, each performing a specific task. The central block contains the combustion chamber, where fuel ignites to generate power. Attached to this are various supportive elements that ensure fuel delivery, exhaust management, and temperature regulation.

Functional Role of Each Element

| Component | Function |

|---|---|

| Combustion Chamber | Converts fuel into mechanical energy through controlled ignition. |

| Fuel System | Delivers the necessary fuel for combustion at precise intervals. |

| Exhaust System | Removes waste gases produced during combustion. |

| Cooling System | Maintains optimal temperature during engine operation. |

Detailed Breakdown of the Fuel System

The fuel system plays a critical role in ensuring the efficient operation of any engine-driven equipment. Understanding the structure and key elements of this mechanism allows for better maintenance and troubleshooting when issues arise. This section will explore the components responsible for the fuel’s journey from storage to combustion, ensuring optimal performance and longevity.

Key Components of the Fuel Path

At the core of the fuel system, several elements work together to deliver the right mixture to the engine. These include the fuel tank, which stores the gasoline, the filter, ensuring no impurities reach the combustion chamber, and the carburetor, where the air-fuel mixture is finely tuned. Each part must function seamlessly for smooth operation.

Maintaining Optimal Fuel Flow

Regular inspection and cleaning of the fuel system components can prevent clogs and ensure a continuous, balanced flow of fuel. Pay special attention to the filter and carburetor, as these are crucial in maintaining the correct air-to-fuel ratio for efficient combustion. A well-maintained system ensures reliable performance and extends the engine’s lifespan.

Essential Electrical Connections and Wiring

Understanding the basic flow of electricity and the paths it follows is critical for maintaining efficient machinery. Proper configuration of these pathways ensures smooth operation, avoiding malfunctions or energy loss. This knowledge allows for troubleshooting and optimizing the entire system.

Wiring systems play a key role in transferring energy across components. Each connection needs to be secured, with the correct conductive materials and well-insulated channels to prevent any potential hazards or interference with the system’s function. Proper wiring not only enhances performance but also extends the longevity of the equipment.

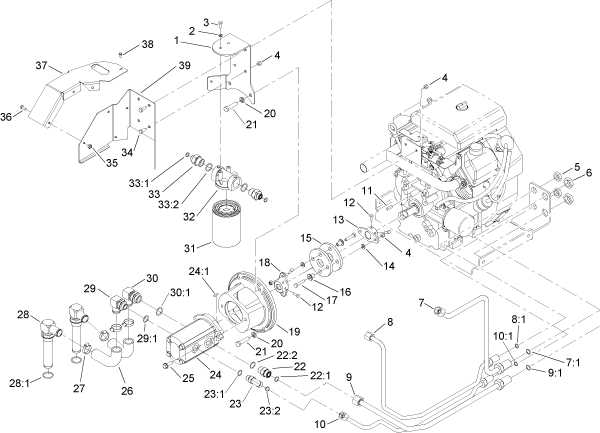

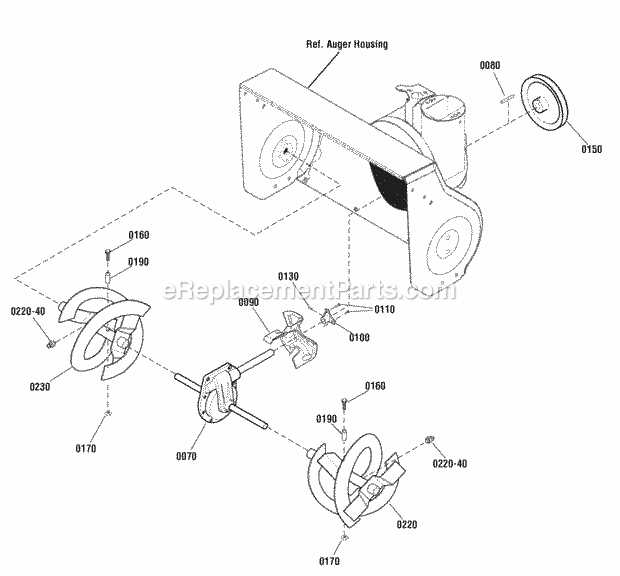

Drive System and Gear Assembly Insights

The mechanism responsible for movement is essential in ensuring efficient operation. This intricate assembly consists of various components that work harmoniously to translate power from the engine to the wheels, providing the necessary torque and speed for optimal performance. Understanding the design and function of these elements can greatly enhance maintenance and troubleshooting efforts.

