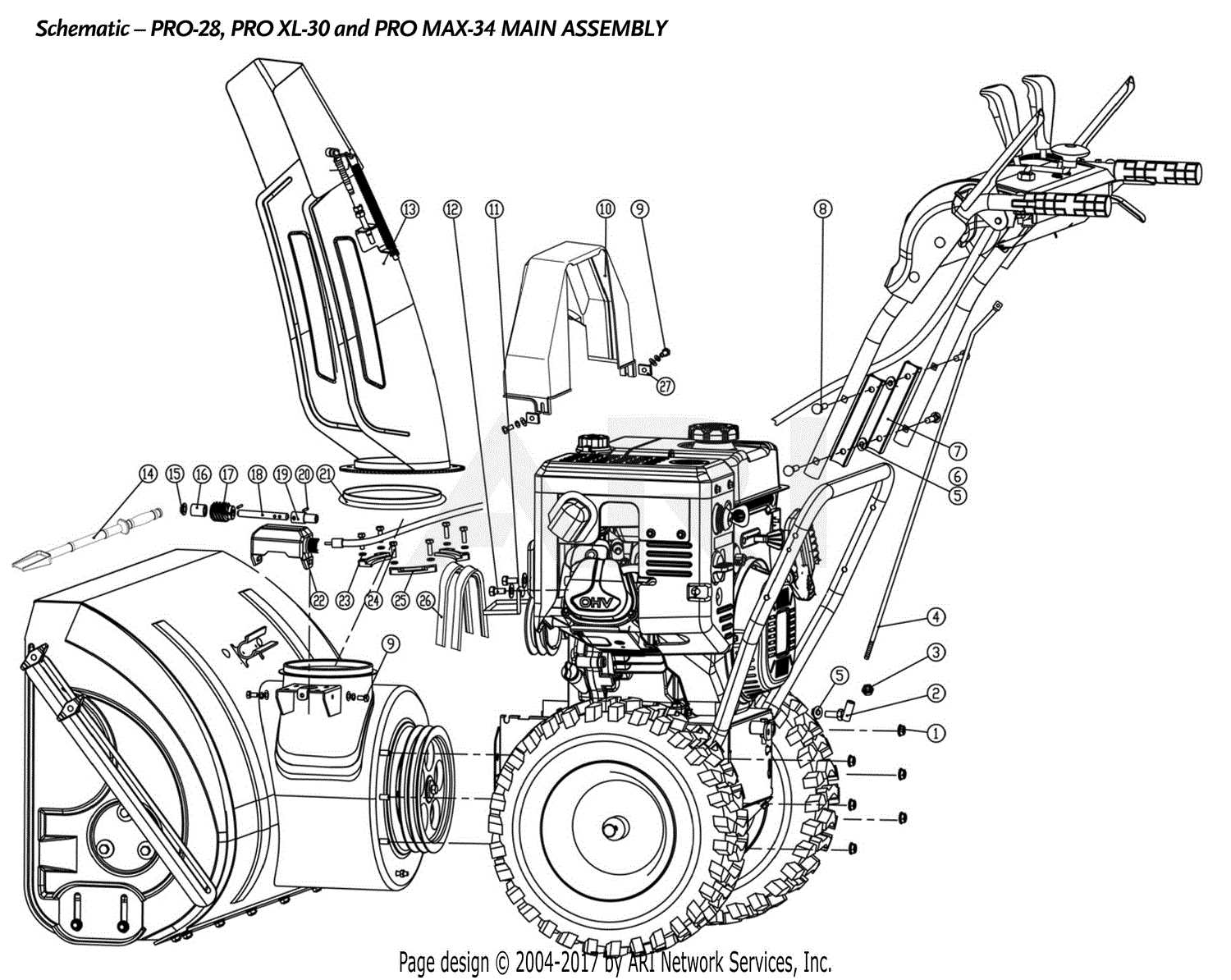

Power Smart Snow Blower Parts Diagram

When the chilly season arrives, having reliable machinery can make all the difference in maintaining your outdoor spaces. Familiarity with the individual components of your device not only enhances its functionality but also ensures proper maintenance and troubleshooting. In this section, we will delve into the intricate assembly that constitutes your winter maintenance equipment, providing insights that can aid in optimizing performance and longevity.

