Understanding the Diagram of Sewing Machine Parts

The intricate world of textile machinery offers a wealth of knowledge for enthusiasts and professionals alike. Delving into the various components that contribute to the functionality of these tools reveals not only their importance but also the craftsmanship involved in their design. Mastering this understanding can enhance both efficiency and creativity in various fabric projects.

Each element plays a specific role, working harmoniously to facilitate the process of creating garments and other fabric-based items. Gaining familiarity with these essential components allows users to troubleshoot issues effectively and perform maintenance, ensuring longevity and reliability in their craft.

In this exploration, we will present a comprehensive overview of the key elements, detailing their functions and significance. By familiarizing oneself with these intricacies, crafters can elevate their skills and navigate their creative journeys with confidence and ease.

Sewing Machine Anatomy Explained

Understanding the inner workings of a textile device can significantly enhance your crafting experience. By familiarizing yourself with its structure, you can troubleshoot issues, maintain it properly, and fully utilize its capabilities. Each component plays a crucial role in the overall functionality, making knowledge of them invaluable.

| Component | Description |

|---|---|

| Needle | Essential for piercing fabric and creating stitches. |

| Bobbin | Holds the lower thread, working in tandem with the needle. |

| Foot | Guides the fabric and helps in even feeding during stitching. |

| Tension Dial | Adjusts the thread tightness for optimal stitching results. |

| Feed Dogs | Move the fabric forward as you sew, ensuring consistent progress. |

Understanding Basic Components

Every creation involves essential elements that work together harmoniously to achieve the desired outcome. Familiarizing oneself with these fundamental elements enhances overall functionality and user experience. Each component plays a specific role, contributing to the seamless operation of the entire system.

First and foremost, the core unit serves as the powerhouse, driving movement and ensuring precision. This is complemented by various attachments that enhance versatility, allowing for different tasks and techniques to be executed effortlessly.

Additionally, guiding mechanisms play a crucial role in directing materials through the process, ensuring accuracy and consistency. The control interface provides the user with options to customize settings, tailoring the experience to individual needs.

Understanding these foundational elements equips users with the knowledge to troubleshoot issues and optimize performance, ultimately leading to more satisfying results in their creative endeavors.

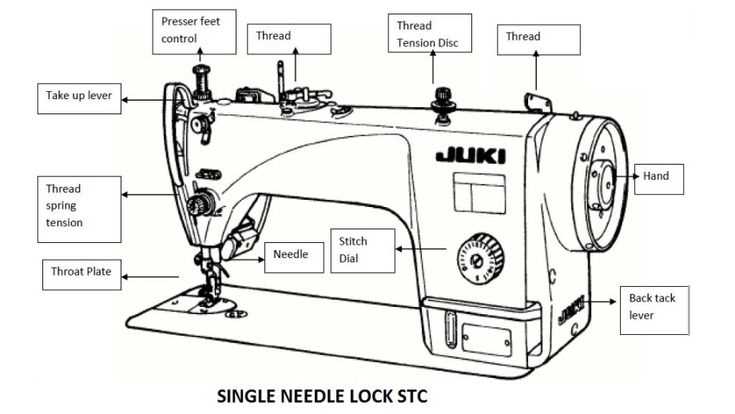

Functions of Each Part

Understanding the various components of a stitching device is essential for effective operation and maintenance. Each element plays a crucial role in ensuring smooth performance and achieving desired results in fabric manipulation.

- Needle: The primary tool for piercing fabric, it facilitates the interlocking of threads.

