Cub Cadet Series 2000 Parts Diagram Overview

Every machinery enthusiast knows the importance of comprehending the intricate elements that make up their tools. A thorough understanding not only enhances performance but also ensures longevity and reliability. This section aims to provide clarity on the various components that contribute to optimal functionality.

Exploring the intricate layout of these vital elements can significantly aid in maintenance and repairs. By familiarizing oneself with the specific arrangement and purpose of each part, users can tackle issues more effectively. This knowledge empowers owners to handle their devices with confidence.

In this discussion, we will delve into the comprehensive breakdown of the essential features, illustrating their connections and functions. This ultimate guide will serve as a valuable resource for anyone looking to enhance their understanding and mastery of their equipment.

Cub Cadet Series 2000 Overview

This section provides a comprehensive understanding of a well-regarded line of lawn maintenance equipment, known for its durability and efficiency. Designed for both residential and commercial use, these machines offer a range of features that cater to diverse landscaping needs.

Key Features

- Robust construction for enhanced longevity

- Powerful engines that deliver consistent performance

- Ergonomic designs for user comfort during operation

- Versatile attachments to tackle various tasks

Applications

- Residential lawn care

- Commercial landscaping projects

- Seasonal snow removal

- Gardening and turf management

This lineup stands out in the market, providing reliable solutions for maintaining outdoor spaces effectively. Whether for personal or professional use, these machines are equipped to handle various tasks with ease.

