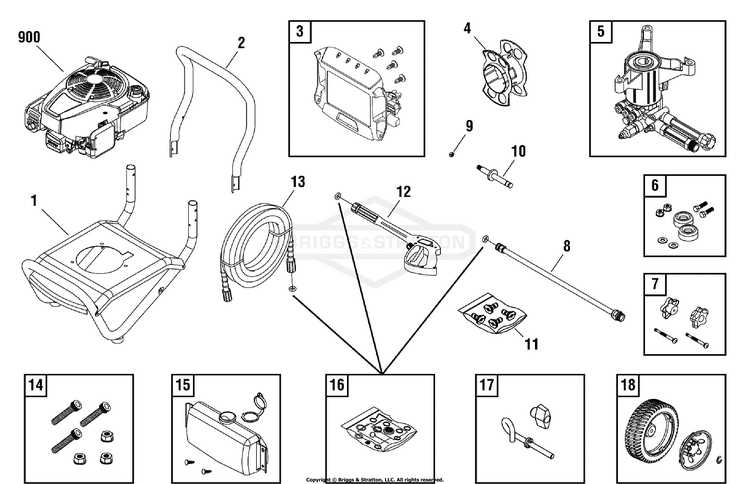

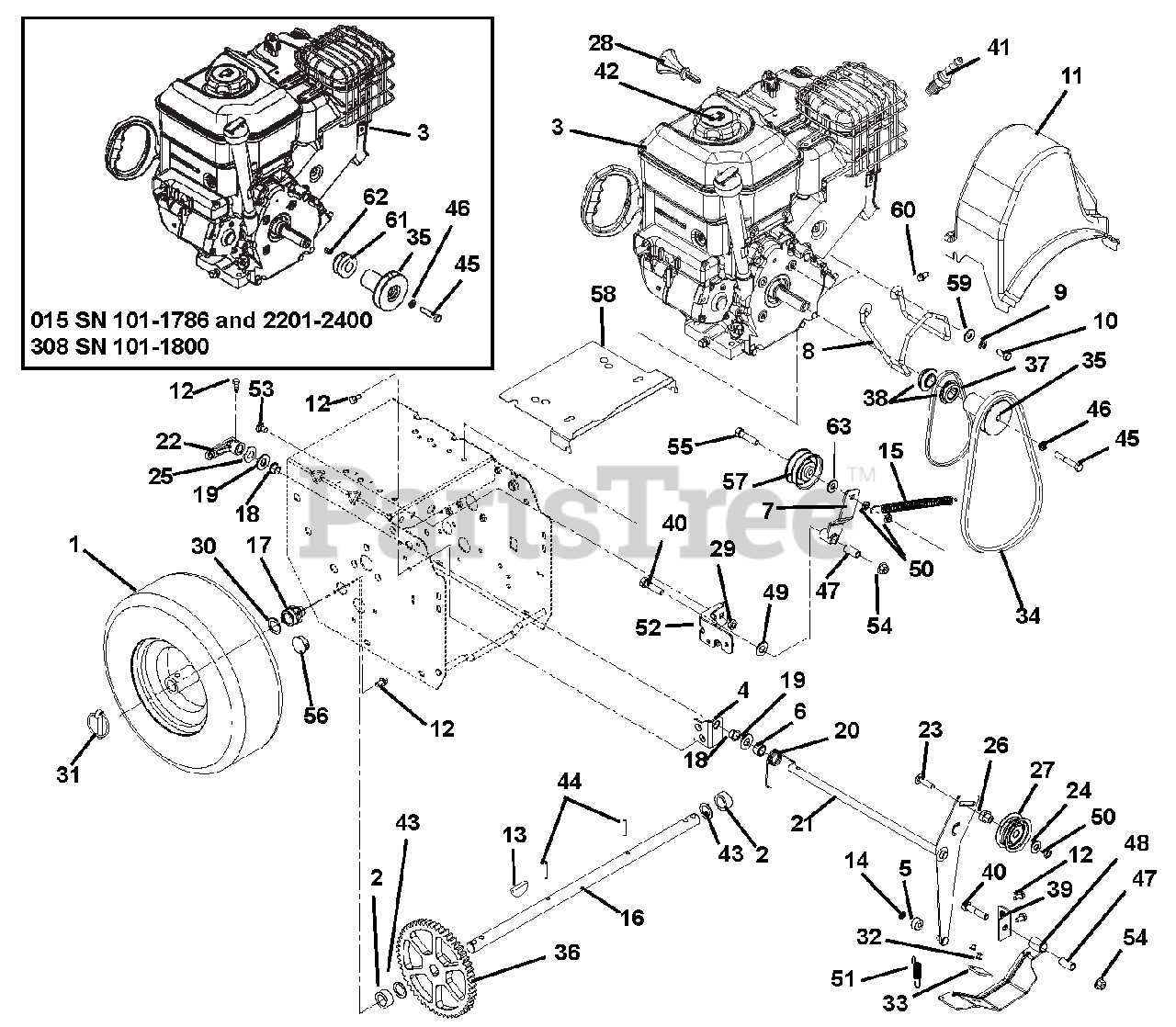

Briggs and Stratton 900 Series Parts Diagram Guide

Understanding the internal structure of small engines can be crucial for maintaining optimal performance. Whether you are a seasoned mechanic or a DIY enthusiast, having a clear view of how everything fits together helps in diagnosing and fixing issues more efficiently. This guide provides a detailed examination of the essential mechanical elements found in popular engines, allowing for better maintenance and repair practices.

Key features of these systems include various moving and stationary elements, each playing a critical role in ensuring smooth operation. By breaking down the core components, this guide aims to offer valuable insights into how the engine functions and how its various sections interact to power different types of machines.

Whether you are dealing with issues related to the fuel system, ignition, or cooling mechanisms, understanding the role of each component is vital. This resource will help you gain a deeper knowledge of the individual elements, enabling more efficient troubleshooting and repair work on your engine.