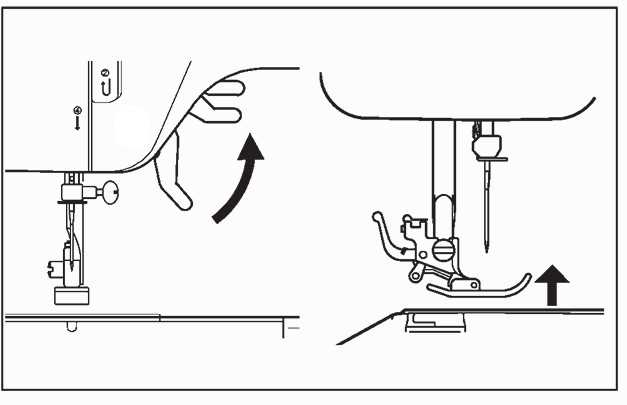

- Presser Foot: This component holds the fabric in place during the stitching process, providing stability and control.

- Feed Dogs: Located beneath the fabric, these assist in moving the material forward as the stitching occurs.

- Bobbin: Holds the lower thread, which works in conjunction with the upper thread to create stitches.

- Throat Plate: Supports the fabric and guides it under the needle while protecting internal mechanisms.

Each of these components interacts harmoniously, allowing for a wide range of techniques and finishes. Recognizing their functions enhances the overall experience and effectiveness of textile projects.

- Understanding each function allows for better troubleshooting and repairs.

- Familiarity with components enhances creativity and efficiency in crafting.