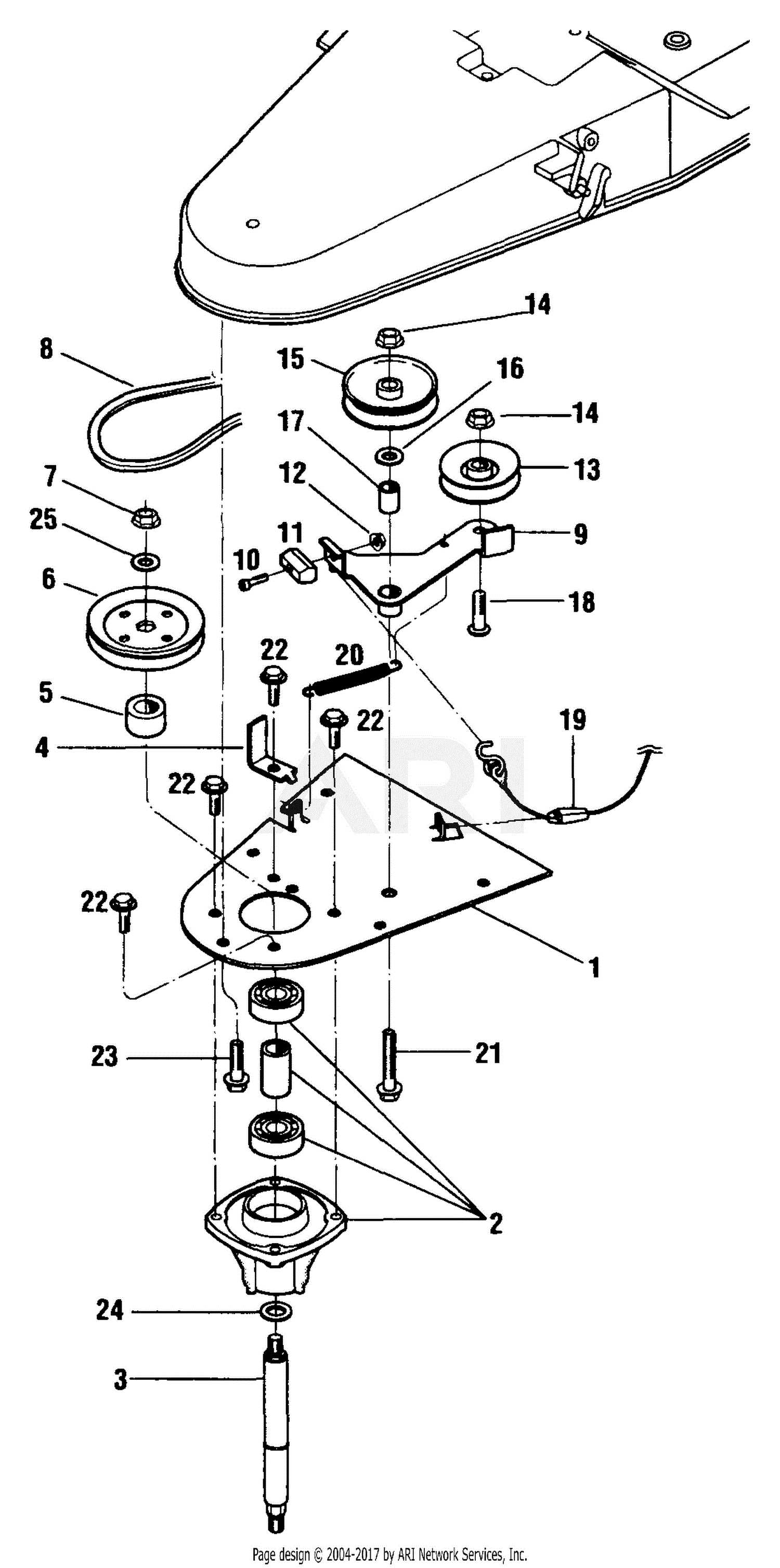

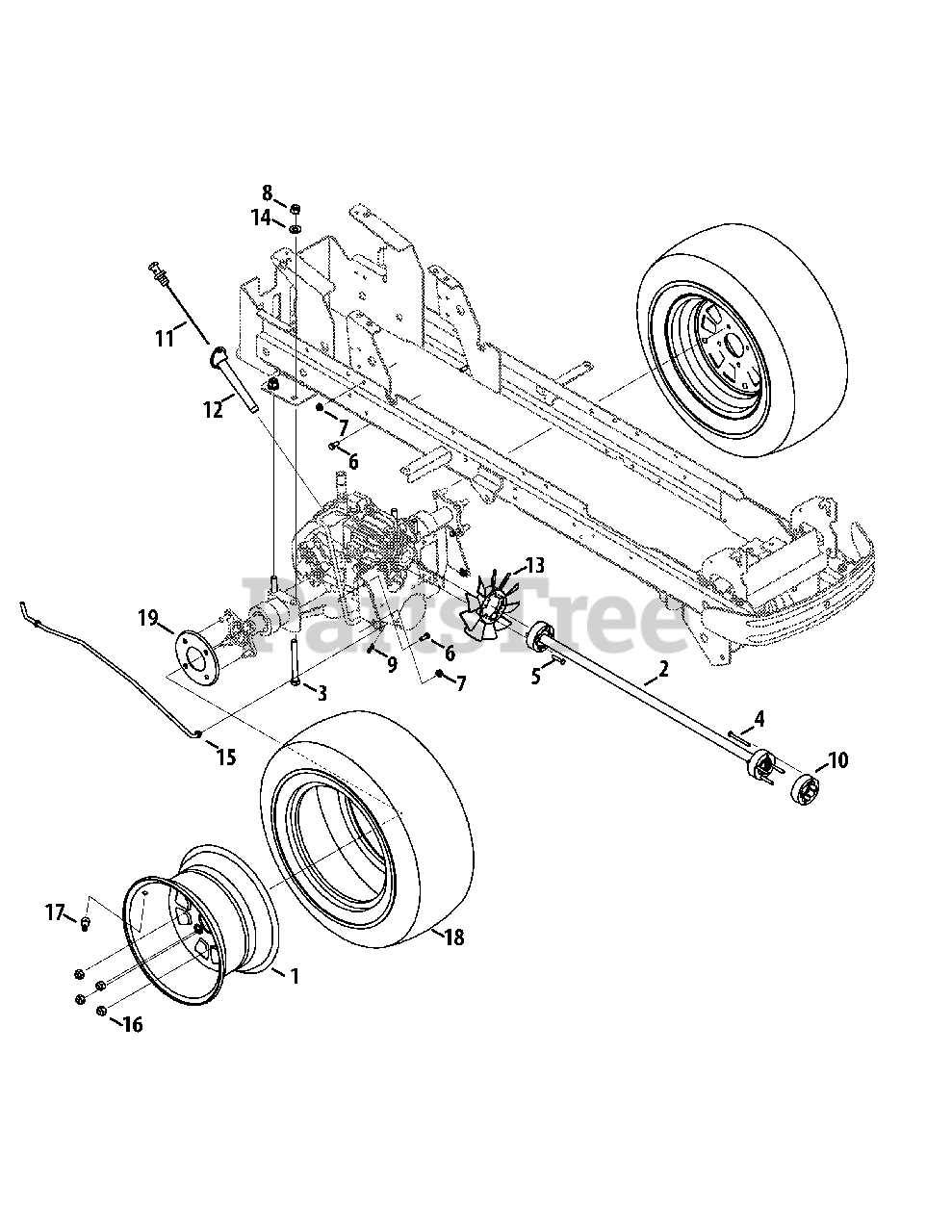

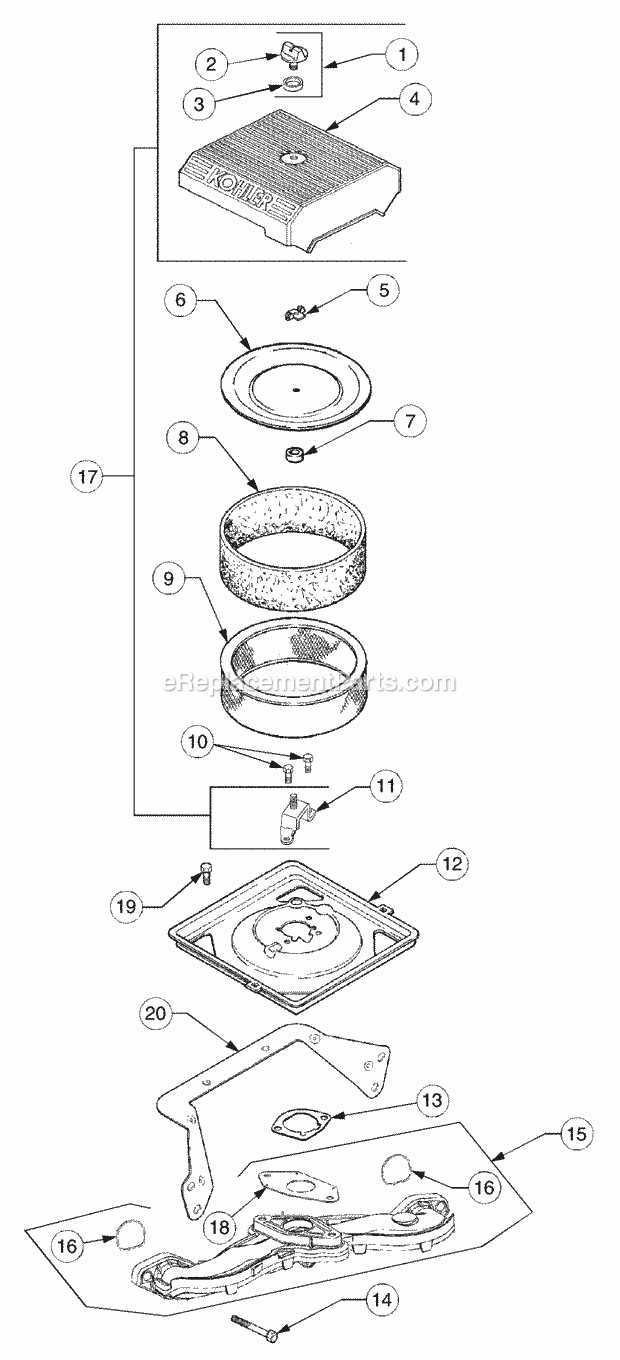

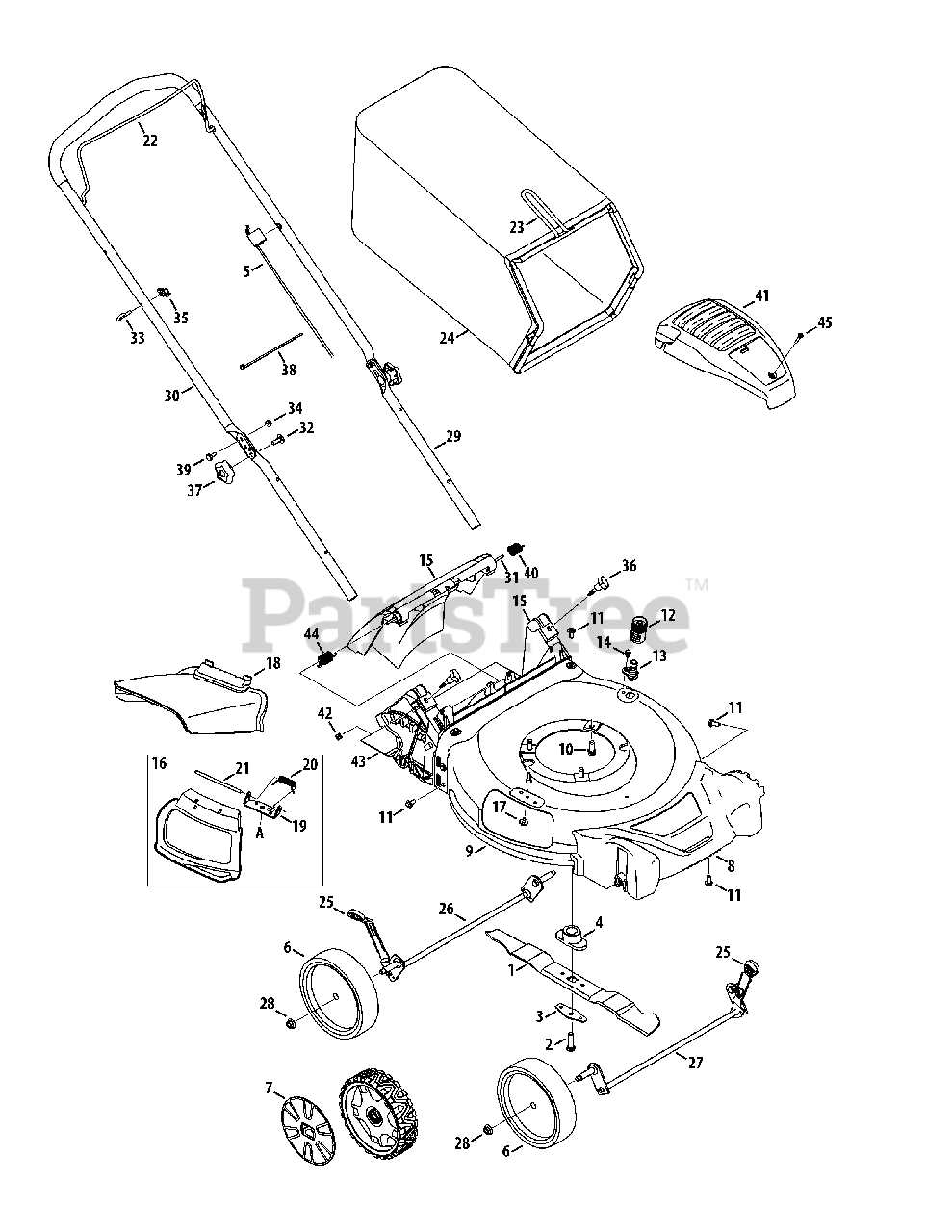

