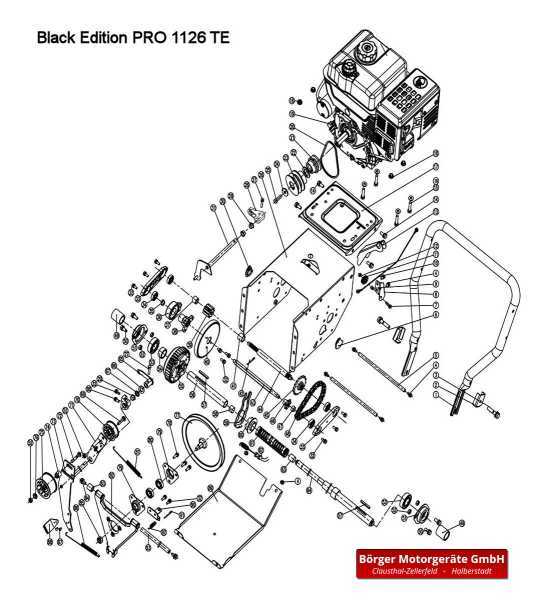

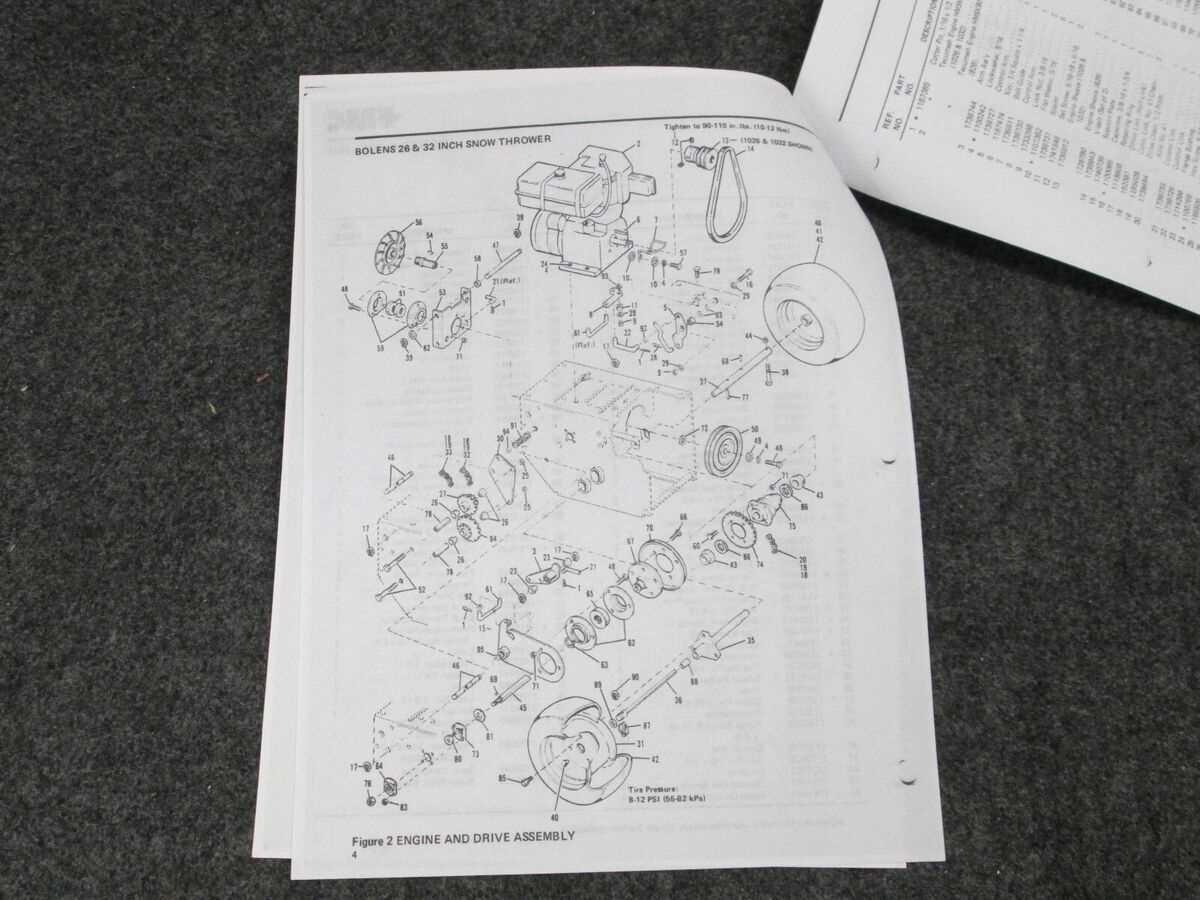

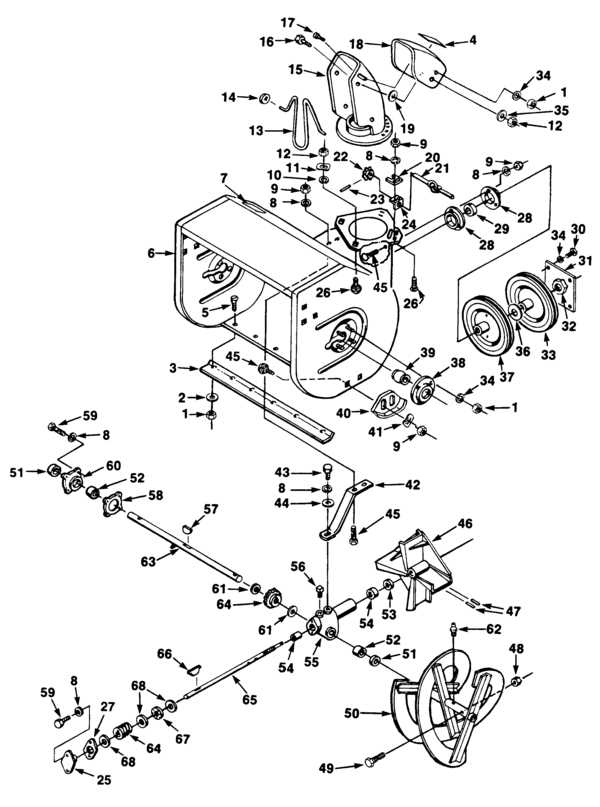

Understanding the Bolens 826 Snowblower Parts Diagram

When it comes to preparing for the cold season, having a reliable machine is essential for efficient snow management. Familiarity with the internal structure and functionality of your equipment can significantly enhance its performance and longevity. Knowing where to find specific components can save time and reduce frustration during maintenance.

In this section, we will explore an illustrative representation of various components related to your winter clearing device. By delving into the arrangement and connections of these elements, users can better comprehend how each part contributes to overall efficiency. This understanding is the ultimate key to troubleshooting and ensuring smooth operation throughout the winter months.

Whether you are a novice or an experienced user, having access to detailed information about your equipment’s layout can be invaluable. It allows for informed decisions regarding repairs and upgrades, ultimately leading to enhanced reliability and performance. Embracing this knowledge empowers you to tackle winter’s challenges with confidence.

Understanding Bolens 826 Snowblower

This section explores the essential components and mechanics of a popular winter tool, designed to handle heavy snowfall with efficiency. Familiarizing oneself with its structure can enhance performance and prolong lifespan.

Key Features

The primary attributes include a robust engine, an efficient propulsion system, and an effective throwing mechanism. Each element plays a crucial role in ensuring that the machine operates smoothly and meets the demands of harsh winter conditions.

Maintenance Tips

Regular upkeep is vital for optimal functionality. Checking the oil levels, inspecting the belts, and ensuring the auger is free of debris are all critical practices. Proper maintenance not only enhances performance but also extends the durability of the equipment.

