Briggs Stratton 675 Series Parts Diagram Overview

The intricate world of engine maintenance often requires a deep dive into the specific arrangements of various elements. Whether for repair or enhancement, comprehending the structure and function of each component is essential for effective management and performance optimization.

In this section, we will explore the visual representation of key engine constituents, offering insights into their placement and relationships. A detailed overview aids in identifying wear and tear, ultimately contributing to informed decisions for upkeep and replacements.

By examining these layouts, enthusiasts and professionals alike can enhance their technical knowledge, ensuring that every piece works harmoniously for the ultimate engine efficiency. This exploration not only facilitates repairs but also fosters a greater appreciation for the engineering behind these powerful machines.

Understanding Briggs & Stratton 675 Series

This segment explores the essential features and functionalities of a well-known engine model designed for outdoor equipment. Its robust construction and reliability make it a popular choice among enthusiasts and professionals alike. Recognizing its components and how they interact can enhance maintenance and performance.

Key Features

One of the standout aspects of this engine is its efficiency. It combines power and durability, ensuring optimal operation across various tasks. Moreover, the user-friendly design allows for straightforward troubleshooting and repairs, making it accessible for both seasoned users and novices.

Maintenance Tips

Regular upkeep is vital for longevity. Focus on checking the oil level, air filter, and spark plug to ensure peak performance. Understanding these elements can significantly impact efficiency and overall functionality. Emphasizing routine checks will ultimately lead to a more reliable and effective machine.

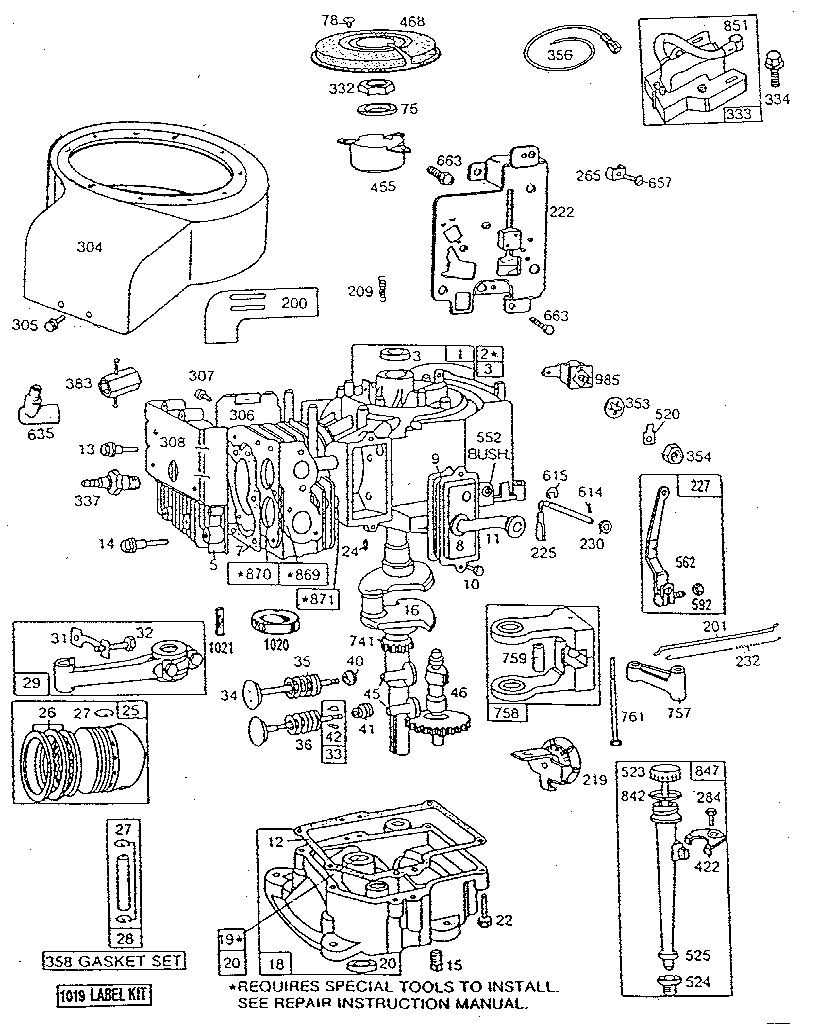

Key Components of the Engine

The functionality and efficiency of a small engine rely on a variety of essential elements working in harmony. Understanding these vital components helps in appreciating how power is generated and transmitted, as well as how maintenance can enhance longevity and performance.

