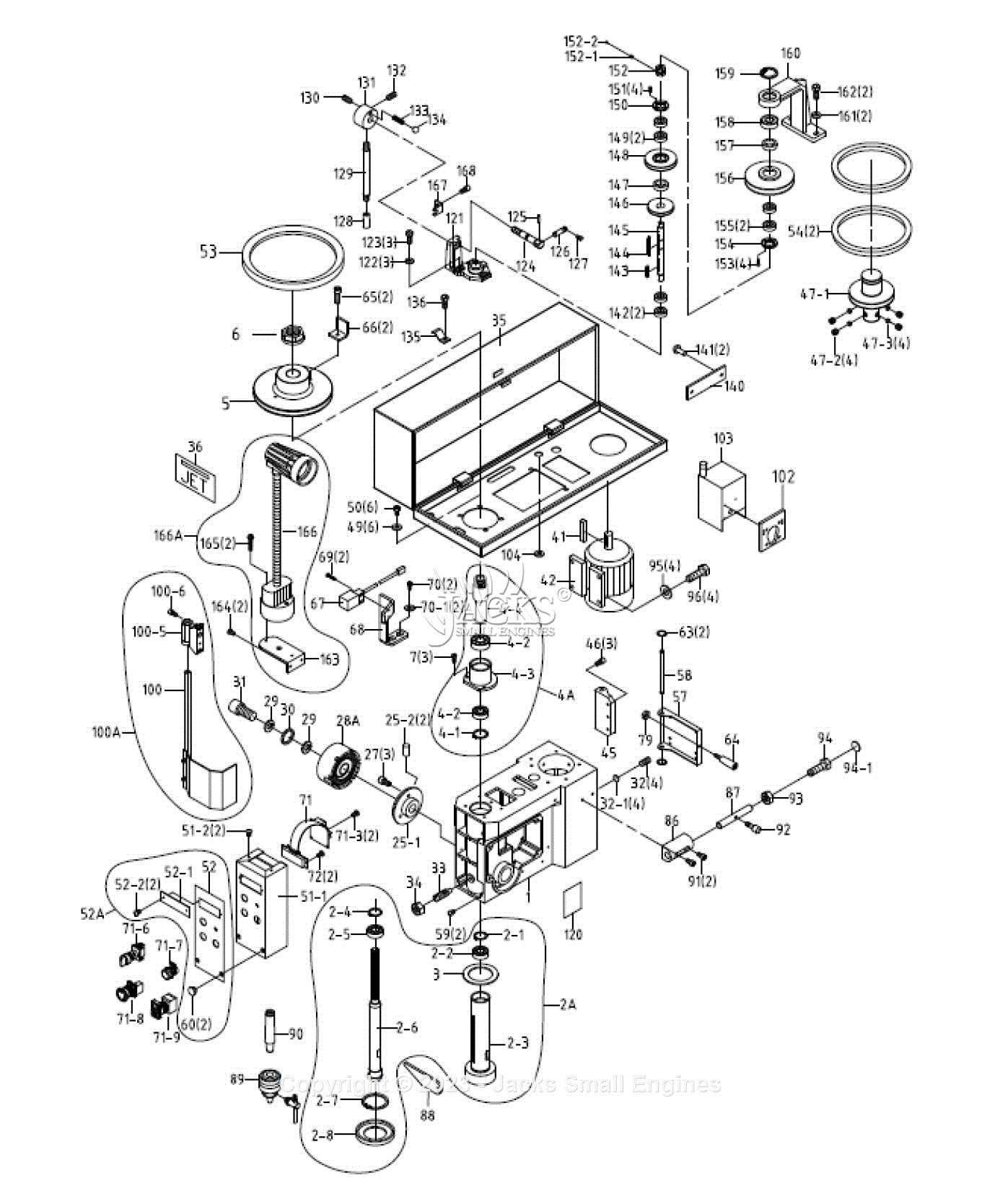

Delta 600 Series Parts Diagram

The layout of various components within machinery plays a crucial role in ensuring optimal functionality and performance. A well-structured visual representation can significantly aid in identifying and understanding the relationships between different elements. Such illustrations serve as valuable resources for both seasoned professionals and newcomers alike.

By exploring the intricate connections between components, users can gain insights into the operational mechanics of their equipment. This knowledge enhances maintenance efforts and fosters a deeper appreciation for the design and engineering behind these tools. Properly interpreting these layouts is essential for effective troubleshooting and repair processes.