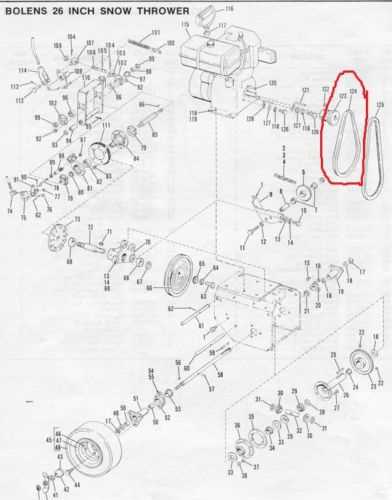

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for maintenance and repair. Visual representations provide clarity, enabling users to identify individual elements and their functions efficiently. These illustrations are indispensable for both novice and experienced operators, ensuring that repairs are executed with precision.

Moreover, having access to clear visuals can significantly reduce the time spent troubleshooting issues. Instead of relying solely on textual descriptions, users can refer to images that depict how components fit together, fostering a deeper comprehension of the equipment’s structure.

| Benefit | Description |

|---|---|

| Enhanced Understanding | Visual aids facilitate easier identification of parts and their roles. |

| Efficient Troubleshooting | Quick reference helps in pinpointing issues without guesswork. |

| Accurate Repairs | Guidance ensures that replacements and adjustments are correctly made. |

| Time-Saving | Visuals streamline the repair process, minimizing downtime. |

In summary, these visual guides are essential tools that contribute to effective maintenance practices, ensuring machinery operates smoothly and reliably.

Common Issues with Bolens 826

When operating a machine designed for winter tasks, users may encounter several frequent challenges that can affect performance and efficiency. Understanding these common problems is essential for maintaining optimal functionality and prolonging the life of the equipment.

Engine Performance Problems

One of the most prevalent issues is related to engine performance. Users often report difficulties in starting, stalling, or reduced power output. These issues can stem from various factors, including fuel quality, spark plug condition, or air filter blockages. Regular maintenance checks can help identify and resolve these problems before they escalate.

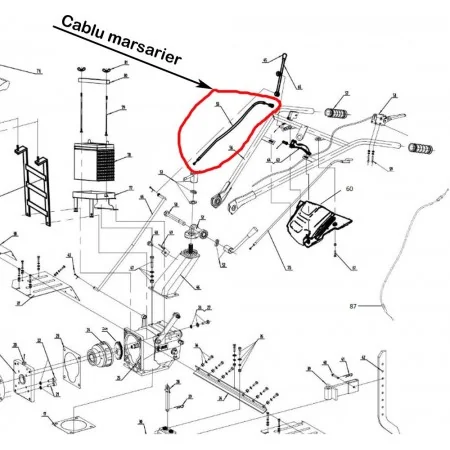

Auger and Drive System Malfunctions

Another area of concern involves the auger and drive systems. Users might notice that the machinery is not effectively moving or clearing snow. Common reasons for these malfunctions include worn belts, damaged gears, or even obstructions within the chute. Conducting routine inspections and ensuring all components are in good condition can significantly enhance operational efficiency.