Understanding the Briggs and Stratton 900 Series Engine

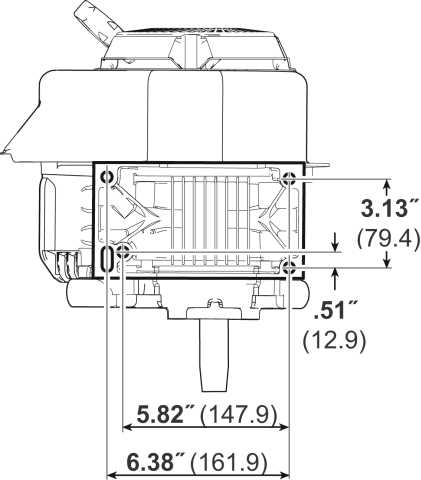

The engine in question is a reliable power source often utilized in various outdoor equipment. It is known for its durability, efficiency, and smooth operation, making it a popular choice for those seeking consistent performance. Designed with precision, it offers the right balance between power output and fuel efficiency, ensuring machines run optimally over long periods of use. Whether you are maintaining a lawn or operating other machinery, this engine serves as a dependable component, offering both strength and reliability.

With a well-thought-out design, the engine’s configuration allows for easy maintenance and repair. The internal components are engineered to provide longevity, reducing the need for frequent replacements. Operators appreciate how the engine delivers dependable operation even under demanding conditions, helping users get the most out of their equipment. For those interested in its inner workings, understanding its features and layout is crucial for maximizing its potential.