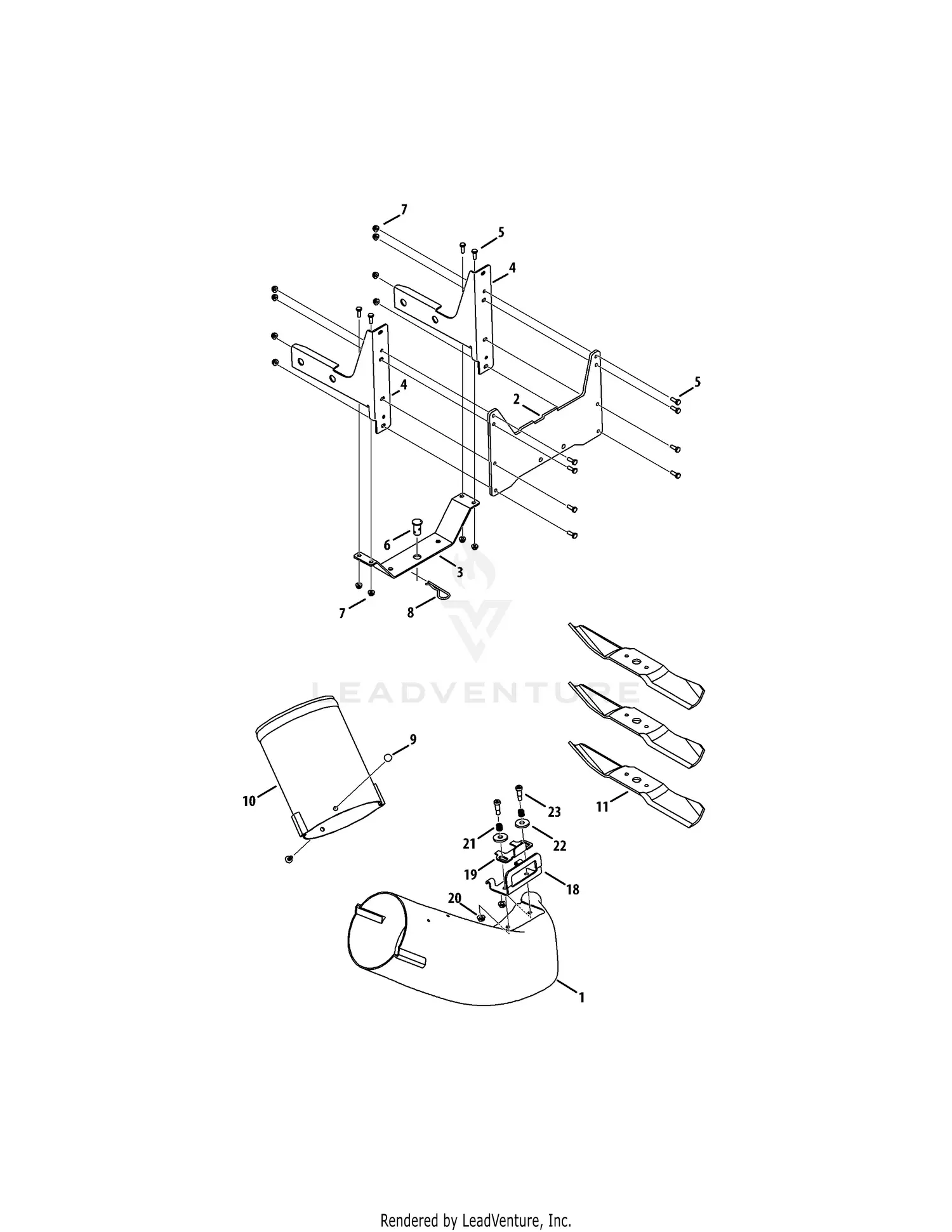

Understanding the Parts Diagram

Grasping the intricacies of an assembly illustration is essential for effective maintenance and repair. Such visual aids serve as valuable references for identifying components, understanding their functions, and ensuring proper reassembly.

Key elements to consider when studying an assembly illustration include:

- Labels: Each section often includes identifiers that make locating parts straightforward.

- Connections: Understanding how components interconnect is vital for troubleshooting issues.