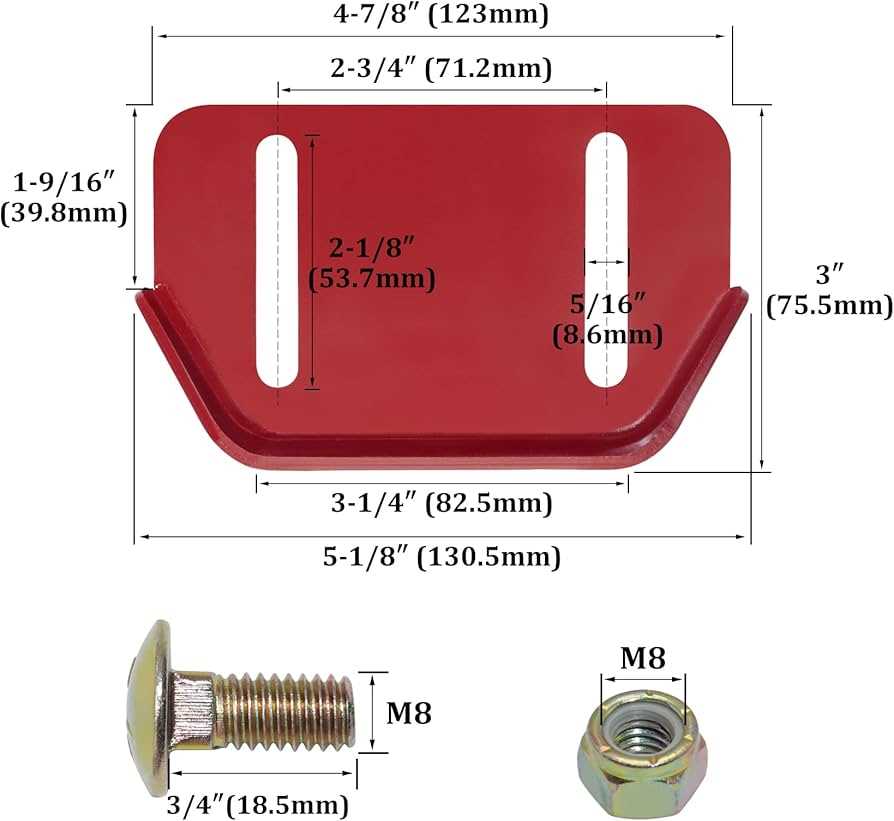

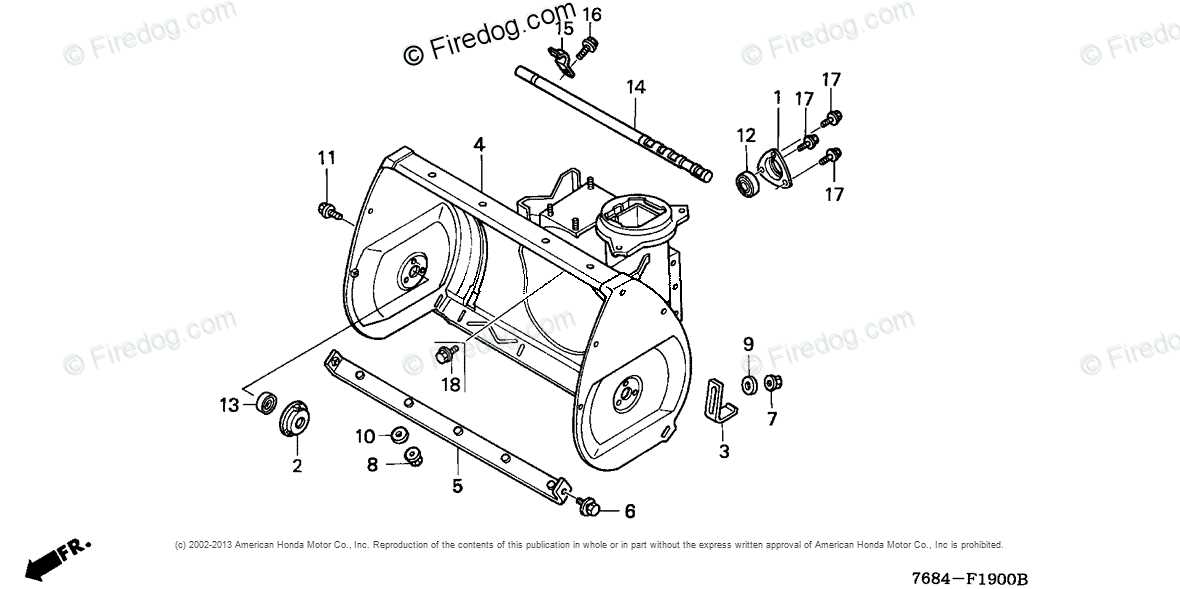

Identifying Key Components

Understanding the essential elements of your equipment is crucial for its effective operation and maintenance. Each component plays a significant role in ensuring optimal performance, and being familiar with their functions can greatly enhance your experience.

Drive System: This section includes mechanisms responsible for movement. It typically consists of gears, belts, and pulleys that work together to provide the necessary power and control.