Key Components of the drive mechanism include gears, belts, and pulleys, each playing a vital role in the overall functionality. Gears facilitate the transfer of motion, allowing for adjustments in speed and force. The belts, often made from durable materials, ensure a secure connection between different parts, while pulleys help redirect power effectively. Maintaining these components is crucial for longevity and reliable operation.

Regular inspections can prevent common issues such as slippage or misalignment, which may lead to reduced efficiency. Identifying wear or damage early can save time and resources in repairs, ensuring the mechanism continues to perform at its best.

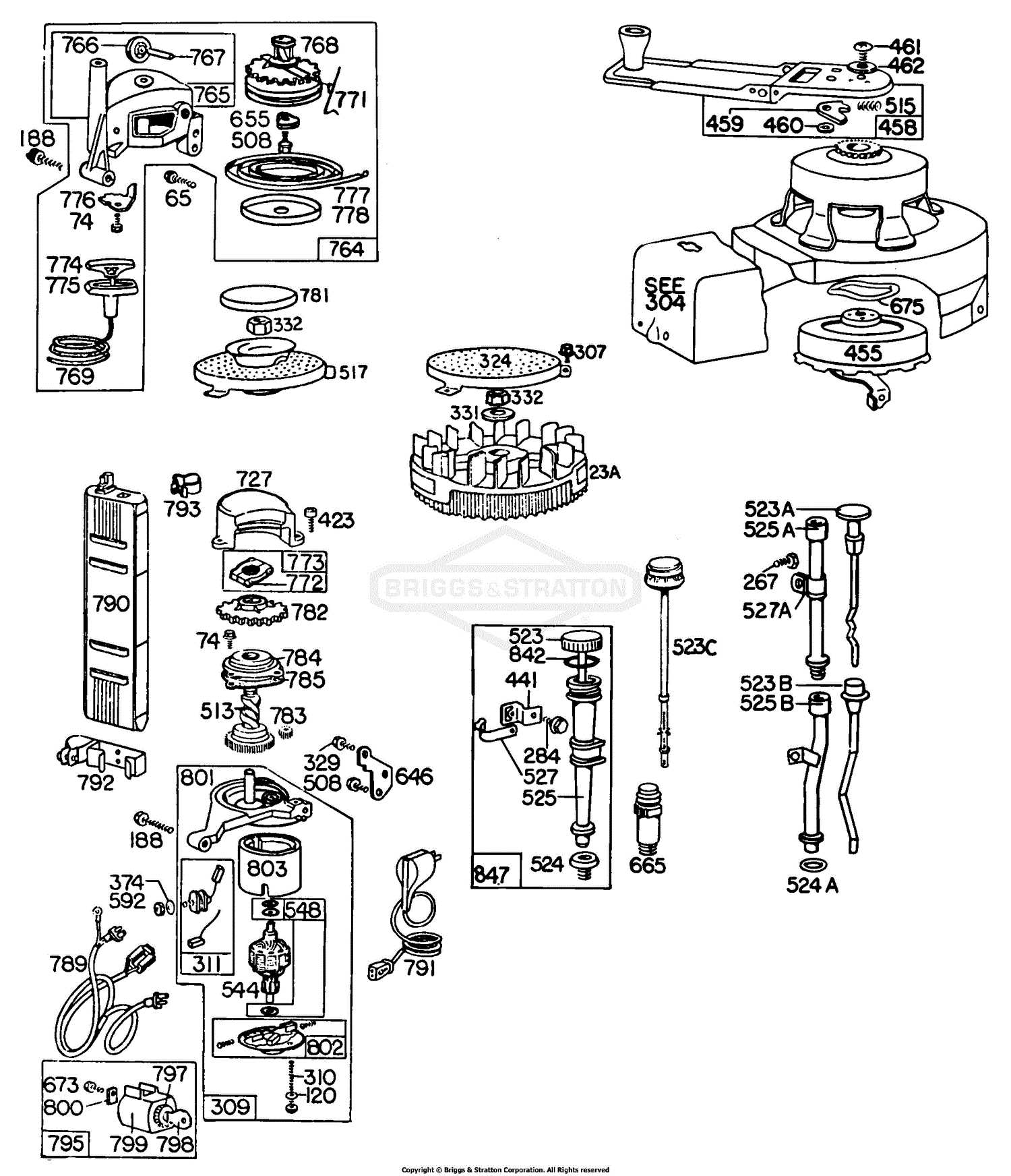

Cooling and Exhaust System Explained

The functionality of any engine relies significantly on the effectiveness of its cooling and exhaust mechanisms. These systems play a critical role in maintaining optimal operating temperatures and ensuring the efficient expulsion of combustion gases. Proper design and maintenance of these components are essential for enhancing performance and longevity.