Powerhead: This is the heart of the engine, where combustion occurs. It houses the cylinder, piston, and crankshaft, transforming fuel into mechanical energy.

Fuel System: The fuel system is responsible for delivering the necessary mixture of air and fuel to the combustion chamber. It typically includes the fuel tank, lines, and carburetor, all designed to ensure efficient combustion.

Ignition System: This system initiates the combustion process by producing a spark at the right moment. It includes components such as the spark plug, ignition coil, and flywheel, each playing a critical role in engine startup and operation.

Cooling System: To prevent overheating, engines are equipped with a cooling system, often utilizing fins or fans to disperse heat generated during operation. This system is crucial for maintaining optimal performance and preventing damage.

Lubrication System: Proper lubrication is essential for reducing friction between moving parts. This system typically includes an oil reservoir, pump, and filter, ensuring that all critical components receive adequate protection and efficiency.

Each of these components plays a crucial role in the overall performance and reliability of the engine. Understanding their functions can aid in troubleshooting and effective maintenance practices.

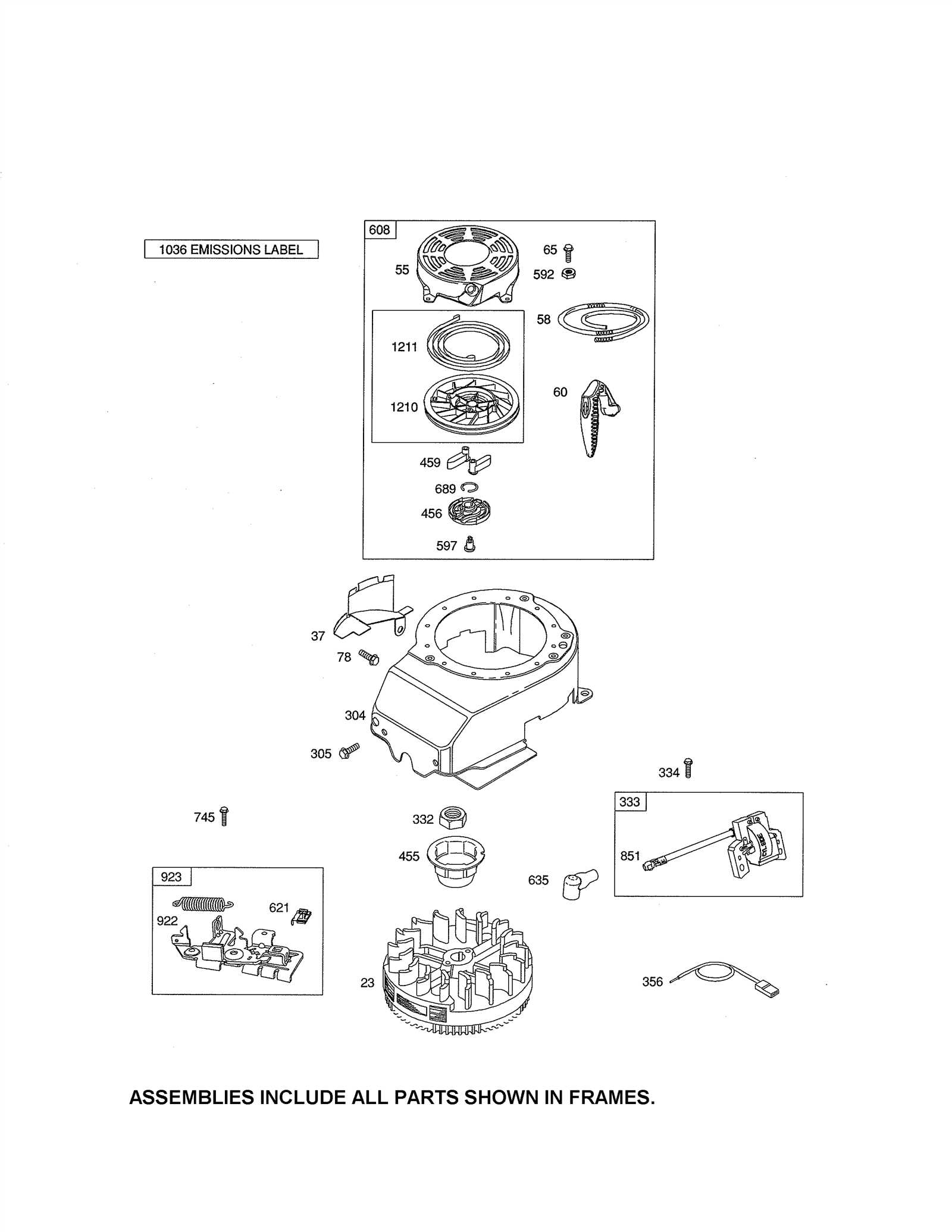

Importance of Parts Diagrams

Understanding the intricate components of a machine is essential for effective maintenance and repair. Visual representations serve as vital tools, allowing users to identify each element and its specific role within the overall system. This clarity not only simplifies troubleshooting but also enhances the efficiency of the repair process.

Accurate identification of components is crucial when replacing or repairing machinery. A well-crafted visual guide minimizes confusion, ensuring that users can quickly locate the necessary items. This not only saves time but also reduces the likelihood of errors, promoting smoother operations.

Furthermore, these illustrations aid in the assembly and disassembly processes. By providing a clear roadmap, they empower users to approach tasks with confidence, making the complex seem manageable. This is particularly beneficial for those who may not have extensive technical knowledge, as it democratizes access to repair and maintenance tasks.