- Assembly Order: Following the sequence outlined can prevent mistakes during reassembly.

By thoroughly examining these visuals, users can enhance their knowledge and skills, ultimately leading to more efficient upkeep of their machinery.

Key Components of the Series 2000

The machinery in question features several essential elements that contribute to its performance and reliability. Understanding these components is crucial for maintenance and optimization. Each part plays a significant role in ensuring efficient operation and longevity.

Core Elements

- Engine: The heart of the system, providing the necessary power for various tasks.

- Transmission: This component facilitates smooth power delivery and speed adjustments.

- Chassis: The foundational structure that supports all other components and ensures stability.

Supporting Features

- Fuel System: Responsible for storing and supplying fuel to the engine for combustion.

- Electrical System: Powers essential functions, including starting and lighting.

- Hydraulic System: Enables the operation of attachments and implements, enhancing versatility.

Each of these components must be regularly inspected and maintained to ensure optimal functionality and to prevent potential issues that could disrupt operations.

How to Read the Diagram

Understanding a schematic representation of components can significantly enhance your ability to identify and replace specific elements within a machine. These illustrations provide a visual roadmap, detailing each part’s location and function, which is essential for effective maintenance and repairs.

Key Elements to Identify

When examining the visual guide, pay attention to the following components:

| Element | Description |

|---|---|

| Symbols | Represent different components, such as bolts, engines, and belts. |

| Numbers | Indicate the specific part identifiers for ordering replacements. |

| Lines | Show connections and pathways between various components. |

Tips for Effective Interpretation

To maximize your understanding, start by familiarizing yourself with the legend, which explains the symbols used. Then, trace the connections to see how components interact, enabling you to delve deeper into the assembly’s ultimate functionality.

Common Issues with Parts

When dealing with outdoor equipment, various complications can arise concerning components that affect performance and longevity. Understanding these frequent challenges can help users maintain their machines effectively and ensure optimal functionality.

Wear and Tear

One of the most prevalent issues involves the gradual deterioration of components due to regular usage. Friction and environmental exposure can lead to decreased efficiency, requiring timely replacements to avoid further damage.

Compatibility Problems

Another common concern is the mismatch of components, which can stem from using aftermarket options that do not fit properly. Ensuring that all replacements are compatible is crucial for maintaining the integrity and performance of the equipment.

Replacing Worn Components Effectively

Maintaining equipment performance is crucial for longevity and efficiency. When components wear out, timely replacement can prevent further damage and ensure optimal functionality. This section focuses on best practices for identifying and replacing these essential elements in your machinery.

Identifying Worn Components

Recognizing signs of wear is the first step in effective replacement. Here are some common indicators:

- Unusual noises during operation

- Reduced efficiency or performance

- Visible damage or corrosion

- Excessive vibrations

Regular inspections and maintenance routines can help catch these issues early, minimizing downtime.

Steps for Effective Replacement

Once worn components are identified, follow these steps for a successful replacement:

- Gather the necessary tools and replacement parts.

- Refer to the equipment manual for specific instructions on disassembly.

- Carefully remove the old component, taking note of its orientation and connection points.

- Install the new part, ensuring it fits securely and aligns properly.

- Test the equipment to confirm that the replacement has resolved the issue.

By adhering to these practices, you can effectively maintain your equipment’s performance and extend its lifespan.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and performance of your equipment. By following a few simple practices, you can extend the lifespan and maintain optimal functionality.

- Clean the machine regularly to prevent buildup of debris and dirt.

- Check and change fluids according to the manufacturer’s schedule.

- Inspect belts and hoses for wear and replace them as needed.

- Sharpen blades periodically to ensure efficient cutting performance.

- Store the equipment in a dry, sheltered location to protect it from the elements.

Implementing these strategies will help you get the most out of your investment and minimize potential issues down the line.

Identifying Genuine Parts

When it comes to maintaining outdoor equipment, distinguishing authentic components from imitations is crucial for optimal performance and longevity. Using genuine components ensures compatibility and reliability, enhancing the overall functionality of your machine.

