Understanding the Brute Snowblower Parts Diagram for Efficient Repairs

When it comes to maintaining your winter clearing equipment, having a comprehensive understanding of its various elements is essential. Each component plays a critical role in ensuring optimal performance, especially during harsh weather conditions. Familiarity with these individual pieces can enhance not only functionality but also longevity.

In this section, we will explore the intricate structure of your machine, shedding light on its vital segments. By gaining insights into how these parts interact, you can make informed decisions regarding upkeep and repairs. This knowledge ultimately empowers you to tackle any challenges that winter may present.

Additionally, recognizing the significance of each component will enable you to identify potential issues before they escalate. Whether you’re a seasoned user or a newcomer, understanding these elements will enhance your overall experience and efficiency during snowy days.

Understanding Brute Snowblower Mechanics

The intricate mechanics behind winter clearing machines are essential for optimal performance. These devices rely on a variety of components working in harmony to tackle the challenges posed by snow accumulation. Understanding how these elements interact can enhance both maintenance and operation, ensuring reliable service during harsh conditions.

Core Components and Their Functions

At the heart of these machines lies a powerful engine, which serves as the driving force. This engine powers several key mechanisms, including the auger, which is responsible for gathering and shredding the snow. The discharge chute, another critical element, directs the expelled snow away from the pathway. Regular checks of these components can prevent malfunctions and prolong the lifespan of the equipment.

Maintenance Tips for Longevity

Proper upkeep is vital for ensuring efficiency and safety. Routine inspections should include examining belts, checking fluid levels, and testing electrical connections. Replacing worn-out parts promptly can prevent more significant issues down the line. Additionally, clearing any debris from the intake area can improve performance and reduce strain on the engine.

In summary, a comprehensive understanding of the mechanics involved in these machines not only facilitates better performance but also empowers users to maintain their equipment effectively.

Essential Components of a Snowblower

When it comes to tackling winter’s challenges, understanding the critical elements that make up a powerful clearing machine is essential. These key components work together seamlessly to ensure efficient operation, enabling users to manage snowfall effectively. Each part plays a vital role in the overall functionality and performance of the equipment.

Drive Mechanism

The drive mechanism is at the heart of the machine, providing the necessary power to propel it forward. Typically consisting of a motor and transmission system, this component ensures smooth movement across various terrains. A robust drive ensures that the equipment can handle deep snow and challenging conditions without faltering.

Auger Assembly

The auger assembly is crucial for the initial collection of snow. This rotating mechanism features sharp blades that cut through compacted snow and ice, breaking it apart for easier removal. The efficiency of the auger directly impacts how quickly and effectively the machine can clear pathways, making it a central feature of winter operations.

Understanding these fundamental elements allows users to appreciate the engineering behind their snow-clearing tools, leading to better maintenance and informed decisions when selecting equipment for winter weather challenges.