In this section, we will delve into the essential aspects of component arrangements, offering a comprehensive guide that highlights key elements and their roles within the system. Understanding these configurations empowers users to engage more effectively with their machinery, ultimately leading to improved efficiency and longevity.

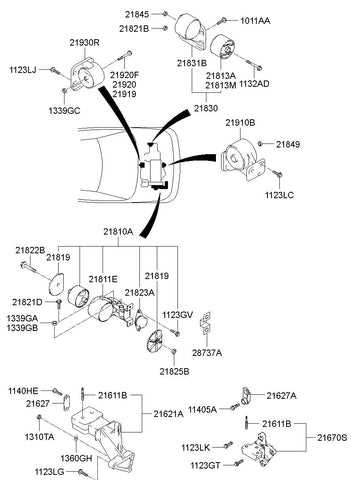

Key Components of the Delta 600

Understanding the essential elements of this model is crucial for effective operation and maintenance. Each component plays a vital role in the overall functionality, contributing to performance and reliability.

- Power Unit: Provides the necessary energy for operation, ensuring optimal performance.

- Control Panel: Enables users to adjust settings and monitor performance easily.

- Framework: The sturdy structure supports all other components, ensuring stability and durability.

- Drive Mechanism: Facilitates movement and operation of the system, crucial for achieving desired results.

- Safety Features: Incorporates mechanisms to prevent accidents and enhance user protection.

Familiarity with these core components allows for better troubleshooting and maintenance practices, ultimately enhancing the user experience.

