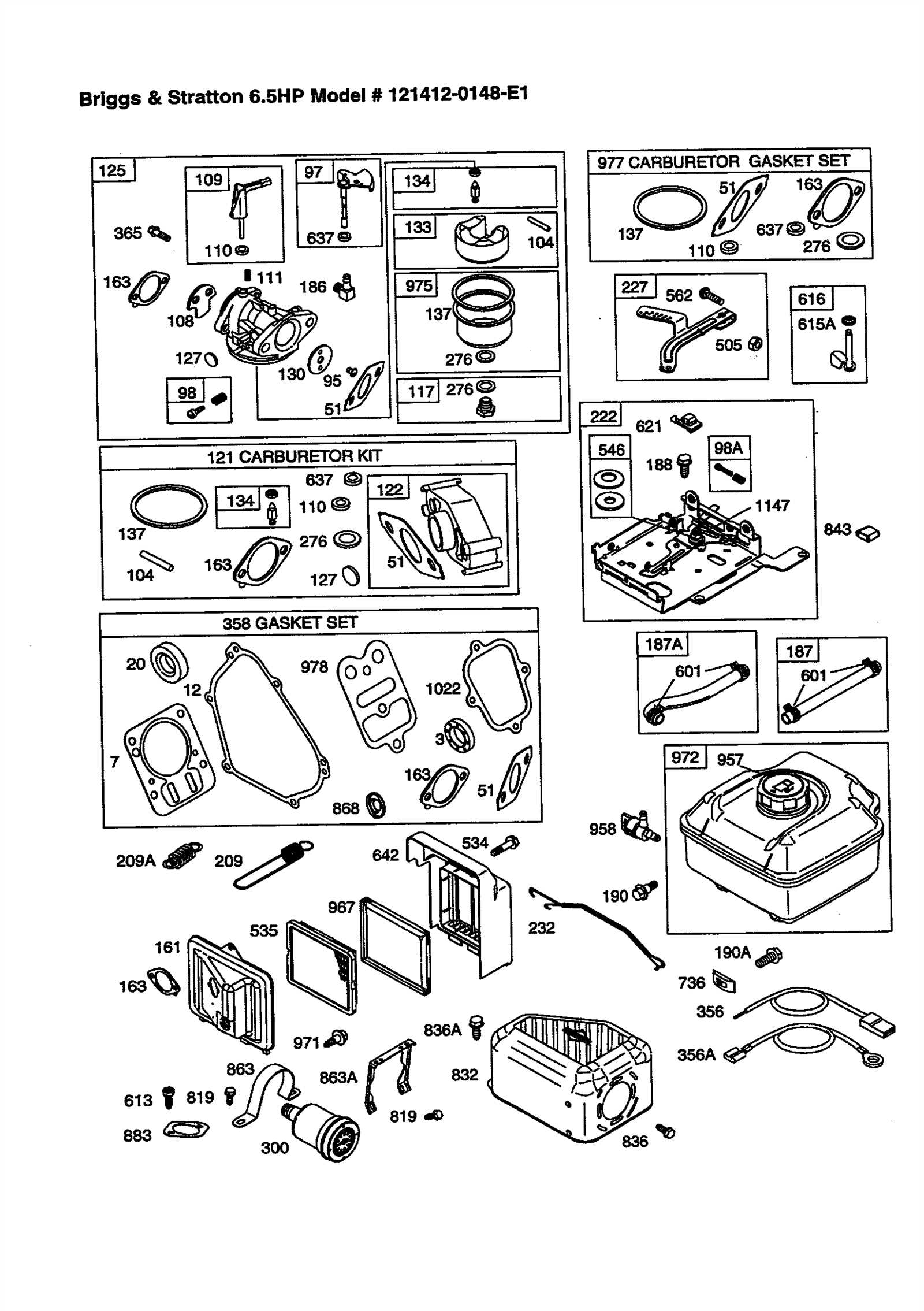

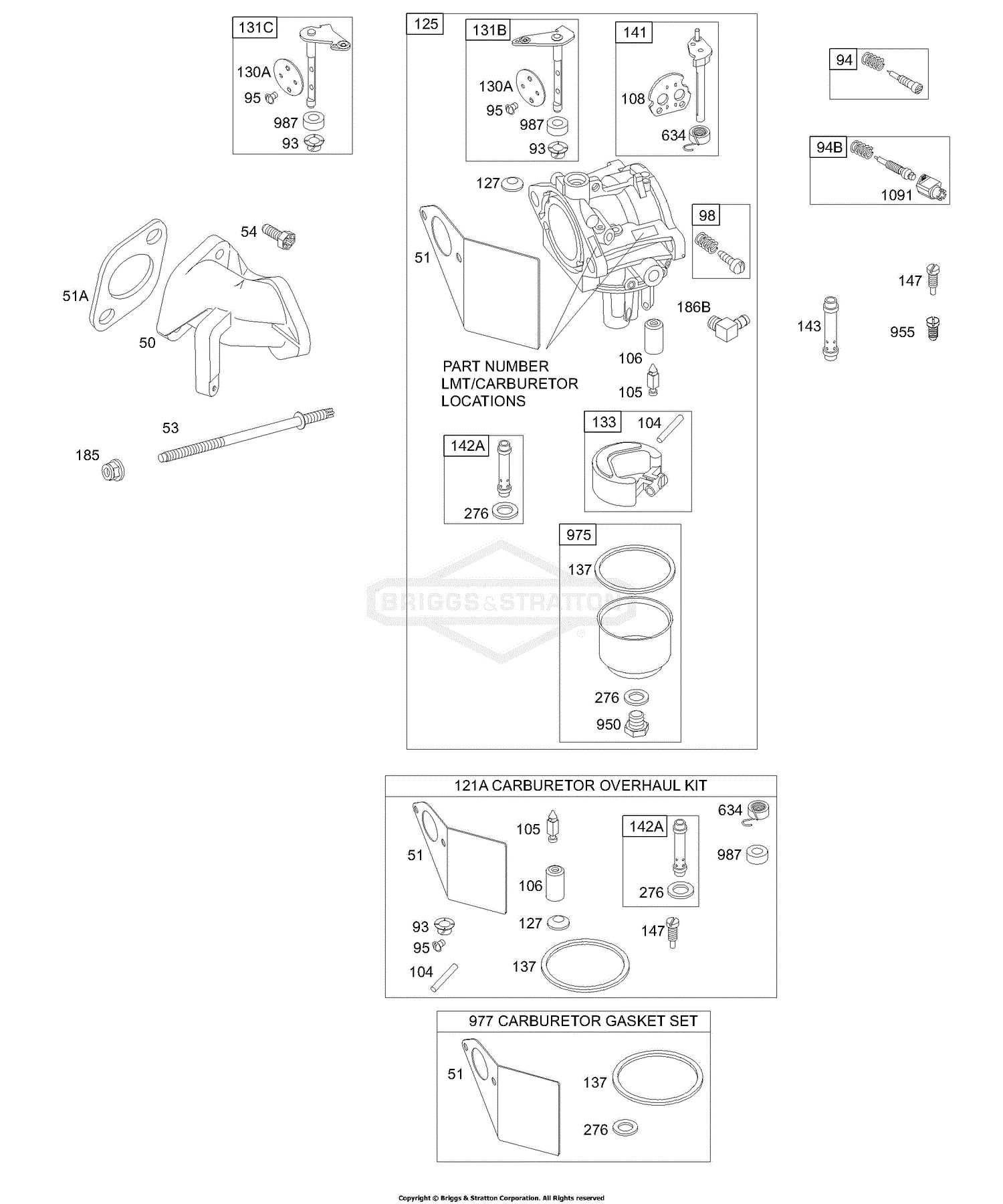

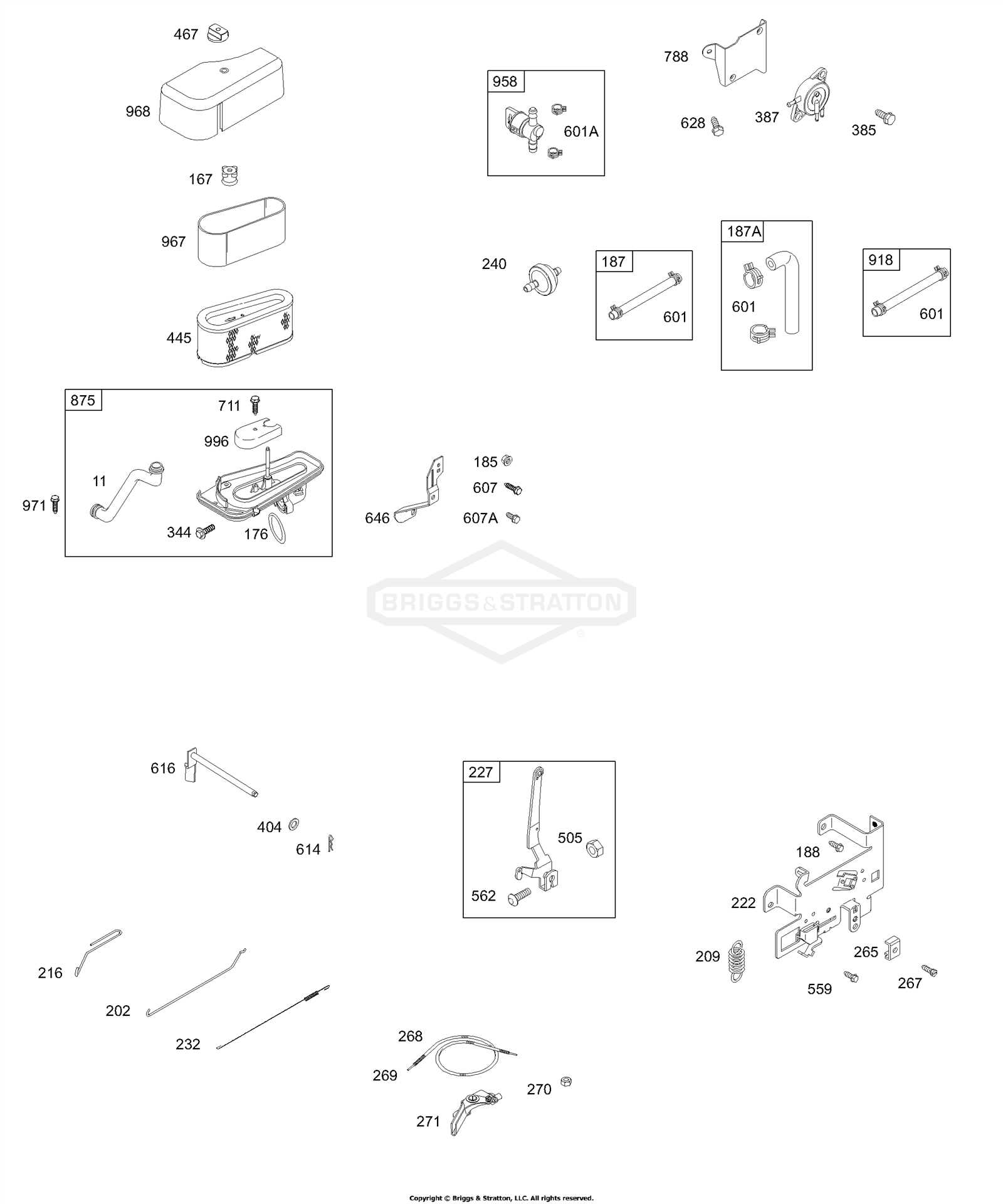

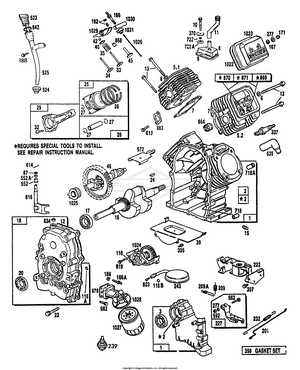

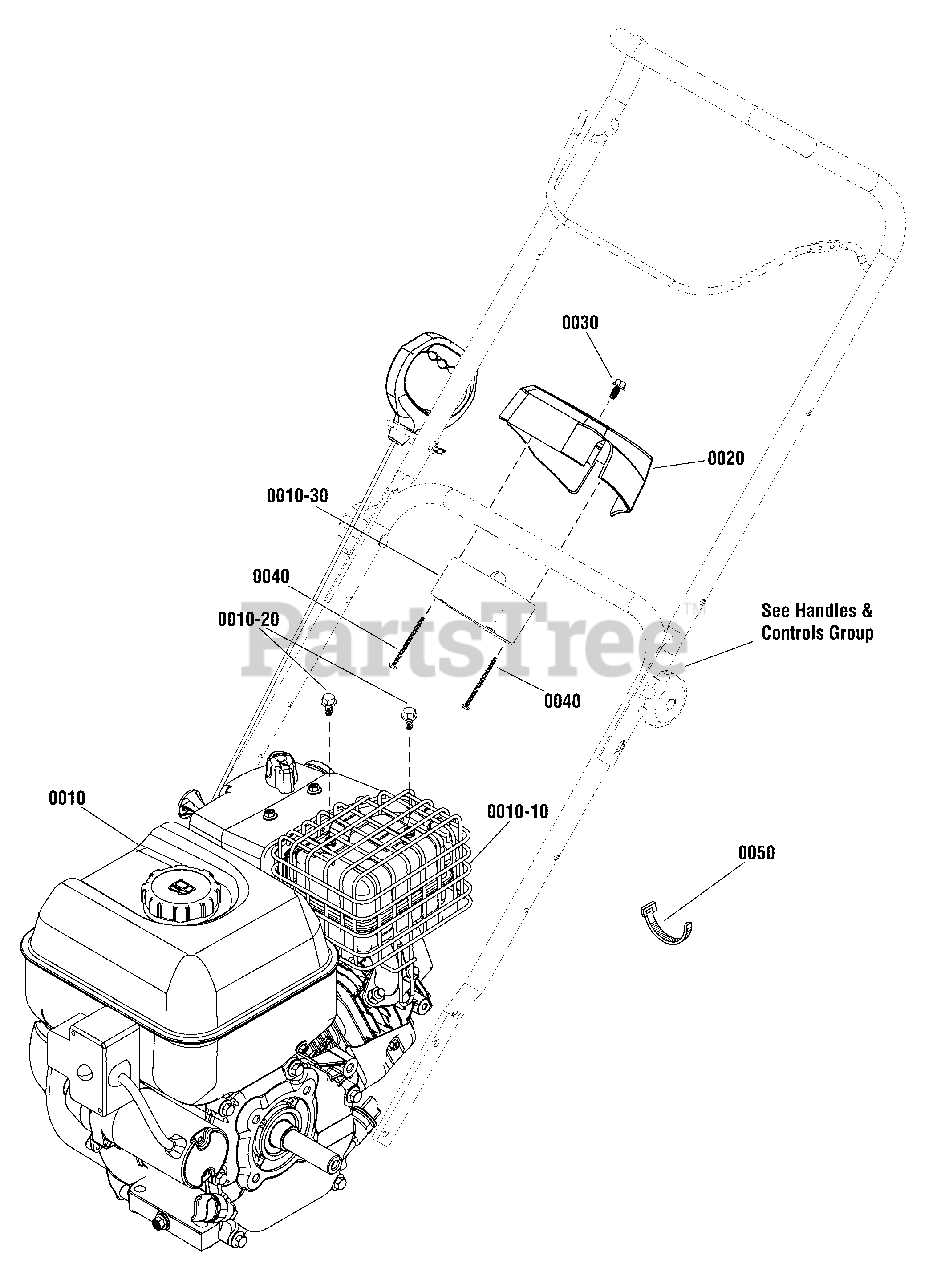

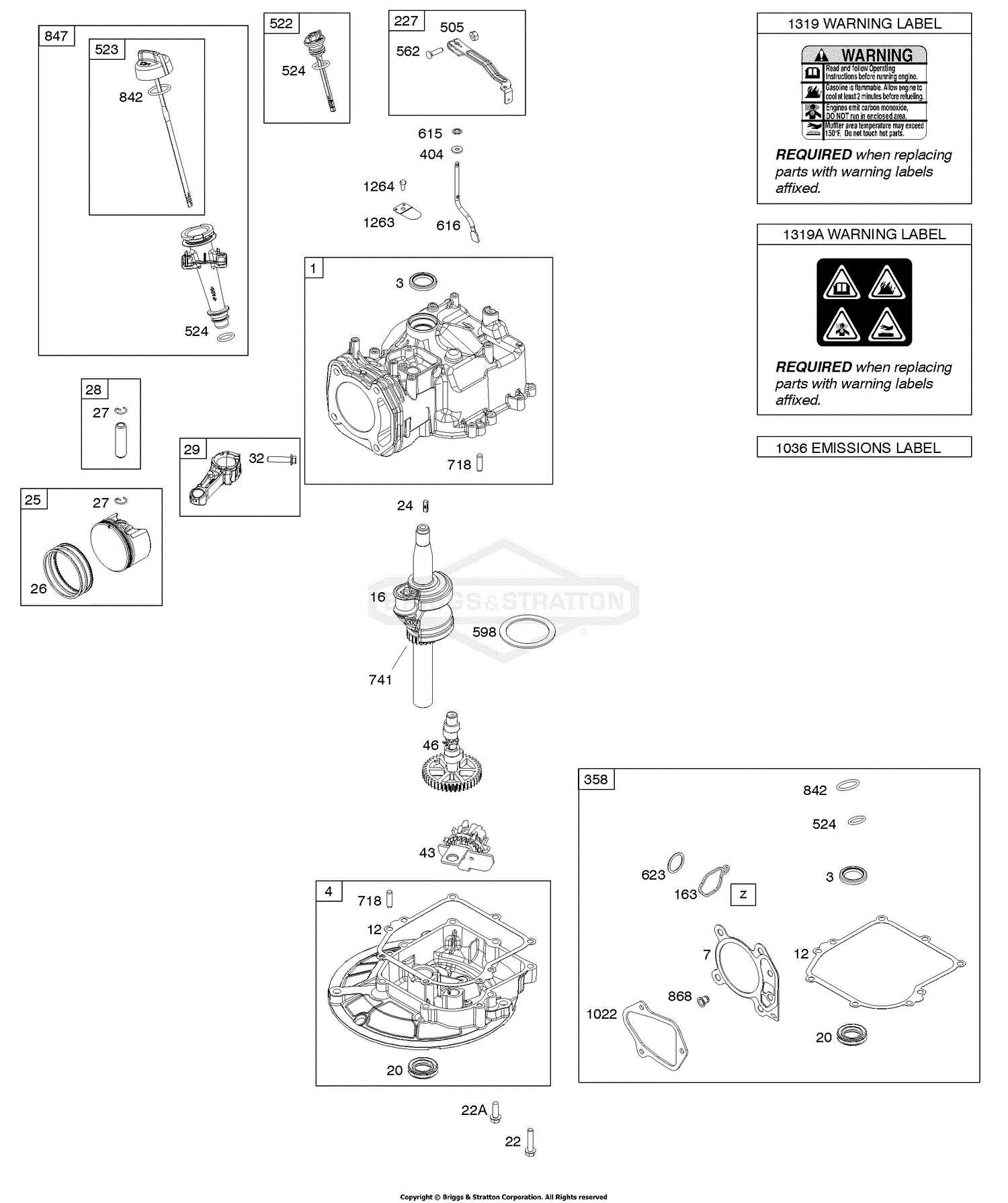

Briggs and Stratton 1022 Snowblower Parts Diagram Overview

Understanding the intricate workings of outdoor machinery is vital for optimal performance during winter months. This section offers a comprehensive exploration of the key elements that