Here are some key indicators to help you identify authentic components:

- Branding: Check for official logos and trademarks that signify originality.

- Quality: Examine the material and craftsmanship; genuine items often exhibit superior build quality.

- Packaging: Authentic components typically come in branded packaging, with clear labeling.

- Supplier Verification: Purchase from authorized dealers or official websites to ensure you receive the real deal.

By following these guidelines, you can ensure that your equipment remains in peak condition, ultimately prolonging its lifespan.

Tools Required for Repairs

When undertaking maintenance or repair tasks on outdoor equipment, having the right tools is crucial for efficiency and effectiveness. This section outlines the essential instruments needed to ensure that repairs are completed smoothly and accurately.

Before starting any repair work, it’s important to gather the following tools:

- Wrenches: A set of adjustable wrenches is vital for loosening and tightening nuts and bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for various fastening tasks.

- Socket Set: A comprehensive socket set allows for quick removal and installation of hardware.

- Pliers: Needle-nose and standard pliers are useful for gripping and manipulating small parts.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications.

- Multimeter: For electrical repairs, a multimeter is essential for diagnosing issues.

In addition to these basic tools, consider including specialized equipment such as:

- Oil Filter Wrench: Helpful for removing and replacing oil filters.

- Grease Gun: Essential for lubrication of moving parts.

- Fuel Line Wrench: Useful for working on fuel systems.

Equipping yourself with these tools will significantly streamline the repair process and enhance the longevity of your equipment.

Where to Purchase Replacement Parts

Finding high-quality components for your equipment can enhance its longevity and performance. Various sources offer a wide range of options, ensuring you can restore functionality efficiently and effectively.

Online Retailers

Numerous online platforms specialize in machinery components, providing detailed catalogs and customer reviews. These websites often feature competitive pricing and the convenience of home delivery.

Local Dealers and Repair Shops

Your nearby dealerships and service centers can be invaluable for sourcing original components. They often have knowledgeable staff who can assist in identifying the correct pieces for your specific needs.

Expert Recommendations for Owners

Maintaining a lawn care machine is essential for optimal performance and longevity. Here are some expert tips to ensure your equipment remains in top shape and provides excellent results throughout its usage.

- Regular Maintenance: Schedule routine inspections to identify any wear and tear. Change the oil, replace filters, and sharpen blades as needed.

- Use Quality Fuel: Always utilize high-grade fuel to enhance engine performance and prevent issues related to fuel quality.

- Keep it Clean: After each use, clean the exterior and undercarriage to prevent rust and debris buildup, which can hinder functionality.

- Store Properly: When not in use, store your machine in a dry, sheltered location to protect it from harsh weather conditions.

Following these guidelines can help maximize the efficiency of your equipment and prolong its lifespan.

- Check Tire Pressure: Ensure that tires are properly inflated for optimal traction and handling.

- Inspect Cables and Belts: Regularly check for fraying or damage to cables and belts, replacing them when necessary.

- Consult the Manual: Refer to the owner’s manual for specific maintenance schedules and troubleshooting tips tailored to your model.

Implementing these practices will not only improve performance but also enhance safety during operation.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components and accessories for outdoor equipment, providing clarity and guidance for users seeking assistance.

What should I do if a component is damaged? It’s essential to assess the damage first. If it’s minor, repairs may be possible; however, if it’s severely compromised, replacement might be the best option.

Where can I find high-quality replacements? Look for authorized dealers or reputable online retailers specializing in outdoor machinery to ensure you receive reliable and durable options.

How can I identify the right component for my model? Refer to the user manual or manufacturer specifications to find the correct identification number, which simplifies the search for the appropriate item.

Is it necessary to use original equipment for replacements? While original parts are designed for optimal performance, aftermarket options can be suitable as long as they meet quality standards.

What is the typical lead time for ordering components? Lead times can vary based on availability and supplier efficiency, so it’s best to check with the vendor for estimated delivery times.