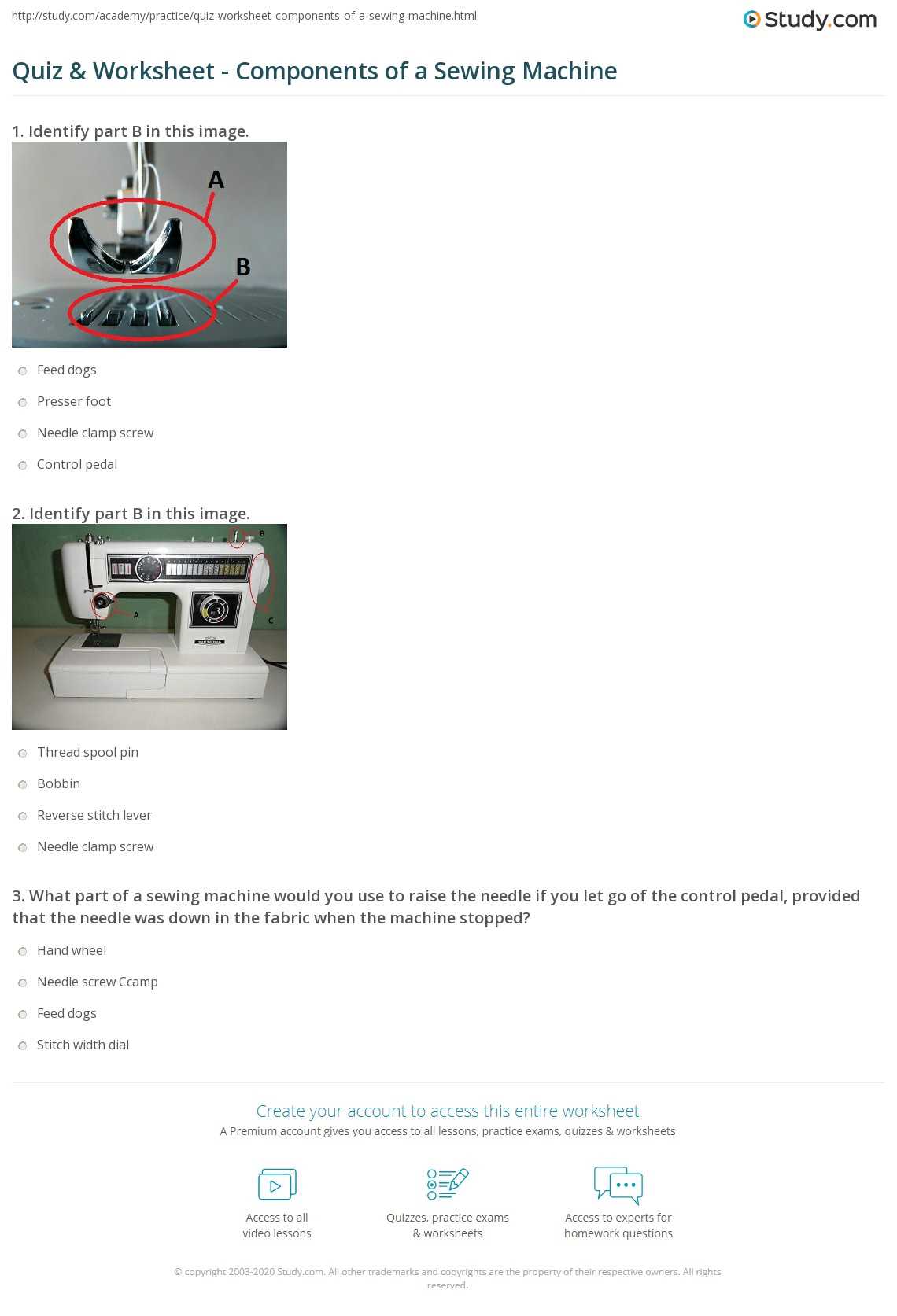

Common Issues with Machine Parts

Understanding the frequent challenges encountered with various components is essential for maintaining optimal functionality. These issues can arise from wear and tear, improper usage, or inadequate maintenance practices.

1. Thread Bunching: This problem often occurs due to incorrect tension settings or tangled threads, leading to a frustrating experience.

2. Skipped Stitches: A common frustration, skipped stitches can be caused by a dull needle or incompatible fabric types, impacting the overall quality of the outcome.

3. Uneven Stitching: This issue may arise from a misaligned feed mechanism or improper threading, resulting in inconsistent seam quality.

4. Noise and Vibrations: Unusual sounds can indicate loose components or lack of lubrication, potentially affecting performance and longevity.

5. Overheating: Excessive heat often results from prolonged use or insufficient cooling mechanisms, leading to possible damage.

By recognizing these common issues, users can take proactive measures to ensure smooth operation and extend the life of their equipment.

Maintenance Tips for Longevity

To ensure optimal performance and extend the lifespan of your crafting tools, regular upkeep is essential. Implementing a few straightforward practices can prevent wear and tear, enhance functionality, and save costs on repairs or replacements. This section outlines key strategies to keep your equipment in top shape.

Regular Cleaning

Dust and debris can accumulate over time, hindering performance. Cleaning your apparatus frequently will help maintain its efficiency. Use a soft brush or cloth to remove lint and dirt from all accessible areas. For deeper cleaning, consult the manufacturer’s guidelines.

Proper Lubrication

Lubricating the moving components is crucial for smooth operation. Select the appropriate oil as specified in the user manual, and apply it sparingly to avoid excess buildup. Regular lubrication minimizes friction, reducing the risk of damage.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Cleaning | Weekly | Prevents buildup and improves efficiency |