Understanding the Cooling Mechanism

The cooling apparatus is designed to regulate the temperature of the engine during operation. By utilizing a combination of air and liquid cooling techniques, this system prevents overheating, which can lead to severe damage. Efficient heat dissipation is crucial, and regular inspections can help identify potential issues before they escalate.

The Role of the Exhaust System

The exhaust configuration is responsible for directing harmful gases away from the engine and the operator. This system not only ensures a safer working environment but also helps improve engine efficiency by reducing back pressure. Routine checks of the exhaust pathways can reveal blockages or leaks, which, if addressed promptly, can enhance overall performance.

Carburetor Configuration and Maintenance Tips

The proper setup and upkeep of the fuel mixing device are crucial for optimal engine performance. A well-tuned mechanism ensures efficient fuel delivery and consistent operation, particularly in challenging weather conditions. This section explores essential guidelines to maintain and configure this vital component, enhancing its functionality and extending its lifespan.

Essential Adjustments for Performance

To achieve optimal performance, it is important to ensure that the air and fuel mixture is correctly calibrated. Adjust the needle settings and idle speed according to the manufacturer’s specifications. Regularly check for any blockages in the fuel passages, as these can hinder the flow and affect engine efficiency. Proper adjustment not only improves performance but also minimizes fuel consumption.

Routine Maintenance Practices

Implementing regular maintenance routines can significantly enhance the longevity of the fuel mixing device. Clean the assembly periodically to remove dirt and debris that may accumulate over time. Replace worn gaskets and seals to prevent leaks that could disrupt fuel delivery. Additionally, inspect the float and needle for wear, ensuring that they function properly to maintain consistent fuel levels.