contribute to effective operation. Knowing how each part functions can enhance maintenance practices and prolong the lifespan of your equipment.

Visual aids play a crucial role in identifying individual components, making it easier to diagnose issues and plan repairs. By examining detailed representations, users can gain clarity on assembly and functionality, ultimately leading to more informed decisions regarding upkeep and replacement.

Whether you’re a seasoned technician or a novice operator, having access to accurate visual resources is essential. This guide will delve into various elements, providing insights that empower you to tackle any challenges with confidence.

Understanding the Briggs and Stratton 1022

When it comes to tackling winter challenges, having reliable equipment is essential. This particular model is designed to efficiently handle snow accumulation, making it a valuable asset for homeowners facing harsh conditions. Familiarizing yourself with its components and functionality can enhance your operational experience and prolong the machine’s lifespan.

This unit features a robust design, ensuring durability and effectiveness in removing snow from various surfaces. Knowing the key elements, such as the auger assembly and chute mechanism, allows users to maintain optimal performance. Regular inspection and understanding of each component’s role can prevent common issues and improve overall efficiency.

In addition, recognizing the importance of routine maintenance can significantly contribute to the longevity of this equipment. By staying informed about its specifications and necessary upkeep, operators can ensure reliable performance season after season.

Key Features of the Snowblower

This section highlights the essential characteristics of a powerful snow-clearing machine, designed to make winter maintenance efficient and effective. Understanding these features can enhance performance and user satisfaction during those heavy snowfall events.