| Lubrication | Monthly | Reduces friction and wear |

| Inspection | Quarterly | Identifies issues before they escalate |

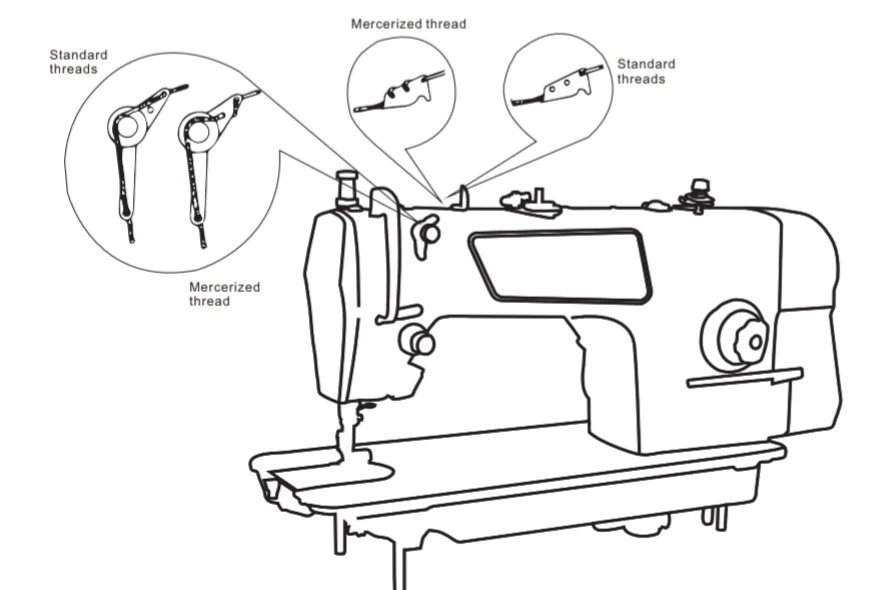

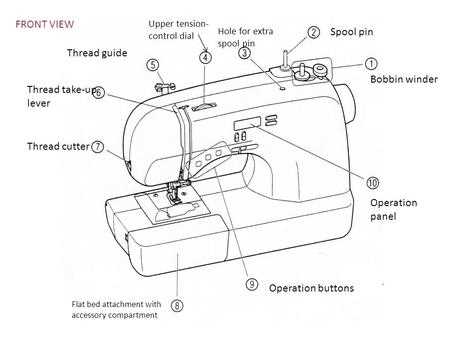

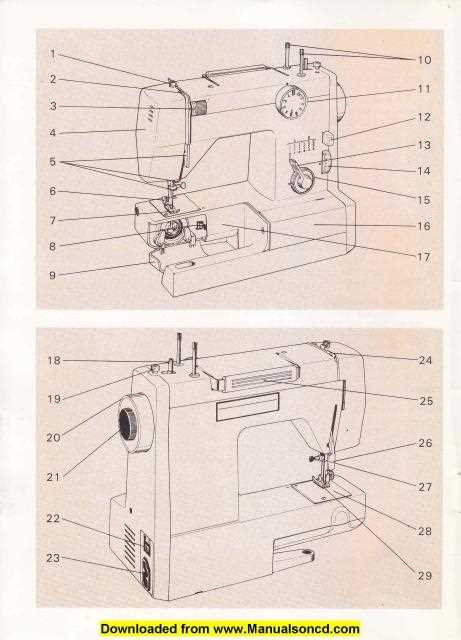

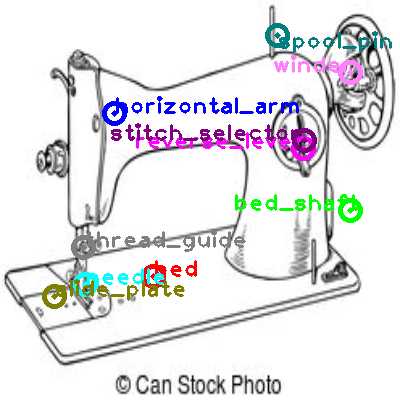

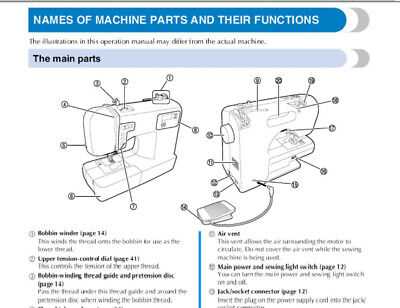

Identifying Parts on a Diagram

Understanding the components illustrated in a visual representation is crucial for effective utilization and maintenance. Each element plays a significant role, contributing to the overall function. Recognizing these features enhances your ability to troubleshoot and perform necessary adjustments.

Key Components

Start by focusing on the essential elements. Commonly identified features include the control mechanisms, structural supports, and feeding systems. Familiarity with these items can lead to more efficient handling and operation.

Practical Applications

Once you can distinguish between the different components, apply this knowledge to real-life scenarios. For instance, when encountering issues, knowing the exact location and function of each element enables targeted solutions. This ultimately leads to improved performance and longevity of the device.