Cutting Mechanism: The heart of the machine, this area encompasses blades or augers designed to effectively manage the material. Their design and sharpness directly affect the efficiency and effectiveness of the operation.

Chassis: The framework that supports the entire unit, ensuring stability and durability. Understanding its structure helps in assessing the overall condition and potential repairs needed.

Controls: This includes levers, buttons, and switches that allow the operator to manage various functions. Familiarity with these elements is vital for safety and operational efficiency.

Power Source: This section is crucial for understanding how the machine is energized. It typically involves either an engine or a motor, which drives all the other components, making it essential for proper functionality.

By recognizing these key elements, you can better navigate maintenance tasks, troubleshoot issues, and ensure your equipment remains in excellent working condition.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular attention and care. By implementing a few straightforward practices, you can enhance performance and extend its lifespan. This section provides essential advice to help you keep your machine running smoothly for years to come.

Regularly check and replace any worn components to prevent further damage. Keeping the engine clean and properly lubricated is crucial, as dirt and debris can lead to significant issues. Additionally, inspect belts and cables frequently, ensuring they remain in good condition and free from wear.

Storage is equally important; when not in use, store the equipment in a dry and protected area to avoid rust and corrosion. Before seasonal use, perform a thorough inspection and tune-up to address any potential problems early. Following these tips will contribute to optimal functionality and longevity.

Where to Find Replacement Parts

When it comes to maintaining your outdoor equipment, sourcing the right components is crucial for optimal performance. Many options are available for finding high-quality replacements, ensuring your machinery remains efficient and reliable.

Online Retailers: Numerous e-commerce platforms specialize in offering a wide array of components. These sites often provide detailed descriptions and customer reviews, helping you make informed decisions.

Local Hardware Stores: Visiting nearby stores can be beneficial. Many establishments stock essential components, and staff can assist in identifying the correct items for your needs.

Manufacturer’s Website: The official website often has a dedicated section for replacements. This can be a trustworthy source, as it ensures compatibility with your machinery.

Forums and Community Groups: Engaging with fellow enthusiasts online can lead to valuable recommendations and tips on where to find hard-to-locate components.

Salvage Yards: For those looking for budget-friendly options, salvage yards can be a treasure trove of used components, often at a fraction of the cost.

Reading Parts Diagrams Effectively

Understanding schematic representations is essential for efficient repairs and maintenance. These visual aids provide a comprehensive overview of components, making it easier to identify and locate necessary elements for servicing machinery.

To maximize the benefits of these illustrations, consider the following strategies:

- Familiarize Yourself with Symbols: Learn the standard symbols used in schematics to quickly interpret the information.

- Follow a Systematic Approach: Start from one section and work your way through to avoid confusion.

- Take Notes: Jot down important details and observations as you explore the representation.

- Use a Reference: Keep manuals or guides handy for additional context and clarification.

By applying these techniques, you can delve deeper into the intricacies of machinery, ensuring a smoother and more effective repair experience.

Tools Needed for Repairs

Performing maintenance and fixes on your equipment requires a variety of essential instruments. Having the right tools not only simplifies the process but also enhances the effectiveness of your repairs, ensuring that everything functions optimally.

Essential Instruments

- Wrenches: For loosening and tightening bolts.

- Screwdrivers: Necessary for adjusting screws of different sizes.

- Socket Set: Ideal for quick and efficient fastening.

- Pliers: Useful for gripping and manipulating small parts.

Additional Equipment

- Lubricants: To ensure smooth operation of moving components.

- Safety Gear: Including gloves and goggles to protect yourself during repairs.

- Measuring Tools: For precise adjustments and replacements.

Steps for Disassembling Snowblower

Disassembling your winter equipment can be a crucial process for maintenance and repairs. Understanding the proper steps ensures efficiency and safety while working on the machinery. This guide will outline the essential phases to take apart your device effectively.