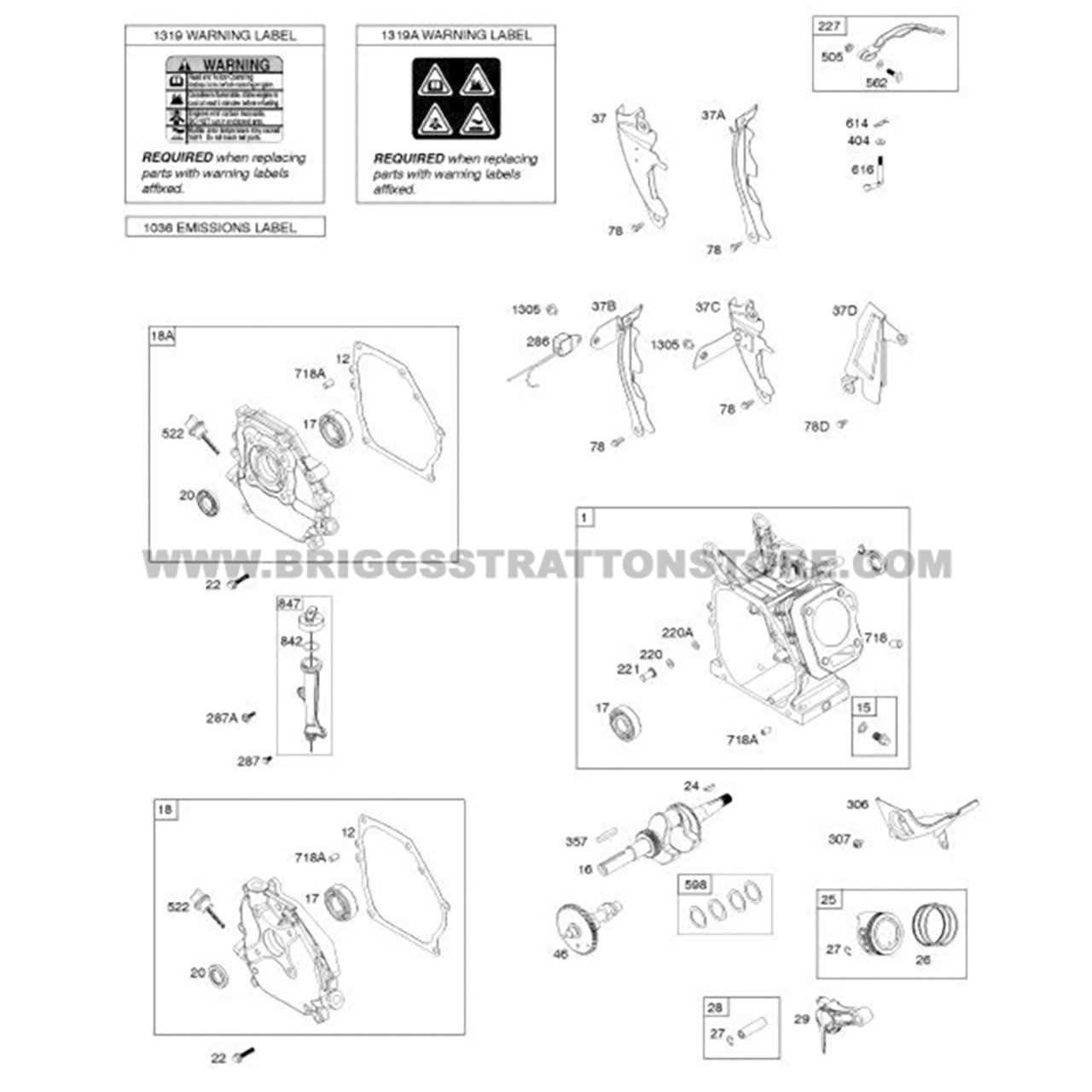

Key Components and Their Functions

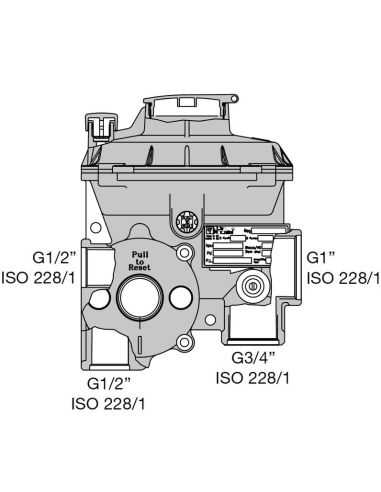

The internal mechanics of small engines rely on various essential elements that work in unison to ensure efficient operation. Each component has a specific role, contributing to the engine’s overall performance and durability. Understanding these elements allows users to diagnose issues and maintain the machine effectively.