In conclusion, visual references play a pivotal role in the upkeep of machinery, fostering both understanding and efficiency. Their value cannot be overstated, as they bridge the gap between technical knowledge and practical application.

Common Issues with 675 Series Parts

Many users encounter frequent challenges when dealing with components of this specific engine line. Understanding these common problems can significantly aid in maintenance and enhance performance. Here are some prevalent issues that may arise.

| Issue | Description | Potential Solutions |

|---|---|---|

| Fuel Leaks | Leaks can occur due to worn gaskets or faulty fuel lines. | Inspect and replace damaged components; ensure tight connections. |

| Starting Problems | Difficulty in starting may result from a clogged air filter or spark plug issues. | Clean or replace the air filter and spark plug; check battery connections. |

| Overheating | Engines may overheat due to inadequate cooling or oil flow. | Regularly check oil levels and coolant; clean the cooling fins. |

| Excessive Vibration | Unusual vibrations can stem from misaligned parts or worn mounts. | Inspect all components for alignment; replace damaged mounts. |

| Poor Performance | Reduced efficiency may occur due to dirty carburetors or fuel filters. | Clean the carburetor and replace the fuel filter as necessary. |

How to Read a Parts Diagram

Understanding an assembly illustration is essential for anyone looking to repair or maintain small engines. These visual representations provide a clear overview of components, their arrangement, and how they interact with one another. Familiarizing yourself with these graphics can simplify the process of identifying necessary items and ensure accurate reassembly.

Key Elements of the Illustration

When examining an assembly illustration, pay attention to the following key aspects:

| Element | Description |

|---|---|

| Labels | Each part is usually assigned a label or number corresponding to a list for easy identification. |

| Connections | Lines or arrows often indicate how components fit together or interact. |

| Groups | Some components may be grouped to illustrate their functional relationship. |

Steps to Interpret the Illustration

To effectively interpret the illustration, follow these steps:

- Identify the labels for each component.