Every mechanism consists of various elements that work in unison to achieve efficient operation. Recognizing these elements, their functions, and how they interact can empower users to tackle repairs or upgrades confidently. This knowledge fosters a deeper understanding of how to keep your equipment operating smoothly, ensuring that you’re prepared to face even the harshest weather conditions with ease.

By exploring the layout of the individual components, users can pinpoint potential issues and implement effective solutions. Whether you are a seasoned user or a newcomer to winter maintenance tools, comprehending the structural layout can enhance your experience, making your outdoor endeavors more manageable and effective.

This section provides a comprehensive examination of the equipment designed for clearing wintry conditions. These machines are engineered to efficiently remove accumulated precipitation from various surfaces, ensuring safety and accessibility. Understanding their structure and components is essential for effective operation and maintenance.

Key Features and Benefits

- Effective clearing of various terrains, including driveways and sidewalks

- Enhanced user comfort with ergonomic designs

- Variety of models to cater to different needs and preferences

Types of Mechanisms

- Single-stage systems for light to moderate conditions

- Two-stage systems for heavier accumulation and tougher environments

- Electric and gas-powered options for diverse usage scenarios

Key Components of Snow Removal Machines

Effective winter maintenance equipment is composed of several critical elements that work in harmony to ensure efficient operation. Understanding these vital components can enhance performance and prolong the lifespan of the equipment. Each part plays a specific role in the functionality and efficiency of the overall system.

| Component | Description |

|---|---|

| Engine | The powerhouse that provides the necessary energy to operate the machine, typically a gas or electric motor. |

| Auger | A rotating blade mechanism that collects and moves the accumulated material toward the discharge chute. |

| Chassis | The framework that houses all components, providing stability and structural integrity during operation. |

| Drive System | A mechanism that propels the machine forward, enabling it to traverse various terrains and surfaces. |

| Discharge Chute | A directing feature that expels the cleared material away from the equipment, allowing for efficient operation. |

| Controls | User interfaces that allow for the regulation of speed, direction, and other operational functions. |

Understanding the Parts Diagram

Interpreting the visual representation of components is essential for maintaining and repairing your equipment. This graphical overview aids users in identifying various elements, their functions, and how they interact within the overall system. By familiarizing oneself with this representation, one can enhance the efficiency of operations and facilitate troubleshooting.

The visual schematic serves as a valuable reference tool, allowing individuals to:

- Locate specific components quickly.

- Understand the relationship between different elements.

- Identify potential issues that may arise during operation.

In addition, grasping the layout can empower users to perform basic repairs and maintenance tasks effectively. Here are some key aspects to consider:

- Component Labels: Each element is typically marked with a label indicating its name or function.

- Connection Points: The representation highlights where parts are connected, aiding in disassembly and reassembly.

- Part Numbers: Often, numerical identifiers are included, which can be useful when ordering replacements.

In conclusion, comprehending this graphical representation not only streamlines the repair process but also fosters a deeper understanding of the equipment’s functionality.

Common Issues with Snow Blower Parts

Understanding the frequent challenges associated with various components of outdoor winter equipment is essential for maintaining their efficiency and longevity. Identifying and addressing these common problems can significantly enhance performance and reduce the likelihood of breakdowns during critical usage periods.

Frequent Problems Encountered

- Wear and Tear: Components often face deterioration due to exposure to harsh weather conditions and heavy use.

- Fuel Issues: Contaminated or stale fuel can lead to engine performance problems, causing inefficient operation.

- Electrical Failures: Wiring issues and faulty connections can result in ignition difficulties or complete equipment failure.

- Mechanical Jams: Debris can get lodged in moving parts, hindering functionality and potentially causing damage.