Powerful Engine Performance

Equipped with a robust engine, this equipment delivers optimal power to tackle even the most stubborn snow. The reliable motor ensures that users can clear large areas quickly, minimizing time spent outdoors in harsh weather conditions.

User-Friendly Design

The ergonomic design promotes ease of operation, featuring intuitive controls and adjustable components. Comfort is prioritized, allowing operators to work without unnecessary strain, while advanced technology enhances overall functionality and safety.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for efficient maintenance and repair. Visual representations of these elements serve as valuable resources for both novices and experienced users. They enhance clarity and facilitate the identification of necessary components during troubleshooting or assembly.

- Enhanced Clarity: Diagrams provide a clear visual guide, making it easier to locate and recognize individual elements.

- Efficient Repairs: Having a visual reference simplifies the repair process, reducing time spent searching for specific parts.

- Accurate Replacements: Knowing the exact part numbers and configurations helps in procuring the right replacements.

- Improved Understanding: Visual aids enhance comprehension of how different components interact within the system.

Incorporating these visual tools into maintenance routines can significantly streamline the repair process, ultimately leading to better performance and longevity of the equipment.

Common Issues with the 1022 Model

This section highlights frequent challenges encountered by users of this particular equipment. Understanding these common problems can aid in effective troubleshooting and maintenance, ensuring optimal performance during harsh winter conditions.

Engine Starting Difficulties

A prevalent issue is related to starting the engine. Users often report that the motor fails to ignite, which can stem from fuel quality, spark plug conditions, or battery issues. Regular maintenance checks can help identify these factors early.

Auger Malfunctions

Another common concern involves the auger system. If it becomes sluggish or entirely unresponsive, it could indicate a blockage or mechanical failure. Clearing debris and ensuring proper lubrication are essential steps to keep this component functioning smoothly.

Essential Maintenance Tips

Proper upkeep is crucial for ensuring optimal performance and longevity of your outdoor equipment. Regular attention can prevent potential issues, enhance efficiency, and save on costly repairs. Focusing on key areas of maintenance will keep your machinery in peak condition.

Begin with regular inspections, checking for any signs of wear or damage. Cleaning the components and ensuring they are free from debris can significantly improve functionality. Additionally, replacing worn parts promptly is essential to maintain seamless operation.

Lubrication is another vital aspect; keeping moving parts well-oiled reduces friction and wear. It’s also advisable to follow the manufacturer’s recommendations regarding fuel and oil types, as using the right products will contribute to the machine’s overall health.

Lastly, storing the equipment properly during off-seasons can prevent rust and other environmental damage. By following these maintenance tips, you can ensure your machinery remains reliable and efficient for many seasons to come.

Identifying Replacement Parts Easily

When it comes to maintaining outdoor equipment, understanding how to recognize essential components can greatly enhance efficiency. Having a clear method to identify specific elements can save time and ensure optimal performance.

Utilizing Reference Guides

Reference materials can be invaluable. Consult manuals or online resources that outline the necessary components for your machinery. These guides often include illustrations that provide clarity on each item’s placement and function.

Consulting Online Communities

Engaging with online forums and communities can also be beneficial. Enthusiasts often share insights, tips, and even personal experiences, making it easier to pinpoint exactly what you need. This collaborative approach can lead to discovering the ultimate solutions for your equipment.

How to Read Parts Diagrams

Understanding the visual representation of components can greatly enhance your ability to maintain and repair equipment. These illustrations provide essential information on the various elements involved, allowing for easier identification and troubleshooting. Mastering this skill can save time and effort when working on your machinery.

Identifying Components

Begin by familiarizing yourself with the symbols and labels used in the illustration. Each part is typically marked with a unique number or letter, which corresponds to a list of items. This connection simplifies the process of locating specific pieces when seeking replacements or repairs.

Following the Assembly Order

Next, pay attention to how components are arranged. The sequence often indicates how parts fit together, which can be crucial for reassembly. Understanding this order can prevent confusion and ensure that everything is reinstalled correctly, leading to optimal functionality.

Where to Find Authentic Parts

Finding genuine components for your equipment is crucial for maintaining its performance and longevity. Ensuring that you select the right elements can significantly enhance the reliability and efficiency of your machinery.

Authorized Dealers

- Visit local authorized retailers that specialize in equipment maintenance.

- Check manufacturer websites for lists of certified distributors.

Online Resources

- Explore e-commerce platforms dedicated to outdoor machinery.