- Cross-reference with the accompanying list to find specific part numbers.

- Observe the connections to understand how each piece fits into the overall structure.

- Note any grouped items that may require collective replacement.

By mastering these techniques, you will enhance your ability to navigate any assembly illustration, making repairs more efficient and accurate.

Maintenance Tips for Longevity

To ensure your engine remains in optimal condition, regular upkeep is essential. By following a few key practices, you can enhance performance and extend its lifespan significantly.

1. Regular Oil Changes: Consistently replacing the oil prevents buildup of debris and ensures smooth operation. Aim for oil changes every 25-50 hours of use, or as recommended by the manufacturer.

2. Air Filter Maintenance: Clean or replace the air filter regularly to ensure proper airflow. A clean filter improves efficiency and reduces wear on engine components.

3. Spark Plug Inspection: Check and replace spark plugs as needed. A healthy spark plug ignites the fuel effectively, contributing to better performance.

4. Fuel Care: Use fresh fuel and consider adding a fuel stabilizer to prevent degradation. This practice helps maintain engine efficiency and reduces starting issues.

5. Clean Cooling Fins: Keep the cooling fins free from debris. This promotes proper airflow and prevents overheating, which can damage engine parts.

6. Routine Checks: Regularly inspect belts, hoses, and other components for signs of wear. Early detection of issues can prevent costly repairs.

By incorporating these maintenance practices, you will not only ensure optimal performance but also achieve the ultimate longevity of your engine.

Where to Find Replacement Parts

Finding suitable components for your outdoor equipment can seem daunting, but numerous resources are available to simplify the process. Whether you need a specific element for maintenance or a complete overhaul, understanding where to search is crucial.

Online Retailers: Numerous e-commerce platforms specialize in outdoor machinery. They often provide detailed catalogs, allowing you to filter your search by model or type. This option offers the convenience of shopping from home and often features competitive pricing.

Local Dealers: Visiting authorized local dealers can be beneficial. They usually have a wide selection of high-quality components and can provide expert advice on compatibility and installation.

Salvage Yards: For those looking to save money, salvage yards can be a treasure trove. Here, you might find gently used items at a fraction of the cost. Just ensure that you inspect any components thoroughly before purchasing.

Manufacturer Websites: Most manufacturers have online resources where you can order direct replacements. These sites often include helpful tools, such as model search functions, to guide you to the correct item.

Community Forums: Engaging with online communities can provide insights into where others have successfully sourced their items. Members often share recommendations and experiences, which can be invaluable in your search.

Comparison with Other Briggs Engines

This section delves into the distinctions and similarities among various engine models produced by the same manufacturer. By exploring key attributes such as performance, design features, and intended applications, readers can gain a comprehensive understanding of how these engines cater to different needs and environments.

Performance Characteristics

When examining engine performance, factors such as horsepower, torque, and fuel efficiency become critical. Some models are optimized for high-output applications, making them ideal for heavy-duty tasks, while others focus on fuel conservation for smaller machinery. This variation enables users to select the most suitable engine based on specific operational demands.

Design and Durability

Design elements play a significant role in engine longevity and user satisfaction. Features such as air filtration systems, cooling mechanisms, and overall construction quality can differ widely. Certain models are designed for rugged conditions, emphasizing durability and resistance to wear, while others may prioritize lightweight design for ease of transport and use.

Tools Needed for Repairs

Having the right instruments is crucial for performing effective maintenance and repairs on small engines. A well-equipped toolbox not only makes the process smoother but also enhances the overall efficiency of your work. Below is a guide to the essential tools that will help you tackle any necessary repairs.

Essential Tools

- Wrenches: A set of various sizes is essential for loosening and tightening nuts and bolts.

- Screwdrivers: Both flathead and Phillips types are necessary for handling different types of screws.

- Socket Set: This tool helps in quickly removing and replacing fasteners.

- Pliers: Useful for gripping and manipulating various components.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

Additional Useful Tools

- Multimeter: Helps in diagnosing electrical issues.