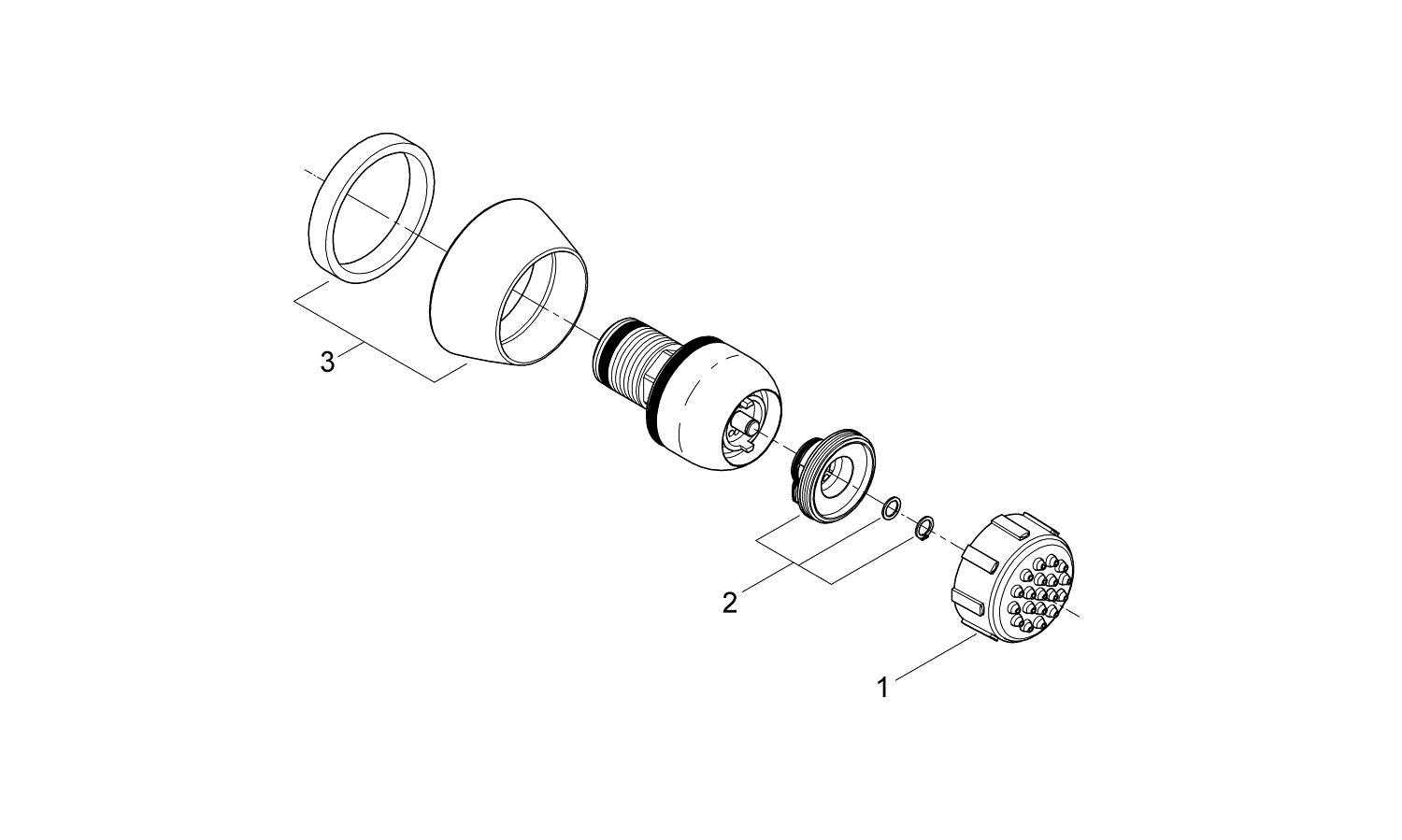

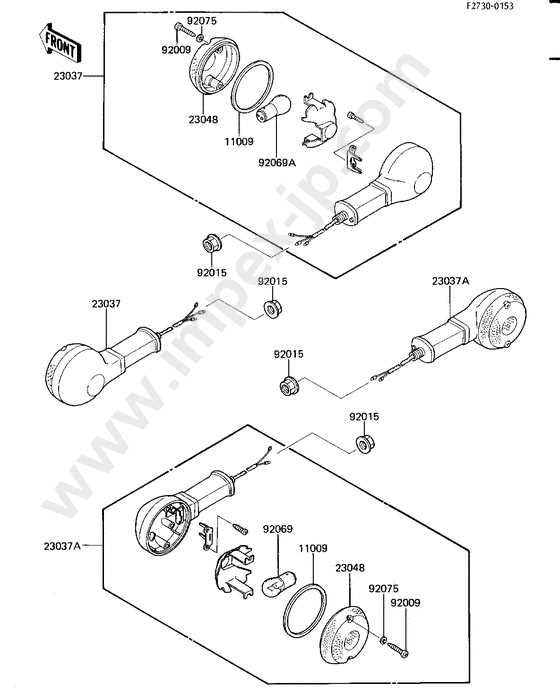

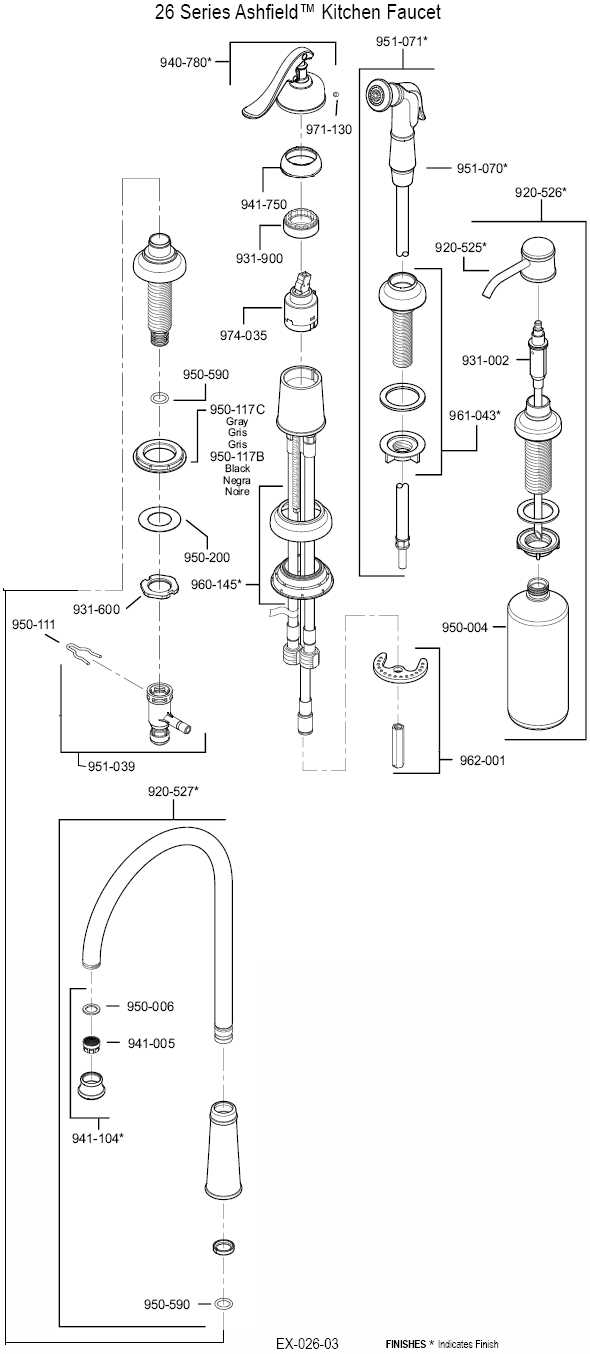

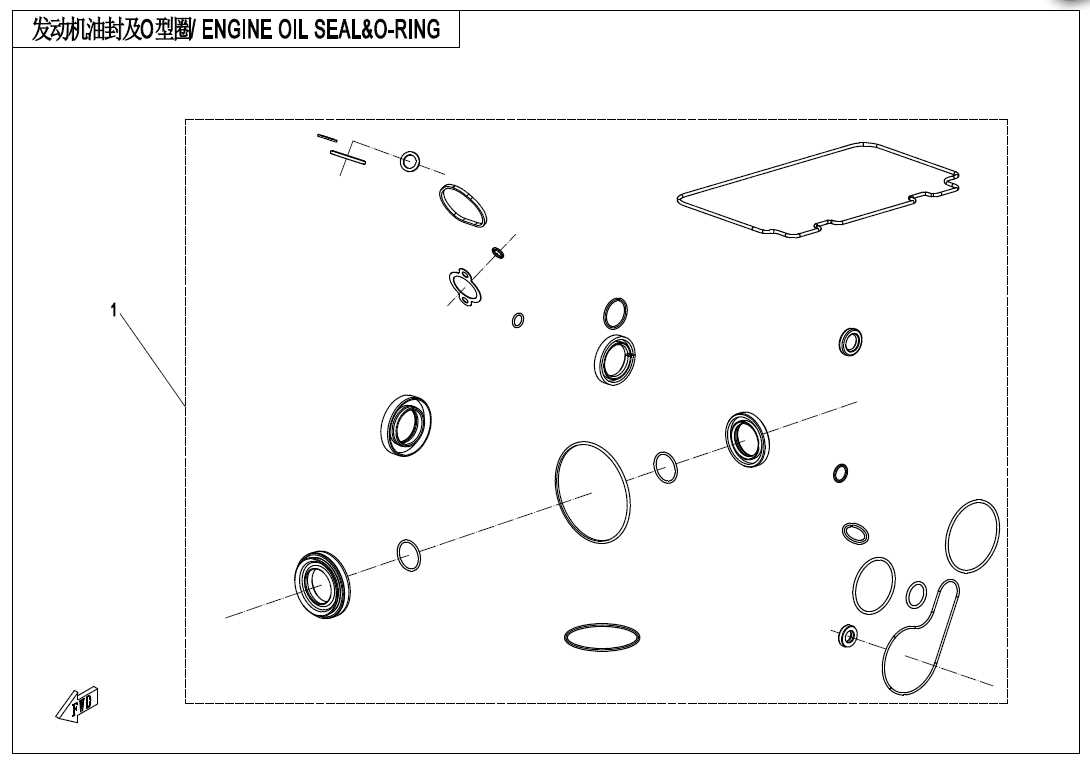

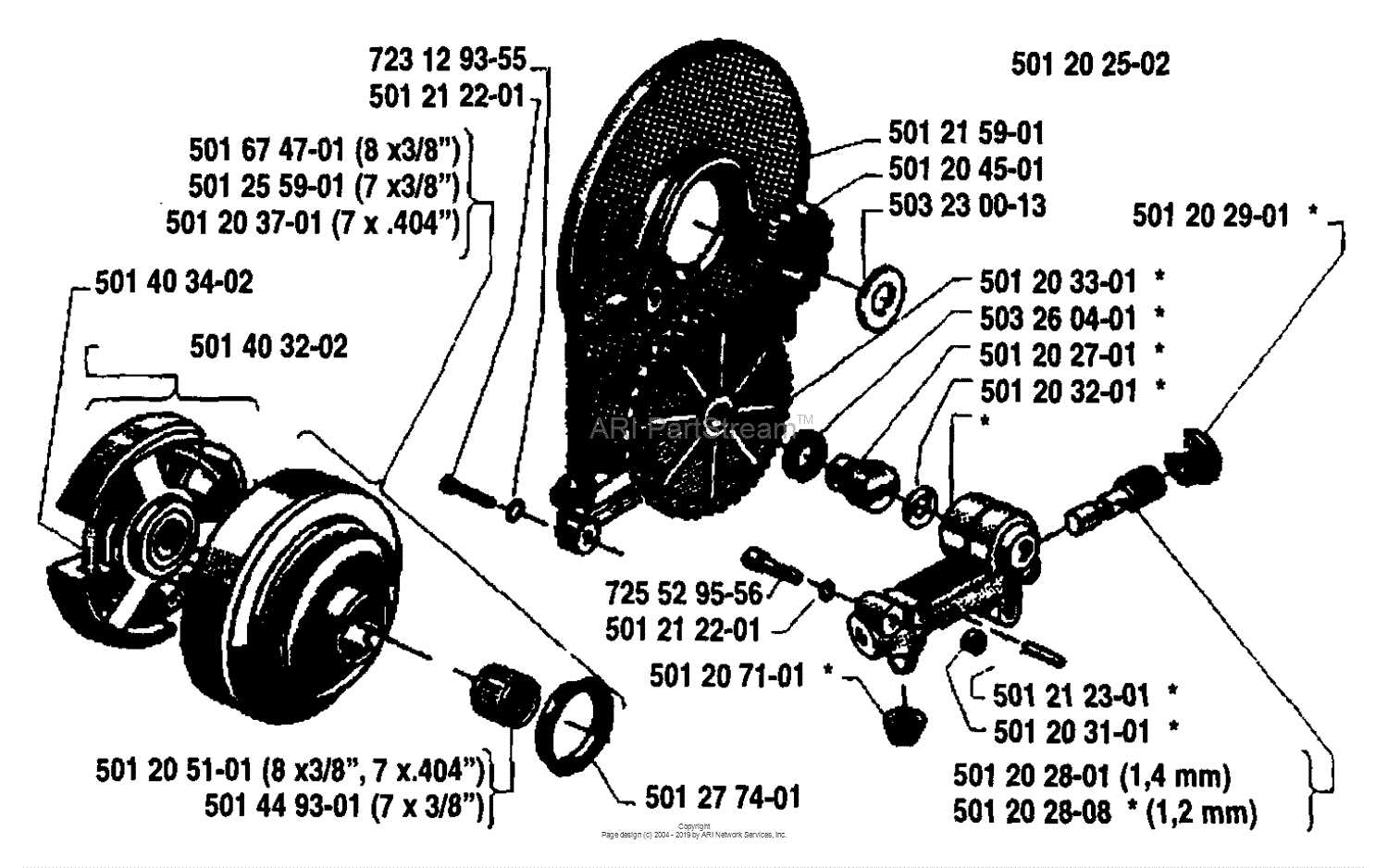

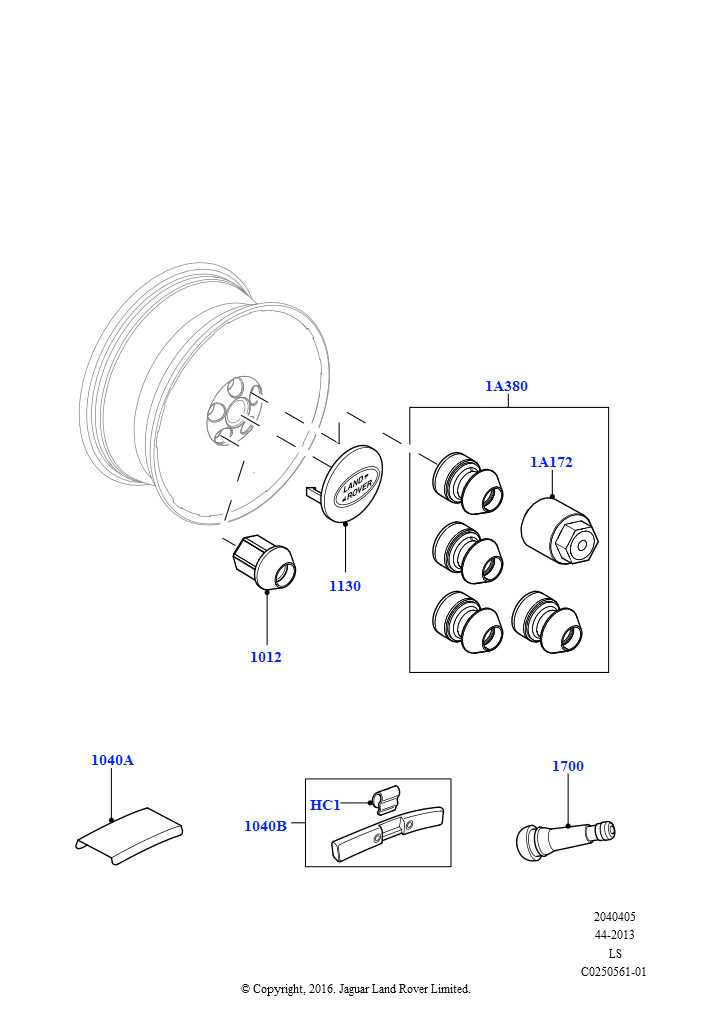

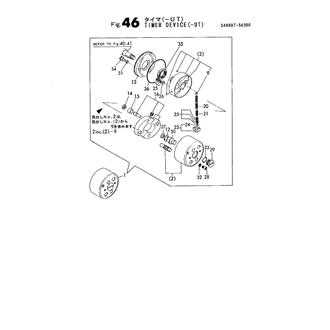

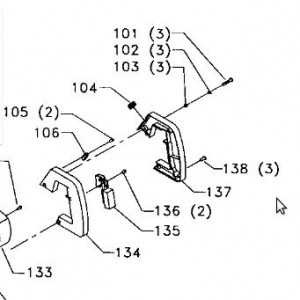

Understanding the Parts Diagram

Grasping the layout of a component schematic is essential for effective maintenance and repair of equipment. This visual representation offers a clear overview of each element’s location and function, making it easier to identify and address issues as they arise.