Signs of Malfunction

- Unusual noises during operation can indicate underlying mechanical issues.

- Inconsistent performance or reduced power suggests possible fuel or engine problems.

- Visible wear on belts and other moving components can be a sign of imminent failure.

Regular inspections and maintenance can help in identifying these issues early, allowing for timely repairs and ensuring that the equipment operates smoothly throughout the winter season.

Maintenance Tips for Snow Equipment

Proper upkeep of your winter machinery is essential to ensure longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents potential issues that could arise during usage. Adopting a systematic approach to caring for your tools can significantly reduce wear and tear, making them reliable during harsh conditions.

Regular Inspections

Conducting frequent checks on your machinery helps identify any signs of wear or damage early on. Look for cracks, rust, or loose components that may need attention. A thorough assessment before each season can save time and money in repairs, ensuring that your equipment is ready for immediate use.

Cleaning and Lubrication

After each use, clean your tools to remove debris and ice buildup. This practice prevents corrosion and maintains functionality. Additionally, apply suitable lubricants to moving parts to minimize friction and enhance performance. Regular lubrication is crucial for extending the lifespan of your machinery.

Identifying Wear and Tear Signs

Recognizing indicators of degradation is crucial for maintaining equipment efficiency and longevity. Early detection of damage can prevent costly repairs and ensure safe operation. Understanding what to look for can help users identify potential issues before they escalate.

Common signs of wear may include:

- Unusual Noises: Any strange sounds, such as grinding or rattling, can indicate mechanical problems.

- Visible Cracks or Fractures: Inspect components for any visible damage, which may compromise functionality.

- Increased Vibration: Excessive vibration during operation can suggest imbalance or wear in moving parts.

- Corrosion: Rust or other forms of corrosion can weaken structures and lead to failure.

- Reduced Performance: Noticeable decreases in efficiency or power output can signal underlying issues.

Regular inspections are vital. Schedule routine checks to assess the condition of your equipment, focusing on:

- All moving components for signs of excessive wear.

- Connections and fasteners for tightness and integrity.

- Fluid levels and leaks that may indicate internal problems.

By staying vigilant and proactive, you can extend the life of your machinery and maintain its performance.

Tools for Parts Replacement

Replacing components in equipment requires the right tools to ensure efficiency and safety. Having a well-organized toolkit can make the task of maintenance straightforward and effective. The following section outlines essential instruments needed for various replacement tasks, emphasizing the importance of each tool.

Essential Instruments

- Screwdrivers: A set of screwdrivers with different sizes and types, including flathead and Phillips, is crucial for loosening and tightening screws.

- Wrenches: Adjustable wrenches and socket sets are necessary for removing bolts and nuts.

- Pliers: Needle-nose and slip-joint pliers help in gripping and manipulating small parts.

- Replacement Components: Always have spare components on hand to facilitate quick replacements.

Additional Helpful Tools

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Multimeter: Useful for diagnosing electrical issues and testing connections.

- Work Gloves: Protects hands during handling and assembly, ensuring a secure grip.

- Safety Glasses: Essential for protecting eyes from debris while working.

By equipping oneself with the right tools, maintenance becomes a manageable task, promoting the longevity and reliability of the equipment.

Exploring Aftermarket Component Options

When considering enhancements or replacements for essential machinery components, a multitude of aftermarket alternatives can be beneficial. These options provide users with greater flexibility in customization, allowing for improved performance and efficiency compared to original equipment offerings.

Choosing aftermarket components can yield several advantages:

- Cost-effectiveness: Often, these options are available at a lower price point than their original counterparts.

- Variety: A wide range of brands and models is available, catering to diverse needs and preferences.

- Upgrades: Aftermarket solutions may offer enhanced features that original parts do not provide.

- Availability: They are frequently easier to find, especially for older models that may have limited original supply.

When exploring these alternatives, it’s important to consider factors such as compatibility, quality, and warranty. Ensuring that the selected components meet or exceed the standards set by the original manufacturer can lead to better long-term performance and reliability.