- Oil Filter Wrench: Assists in removing and installing oil filters.

- Fuel Line Pliers: Simplifies the process of disconnecting fuel lines.

- Cleaning Brushes: Useful for maintaining engine cleanliness.

- Safety Gear: Gloves and goggles are essential for protection during repairs.

Equipping yourself with these tools will greatly improve your ability to perform repairs efficiently and safely, ensuring that your engine remains in optimal condition.

Step-by-Step Repair Process

This section outlines a comprehensive approach to effectively troubleshoot and fix common issues in small engines. By following these structured steps, you can ensure that repairs are executed systematically and efficiently, minimizing downtime and enhancing performance.

Preparation and Tools

Before diving into the repair, gather all necessary tools and equipment. A clean workspace is essential for organization and efficiency. Essential items include wrenches, screwdrivers, and a multimeter for electrical checks.

Disassembly and Inspection

Begin the disassembly process carefully, taking notes or photos to aid in reassembly. Inspect each component thoroughly for signs of wear or damage. Pay special attention to seals, gaskets, and other critical parts that may need replacement. Documenting your findings will help in making informed decisions on repairs or replacements. Delve into each part’s condition to ensure optimal functionality.

Identifying Genuine Parts vs. Counterfeits

When it comes to maintaining and repairing outdoor power equipment, ensuring the authenticity of components is crucial. Genuine items are designed for optimal performance and durability, while imitation parts can lead to inefficiencies and potential damage. Understanding how to differentiate between these options can save time, money, and frustration in the long run.

Key Differences to Look For

- Packaging: Authentic products typically come in high-quality packaging that includes brand logos, part numbers, and clear labeling.

- Material Quality: Genuine components are made from superior materials, ensuring better performance and longevity. Counterfeit items may use inferior materials that compromise function.

- Price: If the cost seems unusually low, it’s a red flag. Genuine items have a consistent pricing structure that reflects their quality.

- Manufacturer Information: Check for manufacturer details and customer service contacts. Legitimate companies provide clear and accessible support.

Steps to Verify Authenticity

- Research the manufacturer’s official website for information about authorized retailers.

- Inspect the item closely for discrepancies in design, logos, and part numbers.

- Seek reviews or feedback from other customers regarding their experiences with specific sellers.

- Request documentation or proof of authenticity from the seller if unsure.

By following these guidelines, users can confidently select components that meet the necessary standards for safety and efficiency, ensuring reliable performance for their equipment.

Customer Support and Resources

In today’s fast-paced world, having reliable assistance and access to essential materials is crucial for maintaining equipment efficiency. Whether you are troubleshooting an issue or seeking guidance on maintenance, a wealth of resources is available to ensure your machinery operates at its best.

Technical Assistance: For immediate help, reaching out to dedicated customer support teams can provide you with expert advice tailored to your specific needs. These professionals are equipped to answer questions and offer solutions quickly.

User Manuals: Comprehensive user manuals serve as invaluable guides, detailing every aspect of operation and upkeep. These documents often include troubleshooting tips, maintenance schedules, and safety protocols to enhance user experience.

Online Forums: Engaging with online communities can be beneficial, as users share their experiences, tips, and solutions. Participating in these discussions allows for a collaborative approach to problem-solving.

Parts Suppliers: Identifying reputable suppliers for necessary components ensures that you have access to quality replacements, minimizing downtime and extending the lifespan of your equipment.

Utilizing these resources effectively can lead to improved performance and satisfaction with your machinery.

Frequently Asked Questions about 675 Series

This section addresses common inquiries related to a specific engine model, focusing on various aspects such as maintenance, troubleshooting, and essential components. Understanding these elements can enhance the user experience and ensure optimal performance.

What are the key components of this engine?

The primary elements include the carburetor, ignition system, and fuel tank. Each plays a crucial role in the overall functionality and efficiency of the unit.

How can I troubleshoot common issues?

Begin by checking fuel levels and ensuring the air filter is clean. If problems persist, inspect the ignition components and consider consulting a repair manual for detailed guidance.