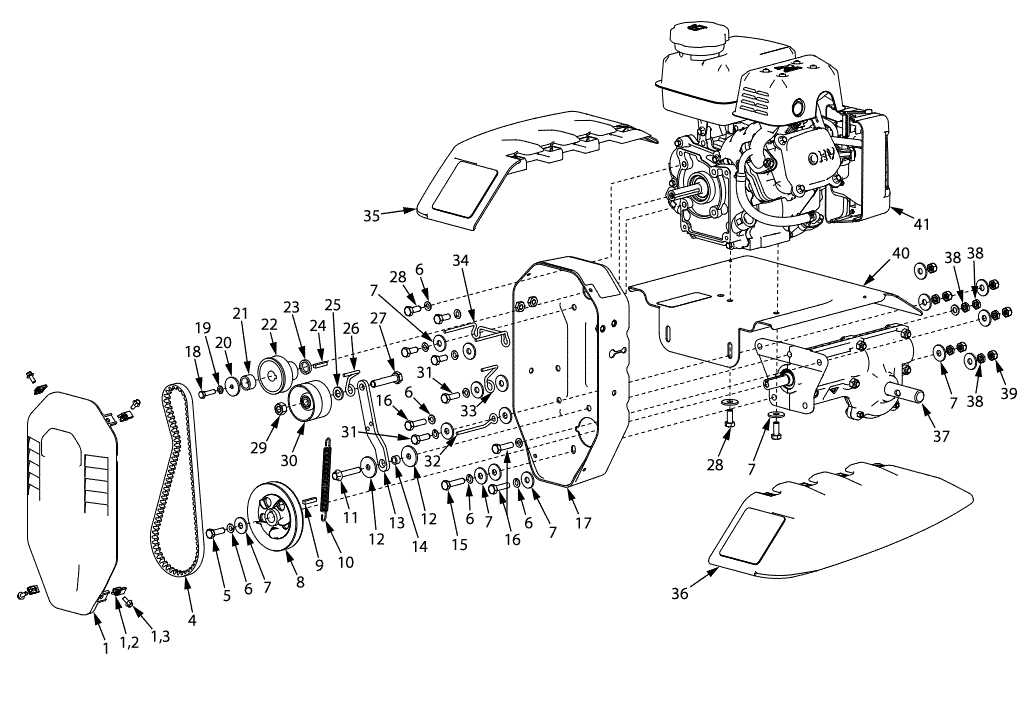

Identifying Parts in a Diagram

Understanding the components within a visual representation is crucial for effective maintenance and repair. Each section offers insights into various elements, ensuring that users can navigate through the complexities with ease. Recognizing these features allows for a more efficient approach to troubleshooting and assembly.

When examining the illustration, pay attention to labels and outlines that highlight individual elements. Familiarity with the layout enhances comprehension, enabling users to pinpoint specific areas quickly. Utilizing a systematic approach in studying the image can significantly reduce confusion and streamline the repair process.

Moreover, cross-referencing with accompanying documentation can provide additional context and clarity. This practice not only reinforces knowledge but also empowers users to take confident action when addressing issues. Ultimately, a thorough understanding of the visual guide is essential for optimal functionality.

Common Snowblower Issues and Solutions

Maintaining outdoor clearing equipment can present various challenges, but understanding typical problems and their remedies can enhance performance and longevity. Below are some frequent concerns faced by users and effective solutions to address them.

- Engine Won’t Start:

- Check the fuel level and quality.

- Inspect the spark plug for wear or damage.

- Ensure the choke is in the correct position.

- Auger Not Turning:

- Examine the drive belt for signs of wear.

- Look for obstructions in the auger housing.

- Verify the engagement lever is functioning properly.

- Excessive Vibrations:

- Check for loose screws or bolts.

- Inspect the blades for damage or imbalance.

- Ensure that all components are securely fastened.

- Difficulty Steering:

- Inspect the skid shoes for wear.

- Adjust the control cables if necessary.

- Ensure tires are properly inflated and aligned.

By addressing these common issues, users can maintain optimal functionality and ensure a smoother experience during winter operations.

Maintenance Tips for Snowblower Longevity

Ensuring the durability of your winter equipment requires consistent care and attention. Proper maintenance not only extends the lifespan but also enhances performance when needed the most.

- Regular Cleaning: Remove any accumulated snow and ice after each use to prevent corrosion.

- Inspect Belts and Cables: Check for wear and tear regularly to avoid unexpected breakdowns.

- Change Oil: Follow the manufacturer’s recommendations for oil changes to keep the engine running smoothly.

- Sharpen Blades: Keep cutting edges sharp for efficient snow removal.

- Fuel Maintenance: Use fresh fuel and consider adding a stabilizer to prevent fuel degradation.

By following these tips, you can ensure that your equipment remains reliable throughout the harshest winter conditions.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair. These visual representations provide a detailed overview of components, making it easier to identify, order, and replace specific items. A clear grasp of how to interpret these visuals can save time and reduce frustration during your repair projects.

Key Components of the Illustration

Each visual guide typically includes several critical elements that facilitate comprehension:

| Element | Description |

|---|---|

| Labels | Each component is usually marked with a unique identifier, allowing for easy reference. |

| Reference Numbers | Corresponding numbers often link to a list that provides further details on each part. |

| Connections | Lines or arrows may indicate how different components interact or are assembled together. |

Steps to Effectively Interpret the Visuals

To maximize your understanding, follow these steps:

- Examine the overall layout to familiarize yourself with the arrangement of items.

- Identify the labeled components and cross-reference them with the accompanying list for specifications.

- Pay attention to connection indicators to understand how each piece fits within the system.

Where to Find Replacement Parts

Locating suitable components for your outdoor equipment can be a straightforward task when you know where to look. Understanding the various resources available will help you maintain the efficiency and longevity of your machinery.