- Utilize forums and communities for recommendations on trustworthy sources.

- Look for online catalogs that offer detailed specifications and diagrams.

Tools Needed for Repairs

When tackling maintenance or fixing tasks, having the right equipment is essential for achieving optimal results. Proper tools not only streamline the process but also enhance safety and efficiency, ensuring that each job is completed with precision.

Essential Tools

- Socket Wrench Set

- Phillips and Flathead Screwdrivers

- Torque Wrench

- Pliers (needle-nose and regular)

- Rubber Mallet

- Multimeter

Additional Supplies

- Oil and Lubricants

- Cleaning Cloths

- Safety Goggles

- Work Gloves

- Replacement Hardware (nuts, bolts, screws)

Having these tools at hand will not only simplify your repair projects but also ensure that you are well-prepared for any challenges that may arise during the process.

Safety Precautions When Repairing

When undertaking maintenance on outdoor power equipment, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions not only ensure personal well-being but also protect the equipment from damage during the repair process.

Always wear protective gear such as gloves and goggles to shield against debris and sharp components. Before starting any repair, disconnect the power source to avoid unintended activation. Additionally, ensure you are working in a well-ventilated area to prevent inhalation of fumes or dust.

Familiarize yourself with the specific tools required for the task, and use them correctly to avoid mishaps. Keeping your workspace organized minimizes the risk of accidents caused by clutter or misplaced tools. Lastly, consult the manufacturer’s guidelines for any specific safety measures related to the equipment.

Upgrading Your Snowblower Components

Enhancing the performance of your winter machine can significantly improve efficiency and durability. By replacing or upgrading certain elements, you can ensure optimal functionality and longevity during harsh conditions. Here are several components worth considering for an upgrade.

- Auger Blades: Upgrading to high-quality or specialized blades can enhance snow removal capabilities, making your machine more effective in heavy snowfall.

- Drive Belts: A stronger, more durable belt can improve power transmission and reduce the risk of wear and tear over time.

- Skids: Adjustable skids allow for better maneuverability and can protect the machine from damage on uneven surfaces.

- Engine Oil: Using high-performance oil can improve engine efficiency, especially in low temperatures, ensuring smooth operation.

Before making any modifications, consult your user manual to ensure compatibility with your specific model. Researching customer reviews and expert opinions can also guide you towards the best options for upgrades.

- Assess current components for wear and performance.

- Identify upgrades based on your specific needs and conditions.

- Install new parts carefully, following manufacturer guidelines.

- Test the machine to ensure that all upgrades function correctly.

Investing in quality enhancements not only improves performance but also extends the lifespan of your equipment, making winter maintenance easier and more efficient.

Customer Reviews and Experiences

This section highlights the feedback and insights shared by users regarding their experiences with a specific model of winter equipment. Understanding customer opinions is crucial for potential buyers to make informed decisions, as firsthand accounts often reveal strengths and weaknesses that specifications alone may not convey.

Positive Feedback

Many users have praised the efficiency and reliability of their units during harsh winter conditions. Customers often mention how well the machinery performs, even in heavy snowfall, providing them with a sense of security and satisfaction.

Common Concerns

Despite the positive reviews, some users have expressed concerns about certain aspects of performance and maintenance. Issues such as difficulty in starting and occasional mechanical problems have been reported, leading to mixed experiences.

| Aspect | Positive Reviews | Negative Reviews |

|---|---|---|

| Performance | Highly efficient in heavy snow | Difficulty starting in extreme cold |

| Maintenance | Easy to maintain with accessible components | Some parts wear out quickly |

| Durability | Sturdy construction noted | Occasional mechanical failures |

Warranty Information for the 1022

The warranty coverage for this equipment provides peace of mind for users, ensuring that any manufacturing defects or issues that arise within a specified period will be addressed. Understanding the terms and conditions is crucial for maintaining the integrity of your machine and maximizing its lifespan.

Coverage Details

This warranty typically covers defects in materials and workmanship under normal use. Specific components may have different coverage periods, which are outlined below:

| Component | Warranty Period |

|---|---|

| Engine | 2 years |

| Transmission | 1 year |

| Frame | Lifetime |

| Other Parts | 90 days |

Claim Process

To initiate a warranty claim, users should retain their purchase receipt and contact the authorized service center. Prompt reporting of issues ensures timely resolution, keeping your equipment in optimal condition.