Engine Block and Cylinder

The engine block serves as the foundation for the entire system. It houses critical parts such as the cylinder, where fuel combustion takes place. The cylinder’s purpose is to channel the energy created by combustion into mechanical power that drives the machine.

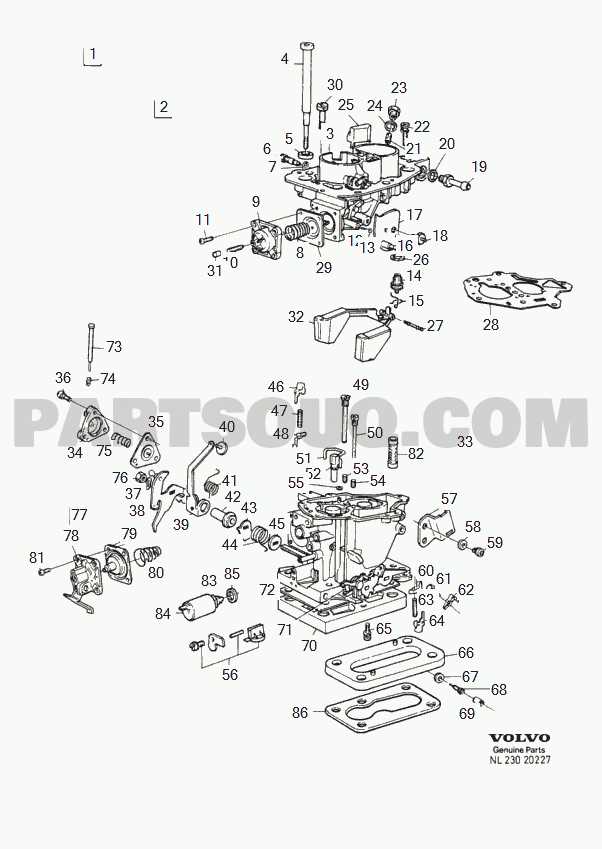

Ignition and Fuel System

The ignition system is responsible for initiating the combustion process. It consists of elements like the spark plug, which creates the necessary spark to ignite the fuel mixture. The fuel system, on the other hand, ensures that the correct amount of fuel is supplied to the cylinder for combustion.

| Component | Function | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Crankshaft |

| Component | Function | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fuel Bowl | Stores fuel before it is mixed with air. | |||||||||||||

| Throttle Valve | Controls the amount of air entering the engine. | |||||||||||||

| Issue | Description | Recommended Action |

|---|---|---|

| Starting Failure | Engine does not initiate when attempting to start. | Check fuel levels, inspect the ignition system, and examine the battery condition. |

| Overheating | Unit becomes excessively hot during operation. | Ensure proper ventilation, check coolant levels, and inspect for debris blocking airflow. |

| Uneven Performance | Machine operates inconsistently, with fluctuations in speed. | Inspect the carburetor settings, air filter, and spark plug condition for wear. |

| Excessive Vibration | Unit exhibits unusual shaking during operation. | Check for loose components and ensure that all parts are securely fastened. |

Visual Aids for Effective Troubleshooting

Visual aids can be invaluable in pinpointing the source of issues. By referencing accurate schematics, operators can track down specific components that may be malfunctioning. Understanding the layout allows for quicker identification of problems, reducing downtime and facilitating efficient repairs.