Preparation and Safety Measures

Before you begin, ensure that the machine is powered off and disconnected from any electrical source. Wear appropriate safety gear, including gloves and goggles. Gather necessary tools, such as wrenches, screwdrivers, and pliers, to streamline the disassembly process.

Step-by-Step Disassembly

Start by removing the outer casing to access the internal components. Carefully detach screws and clips, making sure to keep them organized for reassembly. Once the outer shell is off, proceed to take apart the motor section, noting the wiring and connections. Label each component as you remove it to avoid confusion later. Finally, disconnect the auger and other related mechanisms to complete the disassembly.

Following these structured steps will help maintain your equipment’s longevity and functionality. Always consult the user manual for specific guidance related to your model.

Reassembly Process Explained

The reassembly of complex machinery requires careful attention to detail and a systematic approach. By following a structured method, you can ensure that each component fits correctly and functions as intended. This section outlines the essential steps to effectively put your equipment back together after disassembly.

Begin by gathering all components in an organized manner. This will help prevent any pieces from being misplaced during the process. It’s beneficial to refer to a visual guide or schematic, as this provides a clear reference for the placement and orientation of each part.

Next, start reassembling the main body of the apparatus. Begin with the foundational components, ensuring that each piece aligns with the designated slots or fasteners. As you proceed, tighten screws or bolts gently at first, allowing for adjustments before securing everything firmly.

After the main assembly is complete, focus on the auxiliary elements. Attach any accessories or additional mechanisms, double-checking their functionality as you go. It’s important to maintain a logical sequence, as this reduces the risk of having to backtrack.

Finally, conduct a thorough inspection of the entire assembly. Ensure that all parts are correctly positioned and securely fastened. Testing the functionality of the machine before full operation is crucial to identifying any potential issues early on.

Upgrading Your Snowblower Model

Enhancing your winter equipment can significantly improve its efficiency and performance. By making targeted upgrades, you can ensure that your machine meets the demands of harsh weather conditions while extending its lifespan. This process not only involves replacing old components but also incorporating modern features that elevate functionality.

Choosing the Right Components

When considering enhancements, it’s crucial to identify the specific areas that require improvement. Performance, durability, and user comfort should be your ultimate goals. Evaluate parts that directly impact these aspects, and research high-quality alternatives that fit your model.

Installation and Maintenance

After selecting your upgrades, proper installation is essential. Refer to your equipment manual or seek professional help to ensure everything fits seamlessly. Regular maintenance post-upgrade is equally important; this ensures that your enhancements work effectively and that your equipment remains reliable throughout the winter season.

Seasonal Preparation Checklist

As the colder months approach, it’s essential to ensure your outdoor equipment is ready for the challenges ahead. This checklist will help you assess and prepare your machinery for optimal performance, ensuring you can tackle winter conditions effectively.

Essential Maintenance Tasks

- Inspect and replace any worn or damaged components.

- Change the oil and replace the filter.

- Check the fuel system for leaks and clean any blockages.

- Examine belts and cables for signs of wear.

- Test all electrical connections and replace corroded parts.

Operational Readiness

- Ensure all controls are functioning properly.

- Fill up with fresh fuel to prevent starting issues.

- Run the equipment for a few minutes to confirm performance.

- Store any necessary tools within easy reach.

- Review safety procedures to prepare for winter operations.

FAQs about Bolens 826 Maintenance

This section addresses common inquiries related to the upkeep and care of your equipment, ensuring optimal performance and longevity. Regular maintenance is key to enhancing efficiency and preventing issues.

- How often should I perform maintenance?

It’s advisable to check and maintain your machine at least once a season, or more frequently if used heavily.

- What basic checks should I perform?

Inspect fluid levels, belts, and overall condition regularly. Look for wear and tear that could affect functionality.

- Are there specific parts to focus on?

Pay attention to the engine, auger assembly, and drive system. These areas often require more frequent inspection.

- How can I extend the lifespan of my equipment?

Regular cleaning, timely oil changes, and using the right fuel can significantly enhance durability.

- Where can I find replacement components?

Local retailers, online marketplaces, and authorized service centers are good sources for quality replacements.