Tools for Repairing Sewing Machines

When it comes to maintaining and restoring textile equipment, having the right instruments at your disposal is crucial. Whether you are a hobbyist or a professional, understanding the essential tools can greatly enhance your efficiency and accuracy during the repair process.

1. Screwdrivers: These are fundamental for loosening or tightening various screws that hold components together. A set of both flat-head and Phillips screwdrivers will cover most needs.

2. Pliers: A good pair of pliers can assist in gripping and manipulating small elements, making it easier to handle intricate components.

3. Tweezers: Precision tweezers are invaluable for working with tiny parts, especially in tight spaces where larger tools can’t reach.

4. Seam Ripper: This handy tool allows you to carefully undo stitches without damaging the fabric, which is essential for correcting mistakes or replacing worn areas.

5. Oil and Lubricants: Regular maintenance requires appropriate lubricants to keep moving parts functioning smoothly. Always use products specifically designed for textile equipment.

6. Cleaning Brushes: Dust and lint can accumulate quickly. A small brush can help you keep the interior and exterior clean, ensuring optimal performance.

7. Replacement Needles: Having a variety of needles on hand is essential, as different fabrics require different types for best results.

8. Measuring Tools: Accurate measurements are key in ensuring proper adjustments and fitting, so rulers or tape measures are essential for any repair task.

By equipping yourself with these tools, you can effectively troubleshoot and maintain your equipment, ensuring longevity and optimal performance.

Choosing the Right Machine Parts

Finding the appropriate components for your crafting equipment is essential for optimal performance and longevity. Various factors influence your decision-making process, ensuring you select items that enhance your experience.

- Compatibility: Ensure the selected elements are suitable for your specific model.

- Quality: Opt for high-grade materials to improve durability and efficiency.

- Brand Reputation: Consider well-known manufacturers for reliable options.

- Functionality: Identify the features you require for your projects.

By evaluating these aspects, you can delve into a world of choices and ultimately find the best components for your needs.

Upgrading Your Sewing Machine

Enhancing your crafting device can significantly elevate your projects. Whether you’re looking for improved performance, additional features, or modern technology, various options are available to tailor your equipment to your needs.

Benefits of Upgrading

- Increased efficiency in your projects.

- Access to advanced features for intricate designs.

- Improved durability and reliability.

Considerations Before Upgrading

- Assess your current usage and requirements.

- Research new technologies and features available.

- Set a budget that aligns with your goals.

Safety Precautions When Using Machines

Ensuring safety during the operation of various equipment is crucial to prevent accidents and injuries. Understanding proper protocols and maintaining vigilance can significantly reduce risks associated with their use. It is essential to adhere to specific guidelines to create a safe working environment.

Understanding Your Equipment

Before engaging with any device, familiarize yourself with its components and functions. Read the user manual thoroughly, paying attention to safety instructions. Knowing how to operate the equipment correctly not only enhances efficiency but also minimizes the likelihood of mishaps. Regular maintenance is equally important; ensure that all elements are in good condition and functioning properly.

Personal Protective Measures

Utilizing appropriate personal protective equipment (PPE) is vital when operating any machinery. This may include gloves, goggles, and protective footwear to safeguard against potential hazards. Stay alert and avoid distractions while working, as focus is key to maintaining safety. Furthermore, ensure that your workspace is clean and organized, reducing the risk of accidents caused by clutter.

Resources for Further Learning

Expanding your knowledge in the craft can significantly enhance your skills and creativity. Numerous resources are available that cater to various learning styles, from visual aids to in-depth tutorials.

- Online Courses: Platforms like Coursera and Udemy offer a variety of classes.

- YouTube Channels: Channels dedicated to crafting provide visual guidance and tips.

- Books: Consider titles that focus on techniques and innovative projects.

- Forums and Communities: Engage with others to share insights and experiences.

- Workshops: Local crafting stores often host hands-on sessions.

Utilizing these resources can lead to the ultimate improvement in your craft endeavors.