By familiarizing yourself with the key features of this schematic, you can enhance your troubleshooting skills. Here are some important aspects to consider:

- Component Labels: Each part is usually marked with specific identifiers, allowing for quick reference.

- Connections: Lines or arrows often indicate how different elements interact, which is crucial for understanding workflows.

- Grouping: Related components may be clustered together, helping to simplify the repair process.

- Scale and Proportion: Understanding the size relationship between elements can assist in the physical assembly and disassembly.

Utilizing this schematic effectively can lead to improved efficiency and reduced downtime when working with your equipment.

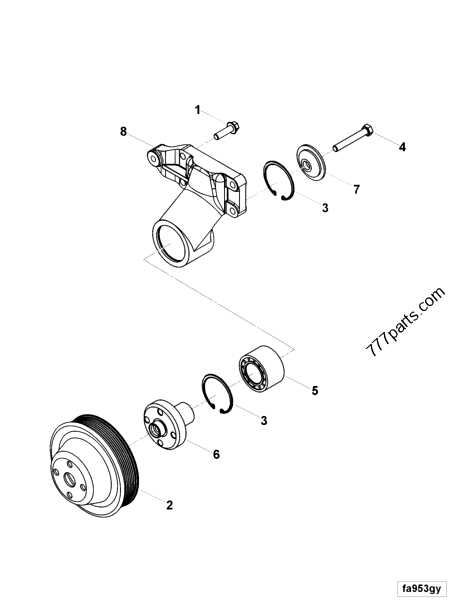

Functionality of Major Parts

This section explores the essential roles played by key components within a specific mechanical system. Understanding how these elements operate can enhance efficiency and facilitate effective maintenance.

- Core Unit: This is the heart of the mechanism, responsible for driving the entire operation. Its performance directly affects the overall effectiveness of the system.

- Control Mechanism: This component allows for user interaction, enabling adjustments and fine-tuning according to specific needs.

- Power Supply: Essential for providing the necessary energy to the entire setup, this unit ensures optimal functionality.

- Support Structure: Serving as the framework, it stabilizes all other components and absorbs operational stresses, enhancing durability.

- Output Module: This part is crucial for delivering the results of the system’s operations, ensuring they meet required standards.

Each of these components plays a vital role in the effective functioning of the whole assembly, contributing to its reliability and performance.