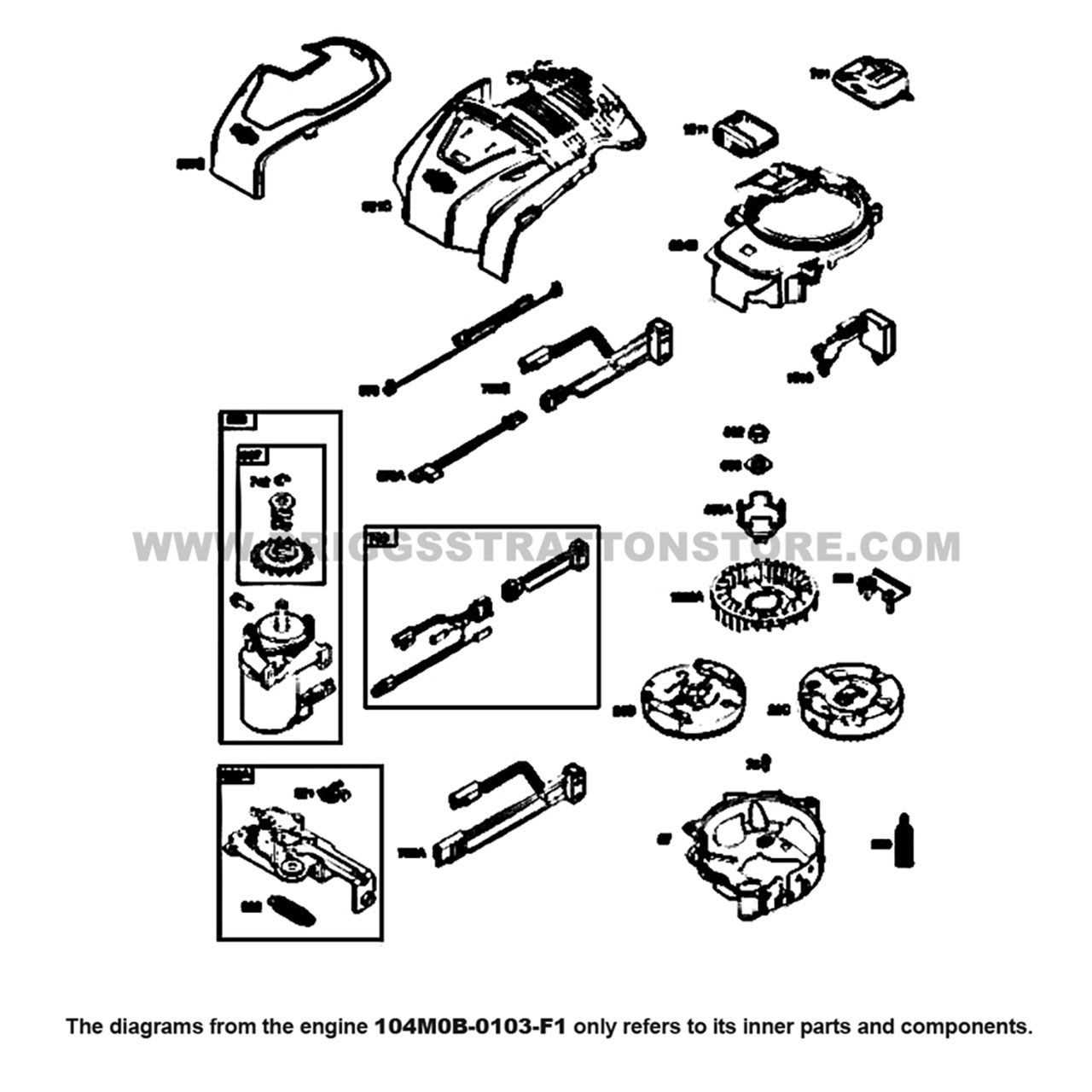

Oil and Lubrication System Overview

The effective functioning of any machinery relies heavily on the proper management of its fluid systems. A well-designed lubrication mechanism plays a crucial role in minimizing friction, preventing wear, and ensuring the smooth operation of internal components. Understanding this system is essential for maintaining optimal performance and longevity.

Essential Components of the lubrication system include an oil reservoir, pump, filters, and delivery channels. The oil reservoir holds the lubricating fluid, which is circulated by the pump through various parts of the engine. Filters are crucial for removing impurities and ensuring that the fluid remains clean, enhancing the efficiency of the entire system.

Maintenance of the lubrication system is vital for preventing overheating and reducing wear on engine components. Regular checks and timely oil changes can significantly extend the life of the engine. Users should refer to specific maintenance guidelines to ensure optimal performance and reliability.

Common Replacement Parts and Compatibility

When maintaining outdoor equipment, understanding the components that require regular updates is essential for optimal performance. Several elements are frequently replaced to ensure longevity and efficiency. This section provides an overview of typical components and their compatibility with various models.

Identifying the right components is crucial, as not all parts are interchangeable across different models. Below are some of the most common replacements and their general compatibility:

- Fuel Filter: Regular replacement of the fuel filter helps maintain engine performance. Ensure compatibility by checking model specifications.

- Air Filter: A clean air filter is vital for proper airflow. Always verify that the air filter fits your specific model.

- Spark Plug: This component is essential for ignition. Refer to the manufacturer’s recommendations for compatible spark plug types.

- Oil Seal: Prevents oil leakage and maintains proper lubrication. Confirm the correct size and fit for your equipment.

- Blade Assembly: For equipment with cutting mechanisms, replacing the blade is necessary for efficient operation. Ensure the blade is compatible with the model.

When purchasing replacement components, always refer to the manufacturer’s guidelines or a compatibility chart. This ensures that the selected parts will function effectively with your specific equipment model.

Maintenance Guide for Optimal Performance

Regular upkeep is essential to ensure the longevity and efficiency of your equipment. By adhering to a systematic maintenance routine, you can prevent potential issues and enhance the overall functionality of your machine. This guide will provide essential tips for maintaining your device to keep it operating at peak performance.

Essential Maintenance Practices

Start with a thorough inspection of your equipment. Look for any signs of wear or damage, especially in key components such as the engine and the ignition system. Cleaning the air filter regularly is crucial, as it helps maintain airflow and prevents debris from entering the engine. Furthermore, ensure that all moving parts are well-lubricated to reduce friction and wear.

Seasonal Checks and Preparations

As seasons change, so should your maintenance approach. Before winter, it is vital to check the fuel system and ensure that it is clean and free of contaminants. Consider using a fuel stabilizer to prevent deterioration during periods of inactivity. Additionally, inspect the spark plug for any signs of damage or wear; replacing it as necessary will enhance ignition reliability.

In summary, consistent maintenance not only prolongs the lifespan of your equipment but also ensures it operates smoothly when you need it the most. By implementing these practices, you can achieve optimal performance and reliability throughout its use.