Online Retailers

Many online platforms specialize in offering a wide selection of equipment components. Websites like Amazon and eBay often have user-friendly interfaces, allowing you to search by model or type. Additionally, manufacturers’ official sites typically provide direct access to authentic items.

Local Supply Stores

Your neighborhood hardware or garden supply shop may also carry essential items. Visiting these stores allows you to consult with knowledgeable staff who can guide you to the right choices. Don’t hesitate to ask for assistance, as they often have insights into the best products for your needs.

DIY Repairs for Your Snowblower

Maintaining your outdoor equipment can save you time and money. By understanding how to troubleshoot and fix common issues, you can ensure that your machine operates smoothly throughout the winter season. This guide provides essential tips for handling typical problems that may arise.

| Issue | Solution |

|---|---|

| Engine won’t start | Check the fuel level and replace spark plug if necessary. |

| Weak throwing power | Inspect the belt for wear and replace if damaged. |

| Stalling during operation | Clean the air filter and ensure the carburetor is functioning properly. |

| Unusual noises | Look for loose bolts and check the oil level. |

By following these straightforward steps, you can effectively address many common challenges, ensuring your equipment remains reliable and efficient.

Comparing Brute Models and Parts

This section delves into the various models available in the market, focusing on their features and components. Understanding the differences among these versions can greatly assist consumers in making informed choices tailored to their specific needs.

When evaluating different units, consider the following aspects:

- Engine Power: Variations in horsepower can significantly impact performance and efficiency.

- Clearing Width: Wider models may handle heavy snowfall more effectively, while narrower versions can be more maneuverable.

- Auger Design: Different configurations can influence how well the equipment handles diverse snow conditions.

- Chassis Durability: Material quality plays a crucial role in longevity and resistance to harsh weather.

Moreover, it’s essential to look into the compatibility of each model with available accessories and replacement elements. Here are key factors to consider:

- Accessory Options: Some models may offer more attachments or enhancements, allowing for greater versatility.

- Maintenance Needs: Different units may require varying levels of upkeep, which can affect long-term satisfaction.

- Warranty Coverage: Understanding the guarantee terms can provide peace of mind regarding potential repairs.

Ultimately, a thorough comparison of these features and components will help users select the ideal model for their specific requirements, ensuring efficiency and reliability in winter conditions.

Upgrades for Enhanced Snow Removal

Improving your winter clearing experience can significantly boost efficiency and effectiveness. By investing in advanced components and enhancements, you can transform your current setup into a powerful tool capable of tackling even the heaviest snowfall. These modifications not only optimize performance but also increase durability, ensuring a reliable solution for years to come.

One popular enhancement is the installation of a high-performance auger. This upgrade increases the ability to break through dense, compacted ice and snow, making the process smoother and faster. Additionally, incorporating a more robust engine can provide the extra power needed for challenging conditions, allowing for quicker operation without sacrificing performance.

Another valuable improvement involves upgrading the chute system. Enhanced designs allow for better snow direction and control, reducing the risk of blowback and improving overall maneuverability. This adjustment can make a significant difference in how effectively you clear your driveway or pathways.

Finally, consider adding heated grips and LED lights. Heated grips provide comfort during extended use in frigid temperatures, while LED lights improve visibility in low-light conditions, ensuring that you can work safely and efficiently at any hour.

Safety Tips for Operating Snowblowers

When tackling winter’s icy challenges, it’s crucial to prioritize safety to ensure a smooth and secure experience. Proper handling of these powerful machines can prevent accidents and injuries while maximizing efficiency. Familiarizing yourself with essential precautions is key to maintaining a safe working environment.

Always wear appropriate protective gear, including gloves and sturdy footwear, to shield yourself from the cold and potential hazards. Before starting, inspect the equipment thoroughly for any damages or loose components that could pose risks during operation. Ensuring that all safety features are functional will help protect you from unexpected malfunctions.

Keep bystanders, especially children and pets, at a safe distance while in use. It’s important to stay alert and maintain focus on your surroundings, as distractions can lead to serious mishaps. Additionally, never attempt to clear blockages with your hands; use a tool instead to avoid injury.

Lastly, adhere to the manufacturer’s instructions regarding operation and maintenance. Regularly scheduled checks and servicing will not only prolong the lifespan of your equipment but also enhance its performance and safety.