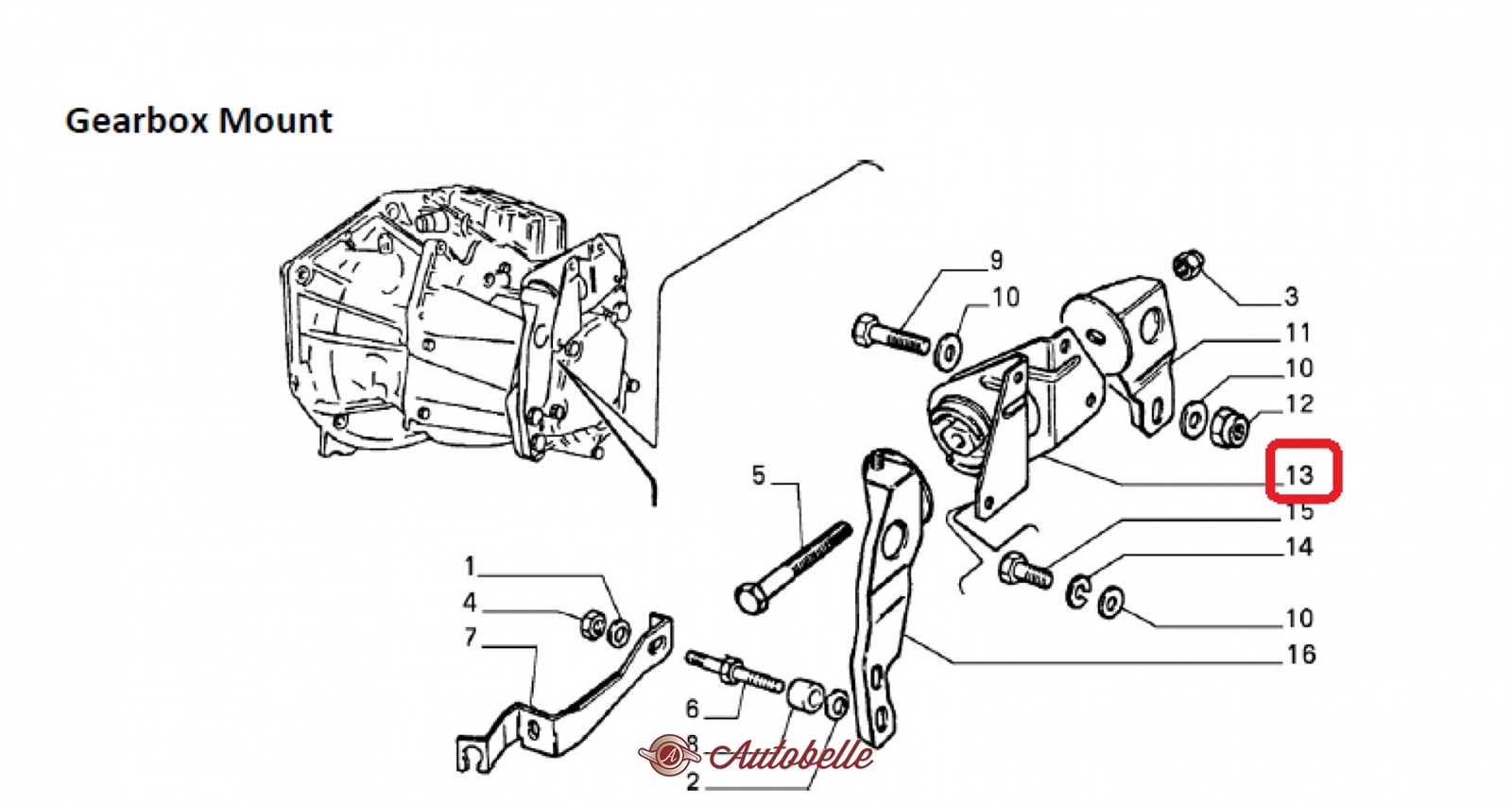

Assembly Instructions for Components

This section provides essential guidelines for assembling various elements of a mechanical system. Proper assembly ensures optimal functionality and longevity of the components.

Preparation Steps

- Gather all necessary tools and materials.

- Review the component specifications and assembly sequence.

- Ensure a clean and organized workspace.

Assembly Process

- Begin by connecting the main body parts according to the outlined sequence.

- Secure joints using appropriate fasteners, ensuring a tight fit.

- Attach auxiliary components, following the manufacturer’s instructions for orientation.

- Perform a final inspection to verify that all parts are properly secured.

Troubleshooting Common Issues

When working with machinery, encountering problems is not uncommon. Understanding typical challenges and their solutions can significantly enhance efficiency and longevity. This section aims to provide insights into frequent malfunctions and how to address them effectively.