Additionally, engaging with reviews and feedback from other users can provide insights into the effectiveness of specific aftermarket options. By doing thorough research, users can make informed decisions that enhance the functionality of their equipment.

Safety Features in Snow Blowers

When operating outdoor equipment designed for clearing pathways and driveways during winter, safety is of paramount importance. These machines are equipped with various features aimed at protecting users and bystanders from potential hazards. Understanding these attributes is essential for ensuring a safe and efficient experience while managing heavy snowfall.

Emergency Shut-off Mechanisms

One of the critical safety elements found in these machines is the emergency shut-off feature. This allows users to quickly deactivate the engine in case of unexpected situations, minimizing the risk of injury. Typically located within easy reach, this function is vital for maintaining control, especially in challenging conditions.

Operator Presence Controls

Another important aspect is the operator presence control, which ensures that the equipment does not operate unless the user is actively engaged. This mechanism helps prevent accidental activation, reducing the likelihood of accidents, particularly when the operator is distracted or when children are nearby. Such controls enhance safety, allowing users to focus on their task without unnecessary worry.

Seasonal Storage Recommendations

Properly preparing equipment for off-season storage is crucial for maintaining its functionality and longevity. By following specific guidelines, users can ensure their machines remain in excellent condition until they are needed again. This section outlines essential practices to safeguard your machinery during extended periods of inactivity.

Before storing, it is advisable to clean the unit thoroughly, removing any debris and contaminants. This step helps prevent corrosion and ensures that all components are free from potential damage. Additionally, checking and replacing fluids, such as oil and fuel, can prevent deterioration and operational issues when the time comes to use the equipment again.

It is also recommended to keep the machinery in a dry, well-ventilated area, protected from extreme temperatures and moisture. Using a cover can further shield the equipment from dust and environmental factors. For added protection, consider periodically inspecting the unit during the storage period to ensure everything remains in optimal condition.

Lastly, refer to the manufacturer’s guidelines for any specific storage instructions tailored to the model. Adhering to these recommendations will provide peace of mind, knowing that the machine will be ready for use when the season changes.

Manufacturer Support and Resources

Access to reliable assistance and comprehensive resources is essential for maintaining and troubleshooting equipment effectively. Manufacturers often provide a range of tools, guides, and customer service options to help users achieve optimal performance from their machines. Utilizing these resources can significantly enhance the ownership experience and ensure that devices operate smoothly throughout their lifespan.

Available Documentation

Users can benefit from an array of documentation provided by the manufacturer, including user manuals, maintenance guides, and troubleshooting resources. These documents typically offer detailed instructions on assembly, operation, and upkeep, empowering owners to make informed decisions regarding their equipment. Additionally, these resources often contain valuable safety information to ensure safe usage.

Customer Support Services

Customer support is a vital aspect of the user experience, offering assistance through various channels such as phone, email, and online chat. Manufacturers typically have dedicated teams trained to address queries related to equipment functionality and provide solutions for common issues. Timely access to knowledgeable support can alleviate frustrations and enhance overall satisfaction with the product.

Upgrading Components for Enhanced Performance

Improving the efficiency and effectiveness of your outdoor equipment can lead to better results and increased longevity. By enhancing specific elements, users can experience superior functionality and make their tasks easier. This section explores various enhancements that can be made to boost overall performance, focusing on critical components and their impact on operation.

Key Areas for Upgrades

Several components can significantly affect the overall performance of outdoor machinery. Consider the following areas for potential enhancements:

| Component | Benefits of Upgrading |

|---|---|

| Motor | Increased power and efficiency for better performance in tough conditions. |

| Auger | Enhanced material handling capabilities for more effective clearing. |

| Chassis | Improved stability and maneuverability, leading to easier operation. |

| Skid Shoes | Better surface protection and adjustment for varying terrain. |

Conclusion

Upgrading specific components can lead to noticeable improvements in operation and efficiency. By focusing on these key areas, users can maximize their equipment’s capabilities, ensuring optimal performance and longevity.