Identifying Common Problems

Recognizing issues early can save time and resources. Here are some prevalent symptoms:

- Unusual noises during operation

- Inconsistent performance

- Visible wear on components

- Difficulty in startup

Suggested Solutions

Addressing these issues can often be straightforward. Consider the following steps:

- Inspect all moving parts for obstructions or damage.

- Ensure proper lubrication is applied to all necessary components.

- Check electrical connections for any signs of wear or disconnection.

- Consult the maintenance manual for detailed guidance on specific components.

Replacement Parts Availability

When it comes to ensuring the longevity and functionality of your equipment, access to suitable components is crucial. Various manufacturers offer a range of options for those looking to replace essential elements, making maintenance and repairs straightforward.

Availability can vary based on location and distributor, so it’s wise to explore both online and local sources. Many retailers provide a selection of these items, ensuring that you can find what you need to keep your device running smoothly.

Additionally, some specialized stores may offer exclusive replacements that are not easily found elsewhere, allowing for more customized solutions. Always check for compatibility with your model before making a purchase, as this ensures optimal performance and fit.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires consistent upkeep and attention. Regular maintenance not only enhances performance but also extends the lifespan of your machinery.

Regular Cleaning

Keeping your device clean is essential for optimal operation. Dust and debris can lead to malfunctions over time. Consider the following steps:

- Wipe down surfaces with a soft cloth.

- Use compressed air to remove particles from hard-to-reach areas.

- Check filters and replace them as necessary.

Periodic Inspections

Routine checks can help identify potential issues before they escalate. Follow these guidelines:

- Inspect for signs of wear and tear.

- Ensure all components are securely fastened.

- Test functionality regularly to catch problems early.

Safety Precautions During Use

Ensuring a safe working environment is essential when handling machinery and equipment. Adhering to proper safety protocols helps prevent accidents and promotes efficient operation.

Before starting any task, users should familiarize themselves with the necessary guidelines and recommendations to mitigate risks. This includes wearing appropriate personal protective equipment and maintaining a tidy workspace.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Always wear gloves, goggles, and ear protection as needed. |

| Work Area Maintenance | Keep the workspace free of clutter and obstructions. |

| Machine Inspection | Regularly check equipment for wear and tear before use. |

| Emergency Procedures | Know the location of emergency shut-offs and first aid kits. |

Comparison with Other Delta Models

When examining various models from the same manufacturer, it becomes clear that each iteration brings unique features and enhancements. This discussion focuses on the distinctions and similarities found among different offerings, emphasizing their functional aspects and user experience.

Key points of comparison include:

- Design Variations: Different models may showcase distinct designs tailored for specific applications.

- Performance Metrics: Variability in power output and efficiency can significantly impact usability.

- Technological Advancements: Newer models often integrate modern technology, improving overall functionality.

- Accessory Compatibility: Examining which accessories are interchangeable can aid in choosing the right equipment.

By analyzing these aspects, users can make informed decisions based on their specific needs and preferences. Ultimately, understanding the nuances among these variations enhances the selection process.

User Reviews and Feedback

This section explores the impressions and opinions shared by users regarding the components and their functionality. Gathering insights from real experiences helps potential buyers make informed decisions and understand the reliability of the items in question.

Many individuals have highlighted various aspects of their encounters:

- Quality: Users frequently mention the durability and performance of the items, noting how well they withstand regular use.

- Installation: Feedback often points to the ease of assembly, with many appreciating clear instructions that facilitate the setup process.

- Value for Money: Reviews commonly address the affordability of these components compared to alternatives, emphasizing the good balance between cost and quality.

- Customer Support: Several users commend the responsive assistance provided, particularly when issues arise or guidance is needed.

Overall, user feedback provides a valuable perspective, revealing strengths and potential areas for improvement that may influence future purchasers.

Resources for Further Information

For those seeking to expand their knowledge and understanding of the topic, numerous resources are available that offer detailed insights and assistance. These materials can guide users in their quest for information, ensuring they have access to reliable data and support.

Online Platforms

Several websites provide comprehensive information related to the subject. These platforms often include user forums, instructional videos, and downloadable manuals that can enhance one’s grasp of the material.

Print and Digital Publications

Books and magazines dedicated to the field are excellent resources. They frequently feature expert advice, troubleshooting tips, and technical specifications that are beneficial for both novices and experienced individuals.

| Resource Type | Examples |

|---|---|

| Websites | Forums, manufacturer sites, educational platforms |

| Books | Technical manuals, instructional guides |

| Videos | Tutorials, webinars, demonstrations |